Graco Mark V Repair Manual Guide for Effective Maintenance

Understanding how to maintain and restore complex equipment is essential for professionals who rely on it daily. This guide delves into crucial steps and expert tips that will help keep your machine operating at its best, covering everything from basic maintenance practices to in-depth component assessments. Ensuring proper upkeep can save time, reduce unexpected breakdowns, and improve overall efficiency.

We explore specific techniques for diagnosing issues, offering insights into common challenges and proven methods for addressing them. With clear explanations on disassembly, part replacement, and reassembly, this guide equips users with practical knowledge for handling even the most intricate aspects of upkeep. Whether you’re a seasoned operator or a newcomer, the detailed instructions provided here aim to make maintenance straightforward and effective.

Alongside practical steps, this resource also includes preventative strategies to help avoid future wear and tear. By implementing these practices, users can extend the lifespan of their equipment while minimizing downtime. From regular checks to advanced repair techniques, this guide is designed to meet the needs of any user looking to maintain reliable performance and prevent costly repairs.

Graco Mark V Repair Manual

For effective upkeep and troubleshooting, having a reliable source of guidance is crucial for maintaining this advanced equipment. A comprehensive guide will help you understand its structure, common issues, and provide clear instructions for resolving problems, allowing for sustained performance and minimizing downtime.

Key Components Overview

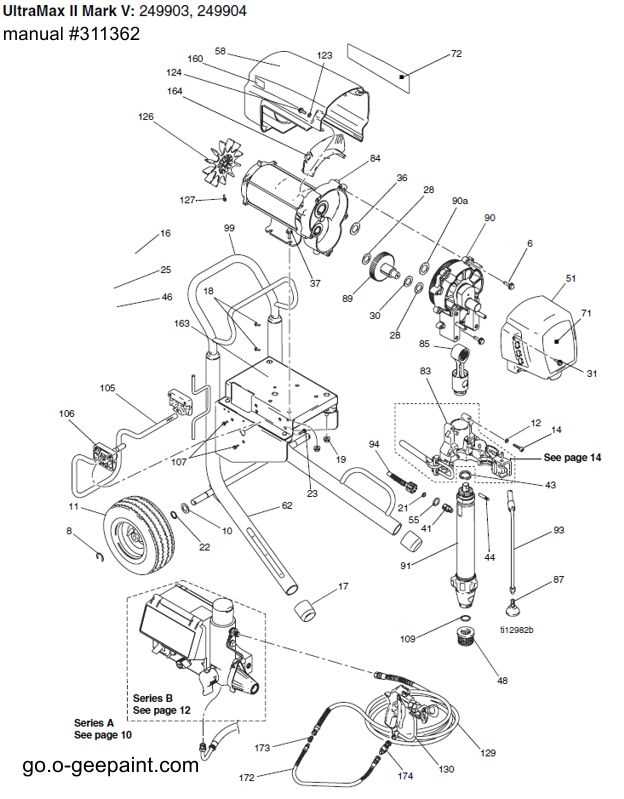

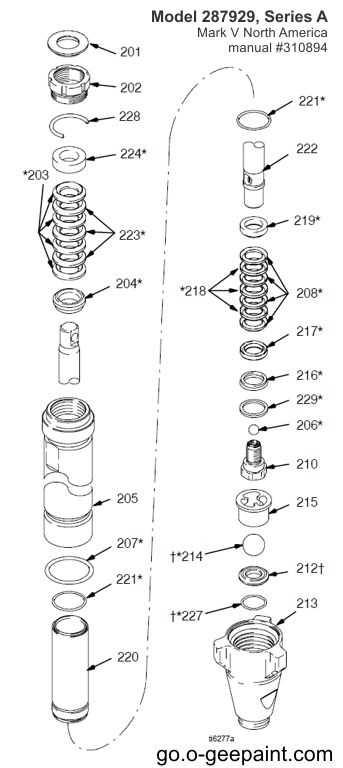

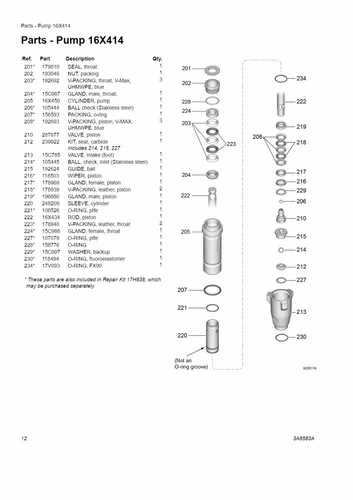

This unit is comprised of multiple intricate parts, each with a unique function to ensure efficient operation. Familiarizing yourself with these core elements is essential for diagnosing potential issues and performing successful maintenance. Below is a breakdown of primary components and their roles:

