Bajaj Three Wheeler Repair Guide

This section focuses on providing essential guidance for the upkeep and troubleshooting of a popular vehicle type known for its utility and efficiency. Understanding the intricacies of these vehicles can enhance their performance and longevity, ensuring a smoother ride for users.

Readers will find detailed insights into various aspects, including common issues, routine checks, and effective solutions. With clear instructions and expert tips, this resource aims to empower owners and technicians alike in maintaining optimal functioning.

Whether addressing minor hiccups or performing standard maintenance, the information presented here serves as a valuable tool for anyone looking to extend the lifespan of these versatile vehicles. Emphasis on practical advice ensures that users can confidently navigate challenges as they arise.

Bajaj Three Wheeler Overview

This section provides an insight into a popular mode of transportation known for its compact design and versatility. Often utilized in urban settings, these vehicles are favored for their ability to navigate through narrow streets and heavy traffic. Their efficiency and economical operation make them a preferred choice for both personal and commercial use.

Key Features

- Compact size for easy maneuverability

- Fuel-efficient engine options

- Versatile usage for transporting goods and passengers

- Robust build quality for durability

Applications

- Urban commuting

- Goods delivery services

- Tourist transportation in crowded areas

- Last-mile connectivity solutions

Common Issues and Solutions

In any vehicle, certain problems may arise that can affect performance and efficiency. Understanding these common challenges and their remedies can enhance reliability and extend the lifespan of the vehicle. This section outlines frequent concerns and their potential solutions.

-

Starting Difficulties:

If the vehicle struggles to start, consider checking the battery charge and connections. Ensure the ignition system is functioning properly.

-

Overheating:

Excessive temperature can lead to severe damage. Check the coolant levels and inspect the radiator for blockages.

-

Noisy Engine:

Unusual sounds may indicate issues with engine components. Regular maintenance can help identify and resolve these problems early.

-

Poor Fuel Efficiency:

Decreased fuel economy can be a sign of various issues, such as clogged filters or improper tire pressure. Regularly inspect and maintain these components.

-

Braking Issues:

If the braking system feels unresponsive or makes noise, inspect the brake pads and fluid levels. Replace worn components promptly.

By addressing these common challenges with timely interventions, vehicle owners can ensure smoother operation and a better overall experience.

Essential Tools for Repairs

When maintaining or fixing your vehicle, having the right instruments at your disposal is crucial. A well-equipped toolkit can significantly enhance efficiency and effectiveness during the maintenance process. Understanding the variety of tools available ensures that you are prepared for various tasks that may arise.

Wrenches are fundamental for loosening or tightening nuts and bolts. A set that includes different sizes is vital for accessing various components. Additionally, screwdrivers come in various types, such as flathead and Phillips, to accommodate different screws.

Plier sets are indispensable for gripping and manipulating small parts, especially in tight spaces. For more delicate tasks, precision tools like tweezers can be invaluable. Furthermore, an impact driver can provide extra torque when needed, making it easier to handle stubborn fasteners.

Don’t forget the importance of a good jack and jack stands for lifting the vehicle safely during maintenance. Lastly, a reliable toolbox or organizer helps keep everything in one place, ensuring you can find what you need when you need it.

Engine Maintenance Guidelines

Regular upkeep of the power unit is crucial for ensuring optimal performance and longevity. Adhering to maintenance protocols not only enhances efficiency but also helps prevent unexpected breakdowns.

Routine Inspections: Schedule frequent examinations to identify any potential issues early. Check for leaks, unusual noises, or vibrations, as these can indicate underlying problems that need addressing.

Fluid Levels: Ensure that all essential fluids, including oil and coolant, are at appropriate levels. Regularly replacing engine oil is vital for minimizing wear and tear on components.

Air Filter Maintenance: Clean or replace the air intake filter as needed. A clean filter ensures optimal airflow, improving combustion and overall performance.

