Comprehensive Guide to Repairing Your Stihl Weed Eater

When it comes to keeping your gardening tools in optimal condition, understanding the intricacies of their operation is essential. This section aims to provide comprehensive insights into the upkeep and troubleshooting of a specific type of outdoor device, ensuring that it performs at its best for all your landscaping needs.

Whether you are a seasoned gardener or a novice enthusiast, encountering issues with your equipment can be frustrating. By delving into the common challenges faced by users and offering practical solutions, this guide seeks to empower you with the knowledge necessary to effectively manage any complications that may arise.

Maintaining your machinery not only enhances its longevity but also improves efficiency, saving you time and effort. With clear instructions and helpful tips, you will be better equipped to handle various aspects of care, ensuring your device remains a reliable companion in your outdoor endeavors.

Understanding Stihl Weed Eater Basics

Familiarizing oneself with the fundamental components and operations of garden trimming equipment is essential for effective maintenance and optimal performance. This knowledge enables users to tackle common challenges and extend the lifespan of their tools, ensuring a tidy and well-kept outdoor space.

Types of Equipment: Various models of trimming devices are available, each designed for specific tasks. Recognizing the differences in size, power, and functionality can help users choose the right tool for their needs, enhancing efficiency during use.

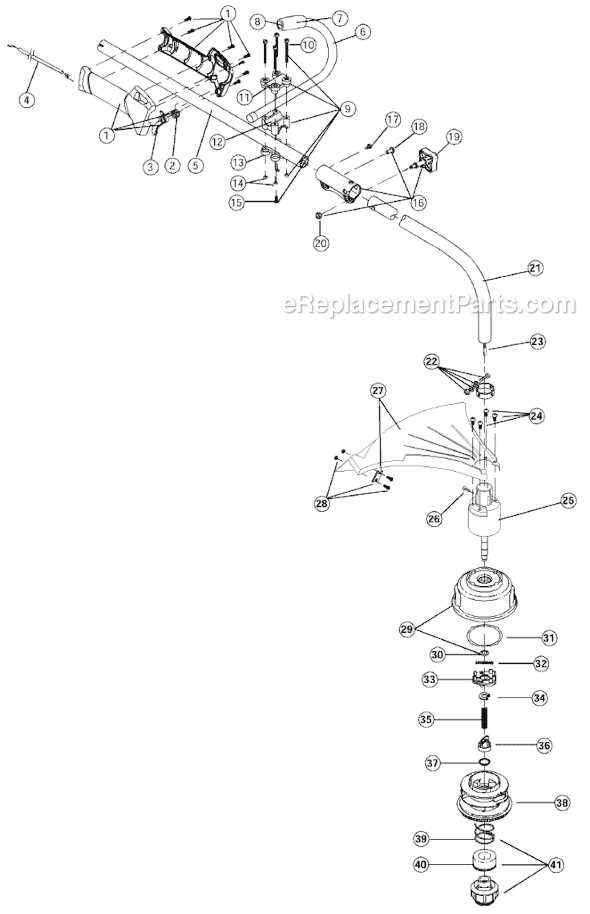

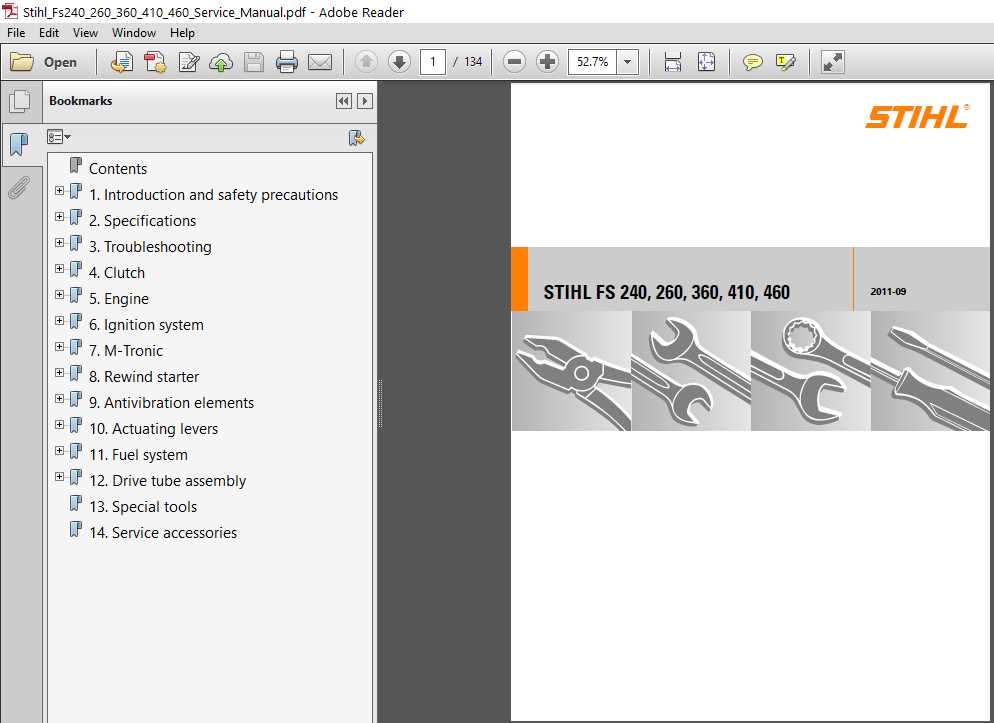

Key Components: Understanding the primary parts, such as the motor, cutting mechanism, and fuel system, is crucial. Each element plays a vital role in the overall operation, and being aware of how they interact can assist in troubleshooting issues when they arise.

Maintenance Tips: Regular upkeep is necessary to ensure peak performance. Routine tasks include cleaning filters, checking spark plugs, and inspecting the cutting line. Adhering to a maintenance schedule can prevent breakdowns and promote longevity.

Safety Considerations: Operating such equipment comes with inherent risks. Employing proper safety gear and understanding the operational guidelines are imperative to minimize the chance of accidents, ensuring a secure working environment.