| Component | Description | Maintenance Tips | |||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Engine Assembly | The power source that drives the entire system, crucial for pressure control. | Regularly check for oil levels and wear in moving parts. | |||||||||||||||||||||||||||||||||||||||||||||

| Pump Module | Responsible for consistent material flow; any issues here affect overall output. | Inspect seals and lubricate as needed to prevent clogs. | |||||||||||||||||||||||||||||||||||||||||||||

| Control Panel | Allows precise adjustments and ensures all settings are optimized. | Check for loose connections and clean dust buildup. | |||||||||||||||||||||||||||||||||||||||||||||

| Issue | Possible Cause | Solution |

|---|---|---|

| Poor or Inconsistent Spray Pattern | Clogged or worn spray tip | Clean or replace the spray tip as necessary |

| Pressure Drop During Operation | Blocked filters or malfunctioning pressure control | Inspect and clean filters; test pressure control unit |

| Motor Overheating | Excessive usage or insufficient ventilation | Allow the motor to cool down, ensure adequate airflow |

| Fluid Leakage | Loose fittings or damaged seals | Tighten fittings; replace worn seals |

| Unit Fails to Prime | Air trapped in the pump or damaged pump components | Release trapped air; inspect and replace pump parts as needed |

Replacing Key Components in the Mark V

Regular upkeep of vital parts ensures that equipment operates smoothly and extends its lifespan. Replacing worn components is essential to maintain peak performance and prevent unexpected breakdowns. In this guide, we’ll focus on identifying and replacing crucial parts that may experience wear over time due to consistent use and exposure to challenging work environments.

Identifying Components for Replacement

Identifying which parts need replacement can be done through a routine inspection process. Look out for visible signs of wear, leakage, or unusual sounds during operation. Addressing these issues early can save time and money in the long run.

- Pump Assembly: A key element that might experience wear, particularly the seals and pistons. Regular inspection helps determine if any leaks or performance drops are due to this part.

- Hose and Fittings: These parts bear pressure and frequent handling, which may lead to small cracks or weaknesses. Replace them when signs of wear become visible to avoid malfunctions.

- Filter Elements: Frequent replacement of filters is necessary for maintaining optimal flow and preventing blockages that could impact system efficiency.

Steps for Replacing Essential Parts

Replacing core components can be straightforward with the right approach. Here’s a step-by-step outline to help you execute replacements with ease:

- Power Down: Always turn off the equipment and disconnect it from any power sources to ensure a safe repair process.

- Disassemble the Required Sections: Access the relevant parts by removing any covers or screws carefully.

- Remove Old Components: Detach the worn parts, taki

Troubleshooting Power Problems with Graco Mark V

Addressing power issues in airless paint sprayers can ensure uninterrupted operation and extend the equipment’s lifespan. Below are common power-related problems and practical steps to identify and resolve these issues.

- No Power When Switched On: If the machine doesn’t start, first check the power source. Inspect for loose connections or faulty cables, as these can prevent electricity from reaching the unit.

- Frequent Power Surges: Power fluctuations may indicate an issue with the sprayer’s motor or circuit board. Ensure that the device is connected to a stable power source. Avoid using extension cords that don’t match the unit’s power requirements, as inadequate cables may cause overheating.

- Motor Fails to Run Continuously: If the motor stops intermittently, inspect the thermal overload switch. This component often triggers due to excess heat, so allow the device to cool down if necessary.

- Power Cord Damage: Regularly inspect the power cord for visible wear or cuts. Replace damaged cords immediately to avoid power loss or short-circuiting, which can impact performance and safety.

By identifying and addressing these common power problems, users can maintain optimal functionality and reduce downtime, ensuring smoother operation and longer-lasting equipment.

Understanding Graco Mark V Pressure Settings

Adjusting the pressure settings on a spray system is crucial for achieving optimal performance and consistent results. Proper pressure levels ensure that the material is applied evenly and efficiently, minimizing waste and enhancing the finish quality. Understanding how to set and manage these pressures can significantly impact the effectiveness of the application process.

The pressure settings on a spray device can vary based on the material being used, the type of job, and the desired finish. It is essential to follow the manufacturer’s recommendations while also making adjustments based on practical experience and specific project needs. Below is a table summarizing common pressure settings for different materials and applications.

