Comprehensive Repair Guide for the 1978 Ford F250

Maintaining a vintage vehicle requires a thorough understanding of its unique mechanics and design. This guide aims to provide enthusiasts with essential information for the upkeep of their beloved classic pickup. From troubleshooting common issues to performing routine tasks, every detail is crucial for preserving the integrity and performance of these iconic machines.

Understanding the Basics of vehicle maintenance is vital for both novice and experienced owners. This section delves into the essential components that contribute to the overall functionality of a classic truck. Knowledge of the engine, transmission, and suspension systems will empower owners to tackle repairs confidently and effectively.

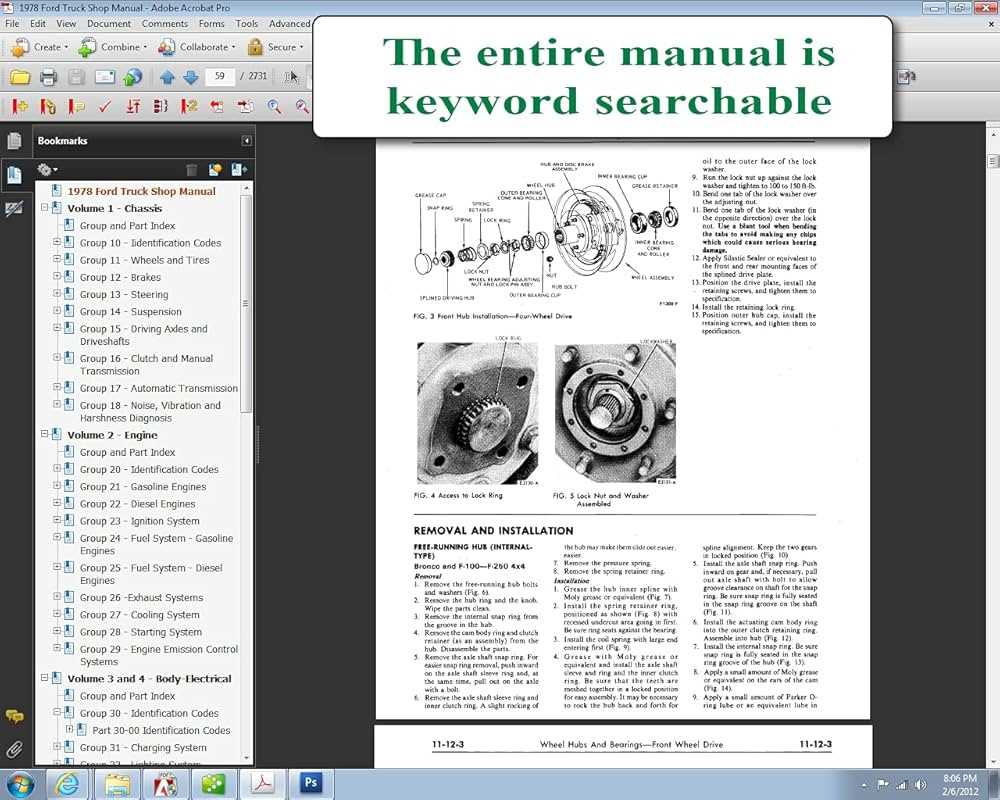

In addition, accessing reliable resources can significantly enhance the restoration process. Whether it’s consulting detailed diagrams or following step-by-step procedures, having the right information at hand can make all the difference in ensuring your classic vehicle runs smoothly and efficiently.

Understanding the 1978 Ford F250

This segment delves into the distinctive features and attributes of a classic pickup truck that has garnered a loyal following over the years. Known for its durability and capability, this vehicle remains a popular choice among enthusiasts and collectors alike. Exploring its mechanics, design, and user experience provides insight into why it has stood the test of time.

Key Features

- Robust engine options that deliver impressive power and torque.

- Sturdy chassis designed for heavy-duty applications.

- Spacious interior with practical design elements for both work and leisure.

Maintenance Considerations

- Regular inspections of the drivetrain to ensure optimal performance.

- Routine checks of the braking system for safety and reliability.

- Keeping up with fluid changes to prolong the lifespan of the vehicle.

