Life Fitness Repair Manual Guide

Understanding how to care for and sustain your workout devices is essential for their longevity and optimal performance. Whether you’re maintaining a complex machine or a simpler piece of equipment, detailed instructions can provide the clarity and confidence needed to address issues effectively. With the right steps, you can prevent unexpected interruptions and enjoy consistent use.

Reliable guidance for keeping devices in top condition is invaluable, especially when it comes to troubleshooting common or recurring issues. Clear and practical directions allow users to perform routine upkeep, identify signs of wear, and make necessary adjustments. This approach ensures that your exercise tools remain both safe and fully functional.

For enthusiasts and professionals alike, having access to comprehensive resources can transform the maintenance process, making it more efficient and accessible. Through these structured guides, users can avoid major repairs, save costs, and extend the lifetime of their equipment.

Guides for Equipment Maintenance

Proper upkeep is essential for ensuring exercise machines perform well over time. Regular servicing can extend the lifespan of the equipment, prevent sudden breakdowns, and improve safety during use. Accessible and clear instructions assist users in addressing minor adjustments and upkeep independently, saving time and resources.

Common Issues and Troubleshooting

With wear and consistent use, some parts of exercise systems may show signs of degradation. Troubleshooting guidelines help in identifying and addressing common challenges such as unresponsive controls, unusual noises, and movement irregularities. Clear steps offer solutions for regular adjustments to reduce the need for extensive servicing.

Importance of Periodic Servicing

Scheduling regular check-ups is crucial to ensure every part functions optimally. Detailed maintenance schedules provide insights into how often various components need attention, preventing larger issues and maintaining optimal performance. Following a structured care plan ultimately enhances user experience and equipment reliability.

Understanding Equipment Maintenance Needs

Regular upkeep of exercise machines is essential to ensure both optimal performance and prolonged durability. Identifying and addressing routine maintenance requirements can prevent unexpected malfunctions, reducing downtime and repair costs.

Identifying Key Maintenance Areas

Each machine consists of various components, each with specific maintenance needs. Regular inspection of these parts allows for early detection of wear and tear, ensuring continuous and safe operation.

- Mechanical parts: Gears, belts, and pulleys are prone to wear and require periodic checks and lubrication.

- Electrical systems: Wires and connections should be inspected for any signs of fraying or loose connections.

- Control panels: Buttons and display screens need occasional cleaning to maintain responsiveness and clarity.

Establishing a Maintenance Schedule

Creating a consistent schedule for inspections and minor repairs is a proactive approach that can save significant time and resources. A well-organized schedule should include weekly, monthly, and quarterly tasks based on usage frequency and equipment type.

- Weekly: Clean external surfaces and inspect moving parts for any abnormalities.

- Monthly: Check for loose bolts or screws, lubricate joints, and perform minor adjustments if needed.

- Quarterly: Conduct a thorough inspection of all internal components and ensure all parts are functioning optimally.

Consistent maintenance routines extend the lifespan of exercise equipment, enhance user safety, and contribute to smoother operation overall.

Identifying Common Issues with Fitness Machines

Understanding typical malfunctions in exercise equipment can help users detect and address problems early, ensuring smoother operation and longer-lasting performance. This section outlines frequent issues found in various types of equipment and provides guidance on recognizing these problems through visual cues and unusual sounds.

Common Problems in Cardio Equipment

- Resistance Malfunctions: Often, the resistance levels may fail to adjust, or the machine might seem too easy or difficult regardless of settings.

- Unusual Noises: Squeaks, grinding, or rattling sounds can indicate loose parts, worn belts, or bearings that need attention.

- Display Issues: Screen malfunctions, flickering, or complete inactivity often result from power supply issues or internal wiring faults.

Frequent Issues in Strength Machines

- Loose or Jammed Cables: Worn-out cables can become slack, affecting resistance, while jammed cables may prevent smooth movement.

- Seat and Handle Adjustments: Difficulty in adjusting seats or handles may be due to worn levers or rust buildup on adjustment mechanisms.

- Frame Instability: Unsteady frames are typically a result of loose bolts, which can cause the equipment to shake during use.