Common Issues and Their Solutions

Every user encounters challenges with their outdoor equipment at some point. Understanding the frequent problems and knowing how to address them can greatly enhance the longevity and performance of these tools. This section explores typical difficulties and offers practical solutions to help you maintain optimal functionality.

Engine Won’t Start

If the engine fails to ignite, it could be due to several factors, such as a clogged fuel filter, stale fuel, or a malfunctioning spark plug. Begin by checking the fuel; if it’s old or contaminated, replace it with fresh fuel. Inspect the fuel lines for blockages and clean or replace the filter if necessary. Additionally, examine the spark plug for wear and tear, ensuring it’s clean and properly gapped before reinserting it.

Excessive Vibration

Excessive shaking during operation can indicate an imbalance in the cutting head or worn components. First, ensure that the cutting attachment is securely fastened. If the issue persists, remove the head and inspect it for damage or debris. Replace any worn parts and make sure the attachment is correctly aligned. Regular maintenance can help prevent these issues from arising.

Essential Tools for Repairs

When it comes to maintaining outdoor equipment, having the right instruments on hand is crucial for effective troubleshooting and adjustments. A well-equipped toolkit can make the difference between a simple fix and a prolonged issue. Below are some fundamental tools that are necessary for any maintenance enthusiast.

1. Screwdrivers: Both flathead and Phillips screwdrivers are indispensable. They are used to tighten or loosen screws, which is often the first step in any disassembly process.

2. Wrenches: A set of adjustable and socket wrenches is vital for handling nuts and bolts of various sizes. These tools provide the leverage needed to secure or release components.

3. Pliers: Needle-nose and slip-joint pliers are useful for gripping and manipulating small parts. They can also help in cutting wires or removing stubborn fasteners.

4. Cleaning Brushes: Maintaining cleanliness is essential for optimal performance. Specialized brushes can help clear debris from intricate areas, ensuring that all parts function smoothly.