Understanding these aspects can enhance appreciation and inform decisions regarding ownership and upkeep of this iconic vehicle.

Common Issues with the F250

Many vehicle enthusiasts encounter various challenges with their heavy-duty trucks. Understanding these common problems can aid in proactive maintenance and enhance the longevity of the vehicle.

Engine Performance Problems

Engine issues can significantly impact the reliability and efficiency of your truck. Here are some frequent concerns:

- Difficulty starting, often due to battery or ignition system failures.

- Excessive oil consumption, which may indicate worn piston rings or valve seals.

- Overheating, often resulting from a malfunctioning cooling system or thermostat.

Transmission Troubles

The transmission is critical for smooth operation and performance. Common transmission-related issues include:

- Slipping gears, which may suggest low fluid levels or internal wear.

- Delayed shifting, often caused by hydraulic issues or worn components.

- Leaking fluid, typically due to damaged seals or gaskets.

Essential Tools for Repairs

When undertaking any vehicle maintenance task, having the right instruments at your disposal is crucial. Quality tools not only enhance efficiency but also ensure that tasks are completed safely and effectively. This section highlights the must-have equipment that every enthusiast should consider for successful automotive work.

Socket Set: A comprehensive socket set is fundamental for various tasks, allowing for the easy loosening and tightening of fasteners. Look for a set that includes both metric and standard sizes to accommodate different components.

Wrenches: A reliable collection of wrenches, including both open-end and box-end varieties, will enable you to tackle numerous jobs. Adjustable wrenches can also be beneficial for those hard-to-reach areas.

Screwdrivers: A selection of screwdrivers in various sizes and types–such as flathead and Phillips–is essential for handling numerous screws found throughout the vehicle.

Jack and Stands: A sturdy jack and a set of jack stands are vital for safely lifting and supporting the vehicle during maintenance tasks. Always ensure these tools meet safety standards for optimal security.

Torque Wrench: To apply the correct amount of force when fastening components, a torque wrench is indispensable. This tool helps prevent damage caused by over-tightening.

Multimeter: For electrical diagnostics, a multimeter can assist in troubleshooting issues related to wiring and electrical components, ensuring that your vehicle’s systems function correctly.

Equipping yourself with these essential tools will not only prepare you for a variety of maintenance tasks but also enhance your overall automotive knowledge and confidence.

Engine Specifications and Maintenance

This section provides essential details regarding engine characteristics and upkeep practices crucial for optimal performance and longevity. Understanding these specifications ensures effective operation and can prevent common issues that arise from neglect or improper care.

| Specification | Details |

|---|---|

| Engine Type | V8 |

| Displacement | 360 cubic inches |

| Horsepower | 200 HP @ 4000 RPM |

| Torque | 380 lb-ft @ 2400 RPM |

| Fuel System | Carbureted |

| Oil Capacity | 6 quarts |

Routine maintenance is vital for sustaining engine health. Regular oil changes, proper coolant levels, and timely replacement of filters contribute to reliable operation. Monitoring these factors helps in identifying potential issues early, preventing costly repairs.

Transmission Troubleshooting Guide

This section aims to assist vehicle owners in diagnosing and resolving common issues related to the transmission system. A well-functioning transmission is crucial for optimal performance, and understanding typical problems can lead to more effective solutions.

Common Symptoms of Transmission Issues

- Unusual noises during shifting

- Delayed engagement when changing gears

- Fluid leaks under the vehicle

- Warning lights illuminated on the dashboard

- Slipping gears or difficulty maintaining speed

Basic Diagnostic Steps

- Check fluid levels and condition: Low or dirty fluid can cause numerous problems.

- Inspect for leaks: Look for signs of transmission fluid under the vehicle.

- Listen for unusual sounds: Grinding or whining noises may indicate mechanical issues.

- Test for slipping: Pay attention to changes in acceleration and shifting behavior.

- Use a diagnostic tool: Scanning for error codes can provide insight into electronic issues.

By following these guidelines, vehicle owners can better understand potential transmission troubles and take appropriate action to maintain their vehicle’s performance.

Electrical System Overview

The electrical system in vehicles serves as the backbone for numerous functionalities, ensuring that all components operate harmoniously. This intricate network is vital for powering essential systems, from ignition to lighting, contributing significantly to the overall performance and safety of the vehicle.

