Comprehensive Guide to Allison Transmission Repair

When it comes to maintaining and enhancing the performance of complex machinery, understanding the intricacies involved is essential. This section focuses on comprehensive strategies for addressing common issues that arise within vital components of heavy equipment. By familiarizing oneself with the fundamentals, operators can ensure longevity and efficiency.

Proper knowledge and techniques not only facilitate smoother operations but also contribute to significant cost savings. By utilizing systematic approaches, individuals can effectively troubleshoot and rectify various challenges encountered during usage.

Furthermore, the importance of routine assessments cannot be overstated. Engaging in preventive measures and regular evaluations ensures that potential problems are identified early, thereby avoiding extensive downtime and costly repairs. This proactive stance cultivates a better understanding of the machinery’s needs and capabilities.

This section aims to provide a comprehensive understanding of a widely utilized vehicle component known for its performance and reliability. We’ll explore the key features, functions, and advantages that make this system essential in modern machinery.

Key Characteristics

The following points highlight the significant traits of this mechanical system:

- Enhanced efficiency in power delivery

- Robust design suitable for various applications

- Advanced technology for smoother operation

Benefits of Proper Maintenance

Maintaining this essential component ensures longevity and optimal performance. Consider these advantages:

- Increased durability and reliability

- Improved fuel efficiency

- Reduced risk of breakdowns

Common Issues in Allison Transmissions

In the world of automotive mechanics, certain challenges tend to arise frequently, particularly concerning complex systems that manage power delivery. Understanding these common problems can help vehicle owners and technicians alike in diagnosing and addressing issues effectively.

One prevalent concern is slipping, where the system fails to engage properly, leading to a lack of acceleration. This can often stem from fluid level deficiencies or contamination. Overheating is another critical issue, which may result from inadequate cooling or excessive load, potentially causing significant damage if not addressed promptly.

Additionally, unexpected noises during operation can indicate internal wear or component failure, warranting immediate attention. Regular maintenance and fluid checks are essential in preventing these issues and ensuring optimal performance.

Step-by-Step Repair Procedures

This section outlines the detailed processes necessary for addressing common issues in vehicle gear systems. Following these organized steps will ensure that each stage is executed efficiently and accurately, minimizing potential complications during the procedure.

1. Preparation: Before starting, gather all necessary tools and equipment. Ensure that the workspace is clean and organized to facilitate a smooth workflow.

2. Disassembly: Carefully remove the components as per the guidelines. Take note of the order of removal to assist with reassembly later. Use labeled containers to store small parts and fasteners.

3. Inspection: Thoroughly examine each component for wear or damage. Look for signs of leakage, corrosion, or other indicators that may require attention. Document any findings for reference.

4. Replacement: Replace any damaged parts with new, high-quality components. Ensure compatibility with the existing system to maintain functionality.

5. Reassembly: Follow the reverse order of disassembly to reassemble the system. Ensure all connections are secure and that components are aligned correctly.

6. Testing: After reassembly, perform thorough testing to verify that the system operates as expected. Monitor for any unusual sounds or performance issues.

7. Final Review: Conduct a final inspection to ensure everything is in place and functioning properly. Make any necessary adjustments before returning the vehicle to service.

Essential Tools for Repairs

When undertaking vehicle maintenance, having the right equipment is crucial for ensuring efficiency and precision. A well-equipped workshop not only facilitates the task at hand but also enhances safety and effectiveness in handling various components. Understanding which instruments are necessary can make the difference between a smooth operation and a frustrating experience.

Basic Hand Tools

Fundamental instruments such as wrenches, screwdrivers, and pliers are indispensable in any maintenance endeavor. These tools enable you to access and secure various parts easily. Investing in a high-quality set can improve your ability to perform tasks swiftly and accurately.

Specialized Equipment

In addition to hand tools, certain specialized equipment may be required for more complex tasks. This can include hydraulic jacks, torque wrenches, and diagnostic devices. These tools help in ensuring that components are not only installed correctly but also function optimally, thereby prolonging the life of the vehicle.

Maintenance Tips for Longevity

To ensure the extended lifespan of your vehicle’s power delivery system, regular upkeep is essential. Proper maintenance practices can help prevent costly issues and enhance performance over time.

Regular Fluid Checks: Ensure that the fluid levels are consistently monitored and topped up as necessary. Clean and adequate fluid is crucial for optimal functionality.

Timely Filter Replacements: Replacing filters at recommended intervals prevents contaminants from affecting the system. This simple step can significantly improve efficiency and durability.