5. Safety Gear: Always prioritize safety by using gloves, goggles, and masks. Protecting yourself while working is just as important as the task at hand.

Equipped with these essential tools, you can tackle various challenges with confidence, ensuring that your outdoor machinery remains in top condition.

Step-by-Step Repair Process

This section outlines a systematic approach to troubleshooting and fixing common issues with your garden trimmer. Following these organized steps will help you restore the equipment’s functionality effectively and efficiently.

Gathering Necessary Tools

Before you begin the troubleshooting process, ensure you have the following tools at hand:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Replacement parts

- Safety goggles

- Gloves

- Cleaning materials

Identifying the Problem

Next, determine the specific issue affecting the performance of your equipment. Here are some common problems to look out for:

- Engine won’t start

- Power loss during operation

- Excessive vibration

- Unusual noises

- Difficulty in handling

Once the problem is identified, you can proceed with the appropriate troubleshooting steps to rectify the situation.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the durability and efficiency of your outdoor equipment. By following a few key practices, you can extend the life of your machinery, keep it running smoothly, and enhance its performance over time. Regular attention not only helps to prevent breakdowns but also promotes safe operation and optimal results.

Regular Cleaning

Cleaning your equipment after each use is vital. Remove any debris, grass clippings, or dirt that may accumulate on the exterior and in the air intake areas. This simple task can prevent clogging and overheating, allowing the engine to operate at peak performance. Additionally, inspect the cutting components for wear and replace them as necessary to maintain efficiency.

Routine Checks and Servicing

Perform routine checks to identify any potential issues before they escalate. Regularly inspect the fuel system, including filters and lines, to ensure there are no leaks or blockages. Schedule periodic servicing with a professional to keep internal components in optimal condition. Staying proactive with maintenance can save you time and money in the long run.

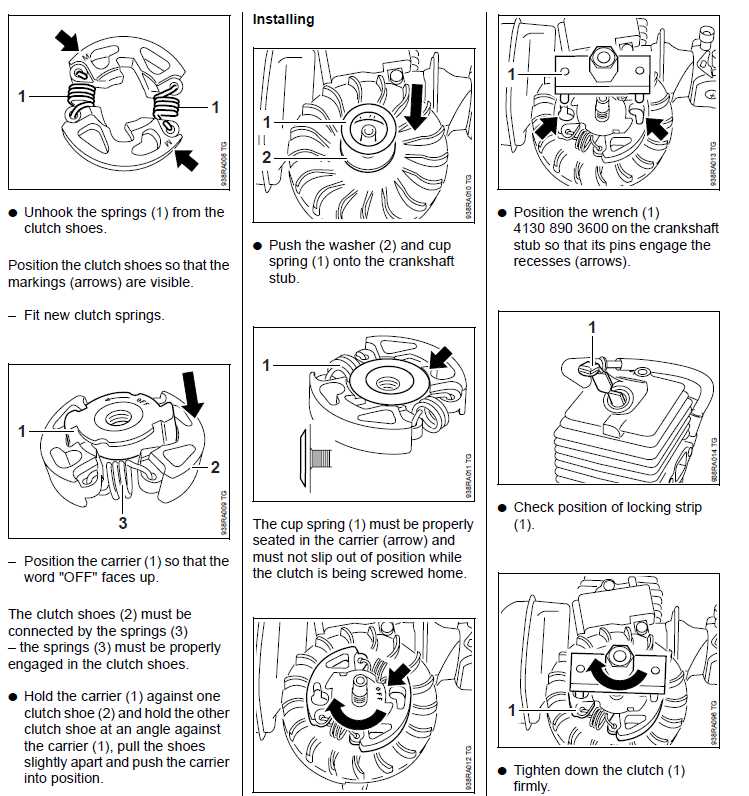

Replacing the Cutting Head

Maintaining optimal performance of your trimming device often requires the replacement of the cutting attachment. This component is essential for achieving clean and efficient results when working in your garden or yard. In this section, we will guide you through the process of removing the old cutting head and installing a new one, ensuring you can tackle your tasks with ease.