Regular inspection of your equipment, along with proper maintenance routines, can reduce the likelihood of encountering these issues, ensuring a safer and more effective workout experience.

Preventive Care for Optimal Performance

Regular preventive care is essential to ensure the longevity and consistent operation of exercise equipment. By following a few fundamental maintenance steps, you can help prevent unexpected issues and maintain a smooth, efficient performance.

- Regular Inspections: Conduct routine visual checks to identify any signs of wear, loose components, or other potential issues. Early detection can prevent small problems from escalating.

- Lubrication: Keep moving parts well-lubricated to reduce friction and prevent unnecessary wear. Follow recommended intervals to ensure parts operate smoothly.

- Cleaning: Dust and debris can accumulate over time, impacting the machine’s performance. Wipe down surfaces, especially around moving parts, and ensure ventilation areas remain clear.

- Tightening and Adjustments: Periodically tighten screws, bolts, and other fasteners. This helps maintain structural stability and reduces the risk of component misalignment.

- Testing Safety Features: Check any safety mechanisms to ensure they function correctly. Confirm that emergency stops and other features operate as intended.

Incorporating these practices into a regular maintenance schedule can enhance the reliability and lifespan of your equipment, allowing for safer and more effective usage over time.

Troubleshooting Electrical Components

Identifying and resolving issues with electrical elements in exercise equipment can greatly extend the lifespan and functionality of the machine. This process often involves diagnosing power-related issues, checking wiring connections, and examining component signals to ensure seamless operation.

Power Supply and Connections

Start by verifying the power supply and all connections to ensure there are no loose wires or disrupted links. Inspect the power cord for visible damage and test outlets with a voltage meter to confirm stable power input. Securing these connections can often prevent larger issues from developing.

Testing Internal Components

Once external connections are secured, examine the internal components. Use a multimeter to measure voltage and resistance in circuits, helping to pinpoint any faulty parts. If certain components show irregular readings, replacement may be necessary to restore full functionality. Always ensure equipment is unplugged before conducting these tests to maintain safety.

How to Fix Console Malfunctions

Issues with display units can significantly hinder the overall experience. Understanding the common problems and their solutions is essential for maintaining optimal performance.

Here are some frequent malfunctions and steps to resolve them:

- No Display:

- Check power connections and ensure the device is plugged in.

- Inspect the power outlet for functionality by testing with another device.

- Look for any blown fuses or tripped breakers in the electrical system.

- Unresponsive Buttons:

- Examine the console for dirt or moisture that may affect button functionality.

- Perform a soft reset by unplugging the device for a few minutes and then reconnecting it.

- Ensure that all connections to the control panel are secure and undamaged.

- Erratic Readings:

- Calibrate the unit according to the manufacturer’s instructions to ensure accuracy.

- Replace batteries if the console uses them, as low power can lead to inconsistent results.

- Check for any loose wiring or connections that may cause signal disruptions.

By following these guidelines, many common issues can be diagnosed and resolved, ensuring the equipment operates smoothly.

Adjusting Resistance and Tension Systems

Proper calibration of resistance and tension mechanisms is essential for optimal performance and user experience. Adjustments ensure that the equipment functions smoothly and meets the diverse needs of users, providing a tailored exercise experience. Understanding how to modify these systems can significantly enhance effectiveness and safety during workouts.

Understanding Resistance Mechanisms

Resistance mechanisms vary widely across different types of exercise equipment. Each system may utilize various methods to create resistance, including mechanical, magnetic, or hydraulic technologies. Familiarity with these variations can aid in selecting the correct adjustments based on the user’s fitness level and preferences.