Routine Inspections: Conduct periodic inspections to identify any potential wear or damage early. Addressing minor issues promptly can prevent more significant complications later.

Driving Habits: Adopting smooth driving techniques can reduce stress on the components. Avoiding abrupt starts and stops contributes to better longevity.

Professional Servicing: Scheduling regular check-ups with a qualified technician can provide peace of mind. Experts can detect issues that may not be apparent to the average driver.

Understanding Transmission Fluid Types

Fluid plays a crucial role in the operation and longevity of automatic gear systems. It not only lubricates moving parts but also aids in cooling and enhancing performance. Selecting the right type of fluid is essential for maintaining optimal functionality and ensuring the system operates smoothly over time.

Types of Fluids Available

Various formulations exist, each designed for specific applications. Understanding these differences can help in choosing the most suitable option for your needs. Below is a comparison of some common fluid types:

| Fluid Type | Characteristics | Common Uses |

|---|---|---|

| Mineral Oil | Traditional option, good lubricating properties | Older vehicle models |

| Synthetic Fluid | Enhanced performance, better temperature resistance | High-performance and modern systems |

| Dexron and Mercon | Specific to certain manufacturers, versatile | Wide range of vehicles |

Choosing the Right Fluid

When selecting fluid, consider the manufacturer’s specifications and the intended use. Regular checks and changes are essential to prevent issues and maintain efficiency. Always consult relevant resources to ensure compatibility and make informed decisions.

Diagnosing Transmission Problems

Identifying issues within a vehicle’s shifting mechanism is crucial for maintaining optimal performance. Various signs can indicate that something is amiss, and recognizing these early can prevent more significant damage. This section outlines essential steps for pinpointing potential difficulties.

Common Symptoms to Look For

Drivers may notice unusual sounds, erratic behavior, or warning lights on the dashboard. Unexplained noises such as grinding or whining can signify underlying concerns. Additionally, difficulty in changing gears or unexpected slips can further hint at malfunctions.

Initial Diagnostic Steps

Start by checking fluid levels, as low or dirty fluids can lead to numerous complications. It’s essential to monitor fluid color and consistency; a burnt smell or dark hue may indicate the need for further investigation. Conducting a visual inspection of external components can also reveal leaks or damage that require attention.

Replacement Parts and Options

When it comes to maintaining and enhancing the performance of your vehicle’s power transfer system, understanding the available components is crucial. This section delves into various alternatives and options that can be considered for effective system management.

High-quality components play a significant role in ensuring optimal performance. Various manufacturers offer a range of parts designed to fit specific requirements, enhancing durability and efficiency. It’s essential to explore both original equipment and aftermarket choices, as each presents unique benefits and considerations.

Moreover, compatibility and installation ease are paramount factors to keep in mind when selecting parts. Consulting with professionals or utilizing detailed guides can aid in making informed decisions, ensuring that the chosen options align with your vehicle’s specifications and performance goals.

Upgrading Allison Transmissions

Enhancing the performance of automatic gear systems can significantly improve vehicle efficiency and responsiveness. This section explores various strategies for optimizing these systems to meet specific operational demands and enhance overall driving experience.

Performance Enhancements

To achieve superior performance, consider integrating advanced components that promote smoother shifting and increased torque handling. Upgrades may include high-performance clutches and enhanced cooling systems, which can help extend the lifespan of your equipment and maintain peak efficiency.

Maintaining Efficiency

Regular maintenance and strategic upgrades can contribute to better fuel economy and reduced wear. Implementing modifications such as electronic control unit tuning can adjust shifting patterns for improved responsiveness, ultimately leading to enhanced operational capabilities.

| Upgrade Type | Benefits | Considerations |

|---|---|---|

| High-Performance Clutches | Smoother engagement, increased torque capacity | Higher cost, may require additional adjustments |

| Cooling Systems | Prevents overheating, extends lifespan | Installation complexity, need for regular checks |

| ECU Tuning | Optimized shifting, improved fuel efficiency | Potential warranty issues, requires expertise |

