Comprehensive Guide to 2012 VW Beetle Repair Manual

In the world of automotive care, understanding the intricacies of your vehicle is paramount. Whether you are a seasoned mechanic or a passionate enthusiast, having a comprehensive resource at your fingertips can make all the difference. This guide aims to provide insightful information on the fundamental aspects of upkeep, allowing you to navigate through common issues with confidence.

Knowing your vehicle inside and out not only enhances performance but also prolongs its lifespan. Familiarity with the inner workings can empower you to tackle repairs and maintenance tasks effectively. This resource is designed to illuminate various components, offering clear instructions and tips that simplify the often complex world of automotive service.

Furthermore, understanding the specific requirements of your model can save time and money, transforming what may seem like daunting challenges into manageable projects. With the right knowledge, you can approach each task systematically, ensuring that every job is done correctly and efficiently.

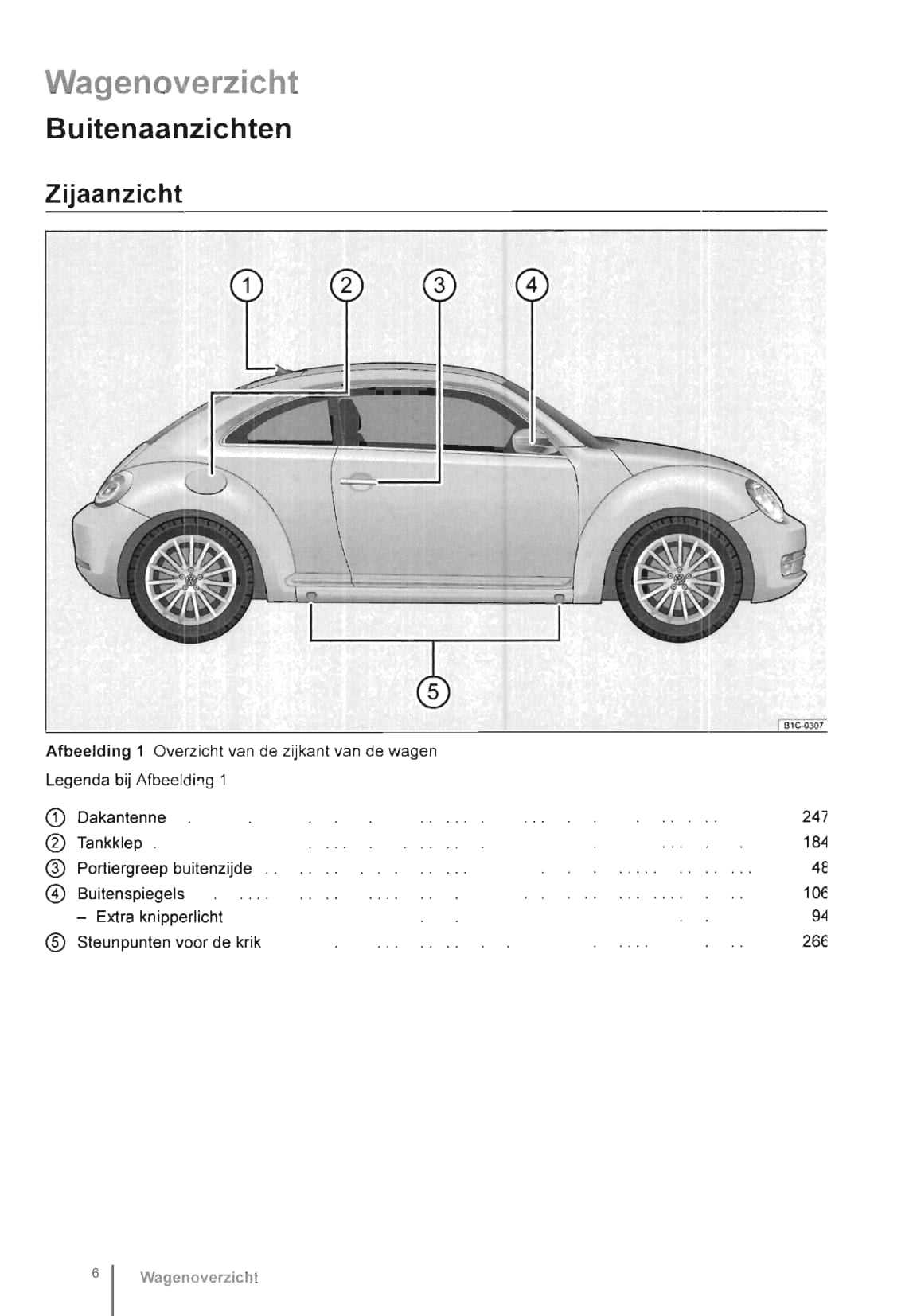

Overview of the 2012 VW Beetle

This section provides a comprehensive look at a distinctive model that embodies a blend of modern engineering and classic design. The vehicle stands out for its unique aesthetic and driving experience, appealing to a wide range of enthusiasts.

