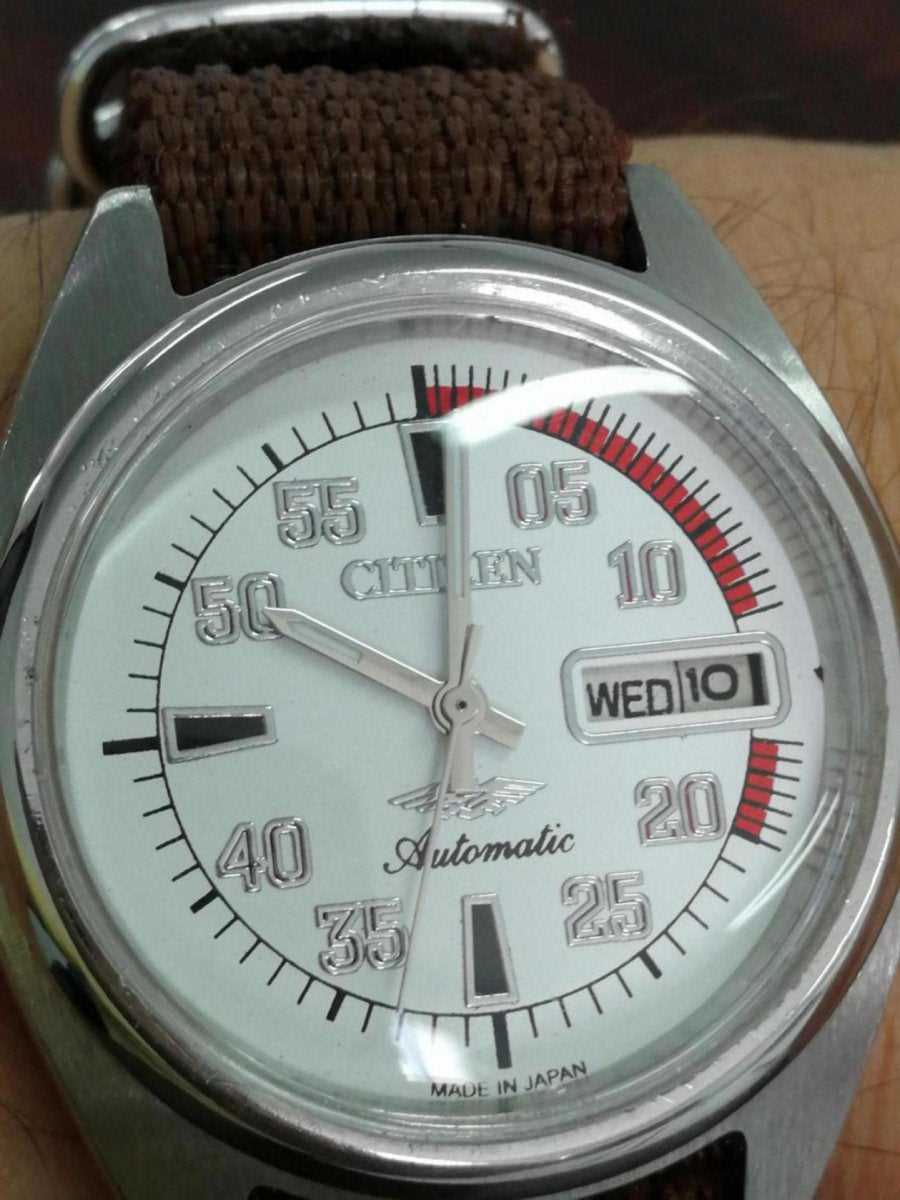

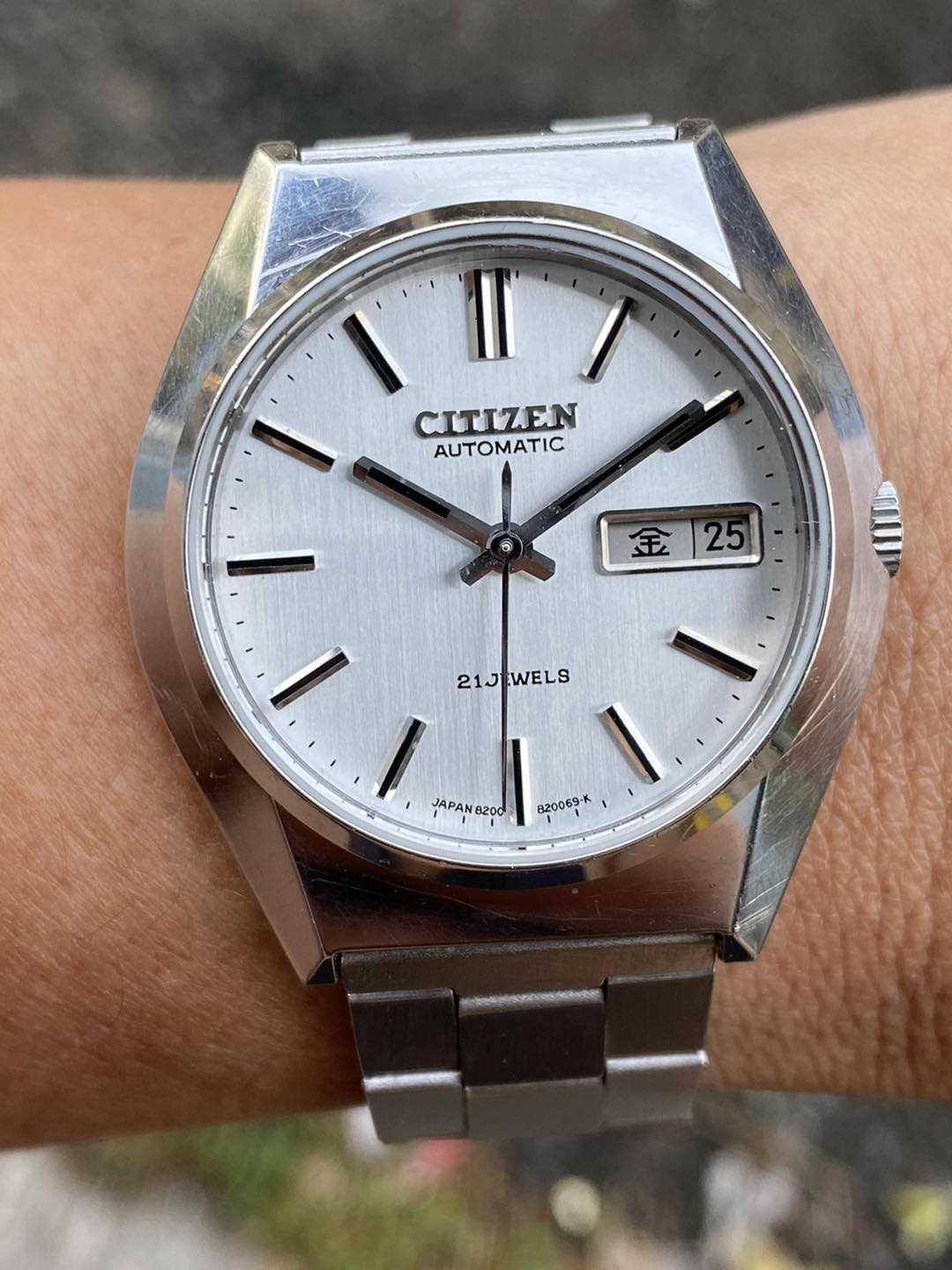

Repair Guide for Citizen 8200A Watch

Understanding the intricacies of a classic watch mechanism can be a fascinating journey for any enthusiast. This guide is designed to help you delve into the world of watch restoration, offering insights into both the essential components and steps involved in bringing a timeless piece back to life.

Maintenance and care are crucial to ensuring the longevity of any watch. Here, we provide an in-depth look at the mechanisms that require regular attention, highlighting adjustments and checks that can help prevent common issues. The guidance in this section will help you keep every part working smoothly for years to come.

For those tackling a timepiece restoration project, an understanding of each part’s function is essential. This guide covers the essentials of reassembling and fine-tuning the internal workings, ensuring that your watch maintains accurate time and remains a treasured accessory. With clear steps and practical advice, you can gain the confidence to handle even intricate repairs with ease.

Understanding the Citizen 8200a Mechanism

The mechanism in this model is designed to provide reliable performance while incorporating intricate parts that work in harmony. Knowing how these components function together can help maintain precision and ensure long-lasting operation. This section delves into the essential elements and the sequence in which they interact, offering insight into how each part contributes to overall functionality.

Core Components and Their Functions

The internal structure includes several key elements that support timing accuracy and durability. Here’s a closer look at the main components involved:

- Main Spring: Powers the entire movement by storing and releasing energy gradually.

- Balance Wheel: Regulates the timekeeping with its oscillating motion.

- Escapement: Controls the release of energy from the mainspring to the gears, allowing consistent time intervals.

- Gear Train: Transmits the power generated by the spring to various parts of the mechanism.

Sequence of Movement

To better understand how these components work together, consider the sequence in which energy is transmitted:

- The main spring stores energy, gradually unwinding and releasing this force.

- The energy flows through the gear train, which reduces and controls the force.

- The escapement then regulates this flow, allowing a measured release of energy to the balance wheel.

- The balance wheel oscillates, maintaining consistent timing and ensuring the hands move accurately across the dial.

By familiarizing yourself with this sequence, it becomes easier to recognize potential issues and appreciate the precision engineering involved in each phase of movement.