Material Type Recommended Pressure (psi) Application Notes Water-Based Paint 1800 – 2400 Ensure even coverage; adjust for thinner materials. Oil-Based Paint 2200 – 2800 Higher pressure may be required for a smooth finish. Stains and Sealers 1500 – 2000 Use lower pressure to prevent overspray. Primers 2000 – 2500 Adjust pressure based on viscosity for better adhesion. Clear Coats 1800 – 2400 Ensure even application for a glossy finish. Monitoring the pressure during operation is vital. Regular checks can help identify any discrepancies that may affect the performance of the equipment. Additionally, understanding how to adjust these settings can lead to improved efficiency and reduced downtime, ensuring that projects are completed to a high standard.

Cleaning and Maintenance for Optimal Performance

Regular upkeep and proper cleaning are essential for ensuring efficient operation and longevity of your equipment. By following systematic procedures, users can prevent wear and tear, enhance performance, and avoid costly repairs. This section outlines key practices to keep your device in top condition.

Essential Cleaning Steps

Maintaining a clean environment is crucial for the smooth functioning of machinery. Here are the fundamental cleaning steps to consider:

Step Description 1. Disconnect Power Ensure the machine is powered off and unplugged to prevent accidents during cleaning. 2. Remove Debris Carefully clear any dust, dirt, or residue from the exterior and interior components. 3. Use Appropriate Cleaners Select cleaning solutions that are compatible with the materials of your device. 4. Wipe Down Surfaces Utilize soft cloths to gently wipe all surfaces, ensuring no moisture is left behind. 5. Inspect Components Check for any signs of wear, damage, or corrosion and address these issues promptly. Maintenance Tips

In addition to regular cleaning, follow these maintenance tips to optimize performance:

- Schedule routine inspections to identify potential issues before they escalate.

- Keep moving parts lubricated to reduce friction and wear.

- Replace worn or damaged parts immediately to maintain efficiency.

- Follow manufacturer guidelines for any specific maintenance requirements.

Adhering to these cleaning and maintenance practices will contribute significantly to the operational efficiency and lifespan of your equipment.

Preventing Overheating in Graco Mark V Systems

Maintaining optimal temperature levels in equipment is crucial for ensuring efficient operation and longevity. Overheating can lead to equipment failure, decreased performance, and costly repairs. Implementing preventive measures can significantly reduce the risk of overheating in various systems, ensuring they function smoothly and effectively.

Regular Maintenance: Consistent upkeep is essential to avoid temperature-related issues. Check for dirt, dust, or debris accumulation that may obstruct airflow. Clean filters and vents periodically to promote proper ventilation and cooling.

Monitor Operating Conditions: Keeping an eye on environmental factors is vital. High ambient temperatures can strain systems, so it’s important to operate in controlled environments whenever possible. Utilizing temperature gauges can help track performance and alert operators to potential overheating scenarios.

Proper Fluid Levels: Ensure that hydraulic or lubrication fluids are at the appropriate levels. Low fluid can lead to increased friction and overheating. Regularly inspect fluid reservoirs and replace fluids according to the manufacturer’s recommendations.

Optimize Load Management: Overloading equipment can cause excessive heat buildup. Always adhere to load specifications to prevent overheating. Properly distribute workloads and allow for breaks to let the system cool down when operating under heavy loads.

Use Quality Components: Utilizing high-quality parts and materials can help prevent overheating. Subpar components may not withstand operational demands, leading to premature failure. Invest in reputable products that meet the necessary standards for your specific system.

By implementing these strategies, operators can effectively minimize the risk of overheating and maintain efficient operation, ultimately enhancing the lifespan of their equipment.

Repairing Fluid Leaks in Graco Mark V

Fluid leaks can significantly impact the performance of your equipment, leading to inefficiencies and potential damage. Identifying and addressing these leaks promptly is essential to maintain optimal operation and prolong the lifespan of the machinery.

Here are some common steps to troubleshoot and fix fluid leaks:

- Identify the Source:

Begin by locating the exact origin of the leak. Check common areas such as:

- Hoses and connections

- Seals and gaskets

- Pump assemblies

- Inspect for Damage:

Examine the identified components for wear or cracks. Signs of damage include:

- Frayed hoses

- Corroded fittings

- Worn seals

- Replace Affected Parts:

If you find any damaged components, replace them with new, compatible parts. Ensure the following:

- Use manufacturer-recommended replacements

- Verify the specifications match the original components

- Tighten Connections:

Loose fittings can often lead to leaks. Check all connections and:

- Tighten as necessary

- Use the appropriate tools to avoid over-tightening

- Test the System:

After making repairs, run the system and observe for any signs of leakage. If any leaks persist, repeat the inspection process.

