Comprehensive Guide to Repairing the 2005 Dodge Ram

For enthusiasts and owners alike, understanding the intricacies of a specific automobile can significantly enhance the ownership experience. This section serves as a vital resource, offering detailed insights into the upkeep and troubleshooting of a notable vehicle model. Knowledge of the internal mechanisms and maintenance procedures not only extends the lifespan of the vehicle but also improves its overall performance.

Within these pages, you will find a wealth of information tailored to assist individuals in navigating common challenges. From basic upkeep tasks to more complex diagnostics, each aspect is covered with clarity and precision. Whether you’re an experienced mechanic or a novice seeking guidance, the following content aims to empower you with the expertise needed to manage your vehicle efficiently.

By engaging with this comprehensive resource, you will gain the confidence to undertake various tasks, ensuring that your automobile remains in peak condition. The insights provided will illuminate the necessary steps to address issues and enhance functionality, making the journey of vehicle ownership more rewarding.

This section provides a comprehensive look at a specific model from the automotive industry, focusing on its features, specifications, and the general context in which it operates. Understanding the foundational aspects of this vehicle helps in appreciating its design and functionality.

- Introduction to the Vehicle:

A brief introduction highlighting the significance of this model in the market and its unique selling points.

- Key Specifications:

Details about engine types, performance metrics, and dimensions that define the vehicle’s capabilities.

- Features Overview:

An outline of the technological and safety features that enhance the driving experience and ensure occupant protection.

- Market Reception:

A summary of consumer feedback and industry reviews that illustrate the model’s standing among competitors.

- Maintenance Considerations:

Insights into routine care practices that help maintain the vehicle’s longevity and performance.

Key Specifications and Features

This section provides an overview of the essential attributes and capabilities of a specific vehicle model, highlighting the characteristics that define its performance, safety, and functionality. Understanding these elements is crucial for both potential buyers and current owners seeking to enhance their knowledge of the vehicle’s capabilities.

The powertrain comprises a robust engine, engineered for optimal performance and efficiency, paired with a reliable transmission system that ensures smooth gear transitions. The suspension system is designed to offer a balanced ride, providing both comfort and stability on various terrains.

Safety features are integrated to protect occupants, including advanced airbag systems and stability control mechanisms. Additionally, the interior design focuses on comfort and convenience, with high-quality materials and user-friendly technology that enhances the driving experience.

Overall, these specifications and features combine to deliver a dependable and versatile vehicle, capable of meeting a range of demands, whether for everyday commuting or more challenging tasks.

Common Issues and Troubleshooting

When dealing with automotive challenges, it is essential to recognize frequent malfunctions that may arise. This section highlights typical problems encountered in vehicles of this make and model, along with effective strategies for resolution. By understanding these common difficulties, owners can enhance their troubleshooting skills and maintain optimal performance.

Electrical System Failures

One prevalent issue involves the electrical framework, which may manifest as intermittent power loss or malfunctioning components. Owners should first inspect fuses and wiring connections. Regular maintenance and addressing any signs of wear can help prevent these setbacks. In cases where problems persist, consulting a professional may be necessary.

Transmission Concerns

Another frequent complication is related to the transmission. Symptoms such as slipping gears or delayed shifting can indicate underlying issues. It is advisable to check fluid levels and for any leaks. Prompt attention to these signs can mitigate more severe problems down the line, ensuring smoother operation.

Engine Maintenance Guidelines

Regular upkeep of the powertrain is essential for optimal performance and longevity. Adhering to specific recommendations can help prevent issues, improve efficiency, and ensure that the system operates smoothly under various conditions.

Routine Inspections

Conducting frequent examinations of key components such as the oil level, belts, and hoses is vital. This proactive approach allows for early detection of wear or potential failures, ensuring timely interventions and minimizing downtime.

Fluid Management

Maintaining appropriate fluid levels is crucial for the functionality of the engine. Regularly checking and changing the engine oil, coolant, and transmission fluid helps prevent overheating and maintains optimal lubrication, ultimately enhancing the overall efficiency of the vehicle.

