Comprehensive Guide to Repairing the John Deere F525

Owning high-quality outdoor machinery can significantly enhance your landscaping experience. However, ensuring that these devices operate at their best requires understanding their intricacies and proper care. Regular upkeep not only extends the life of your tools but also improves their efficiency, making your yard work less of a chore and more of a pleasure.

Within this guide, you will find essential insights into the servicing of specific models designed for grass management. Whether you are facing minor issues or preparing for a comprehensive tune-up, this resource aims to equip you with the knowledge needed to tackle various challenges effectively. From troubleshooting common problems to performing routine checks, every detail is vital for maintaining optimal functionality.

As you delve into the specifics of upkeep, you will discover step-by-step instructions that simplify complex processes. Empower yourself with the confidence to manage maintenance tasks and ensure your equipment continues to deliver peak performance for years to come. With the right approach, even the most daunting repairs can be manageable and rewarding.

Understanding the John Deere F525

This section aims to provide insights into a specific model known for its reliability and efficiency in landscaping tasks. It serves as a great companion for both professional landscapers and homeowners, delivering powerful performance in a compact design.

Key features that contribute to its popularity include:

- Robust engine options that ensure consistent power delivery.

- Agile maneuverability, making it easy to navigate through tight spaces.

- User-friendly controls that simplify operation for users of all experience levels.

Maintaining this machine is crucial for optimal performance. Regular checks and maintenance routines can enhance longevity and prevent common issues. Essential maintenance tasks include:

- Checking and changing the oil to ensure the engine runs smoothly.

- Inspecting the blades for wear and sharpening them as needed.

- Cleaning or replacing air filters to maintain airflow and efficiency.

Understanding the essential components and their functions will further aid users in making informed decisions regarding upkeep and operation. Knowledge about the system’s mechanics can significantly enhance the overall user experience.

Common Issues with F525 Models

The maintenance of outdoor power equipment often reveals a range of typical complications that users encounter. Understanding these frequent challenges can help in timely troubleshooting and ensure the longevity of the machinery.

One of the most prevalent concerns is related to the engine’s performance. Users may experience difficulty starting the machine or notice irregular engine behavior during operation. These issues can stem from fuel system problems, including clogged filters or stale gasoline.

Another common issue involves the cutting deck. Users might observe uneven cuts or the blades not engaging properly. This can often be attributed to dull blades, misalignment, or blockages caused by grass buildup.

Transmission troubles can also arise, manifesting as slow or unresponsive movement. This may indicate problems with the drive belts or other components within the transmission system.

Lastly, electrical issues can occur, affecting everything from ignition to lighting systems. Checking connections and ensuring proper battery maintenance can alleviate many of these concerns.

Tools Needed for Repairs

When tackling maintenance tasks, having the right equipment is essential for achieving effective results. The correct tools not only streamline the process but also ensure safety and accuracy during each step of the work. A well-prepared toolkit can significantly enhance your ability to address various issues that may arise.

Essential Hand Tools

First and foremost, a selection of hand tools forms the backbone of any maintenance effort. Basic items such as wrenches, screwdrivers, and pliers are crucial for disassembling and reassembling components. Additionally, a good set of socket sets can provide the leverage needed for stubborn fasteners, while a hammer can assist in driving parts into place.

Power Tools for Efficiency

Incorporating power tools can elevate the efficiency of your tasks. An electric drill is indispensable for creating holes or driving screws quickly. A grinder can help with smoothing out rough edges or removing rust. Finally, a multimeter is vital for troubleshooting electrical issues, allowing for precise measurements of voltage and current.

Step-by-Step Maintenance Guide

Regular upkeep is essential for optimal performance and longevity of your equipment. This guide provides a clear and systematic approach to maintaining your machine, ensuring it operates smoothly and efficiently throughout its lifespan.

Preparation

Before starting the maintenance process, gather the necessary tools and materials. A well-prepared workspace will enhance efficiency and safety. Follow these steps:

- Identify the tools required for various tasks, such as wrenches, screwdrivers, and oil filters.

- Collect replacement parts, including air filters, spark plugs, and belts.

- Ensure you have safety equipment, such as gloves and goggles.

Maintenance Steps

Follow these sequential steps to ensure thorough maintenance:

- Check the Oil: Inspect the oil level and quality. Replace it if it appears dark or gritty.

- Clean the Air Filter: Remove the air filter and clean it with compressed air or replace it if damaged.

- Inspect Belts: Look for signs of wear or fraying. Replace any belts that show damage.

- Sharpen the Blades: Remove the blades and sharpen them to ensure a clean cut.