Key Components

At the heart of the electrical architecture are several critical elements. The battery provides the necessary power to start the engine and energize various systems. The alternator, on the other hand, replenishes the battery while the engine runs, maintaining optimal voltage levels. Additionally, fuses and relays act as protective devices, safeguarding circuits from overloads and ensuring reliable operation.

Troubleshooting Common Issues

Understanding typical problems within the electrical framework can enhance maintenance and longevity. Symptoms such as dim lights or a sluggish starter often indicate battery or alternator issues. Regular inspections and diagnostics can help identify these challenges early, preventing more significant complications down the road. Emphasizing the importance of a well-functioning electrical system is crucial for any vehicle owner.

Suspension Components and Upkeep

The effectiveness of a vehicle’s ride and handling largely relies on its suspension system. This intricate assembly not only enhances comfort but also ensures stability during various driving conditions. Proper maintenance and understanding of these components are crucial for optimal performance and longevity.

Key Components of the Suspension System

A suspension system typically comprises several essential elements, including springs, shock absorbers, control arms, and bushings. Springs serve to support the vehicle’s weight and absorb bumps, while shock absorbers dampen the oscillations caused by the springs, ensuring a smoother ride. Control arms connect the suspension to the vehicle’s frame, allowing for controlled movement of the wheels, and bushings provide cushioning and reduce noise.

Maintenance Tips for Longevity

Regular inspection and maintenance of suspension components are vital for performance. Check for signs of wear, such as cracked bushings or leaking shocks. Routine lubrication can prevent premature wear, and ensuring proper alignment can enhance handling and tire life. Addressing any issues promptly will not only improve safety but also prolong the lifespan of the entire suspension system.

Brake System Diagnostics

Effective troubleshooting of a vehicle’s stopping mechanism is crucial for ensuring safety and performance. A systematic approach to identifying issues can help prevent accidents and costly repairs. This section outlines the essential steps and considerations for diagnosing problems within the braking system.

Common Symptoms

Awareness of typical warning signs can facilitate early detection of braking issues. Look for unusual noises such as grinding or squeaking, which may indicate worn components. Additionally, a soft or spongy pedal often suggests air in the hydraulic lines or fluid leaks. Pay attention to any pulling to one side when braking, as this may point to uneven wear or malfunctioning calipers.

Diagnostic Process

Start with a visual inspection of the entire braking assembly, checking for leaks, corrosion, or damage. Proceed to test the brake fluid for contamination and ensure the fluid level is adequate. Use a pressure gauge to assess the hydraulic system’s performance. Finally, perform a road test to evaluate the effectiveness of the braking system under various conditions.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is essential for ensuring optimal performance and longevity of your vehicle’s engine. Regular maintenance can help prevent overheating and costly repairs, keeping your ride smooth and reliable.

Start by checking the coolant level frequently. Make sure the mixture of antifreeze and water is at the recommended level to avoid any potential damage. If the coolant appears discolored or contaminated, it’s time to flush the system and refill it with fresh fluid.

Inspect hoses and connections for any signs of wear or leaks. Cracked or brittle hoses can lead to serious issues, so replacing them proactively can save you from unexpected breakdowns. Ensure that all clamps are secure to maintain proper pressure.

Additionally, monitor the radiator and its cap. A clean radiator allows for efficient heat exchange, while a faulty cap can cause coolant loss and pressure issues. Regularly cleaning the radiator and checking the cap for any damage can greatly enhance the cooling system’s effectiveness.

Finally, don’t overlook the water pump. Listen for unusual noises that might indicate wear, and ensure it’s functioning correctly. Keeping an eye on these components will help maintain a robust cooling system and contribute to the overall health of your engine.

Exhaust System Care and Repair

The exhaust system plays a crucial role in the overall performance and efficiency of a vehicle. Proper maintenance is essential to ensure it functions optimally and to prolong its lifespan. Neglecting this system can lead to various issues, including decreased power, increased emissions, and unpleasant noises.

Regular inspection and maintenance of the exhaust system can prevent many common problems. Here are some key areas to focus on:

- Visual Inspections: Regularly check for rust, corrosion, or damage to pipes and components.