Transmission Repair Procedures

This section outlines essential steps and guidelines for addressing issues related to the transmission system of the vehicle. Proper understanding of these methods ensures efficient troubleshooting and maintenance, enhancing the overall performance of the drivetrain.

Before starting any service, ensure the following tools and equipment are available:

- Wrenches and sockets

- Transmission fluid

- Torque wrench

- Sealant and gaskets

- Diagnostic scanner

Follow these general procedures when working on the transmission:

- Preparation: Begin by disconnecting the battery to prevent electrical hazards. Raise the vehicle securely using jack stands.

- Fluid Inspection: Check the transmission fluid level and condition. Replace if contaminated or low.

- Removal: Detach the transmission from the engine. This may involve unbolting various components such as the bell housing and drive shafts.

- Disassembly: Carefully take apart the transmission casing to access internal parts. Document the arrangement of components for reassembly.

- Inspection: Examine gears, seals, and other components for wear or damage. Replace any defective parts as necessary.

- Reassembly: Follow the documented arrangement to reassemble the transmission. Ensure all seals and gaskets are replaced to prevent leaks.

- Installation: Reattach the transmission to the engine and reconnect any previously disconnected components.

- Final Checks: Refill the transmission with the appropriate fluid, reconnect the battery, and conduct a test drive to ensure proper operation.

Adhering to these procedures will facilitate a successful overhaul of the transmission system, promoting longevity and reliability.

Electrical System Diagnostics

The evaluation of an automobile’s electrical system is essential for ensuring optimal performance and reliability. This process involves identifying issues within the wiring, components, and connections that may hinder functionality. Effective troubleshooting techniques can help in pinpointing faults and restoring proper operation.

Utilizing advanced diagnostic tools can significantly enhance the accuracy of assessments. Voltage measurements, continuity tests, and circuit analysis are fundamental procedures employed during this evaluation. These methods allow for the detection of anomalies and ensure that electrical pathways are functioning as intended.

Furthermore, understanding the layout of the electrical components, such as batteries, alternators, and fuses, is crucial. Regular inspections and preventative maintenance can mitigate potential problems, leading to a more reliable and efficient vehicle. Addressing electrical issues promptly can prevent more extensive damage and costly repairs in the long run.

Body and Frame Repair Tips

Maintaining the integrity of a vehicle’s structure is essential for both aesthetics and safety. Whether addressing minor dents or significant damage, understanding the basics of the outer shell and supporting structure can greatly enhance the restoration process.

Assessing Damage: Begin by thoroughly evaluating the extent of any issues. Look for signs of misalignment, rust, or corrosion. Take note of areas that may require further attention to ensure a solid foundation for subsequent work.

Using Quality Materials: When undertaking fixes, always opt for high-quality components. This includes selecting appropriate adhesives, sealants, and metal reinforcements that match the vehicle’s specifications for strength and durability.

Alignment Techniques: Correct alignment is crucial for optimal performance. Utilize specialized tools to ensure that panels and frames are positioned accurately. A misaligned structure can lead to uneven wear and potential safety hazards.

Finishing Touches: After repairs are completed, focus on surface treatment. Proper sanding and priming are vital before applying paint. This ensures a smooth, professional-looking finish while protecting against future environmental damage.

Consulting Resources: For detailed guidance, consider accessing additional literature or expert resources. They can provide invaluable insights and techniques that enhance your skills and knowledge in vehicle restoration.