Design and Features

The vehicle showcases an iconic silhouette that has been reimagined for contemporary audiences. Key elements include:

- Curvy exterior lines that enhance aerodynamics

- A spacious interior that balances comfort and functionality

- High-quality materials that elevate the overall feel

Performance and Efficiency

This model is equipped with an array of powertrains designed to deliver a satisfying drive while maintaining fuel efficiency. Notable aspects include:

- Responsive handling that offers a sporty driving experience

- Multiple engine options to suit diverse preferences

- Advanced technology features for enhanced safety and connectivity

Overall, this vehicle is a celebration of heritage and innovation, making it a compelling choice for those seeking a blend of nostalgia and modernity.

Common Issues in the 2012 Model

Owners of this iconic vehicle have reported several prevalent challenges that can affect performance and overall driving experience. Understanding these issues can help in identifying symptoms early and facilitating timely interventions to maintain optimal functionality.

Electrical System Concerns

One of the most frequently encountered problems relates to the electrical components. Drivers have experienced issues ranging from malfunctioning lights to intermittent failures in the ignition system. These irregularities can often be traced back to faulty wiring or aging fuses.

Transmission and Engine Performance

Another area of concern involves the vehicle’s transmission and engine dynamics. Many users have noted sluggish acceleration and unusual shifting behaviors. Such symptoms can indicate transmission fluid degradation or issues with the engine control unit, both of which require attention to prevent further complications.

| Issue | Symptoms | Potential Causes |

|---|---|---|

| Electrical Failure | Flickering lights, ignition issues | Faulty wiring, aging fuses |

| Transmission Problems | Sluggish acceleration, rough shifts | Fluid degradation, ECU issues |

Essential Tools for Repairs

When it comes to maintaining and fixing vehicles, having the right instruments is crucial. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are performed with precision. Understanding which tools are indispensable can greatly simplify the process, making even complex jobs manageable.

Basic Hand Tools

Fundamental hand tools are the cornerstone of any automotive maintenance kit. Wrenches, pliers, and screwdrivers in various sizes allow for tackling a wide range of tasks, from tightening bolts to removing components. Investing in high-quality versions of these essentials can significantly improve your experience, providing reliability and durability.

Diagnostic Equipment

In addition to hand tools, diagnostic devices play a pivotal role in modern vehicle upkeep. Tools such as OBD-II scanners help identify issues within the vehicle’s systems, allowing for targeted troubleshooting. This technology not only saves time but also helps in preventing unnecessary repairs by pinpointing exact problems.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. By following systematic methods, you can address various aspects of care, from fluid checks to tire rotations, ultimately enhancing reliability and safety.

The following procedures outline crucial maintenance tasks that should be performed periodically:

-

Oil Change

- Gather necessary tools: wrench, oil filter wrench, and oil pan.

- Remove the old oil using the drain plug.

- Replace the oil filter.

- Fill with new oil, ensuring it meets manufacturer specifications.

-

Tire Inspection

- Check tire pressure using a gauge.

- Inspect tread depth and look for any signs of wear.

- Rotate tires according to the recommended schedule.

-

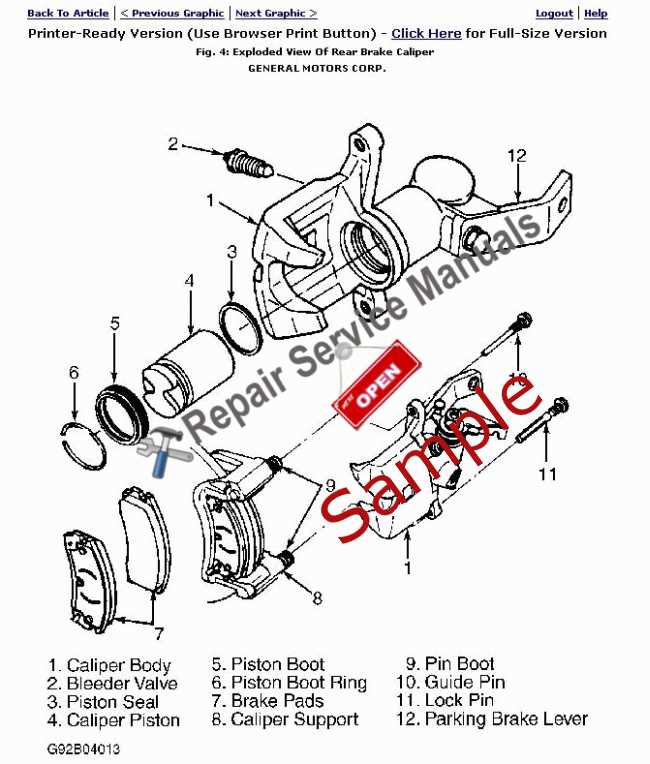

Brake System Check

- Inspect brake pads for wear.