Belts and Hoses: Inspect belts and hoses for signs of wear, cracks, or fraying. Replace any damaged parts promptly to avoid further complications.

Spark Plugs: Regularly check and replace spark plugs to ensure efficient ignition and fuel combustion. This simple task can greatly affect engine performance.

Cleaning: Keep the engine compartment clean and free of debris. This not only aids in performance but also allows for easier identification of potential issues.

By following these maintenance guidelines, operators can ensure a reliable and efficient engine, contributing to a smoother overall experience.

Transmission System Troubleshooting

Troubleshooting the transmission system is essential for ensuring smooth operation and reliability of any vehicle. Identifying common issues can prevent further complications and improve performance. This section will guide you through the necessary steps to diagnose and resolve transmission-related problems.

Common Symptoms and Their Causes

Understanding the signs of transmission trouble is the first step in addressing potential issues. Common symptoms include unusual noises, difficulty shifting gears, or slipping of the transmission. These problems can stem from various causes, such as low fluid levels, worn components, or damaged seals. Regular inspection and maintenance can help mitigate these issues before they escalate.

Diagnostic Steps

To effectively troubleshoot transmission issues, start by checking the fluid level and condition. Ensure the fluid is clean and at the correct level. If you notice any discoloration or a burnt smell, it may indicate a need for replacement. Next, inspect the linkage and cables for proper adjustment. A misaligned linkage can cause shifting problems. Finally, conduct a thorough visual inspection for leaks or damage to the transmission case.

Electrical Components and Repairs

This section focuses on the essential electronic elements and their maintenance procedures within compact vehicles. Understanding these components is crucial for ensuring optimal performance and reliability.

Wiring Systems: The wiring networks are vital for connecting various parts of the vehicle. Regular inspection for wear, corrosion, or loose connections can prevent electrical failures.

Battery Maintenance: The energy source must be kept in good condition. Checking the fluid levels, terminals, and overall health can extend its lifespan significantly.

Lighting Fixtures: Proper illumination is essential for safety. Regularly examine bulbs and connections to ensure they function correctly, replacing any that are burnt out or damaged.

Fuse Box: This component protects the electrical system from overloads. Familiarity with the fuse layout and understanding how to replace blown fuses is necessary for maintaining functionality.

Alternator: The device responsible for generating electrical power while the engine runs should be routinely tested. Signs of wear or unusual noises can indicate the need for servicing or replacement.

Diagnostic Tools: Utilizing electronic diagnostic tools can help identify issues within the electrical system efficiently. Regular diagnostics can save time and reduce costs associated with unforeseen repairs.

Braking System Inspection Tips

Ensuring the functionality of the stopping mechanism is crucial for safe operation. Regular assessment can help identify potential issues before they escalate, contributing to overall vehicle performance and safety.

Key Components to Check

Focus on the essential parts of the stopping system to guarantee reliability:

| Component | Inspection Checklist |

|---|---|

| Pads | Check for wear and even thickness; replace if less than recommended. |

| Rotors | Look for grooves, warping, and surface damage; measure thickness. |

| Fluid | Inspect fluid level and condition; flush if contaminated. |

Common Issues to Watch For

Be aware of these frequent problems that may arise:

- Unusual noises during application.

- Vibration or pulling to one side when stopping.

- Soft or spongy pedal feel.

Wheel Alignment and Suspension Care

Maintaining proper alignment and suspension is essential for the smooth operation and longevity of your vehicle. Ensuring that all components function harmoniously contributes to improved handling, comfort, and safety while driving.

Regular checks of alignment and suspension can prevent uneven tire wear and enhance fuel efficiency. Here are some key points to consider:

- Regular Inspections: Schedule periodic inspections to identify any misalignments or issues with suspension components.

- Tire Condition: Monitor tire wear patterns; uneven wear may indicate alignment problems.

- Impact Awareness: Be cautious of potholes and road irregularities, as these can negatively affect alignment and suspension.