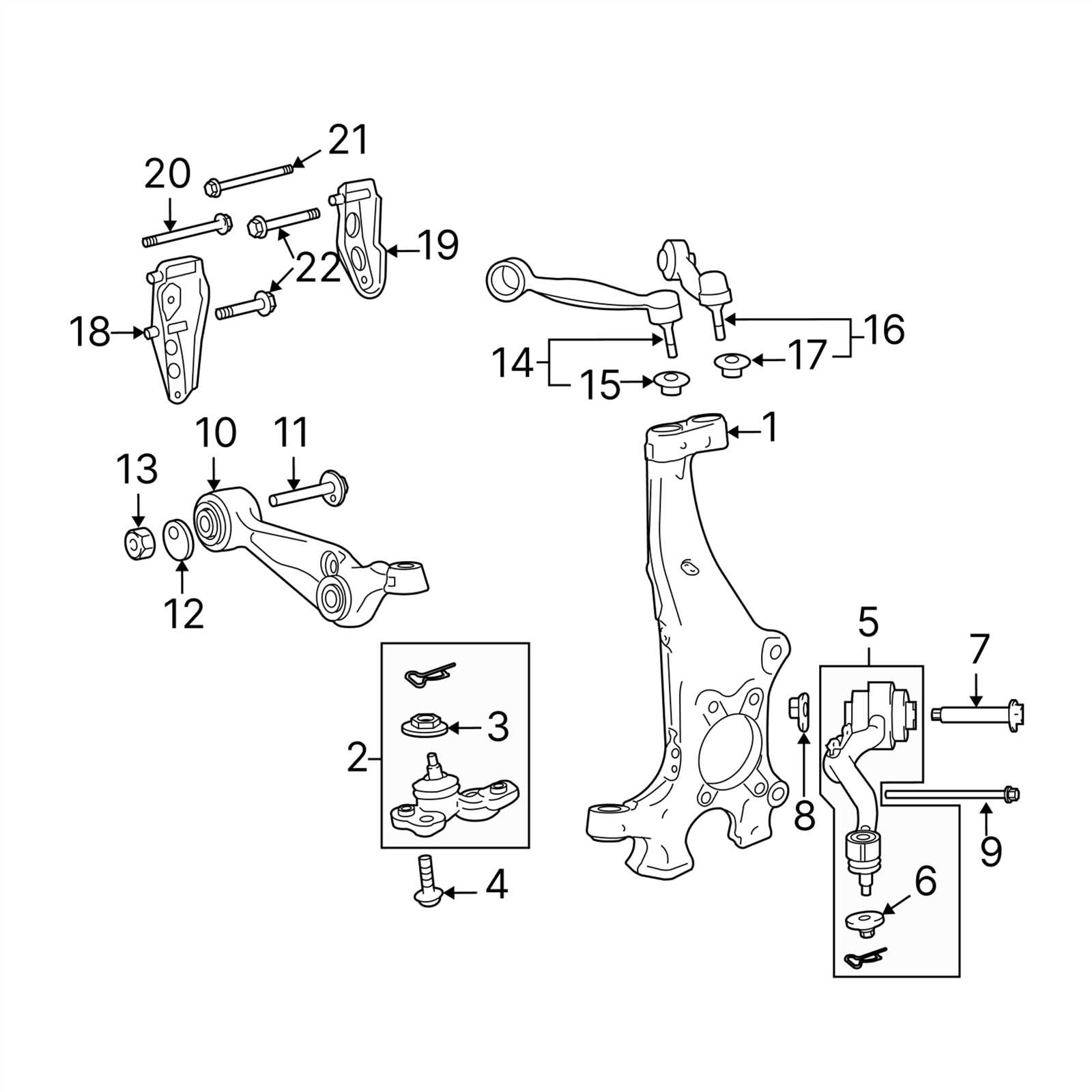

Suspension and Steering Adjustments

Proper calibration of the suspension and steering systems is crucial for optimal vehicle performance and handling. These adjustments enhance ride comfort, improve stability, and ensure accurate steering response. This section delves into essential procedures for achieving the desired settings in the suspension and steering components.

Before proceeding with adjustments, it’s important to understand the key areas that require attention:

- Alignment of wheels

- Tire pressure settings

- Spring and shock absorber calibration

- Steering linkage inspection

Follow these general steps for effective adjustment:

- Check and adjust the tire pressure according to manufacturer specifications.

- Perform a wheel alignment to ensure all four wheels are parallel and aligned with the vehicle’s frame.

- Inspect the suspension components for wear or damage, replacing parts as necessary.