Tools Required

Before starting the replacement process, gather the necessary tools. You will typically need a screwdriver, a socket wrench, and possibly a pair of pliers. Ensuring you have these items on hand will streamline the procedure and help avoid interruptions.

Step-by-Step Replacement Process

Begin by ensuring the device is turned off and disconnected from any power source. Locate the cutting head and identify the locking mechanism. Use the screwdriver or wrench to carefully detach the old head, taking care not to damage any surrounding components. Once removed, align the new cutting head with the attachment point and secure it tightly, ensuring it is fastened properly to avoid any operational issues during use.

Electrical System Troubleshooting

Diagnosing issues within the electrical framework of outdoor power tools is essential for maintaining optimal performance. This section provides guidance on identifying common electrical problems and offers systematic approaches to resolve them effectively.

When facing electrical difficulties, start by checking the power source and connections. Ensure that the battery or power cord is intact and functioning. Loose or corroded terminals can often lead to intermittent power supply.

| Issue | Possible Cause | Solution |

|---|---|---|

| Tool does not start | Dead battery or faulty power cord | Replace or recharge the battery; inspect and replace the cord if necessary |

| Intermittent operation | Loose connections | Tighten or clean connections to ensure a secure fit |

| Overheating | Blocked vents or faulty components | Clear any obstructions; check for damaged parts and replace if needed |

| No power to accessories | Faulty switches or wiring | Test switches for continuity; repair or replace damaged wiring |

By systematically following these troubleshooting steps, users can effectively address and resolve electrical challenges, ensuring reliable operation and extending the lifespan of the equipment.