- Seal Integrity: Ensure all joints and connections are tight to prevent leaks.

- Hangars and Supports: Inspect hangars for wear and tear, replacing them if necessary to prevent sagging.

- Performance Monitoring: Pay attention to changes in engine performance or unusual noises that could indicate exhaust issues.

If problems are detected, it’s important to address them promptly. Common repairs include:

- Replacing Gaskets: Worn gaskets can cause leaks, leading to decreased efficiency.

- Fixing or Replacing Pipes: Damaged pipes should be repaired or replaced to maintain proper exhaust flow.

- Muffler Service: A faulty muffler can create excessive noise; ensure it is in good condition or replace it if necessary.

By keeping a close eye on the exhaust system and addressing issues as they arise, you can maintain your vehicle’s performance and reduce environmental impact.

Bodywork and Frame Inspection

Assessing the integrity of the vehicle’s exterior and structural components is crucial for ensuring safety and longevity. This section focuses on techniques and considerations for evaluating the body and frame, helping to identify any signs of wear, damage, or corrosion that could compromise performance.

Visual Inspection: Begin with a thorough visual examination of the body panels. Look for dents, scratches, and signs of rust. Pay special attention to areas around the wheel wells, undercarriage, and joints, as these are prone to damage.

Frame Assessment: Inspect the frame for any signs of bending, cracking, or previous repairs. Use a straight edge to check for alignment and ensure that all mounting points are intact. A compromised frame can significantly affect the vehicle’s handling and safety.

Rust Treatment: If rust is present, it should be addressed promptly. Clean the affected areas and consider using a rust inhibitor or protective coating to prevent further deterioration.

Body Panel Alignment: Check the alignment of doors, hoods, and fenders. Gaps should be consistent, and all components should open and close smoothly. Misalignment may indicate underlying frame issues.

Final Recommendations: After completing the inspection, document any findings and prioritize repairs as necessary. Regular checks and maintenance of bodywork and frame components can enhance the vehicle’s overall reliability and aesthetic appeal.

Finding Replacement Parts

Locating suitable components for vintage vehicles can be a rewarding yet challenging endeavor. Understanding where to search and how to evaluate options is crucial for successful restoration or maintenance projects. Below are some effective strategies for sourcing high-quality parts.

- Online Marketplaces:

- Websites dedicated to auto parts often have extensive inventories.

- Popular platforms like eBay and Amazon can yield both new and used items.

- Specialty Stores:

- Local shops focusing on classic automobiles may carry specific parts or can order them.

- Attending car shows can also connect you with vendors specializing in vintage components.

- Salvage Yards:

- Visiting junkyards can provide opportunities to find rare parts at lower prices.

- Developing a good relationship with yard owners can lead to helpful tips and resources.

- Online Forums and Communities:

- Engaging with enthusiasts on forums can offer leads on where to find specific parts.

- Social media groups often share valuable information and sales opportunities.

- OEM and Aftermarket Suppliers:

- Research manufacturers that produce original equipment or compatible aftermarket parts.

- Reading reviews and comparing warranties can help in making informed choices.

By utilizing these avenues, enthusiasts can enhance their chances of finding the exact components needed for their projects, ensuring both quality and compatibility.

Resources for DIY Enthusiasts

For those who relish the satisfaction of tackling projects themselves, having access to the right information and tools is crucial. Whether you’re looking to enhance your skills, solve specific issues, or simply enjoy the process of hands-on work, a variety of resources can guide you along the way.

Online Forums and Communities

Participating in online forums and communities can be incredibly beneficial. These platforms allow enthusiasts to share experiences, ask questions, and offer advice. Engaging with others who have faced similar challenges can provide insights that are not always found in traditional literature. Websites like Reddit and specialized forums often host threads that cover everything from troubleshooting tips to modification ideas.

Video Tutorials and Workshops

Visual learning has become increasingly popular among DIYers. Platforms such as YouTube offer countless video tutorials that demonstrate techniques and procedures step-by-step. Additionally, many local workshops provide hands-on training sessions. Participating in these workshops can enhance your practical skills and provide opportunities to network with fellow enthusiasts.