Addressing alignment and suspension concerns promptly can enhance vehicle performance and ensure a safer driving experience. It’s advisable to consult a professional if you notice any significant issues.

Fuel System Cleaning Procedures

Proper maintenance of the fuel delivery system is essential for optimal engine performance and longevity. Regular cleaning helps to remove deposits and contaminants that can hinder the flow of fuel, ensuring that the engine runs smoothly and efficiently.

Preparation Steps

Before commencing the cleaning process, gather all necessary tools and materials. Ensure that the engine is cool and the vehicle is parked in a well-ventilated area. It is crucial to follow safety protocols to avoid any hazards during the procedure.

Cleaning Procedure

Follow these steps to effectively clean the fuel system:

| Step | Description |

|---|---|

| 1 | Disconnect the battery to prevent any electrical hazards. |

| 2 | Remove the fuel filter and inspect it for any signs of clogging or damage. |

| 3 | Use a fuel system cleaner additive as per the manufacturer’s instructions to clean the injectors. |

| 4 | Flush the fuel lines with a suitable solvent to remove any residue. |

| 5 | Replace the fuel filter with a new one to ensure proper flow. |

| 6 | Reconnect the battery and start the engine, checking for any leaks. |

Regular cleaning of the fuel system is a proactive approach to maintaining vehicle performance and efficiency. Following these procedures can help prevent potential issues that may arise from neglecting this vital component.

Regular Maintenance Schedule

Ensuring the longevity and efficiency of your vehicle requires a systematic approach to upkeep. Regular checks and timely interventions can prevent major issues and enhance performance, making it essential to adhere to a well-defined schedule.

The following table outlines the recommended intervals for essential maintenance tasks, providing a clear guide for optimal vehicle care:

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 3,000 kilometers |

| Air Filter Inspection | Every 5,000 kilometers |

| Tire Rotation | Every 6,000 kilometers |

| Brake System Check | Every 10,000 kilometers |

| Battery Condition Assessment | Every 12 months |

| Coolant Level Check | Every 6 months |

Following this schedule diligently will help in maintaining the functionality and reliability of your vehicle, ensuring a safe and smooth ride.

Safety Precautions During Repairs

When undertaking maintenance on vehicles, adhering to safety guidelines is essential to ensure a secure environment for both the technician and the equipment. Prioritizing protection helps to prevent accidents and injuries, fostering a more effective workspace.

Personal Protective Equipment

Always wear appropriate personal protective gear, including gloves, safety glasses, and sturdy footwear. This equipment serves as a barrier against potential hazards such as sharp objects, chemicals, and heavy components.

Work Environment Organization

Keep the workspace clean and organized. Remove any unnecessary items that may obstruct movement or pose tripping hazards. Properly store tools and materials to reduce the risk of accidents, ensuring easy access when needed.

Frequently Asked Questions

This section aims to address common inquiries regarding maintenance and troubleshooting for compact vehicles commonly used in urban settings. Here, you will find answers that help clarify common concerns and enhance understanding of operational procedures.

What should I do if my vehicle won’t start?

If the ignition fails, check the battery connections and ensure they are secure. Also, examine the fuel level and consider potential issues with the starter system.

How often should I perform maintenance on my vehicle?

Regular upkeep is essential. It is advisable to conduct checks and services at least every 5,000 kilometers or as recommended by the manufacturer to ensure optimal performance.

What are the signs of engine trouble?

Indicators include unusual noises, a drop in power, or warning lights on the dashboard. Early detection can prevent more serious issues.

Can I perform maintenance myself?

Yes, basic tasks such as oil changes and filter replacements can be done at home with the right tools and knowledge. However, more complex issues should be handled by professionals.