Fuel System Inspection Techniques

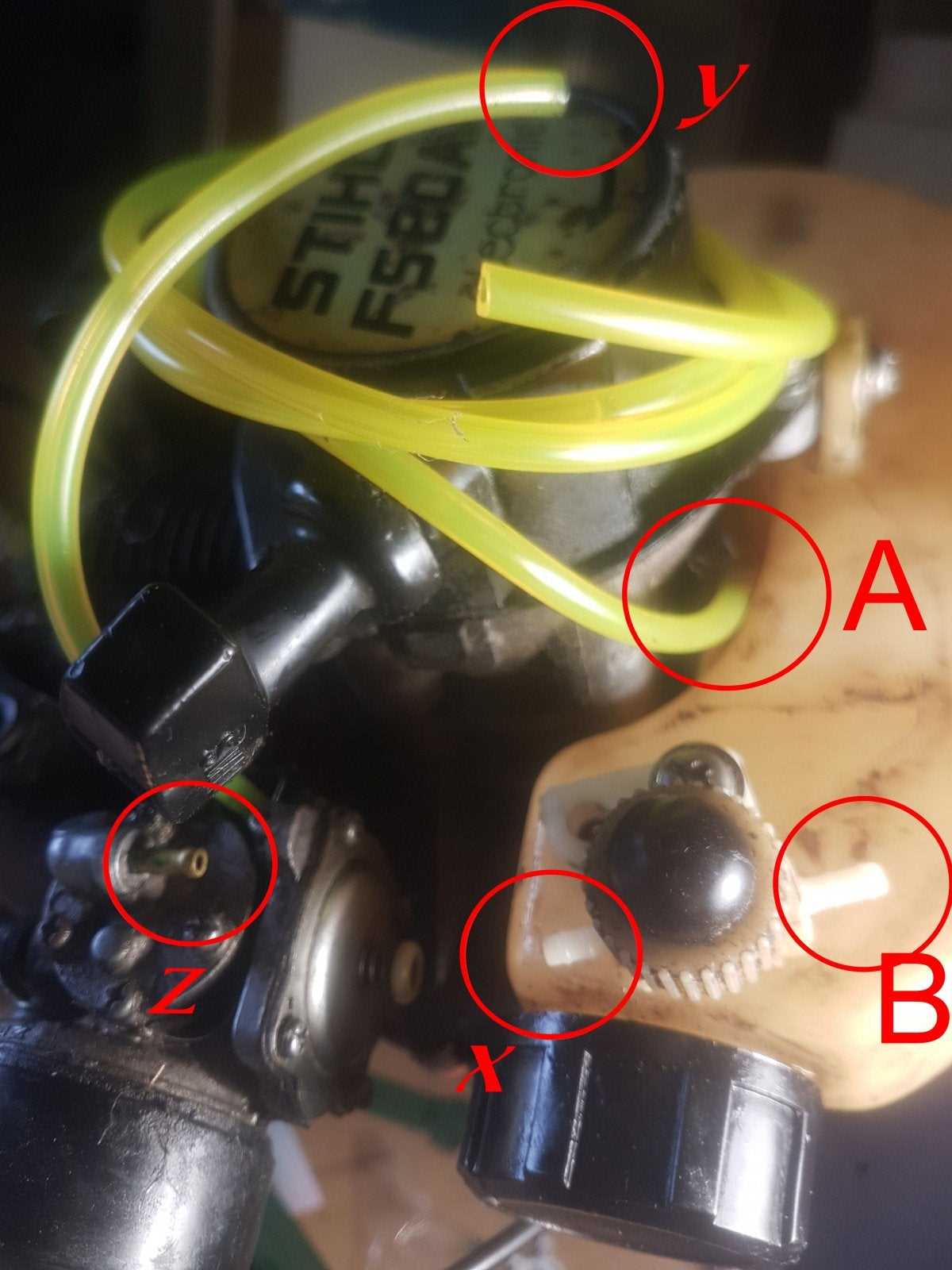

Inspecting the fuel system of outdoor power equipment is crucial for ensuring optimal performance and longevity. Proper assessment techniques can help identify issues that may affect the efficiency and reliability of the engine. Here are several effective methods for conducting a thorough evaluation.

- Visual Inspection:

- Check for cracks or damage in fuel lines.

- Inspect the fuel filter for clogs or contamination.

- Examine the fuel tank for any signs of leaks or corrosion.

- Fuel Quality Assessment:

- Smell the fuel for any unusual odors, indicating possible degradation.

- Inspect the color of the fuel; it should be clean and clear.

- Check for sediment or particles in the fuel container.

- Pressure Testing:

- Use a pressure gauge to assess the system’s integrity.

- Monitor for any drops in pressure that could indicate leaks.

- Component Functionality Check:

- Test the fuel pump for proper operation and pressure delivery.

- Evaluate the carburetor for clogs or misadjustments.

By employing these inspection techniques, you can effectively diagnose and address any issues within the fuel system, leading to improved performance and reduced downtime.

When to Seek Professional Help

Knowing when to enlist the expertise of a professional can save time, money, and frustration. While many maintenance tasks can be performed independently, certain situations demand the attention of an experienced technician. Recognizing these scenarios is crucial for effective equipment management.

Unusual Sounds or Smells: If you notice strange noises or odors during operation, it may indicate an underlying issue. These signs often suggest mechanical problems that require specialized knowledge to diagnose and fix.

Persistent Performance Issues: When your equipment consistently fails to function correctly despite troubleshooting efforts, it may be time to consult an expert. Ongoing difficulties can signal deeper problems that aren’t easily identifiable.

Safety Concerns: If you’re unsure about the safe operation of your tools, don’t hesitate to reach out for assistance. Professionals can provide guidance and ensure that your equipment meets safety standards, minimizing the risk of accidents.

Complex Repairs: Some repairs involve intricate components that are best handled by someone with specific training. If a task seems beyond your skill level, it’s wise to seek help rather than risking further damage.

In conclusion, understanding when to call in a professional can enhance the longevity and reliability of your tools. Recognizing the signs of potential issues and addressing them promptly will ensure optimal performance and safety.