- Check fluid levels in the reservoir.

- Examine brake lines for leaks or damage.

-

Battery Maintenance

- Inspect battery terminals for corrosion.

- Check fluid levels (if applicable).

- Ensure a secure connection to prevent power loss.

Following these essential steps regularly will help maintain your vehicle’s performance and safety. Always refer to specific guidelines for your model for best practices.

Electrical System Troubleshooting

Tackling issues within the electrical system can often be daunting, yet it is essential for maintaining optimal vehicle performance. A systematic approach is crucial to identify and rectify malfunctions effectively. Understanding the components and their functions will aid in isolating problems and implementing appropriate solutions.

Start by inspecting the battery. A weak or dead battery is a common culprit for electrical failures. Ensure that the terminals are clean and tightly connected. Use a multimeter to check the voltage; a healthy battery should read around 12.6 volts when fully charged. If the voltage is low, consider recharging or replacing the battery.

Next, examine the fuses. Blown fuses can disrupt power supply to various systems. Locate the fuse box and check for any damaged fuses, replacing them as necessary. Be sure to use fuses of the correct amperage to prevent future issues.

Wiring integrity is another key factor. Look for signs of wear, fraying, or corrosion on the wiring harness. Damaged wires can lead to shorts or open circuits, resulting in inconsistent electrical performance. Repair or replace any compromised wiring to restore functionality.

Lastly, consider the vehicle’s ground connections. Poor grounding can cause erratic electrical behavior. Ensure that ground points are clean and secure, as this will enhance the overall efficiency of the electrical system.

By following these troubleshooting steps, one can systematically diagnose and resolve electrical issues, ensuring a reliable and efficient vehicle operation.

Engine Repair Techniques Explained

When it comes to maintaining optimal performance, understanding various methods for addressing engine issues is crucial. This section delves into the fundamental approaches that mechanics utilize to diagnose and resolve complications effectively.

Diagnostic Procedures are the first step in any mechanical intervention. Technicians employ specialized tools to identify underlying problems, ensuring that repairs target the root cause rather than just surface symptoms. Utilizing advanced diagnostics enhances the precision of the subsequent work.

Disassembly and Inspection follow the diagnostic phase. This involves carefully taking apart engine components to assess their condition. Each part is scrutinized for wear and damage, allowing for informed decisions about which elements require replacement or servicing.

Reconditioning Techniques are often employed to extend the lifespan of various engine components. Methods such as machining, honing, or resurfacing can restore parts to their original specifications, thereby enhancing performance without the need for complete replacements.

Reassembly and Testing conclude the repair process. Once all necessary adjustments and replacements are made, the engine is carefully reassembled. Rigorous testing follows to ensure that everything functions as intended, verifying that the issues have been resolved and the system operates smoothly.

In summary, a comprehensive understanding of these techniques is essential for anyone involved in engine maintenance. Mastery of these methods leads to more effective and reliable vehicle performance.