- Check Tires: Inspect tire pressure and tread depth. Inflate or replace tires as necessary.

- Battery Maintenance: Clean battery terminals and ensure proper charge levels.

Following this guide will help you maintain your equipment effectively, preventing potential issues and enhancing its performance.

Engine Troubleshooting Techniques

Diagnosing issues within an engine requires a systematic approach to identify the root cause of problems. Understanding common symptoms and implementing effective techniques can help restore optimal performance. This section outlines essential methods for troubleshooting engine-related concerns.

Common Symptoms and Initial Checks

- Engine won’t start: Check the battery, fuel supply, and ignition system.

- Rough idling: Inspect for air leaks and evaluate the fuel mixture.

- Overheating: Examine the cooling system, including the radiator and coolant levels.

- Excessive smoke: Determine the type of smoke (white, blue, black) and diagnose accordingly.

Step-by-Step Diagnostic Process

- Perform a visual inspection for leaks and damaged components.

- Utilize diagnostic tools, such as multimeters and compression testers.

- Listen for unusual noises while the engine is running.

- Check for error codes using an OBD-II scanner, if applicable.

- Review maintenance history for any recent changes or issues.

By following these techniques, you can effectively pinpoint engine problems and implement appropriate solutions to enhance functionality and reliability.

Replacing Belts and Blades

Maintaining optimal performance of lawn equipment requires periodic replacement of essential components like belts and blades. These parts play a critical role in ensuring efficient operation, and their timely servicing can greatly extend the lifespan of the machinery.

When to Replace Belts

Belts are crucial for transferring power to various parts of the equipment. Signs that indicate a need for replacement include:

- Visible wear and fraying

- Squeaking or slipping sounds during operation

- Inconsistent power delivery to blades

Regular inspections can help identify these issues before they lead to more serious damage.

How to Replace Blades

Blades must be sharp to ensure a clean cut and healthy grass. Follow these steps for effective blade replacement:

- Disconnect the power source for safety.

- Lift the mower deck to access the blades easily.

- Remove the old blades using appropriate tools.

- Install the new blades, ensuring they are securely fastened.

- Lower the deck and reconnect the power source.

Routine maintenance of belts and blades will not only enhance performance but also contribute to a healthier lawn. Regular checks and timely replacements are key to achieving the best results.

Electrical System Diagnostics

Diagnosing issues within the electrical framework of outdoor machinery is crucial for maintaining optimal performance and preventing breakdowns. A systematic approach can identify problems efficiently, ensuring that all components function correctly. This section outlines key procedures and considerations for effective troubleshooting.

Common Symptoms of Electrical Issues

- Inconsistent power supply

- Unresponsive controls

- Dim or flickering lights

- Battery drainage

- Overheating components

Diagnostic Steps

- Inspect the battery connections for corrosion and tightness.

- Test the battery voltage using a multimeter to ensure it meets specifications.

- Examine fuses for any signs of damage or failure.

- Check wiring harnesses for frays, breaks, or loose connections.

- Utilize diagnostic tools to read any error codes from the control module.

By following these steps, one can effectively pinpoint electrical malfunctions and take corrective actions to restore the system’s functionality.

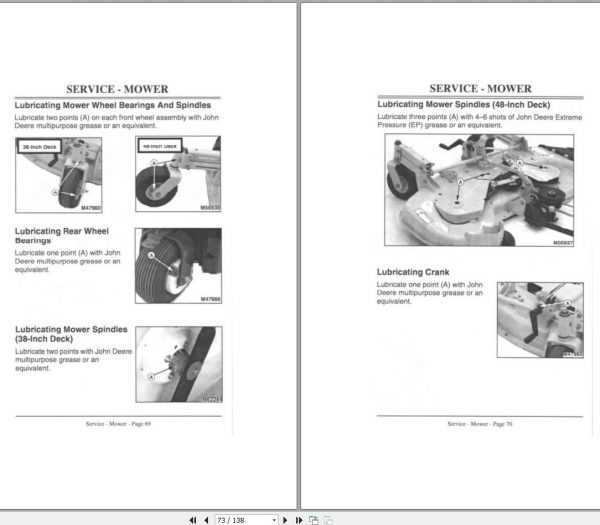

Proper Lubrication Practices

Effective maintenance of machinery is essential for optimal performance and longevity. A crucial aspect of this maintenance is ensuring that all moving components are properly lubricated. Adequate lubrication minimizes friction, reduces wear, and prevents overheating, ultimately enhancing the reliability of the equipment.

