Comprehensive Guide to Repairing the Pfaff 1222e Sewing Machine

Maintaining a sewing device can often seem daunting, especially when unexpected issues arise. Understanding the intricacies of your equipment not only enhances its performance but also extends its lifespan. This guide aims to equip you with essential knowledge to address common challenges effectively.

From basic maintenance tasks to more complex adjustments, mastering these skills will empower you to tackle any problem confidently. Whether you’re an experienced seamstress or just starting, having a reliable reference can make a significant difference in your crafting experience.

In this section, we will delve into key techniques and solutions to common complications. You’ll find valuable insights that will help you keep your machine in optimal condition and ensure smooth operation during every project.

Understanding Pfaff 1222e Features

Exploring the functionality of a high-quality sewing machine reveals a wealth of innovative features designed to enhance the crafting experience. These attributes not only facilitate precise stitching but also allow for a variety of creative expressions. Understanding these elements can empower users to maximize their potential and produce professional-level results.

One of the standout qualities of this model is its versatility, offering numerous stitch options that cater to different fabric types and project requirements. The adjustable settings enable users to customize their work, whether they are tackling delicate materials or heavy-duty fabrics. Furthermore, the presence of an integrated walking foot ensures smooth feeding, eliminating the frustrations often associated with layers slipping during sewing.

Another significant aspect is the user-friendly interface, which includes an intuitive display and easily accessible controls. This design consideration minimizes the learning curve, allowing both beginners and experienced sewers to navigate functions effortlessly. Additionally, features such as automatic needle threading and programmable patterns streamline the process, making it more efficient and enjoyable.

Durability is also a key feature, with a robust construction that promises longevity. This reliability is essential for those who engage in frequent use, as it assures consistent performance over time. Coupled with a smooth operation, this machine stands out as an excellent investment for any sewing enthusiast.

In summary, the combination of versatile options, user-friendly design, and robust construction makes this sewing machine a valuable tool. Understanding these features can enhance creativity and ensure satisfaction in every project undertaken.

Common Issues with Pfaff 1222e

When working with sewing machines, users may encounter several recurring problems that can affect performance and efficiency. Understanding these challenges is crucial for maintaining optimal functionality and ensuring a smooth sewing experience.

Thread Jamming: One prevalent issue is thread jamming, which often occurs when the upper or lower thread fails to feed correctly. This can lead to frustrating interruptions and potential damage to the fabric being used.

Needle Breakage: Another common concern is needle breakage, which can happen for various reasons, including improper needle size or threading issues. Regular inspection of the needle and its alignment is essential to prevent this problem.

Tension Problems: Many users also report issues with thread tension. Incorrect tension can result in uneven stitches or fabric puckering. Adjusting the tension settings carefully can help alleviate this issue.

Motor Malfunctions: Motor-related problems may arise, causing the machine to operate inconsistently or not at all. Regular maintenance, such as cleaning and oiling, can help keep the motor running smoothly.

Stitch Selection Issues: Some operators may experience difficulties when selecting stitches. This can stem from mechanical wear or electronic component failures, necessitating a closer examination of the selection mechanism.

By recognizing these common issues, users can take proactive steps to troubleshoot and maintain their machines, ensuring they continue to deliver reliable performance for various sewing projects.

Tools Needed for Repairs

When it comes to maintaining and restoring a sewing machine, having the right instruments on hand is crucial. The proper tools not only facilitate the process but also ensure that tasks are completed efficiently and effectively. Below is a comprehensive list of essential equipment that can assist in various maintenance and troubleshooting activities.

Essential Instruments

- Screwdrivers (flathead and Phillips)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and regular)

- Seam ripper

- Cleaning brushes

- Lint-free cloths

Specialized Equipment

- Oil for lubricating moving parts

- Replacement needles (various sizes)

- Thread cutter

- Calibration tools (for tension adjustment)

- Light source (for better visibility during work)

Equipping yourself with these tools will streamline the upkeep process and contribute to the longevity of your sewing device.

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to identifying and resolving common issues that may arise during the operation of your sewing machine. Following these steps can help ensure that your device runs smoothly and efficiently, minimizing downtime and frustration.