Steps for Adjustment

To effectively adjust resistance and tension systems, follow these guidelines:

| Step | Description |

|---|---|

| 1 | Identify the type of resistance system used in the equipment. |

| 2 | Consult the specifications for recommended tension levels. |

| 3 | Make gradual adjustments to find the desired resistance. |

| 4 | Test the equipment to ensure smooth operation. |

| 5 | Regularly check settings for consistency and performance. |

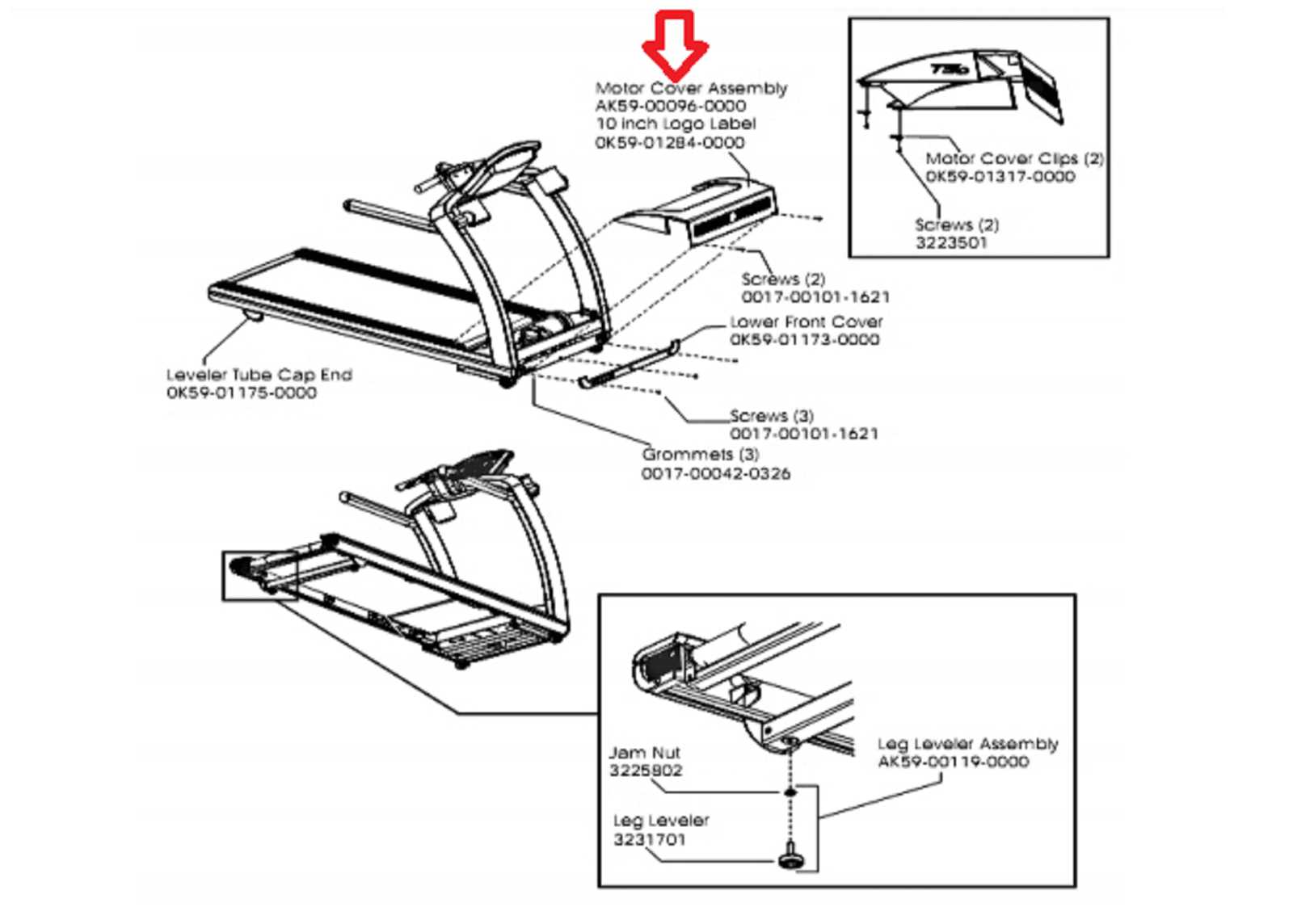

Replacing Worn or Damaged Parts

Ensuring the longevity and optimal performance of your equipment often involves addressing issues related to worn or damaged components. Identifying and replacing these parts promptly can prevent further damage and maintain functionality.