Essential Tools for Citizen 8200a Repairs

To ensure successful maintenance and adjustments of mechanical timepieces, having a precise and well-rounded toolkit is crucial. Each item plays a significant role in achieving accuracy and preserving the integrity of delicate parts.

Primary Instruments for Precision

- Screwdriver Set: A collection of fine screwdrivers with various tip sizes is essential for handling tiny screws without damaging surfaces.

- Tweezers: Precision tweezers aid in positioning and adjusting small components without risking scratches or misalignment.

- Loupe: A high-quality magnifying loupe allows for close inspection of intricate parts, ensuring detailed observation during adjustments.

Additional Tools for Effective Maintenance

- Cleaning Solution: Specially formulated solutions help remove dust and oil buildup, ensuring smooth functionality.

- Oil Applicator: A precise oiler provides lubrication to specific points, essential for reducing friction and prolonging the lifespan of components.

- Timegrapher: This tool measures the accuracy of the device’s rhythm, making it possible to detect and correct deviations in timing.

Using these tools with care enables thorough servicing, helping to sustain peak performance and prolong the functional life of the device.

Identifying Common Issues in the 8200a Model

Understanding the typical challenges faced by this model can help users maintain its performance and longevity. By recognizing the patterns in frequent issues, owners can preemptively address potential disruptions and ensure consistent operation.

Timing Inconsistencies: Over time, some mechanisms may experience slight shifts that impact accuracy. Regular checks and periodic adjustments can mitigate these effects, keeping the timekeeping function precise.

Power Retention Concerns: Certain internal components may struggle to hold power consistently, leading to unplanned stops. Inspecting the energy storage and transfer areas can often reveal whether specific replacements or recalibrations are necessary.

Environmental Sensitivity: Exposure to moisture or extreme temperatures can interfere with internal processes. Ensuring the device stays within optimal conditions can prevent accelerated wear and maintain its structural integrity.

By routinely observing these potential issues, users can significantly extend the functionality of their device, reducing the need for extensive servicing.

Step-by-Step Disassembly of This Timepiece Mechanism

This guide provides a detailed breakdown of how to carefully take apart this specific watch movement, ensuring each component is handled with precision. Following these steps enables a smooth disassembly process, which is essential for maintaining the mechanism’s condition and functionality.

Preparation: Before beginning, ensure you have a clean workspace and suitable tools. A soft surface prevents scratches on delicate parts, and well-organized tools contribute to a seamless workflow.

Removing the Back Cover: Start by gently releasing the back cover using a specialized tool, taking care not to damage any surrounding elements. Once open, proceed with caution, observing the position of each part.

Detaching the Movement: The main mechanism can now be accessed. Carefully release it from its casing by loosening the screws or clamps holding it in place. Place each removed part in an organized layout for easy reassembly.

Disassembling the Components: With the movement free, proceed to detach each component methodically. Begin with larger elements and work down to smaller, intricate pieces. Make note of their positioning to ensure a successful reassembly later.

Conclusion: Proper handling during this disassembly phase protects the integrity of the movement. Take your time, and remember to store each component securely to avoid misplacement or damage.

Cleaning and Maintenance Tips for Longevity

Regular upkeep is essential for ensuring that your timepiece operates smoothly over many years. Consistent attention to cleanliness and minor adjustments can help keep every component in optimal working condition.

Basic Cleaning Practices

Begin by gently wiping the surface with a soft, dry cloth to remove dust and oils. For tougher residues, lightly dampen the cloth, avoiding direct exposure to water. Pay attention to the bracelet and clasp areas, where debris often accumulates. If accessible, use a small brush with soft bristles to reach tighter spaces.

Maintaining Inner Components

For parts inside the mechanism, it is crucial to follow a systematic approach to avoid any damage. Consider occasional internal maintenance by a professional to prevent wear. During this process, any worn-out parts can be replaced to maintain peak function.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Surface cleaning | Weekly | Use a microfiber cloth |

| Strap and clasp check | Monthly | Inspect for any looseness |

| Internal mechanism review | Yearly | Performed by a professional |

Following these guidelines will contribute to the extended lifespan of your timepiece, keeping it reliable and maintaining its precision over time.

Replacing Worn-Out Components Effectively

Over time, various elements of a device may become inefficient or fail to perform as intended, necessitating their replacement to ensure optimal functionality. Addressing this issue promptly not only extends the lifespan of the equipment but also enhances its performance.

When it comes to swapping out degraded parts, it is essential to identify the components that are most susceptible to wear. Regular inspections can help detect signs of deterioration early, allowing for timely interventions. Utilizing high-quality replacements is critical, as subpar components may lead to further issues down the line. Additionally, ensuring proper installation techniques will significantly influence the overall effectiveness of the repairs.