1. Check the Power Supply

Ensure that the machine is properly plugged in and that the outlet is functioning. You can test the outlet with another device to confirm it is providing power.

2. Inspect the Foot Pedal

Examine the foot pedal for any visible damage or loose connections. Make sure it is securely connected to the machine and that there are no obstructions affecting its operation.

3. Examine the Needle

Check if the needle is correctly installed and undamaged. Replace it if it is bent or dull, as this can cause stitching issues.

4. Assess Thread Tension

Adjust the upper and lower thread tension settings. Incorrect tension can lead to uneven stitches, so refer to your device’s guidelines for the correct settings.

5. Clean the Machine

Remove lint and debris from the bobbin area and feed dogs. Regular cleaning can prevent many operational issues.

6. Test the Stitch Settings

Ensure that the selected stitch type is appropriate for the fabric being used. Incorrect settings can lead to unsatisfactory stitching results.

7. Re-thread the Machine

If problems persist, unthread and re-thread the machine, ensuring that the thread is correctly positioned in all guides and the tension disks.

8. Consult the Documentation

If issues remain unresolved, refer to the instruction booklet for specific troubleshooting advice tailored to your model.

By following these steps methodically, you can effectively diagnose and rectify problems, enhancing your sewing experience.

Maintenance Tips for Longevity

Ensuring the long-lasting performance of your sewing machine requires consistent care and attention. Regular maintenance not only enhances the efficiency of the device but also prolongs its lifespan. Here are some essential tips to keep your equipment in top condition.

Regular Cleaning

Dust and lint can accumulate quickly and affect the functionality of your machine. To prevent issues, follow these steps:

- Unplug the machine before cleaning.

- Remove the needle plate and clean the feed dogs with a small brush.

- Use a lint brush or vacuum to clear out any debris from the interior.

- Wipe the exterior with a soft, dry cloth.

Lubrication

Proper lubrication is crucial for smooth operation. Adhere to these guidelines:

- Refer to the user guide for recommended lubricant types.

- Apply oil to designated points as indicated, usually around moving parts.

- Avoid over-oiling, which can attract dust and create build-up.

By following these maintenance practices, you can enhance the reliability and durability of your sewing machine, ensuring it serves you well for years to come.

How to Clean Your Sewing Machine

Maintaining your sewing device is crucial for its longevity and optimal performance. Regular cleaning helps prevent thread jams, maintains stitch quality, and extends the lifespan of the equipment. Here’s a straightforward guide to ensure your machine stays in top condition.

Follow these steps to effectively clean your sewing device:

- Gather Your Supplies:

- Soft brush or lint brush

- Microfiber cloth

- Small screwdriver

- Vacuum with a nozzle attachment (optional)

- Oil (if recommended by the manufacturer)

- Unplug the Machine: Always ensure the power source is disconnected before starting any cleaning process.

- Remove the Needle and Presser Foot: This will allow for better access to the areas that need cleaning.

- Clean the Bobbin Area:

- Take out the bobbin case and remove any lint or debris using the soft brush.

- If necessary, use a vacuum to reach small crevices.

- Wipe the Exterior: Use the microfiber cloth to gently clean the outer surfaces of the machine.

- Check the Feed Dogs: Ensure there is no buildup of lint. Clean around this area with the brush.

- Reassemble the Machine: Once everything is clean, carefully put back the needle, presser foot, and bobbin case.

- Oil the Machine: If your equipment requires lubrication, apply oil as specified by the manufacturer.

By regularly cleaning your sewing device, you’ll ensure it runs smoothly and efficiently, providing you with the best sewing experience possible.