Choosing the Right Lubricant

Selecting an appropriate lubricant is vital. Different parts of machinery may require specific types of oils or greases, depending on their operating conditions and materials. Always refer to the manufacturer’s guidelines for recommended products to ensure compatibility and effectiveness.

Application Techniques

Applying lubricant correctly is just as important as choosing the right one. Use clean tools and ensure that the areas to be lubricated are free from dirt and debris. Apply the lubricant in the correct quantity; both under-lubrication and over-lubrication can lead to operational issues. Regular checks and timely reapplication are essential to maintain optimal performance.

Cleaning and Caring for the Deck

Maintaining the deck of your lawn mower is essential for ensuring optimal performance and longevity. A clean and well-cared-for deck not only enhances the appearance of your equipment but also promotes efficient grass cutting. Regular maintenance can prevent rust and damage, ensuring that your mower operates smoothly.

1. Regular Cleaning: After each use, it is important to remove any grass clippings, dirt, and debris from the deck. This can be done using a stiff brush or a hose. Avoid using a pressure washer, as it may damage components. Ensure the mower is turned off and completely cool before cleaning.

2. Inspect for Damage: While cleaning, take the opportunity to inspect the deck for any signs of wear or damage. Look for cracks, dents, or rust spots that may need attention. Addressing these issues early can prevent more significant problems down the line.

3. Protecting the Surface: To prevent grass clippings from sticking to the deck, consider applying a silicone spray or specialized deck protectant. This creates a barrier that makes cleaning easier and helps maintain the integrity of the surface.

4. Regular Maintenance Schedule: Establish a regular maintenance schedule to keep your mower in top condition. This includes cleaning the deck, inspecting for damage, and applying protective treatments. Consistency is key to prolonging the life of your equipment.

By following these steps, you can ensure that the deck remains in excellent condition, allowing for efficient operation and a beautifully manicured lawn.

Identifying Transmission Problems

Recognizing issues within the transmission system is crucial for maintaining optimal performance in your machinery. Various symptoms can indicate that the transmission requires attention, and understanding these signs can help prevent further damage.

Common indicators of transmission trouble include:

- Unusual Noises: Grinding, whining, or clunking sounds may suggest internal wear or a lack of lubrication.

- Slipping Gears: Difficulty in maintaining gear engagement can lead to a loss of power and control.

- Fluid Leaks: Puddles of fluid under the machine may signal a leak that needs immediate investigation.

- Delayed Engagement: Hesitation when shifting into gear can indicate problems within the system.

- Warning Lights: Dashboard indicators related to the transmission should not be ignored.

To accurately diagnose these issues, consider the following steps:

- Inspect Fluid Levels: Ensure that the transmission fluid is at the correct level and check its condition.

- Listen for Sounds: Pay close attention to any irregular noises when the machine is in operation.

- Check for Leaks: Look under the machinery for any signs of leaking fluid.

- Test Gear Shifts: Evaluate the responsiveness of the gears when shifting.

- Consult Diagnostic Tools: Use appropriate diagnostic equipment to identify error codes.

Addressing transmission concerns promptly can extend the life of your equipment and enhance its efficiency.

Storage Tips for Off-Season

Properly storing your equipment during the off-season is crucial for maintaining its longevity and performance. By following a few essential practices, you can ensure that your machinery remains in excellent condition until it is needed again. Here are some effective strategies to consider.

Cleaning and Maintenance

Before putting away your equipment, take the time to thoroughly clean it. Remove any dirt, debris, or residue that may have accumulated. Inspect all components for wear and tear, addressing any issues immediately. Lubricate moving parts to prevent rust and ensure smooth operation when it’s time to use the machinery again.

Safe and Dry Environment

Store your equipment in a dry, sheltered area to protect it from harsh weather conditions. If possible, use a cover to shield it from dust and moisture. Keeping the machinery elevated off the ground can also prevent water damage. Maintaining a stable environment helps prolong the lifespan of your equipment.

Where to Find Replacement Parts

Locating quality components for machinery can significantly enhance its performance and longevity. Understanding the best sources for these parts is essential for maintaining your equipment effectively. Whether you are looking for OEM or aftermarket options, there are several avenues to explore.

Online Retailers

- Visit specialized websites that focus on machinery components.

- Explore large e-commerce platforms that offer a wide range of options.

- Check manufacturer websites for official parts and specifications.

Local Dealers and Suppliers

- Identify local dealers who specialize in equipment and can provide expert advice.

- Look for agricultural supply stores that often stock relevant components.

- Attend local trade shows or expos where vendors showcase their products.

By utilizing these resources, you can ensure that your machinery remains in optimal condition with the right parts at your disposal.