Regular maintenance and inspection can help prevent leaks from occurring in the first place, ensuring your equipment remains in top condition.

Identifying Electrical Malfunctions in Mark V

Recognizing electrical issues is crucial for maintaining optimal performance in any machinery. By understanding common signs of malfunction, operators can swiftly address problems, ensuring longevity and efficiency of the equipment. This section will outline key indicators and diagnostic steps to identify electrical failures effectively.

Common Signs of Electrical Problems

- Intermittent or inconsistent operation

- Unusual noises or vibrations during operation

- Unresponsive controls or components

- Frequent tripping of circuit breakers

- Burning smell or signs of overheating

Diagnostic Steps

- Inspect power supply connections for looseness or corrosion.

- Examine wiring for signs of wear, fraying, or damage.

- Utilize a multimeter to check voltage levels at key points.

- Test components such as switches and relays for proper functionality.

- Consult the equipment’s specifications to compare expected readings with actual measurements.

By following these guidelines, operators can effectively identify and address electrical malfunctions, contributing to the smooth operation of the machinery.

Calibrating Graco Mark V for Accurate Spraying

Ensuring precision in your spraying tasks is essential for achieving professional results. Proper calibration of your equipment is a critical step that enhances performance and maintains consistency in application. This section focuses on the essential procedures for adjusting the settings of your device to optimize its functionality and accuracy.

Steps for Calibration

- Begin by cleaning the spray gun and checking all components for wear or damage.

- Choose the appropriate tip size for your material, ensuring it aligns with the manufacturer’s recommendations.

- Set the pressure according to the specifications needed for the coating being applied. Start with a lower pressure and gradually increase it until optimal results are achieved.

- Test the spray pattern on a piece of cardboard or a similar surface to evaluate the output.

- Make any necessary adjustments to the fan width and fluid flow to ensure an even application.

- Repeat the testing process until the desired spray pattern and consistency are reached.

Important Considerations

- Always use clean and compatible materials to prevent clogs and enhance spray quality.

- Regular maintenance is vital for long-term performance; inspect seals and filters frequently.

- Document the calibration settings for future reference, ensuring consistency in subsequent jobs.

- Practice on test surfaces before proceeding to actual projects to build confidence in your calibrated settings.

Parts Replacement Guide for Graco Mark V

This section provides a comprehensive overview of the components that may require substitution in your equipment. Understanding the different parts and their functions will help ensure optimal performance and longevity.

Key Components to Consider

- Power Supply Unit

- Hydraulic Pump Assembly

- Fluid Pressure Regulator

- Control Board

- Hoses and Connectors

Steps for Effective Replacement

- Identify the component that needs to be replaced by consulting the schematics.

- Gather necessary tools and replacement parts to streamline the process.

- Follow the disassembly procedures carefully to avoid damage to surrounding components.

- Install the new part, ensuring all connections are secure and correctly oriented.

- Test the system after installation to confirm proper functionality.

Regular maintenance and timely substitution of parts will significantly enhance the efficiency and reliability of your machinery. Always refer to the specific guidelines provided for each component for best practices.

Upgrading and Modifying Your Graco Mark V

Enhancing the performance and functionality of your equipment can lead to improved efficiency and better results in your projects. By focusing on specific upgrades and modifications, you can customize your device to meet your unique needs and preferences. Whether you aim to boost power, increase durability, or enhance user comfort, various options are available for you to consider.

Performance Enhancements: One of the first steps in customization involves upgrading internal components. Consider investing in a high-efficiency pump to increase output and reduce energy consumption. Replacing outdated parts with advanced alternatives can significantly elevate operational effectiveness.

Durability Improvements: To ensure longevity, examine the materials used in your device. Upgrading to more robust components can withstand the rigors of frequent use. Additionally, applying protective coatings can shield vulnerable areas from wear and tear, thereby extending the lifespan of your equipment.

User Comfort: Modifying the design to enhance ergonomics can make a substantial difference in user experience. Adding padded grips, adjustable settings, or customizable controls can significantly improve handling and reduce fatigue during prolonged usage.

Customization Options: Explore a variety of accessories that can complement your device. From specialized attachments to enhanced safety features, these additions can expand your machine’s capabilities, making it versatile for different applications.

In conclusion, focusing on upgrades and modifications allows you to tailor your equipment to better suit your specific tasks. With careful consideration and strategic enhancements, you can transform your device into a powerful tool that meets your evolving needs.