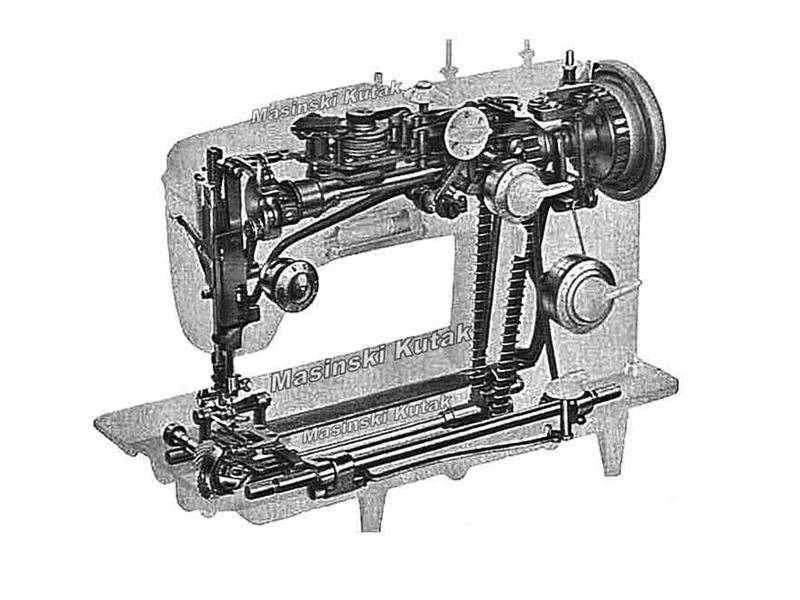

Replacing Parts on Pfaff 1222e

Maintaining sewing machines often involves the replacement of worn or damaged components. This process ensures optimal performance and longevity of the device. Understanding how to effectively change parts can empower users to troubleshoot issues and enhance their sewing experience.

Common Components to Replace

- Needles: Regularly changing needles can prevent skipped stitches and fabric snags.

- Presser Feet: Different presser feet are designed for various techniques; swapping them can improve results.

- Bobbins: Ensuring that bobbins are in good condition helps maintain consistent tension and stitch quality.

- Belt: A worn belt can lead to decreased power; replacing it can restore functionality.

Steps for Replacement

- Turn off the machine: Always ensure the device is powered down to prevent accidents.

- Access the component: Depending on the part, you may need to remove panels or covers.

- Remove the old part: Carefully detach the worn component, taking note of how it’s connected.

- Install the new part: Position the new component as per the manufacturer’s specifications.

- Reassemble and test: Once everything is back in place, power on the machine and test functionality.

Updating Software and Settings

Keeping your device up-to-date is essential for optimal performance and enhanced features. Regular updates can improve functionality, fix bugs, and ensure compatibility with new technologies. Additionally, adjusting settings allows users to tailor the machine to their specific needs, ensuring a more personalized experience.

To initiate the update process, connect your device to a stable internet connection. Navigate to the system menu and look for the update section. Follow the prompts to download and install the latest software version. It is advisable to back up any important settings or data before proceeding with the update.

After the installation is complete, revisit the settings menu. Here, you can customize various options, such as stitch preferences, speed settings, and other functionalities to match your sewing style. Familiarizing yourself with these settings can significantly enhance your overall experience and efficiency.

Remember to periodically check for new updates and review your settings to adapt to any changes in your crafting needs. This proactive approach will ensure your device remains in top condition and serves you well for years to come.

Finding Replacement Accessories

When it comes to maintaining and enhancing the functionality of your sewing machine, locating suitable replacement components is crucial. These accessories not only ensure smooth operation but also allow you to explore a wider range of sewing techniques. Whether you’re looking for presser feet, needles, or bobbins, knowing where to find quality replacements can make all the difference.

Below is a table outlining various sources for obtaining compatible accessories:

| Source | Description |

|---|---|

| Authorized Dealers | Official retailers often stock genuine parts that guarantee compatibility and quality. |

| Online Marketplaces | Websites like Amazon and eBay offer a vast selection of items, but check seller ratings and reviews. |

| Sewing Supply Stores | Local shops may carry a variety of tools and accessories, allowing you to see items before purchasing. |

| Craft Fairs and Expos | Events often feature vendors selling unique and specialized accessories, providing opportunities for hands-on exploration. |

| Second-Hand Shops | Thrift stores may have old machines with usable parts, offering a cost-effective way to find accessories. |

By exploring these avenues, you can ensure that your sewing experience remains enjoyable and efficient, equipped with the right tools for any project.