- Adjust the height of the springs or shocks to achieve the desired ride height.

- Examine the steering components and make necessary adjustments to the steering linkage.

Regular maintenance and fine-tuning of these systems will not only enhance driving experience but also extend the lifespan of the vehicle’s components.

Brake System Servicing

The effective performance of the braking mechanism is crucial for safe vehicle operation. Regular maintenance and thorough inspection of the braking components ensure optimal functionality and enhance safety on the road. This section outlines essential procedures and guidelines for maintaining the braking system, focusing on both preventative measures and necessary repairs.

Inspection and Maintenance

Routine checks of the braking assembly are vital to identify wear and tear. Begin by examining brake pads, rotors, and fluid levels. Look for signs of excessive wear on pads and ensure that the rotors are free from cracks and warping. Regularly topping off brake fluid is also important, as low levels can lead to diminished braking efficiency.

Replacing Components

When servicing the braking system, it may be necessary to replace worn-out parts. This includes installing new brake pads, resurfacing or replacing rotors, and bleeding the braking fluid to remove any air bubbles. Follow manufacturer specifications for torque settings during reassembly to guarantee safety and performance.

Wiring Diagrams and Schematics

Understanding electrical connections and layouts is crucial for any maintenance task. These visual representations provide essential guidance for identifying and tracing electrical pathways, ensuring effective troubleshooting and repairs. By using these diagrams, technicians can systematically approach complex wiring systems, enhancing the efficiency of their work.

Importance of Accurate Diagrams

Accurate schematics play a vital role in facilitating the diagnosis of electrical issues. They help to clarify the relationships between various components, making it easier to pinpoint faults. Without clear illustrations, navigating intricate electrical systems can be daunting, leading to potential errors and time loss.

Utilizing Schematics Effectively

To make the most of these diagrams, it is essential to familiarize oneself with common symbols and notation. This knowledge allows for a quicker understanding of the layout and function of each element within the system. Moreover, regularly referring to these resources can significantly improve overall troubleshooting skills.

Tools and Equipment Needed

Successful maintenance and restoration of vehicles require a comprehensive set of instruments and devices. Proper selection of these tools ensures efficiency and accuracy during the procedures, making tasks simpler and more effective. This section outlines the essential items that should be available for optimal performance in the workshop.

Essential Hand Tools

Hand tools play a vital role in vehicle upkeep, allowing for precise adjustments and repairs. A variety of instruments should be included in any toolkit to address common issues effectively.

| Tool | Purpose |

|---|---|

| Wrenches | Used for tightening and loosening nuts and bolts. |

| Screwdrivers | Essential for removing and securing screws. |

| Pliers | Helpful for gripping, twisting, and cutting wires. |

| Socket Set | Facilitates easy access to fasteners in confined spaces. |

Specialized Equipment

In addition to hand tools, certain specialized equipment can enhance repair capabilities. These devices aid in more complex tasks, ensuring high-quality results.

| Equipment | Function |

|---|---|

| Jack and Jack Stands | Used for lifting the vehicle safely during maintenance. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | Measures electrical values for troubleshooting electrical issues. |

| Diagnostic Scanner | Reads error codes from the vehicle’s onboard computer system. |

Safety Precautions for Repairs

When undertaking maintenance tasks, it is essential to prioritize safety to prevent accidents and ensure a smooth process. Adhering to appropriate guidelines can significantly reduce risks associated with mechanical work.

First and foremost, always wear protective gear, including gloves and safety glasses, to safeguard against potential injuries from sharp objects or hazardous materials. Additionally, ensure that the workspace is well-ventilated to avoid inhaling harmful fumes that may arise during various procedures.

Furthermore, before beginning any task, it is crucial to disconnect the power source to avoid electrical shocks. Always refer to the relevant documentation for specific instructions regarding component handling and installation to prevent mistakes that could lead to further complications.

Lastly, keep your workspace organized and free of clutter to minimize the risk of accidents. By following these precautions, you can create a safer environment and enhance the overall effectiveness of your maintenance efforts.