In summary, a systematic approach to replacing worn parts can greatly improve the longevity and reliability of your equipment. Investing time in understanding the replacement process and selecting appropriate components will pay off in the long run.

Lubrication Guide for Smooth Performance

Maintaining optimal functionality in mechanical devices is crucial for longevity and reliability. Proper lubrication not only reduces friction but also helps in dissipating heat and preventing wear and tear. This guide provides essential information on the types of lubricants to use and the recommended intervals for application to ensure seamless operation.

Types of Lubricants

Different components require specific types of lubricants to function effectively. Below are the commonly used lubricants suitable for various applications:

| Component | Recommended Lubricant | Application Method |

|---|---|---|

| Gears | High-viscosity oil | Dropper or syringe |

| Bearings | Grease | Grease gun |

| Pivots | Light oil | Spray or dropper |

Lubrication Schedule

Establishing a regular lubrication schedule is vital for maintaining performance. Here is a suggested timeline for application:

| Frequency | Action |

|---|---|

| Every Month | Inspect and apply lubricants to all components |

| Every Six Months | Thorough cleaning and reapplication of grease in bearings |

| Annually | Complete system inspection and replacement of lubricants if necessary |

Troubleshooting Timing Inconsistencies

Addressing timing discrepancies is essential for ensuring optimal performance and accuracy in your timekeeping device. Various factors can contribute to these inconsistencies, and understanding them can facilitate effective problem-solving. This section outlines common issues and solutions related to timing irregularities.

- Battery Status: A weak or depleted power source can cause fluctuations in timekeeping. Check the battery level and replace it if necessary.

- Environmental Factors: Extreme temperatures or humidity can affect the internal mechanisms. Ensure the device is stored and operated in a stable environment.

- Mechanical Obstructions: Dirt or debris within the casing can impede movement. Regular cleaning and maintenance are crucial to prevent such issues.

- Calibration Issues: If the device has not been calibrated properly, it may not keep accurate time. Follow the calibration procedure as outlined in the guidelines.

By systematically checking these potential sources of timing inconsistencies, users can restore their timekeeping devices to proper functionality.

Reassembling the Citizen 8200a Correctly

Reassembling this particular timekeeping device requires precision and attention to detail to ensure its proper functionality. Following a systematic approach will help in restoring it to its original state, preventing any potential issues during operation.

Here are the key steps to consider when putting the components back together:

- Gather All Parts: Ensure that you have all the necessary components, including screws, gears, and covers, before starting the reassembly process.

- Inspect Each Component: Check for any signs of wear or damage. Replace any defective parts as needed.

- Follow the Original Assembly Order: Reassembling in the reverse order of disassembly can help avoid missing any crucial steps.

- Secure Fasteners Properly: Tighten screws and fasteners appropriately, ensuring they are not overly tight to avoid damaging the components.

- Test the Mechanism: Before sealing the case, check the movement and functionality of the internal parts to confirm everything is operating smoothly.

By adhering to these guidelines, you can effectively reassemble the device, ensuring it remains accurate and reliable for continued use.

Testing Functionality Post-Repair

After addressing issues in a timepiece, it is crucial to verify that all features operate as intended. This step ensures that the adjustments made have resolved any previous malfunctions and that the device meets performance standards.

Begin by conducting a systematic evaluation of the various functions:

- Timekeeping Accuracy: Check if the timepiece maintains accurate time over a specified period.

- Chronograph Function: Test the stopwatch feature to ensure it starts, stops, and resets correctly.

- Date Display: Verify that the date changes accurately, especially at the transition between months.

- Power Reserve: Assess how long the timepiece runs without additional winding or charging.

- Water Resistance: If applicable, perform a water resistance test to confirm that the seals are intact.

Each test should be documented to track performance and identify any further adjustments needed. Consistent checks will aid in maintaining the reliability and longevity of the timekeeping device.

Preventative Care for Future Reliability

Ensuring the longevity and dependable performance of any timekeeping device hinges on the implementation of consistent maintenance practices. By adopting a proactive approach, users can significantly reduce the likelihood of malfunctions and enhance the overall durability of their instruments.

Regularly inspecting the device for signs of wear and tear is essential. This includes checking for any visible damage or misalignment that may affect its functionality. Additionally, it is advisable to clean the exterior to prevent dust and grime buildup, which can compromise both aesthetics and operation.

Utilizing appropriate storage solutions can also extend the lifespan of the equipment. Keeping it in a controlled environment, away from extreme temperatures and humidity, will help maintain its precision and reliability. Furthermore, seeking professional servicing at recommended intervals ensures that any potential issues are addressed before they escalate into more serious concerns.

Finally, remaining informed about best practices for care will empower users to make knowledgeable decisions regarding their timekeeping instruments, leading to a rewarding ownership experience and sustained reliability over time.