First, it is essential to diagnose the specific issues affecting the machinery. Regular inspections can help pinpoint components that show signs of wear, such as unusual noises or decreased efficiency. Once identified, sourcing appropriate replacements is crucial. Look for parts that meet the original specifications to ensure compatibility.

When preparing for replacement, make sure to disconnect the power supply to the unit to ensure safety. Use the correct tools to carefully remove the damaged components, following any relevant guidelines to avoid damaging surrounding areas. After installing the new parts, conduct a thorough test to ensure everything is functioning correctly before resuming normal operation.

Calibration Tips for Accurate Readings

Ensuring precise measurements is crucial for optimal performance and reliability of any equipment. Proper calibration helps maintain accuracy, which is essential for effective monitoring and assessment. Follow these guidelines to achieve reliable results and enhance the overall functionality of your apparatus.

Regular Checks: Schedule routine inspections to confirm that all settings are within the recommended parameters. Consistency in checking can help identify any discrepancies early.

Use Standardized Equipment: When calibrating, utilize reference tools that are calibrated to national or international standards. This practice ensures that your readings are compared against a reliable baseline.

Environmental Considerations: Be aware of the surroundings where calibration takes place. Temperature, humidity, and other factors can influence the accuracy of readings. Perform calibrations in controlled environments whenever possible.

Follow Manufacturer Guidelines: Adhere strictly to the instructions provided by the device manufacturer. Each piece of equipment has unique calibration requirements that should be respected for optimal performance.

Document Calibration Procedures: Keep detailed records of all calibration activities, including dates, settings, and any adjustments made. This documentation will aid in tracking performance over time and facilitate troubleshooting if issues arise.

Implementing these practices will help ensure that the readings obtained are both accurate and reliable, leading to improved performance and user satisfaction.

Ensuring Proper Lubrication for Longevity

Maintaining optimal functionality of equipment is crucial for its durability and performance. One of the key aspects in achieving this is through adequate lubrication. Properly applied lubricants reduce friction, prevent wear and tear, and significantly extend the lifespan of mechanical components.

Types of Lubricants

There are various lubricants available, including oils, greases, and specialized compounds. Each type serves different purposes and is suitable for specific environments. Selecting the right lubricant based on the machinery’s requirements is essential for effective operation.

Application Techniques

Applying lubricants correctly can enhance their effectiveness. It is important to follow recommended procedures, ensuring that the lubricant penetrates all moving parts. Regular inspections and timely reapplication will help maintain optimal performance and prevent potential damage.

Cleaning Guidelines for Machine Durability

Maintaining the longevity of equipment is essential for ensuring optimal performance and safety. Regular cleaning not only enhances the aesthetic appeal but also prevents the accumulation of dust, grime, and other contaminants that can lead to malfunctions. Following proper cleaning protocols contributes significantly to extending the lifespan of machines.

Daily Cleaning Practices

Establishing a routine for daily cleaning is vital. Wipe down surfaces with a damp cloth to remove sweat and debris. Use mild, non-abrasive cleaners to avoid damaging surfaces. Ensure that all electronic components are dry before using the equipment again to prevent short circuits.

Periodic Maintenance Tasks

In addition to daily cleaning, schedule regular maintenance sessions. Inspect and clean moving parts, lubricating them as necessary to minimize wear. Pay attention to the areas where dust tends to accumulate, such as vents and filters. A thorough check every few weeks will help identify potential issues before they escalate, ensuring smooth operation and durability.

Safety Tips for DIY Repairs

Engaging in self-repairs can be a rewarding experience, but it is essential to prioritize safety. Understanding potential hazards and implementing proper precautions can ensure a smooth process while minimizing risks.

Here are some vital safety recommendations to keep in mind:

- Always disconnect power sources before beginning any work.

- Use appropriate tools and equipment designed for the specific task.

- Wear protective gear, including gloves and safety goggles, to shield against injuries.

- Read all available documentation to familiarize yourself with the item and its components.

- Ensure your workspace is clean and organized to prevent accidents.

By following these guidelines, you can enhance your safety and confidence while tackling home projects.