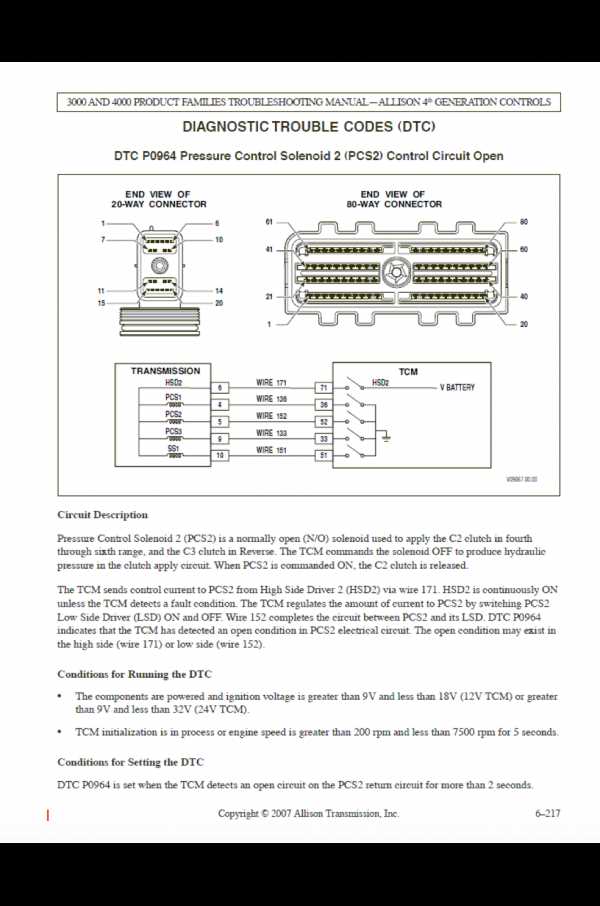

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of a vehicle is crucial for ensuring optimal performance and reliability. This section outlines the fundamental steps to identify and resolve common electrical problems, enhancing the overall functionality of the system.

Understanding Symptoms

Recognizing the signs of electrical malfunctions is the first step. Symptoms may include inconsistent performance, warning lights on the dashboard, or failures in components such as lights and sensors. Each indicator can point to specific issues that require thorough investigation.

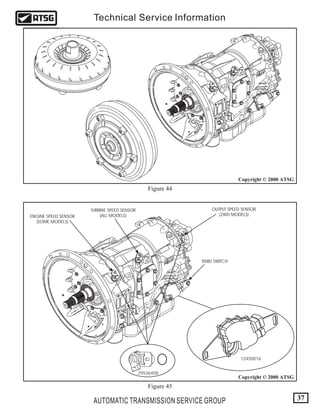

Utilizing Diagnostic Tools

Employing appropriate diagnostic equipment, such as multimeters and scanners, is essential. These tools assist in measuring voltage, current, and resistance, helping to pinpoint the source of the problem effectively. Regular checks can prevent minor issues from escalating.

Inspecting Connections

Loose or corroded connections are common culprits in electrical failures. Inspect all wiring and terminals for signs of wear or damage. Ensuring solid connections can significantly improve the system’s reliability and efficiency.

Testing Components

Each electrical component should be tested individually to verify its functionality. This includes checking fuses, relays, and switches. By isolating each part, one can determine whether it is operating within specified parameters or requires replacement.

Consulting Documentation

Having access to specific documentation related to the vehicle’s electrical system can provide invaluable insights. Referencing diagrams and troubleshooting charts can clarify complex issues and guide the diagnostic process.

Preventative Measures to Avoid Repairs

Implementing proactive strategies can significantly reduce the likelihood of malfunctions in your vehicle’s systems. Regular maintenance and careful operation are essential components in prolonging the lifespan of complex machinery.

Regular Maintenance Checks

Scheduling frequent inspections can help identify potential issues before they escalate. Here are key aspects to focus on:

- Fluid levels and quality

- Component wear and tear

- Electrical connections and wiring

- Seals and gaskets integrity

Operating Best Practices

Adhering to recommended usage guidelines can enhance performance and minimize the risk of damage. Consider the following practices:

- Avoid overloading the vehicle beyond its capacity.

- Use appropriate driving techniques, especially in challenging conditions.

- Allow the machinery to warm up before heavy use.

- Be mindful of unusual sounds or behaviors during operation.

Resources for Further Information

When seeking knowledge about specific mechanisms and their maintenance, a variety of resources can provide valuable insights. These tools and materials can enhance understanding and assist in troubleshooting effectively.

Online Platforms

- Forums dedicated to automotive discussions often feature expert opinions and user experiences.

- Video tutorials available on streaming platforms can visually guide through various processes.

- Websites specializing in vehicle maintenance offer comprehensive articles and guides.

Books and Publications

- Technical books authored by industry professionals can provide in-depth analysis and detailed instructions.

- Trade magazines frequently cover new technologies and best practices in the field.

- Workshops and manuals available at local libraries can serve as practical references.