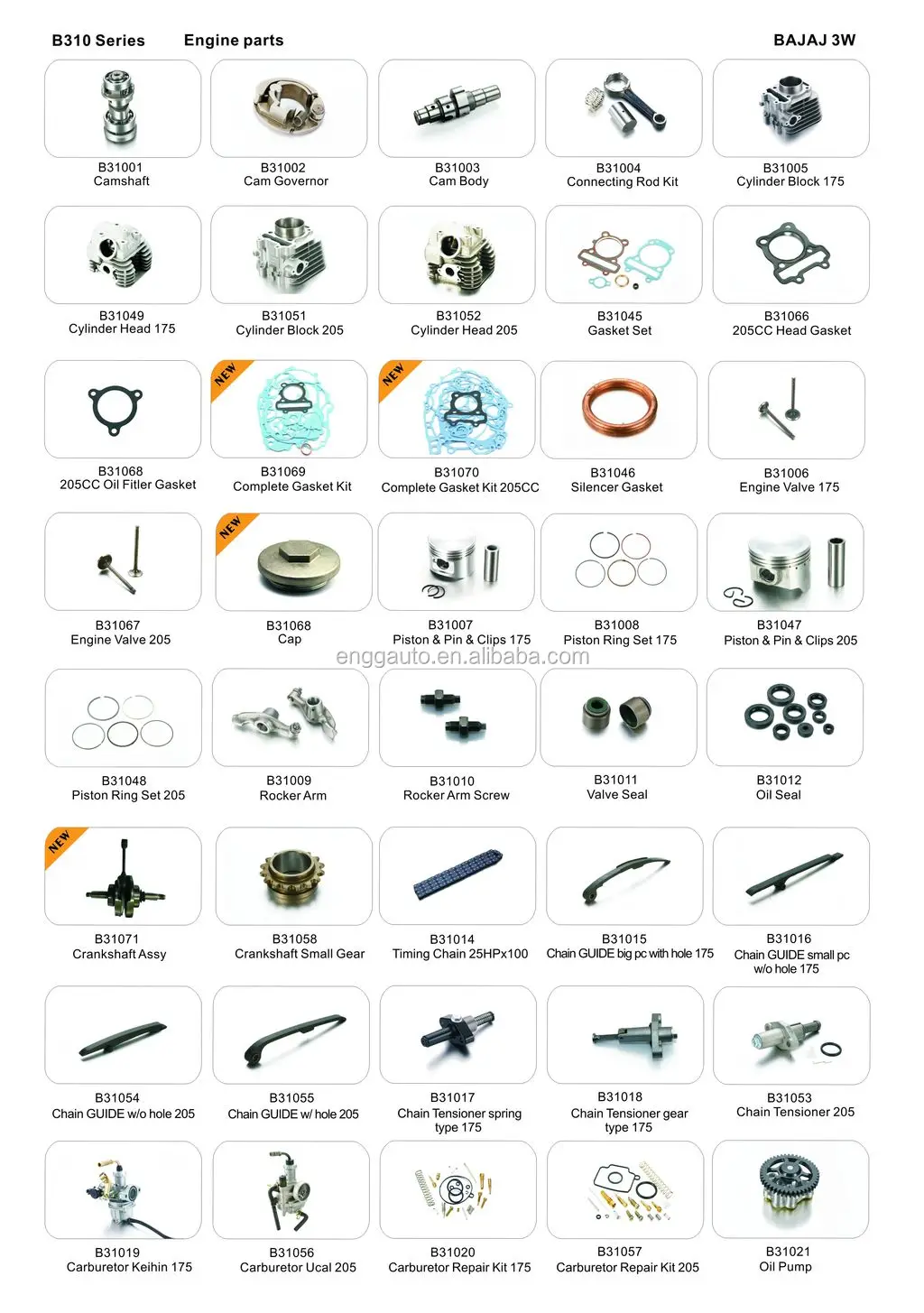

Where can I find replacement parts?

Replacement components can typically be sourced from authorized dealers, local auto parts stores, or online platforms specializing in automotive supplies.