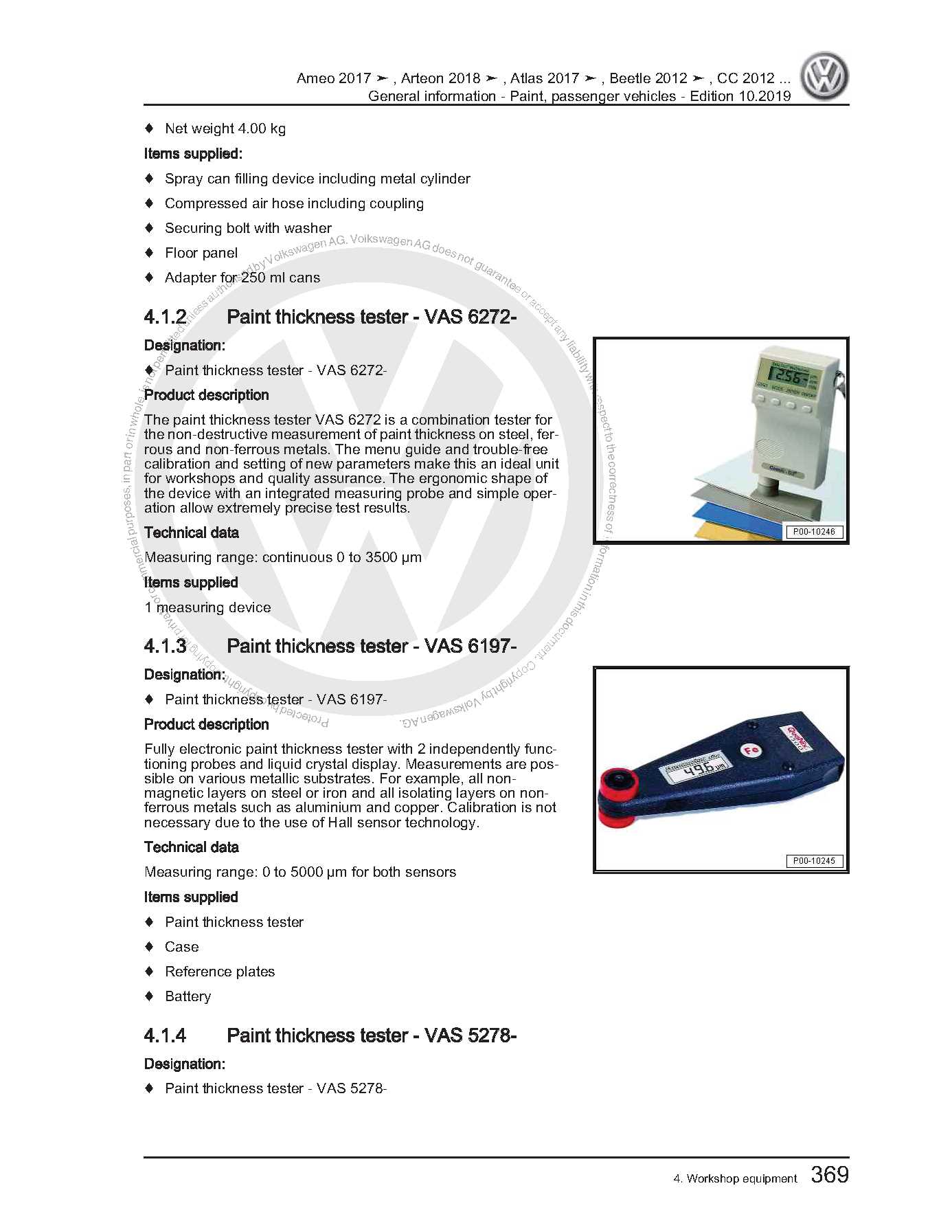

Bodywork and Cosmetic Fixes

Maintaining the exterior appearance of your vehicle is essential for both aesthetic appeal and longevity. Addressing minor imperfections, such as scratches, dents, and rust, not only enhances the look but also prevents further damage. This section focuses on common cosmetic issues and their remedies, ensuring your ride remains in top condition.

For surface scratches, applying a suitable polish can often restore the shine. For deeper marks, consider using touch-up paint that matches the original color. When dealing with dents, techniques like using a hairdryer followed by ice can help pop them out without damaging the paint. If a dent proves stubborn, specialized tools or professional services may be necessary.

Rust can be particularly detrimental, so prompt action is crucial. Sanding down affected areas and applying a rust-inhibiting primer can halt its spread. Once the surface is prepared, a topcoat of matching paint will blend the repair seamlessly with the rest of the bodywork.

For larger repairs or cosmetic upgrades, consider adding protective films or vinyl wraps to areas prone to wear. This not only improves durability but can also give your vehicle a personalized touch. Regular waxing and detailing will further protect the finish and maintain its shine.

Understanding the Transmission System

The transmission system is a vital component that facilitates the transfer of power from the engine to the wheels, enabling smooth and efficient movement of the vehicle. This intricate network consists of various elements that work in harmony to ensure optimal performance and drivability.

Key Components

- Transmission Housing

- Gear Sets

- Clutch Mechanism

- Fluid Pump

- Control Modules

Types of Transmission

- Manual Transmission

- Automatic Transmission

- Continuously Variable Transmission (CVT)

Understanding these components and types allows for better insight into the ultimate functionality and maintenance needs of the system, enhancing overall vehicle performance.

Routine Maintenance Schedule Recommendations

Establishing a regular maintenance routine is essential for ensuring optimal performance and longevity of your vehicle. Adhering to a well-structured schedule helps to identify potential issues early, minimizing the risk of unexpected breakdowns and costly repairs. This guide outlines key recommendations for maintaining your automobile effectively.

Every 5,000 Miles: It is advisable to change the engine oil and replace the oil filter. This routine helps to keep the engine running smoothly and efficiently, ensuring that lubricants perform as intended.

Every 10,000 Miles: Inspect the air filter and replace it if necessary. A clean air filter enhances engine performance and fuel efficiency. Additionally, check tire pressure and tread depth regularly to ensure safety and optimal handling.

Every 20,000 Miles: Brake components should be inspected for wear and tear. This includes pads, rotors, and fluid levels. Maintaining the braking system is crucial for safety.

Every 30,000 Miles: It is recommended to flush the coolant system to prevent overheating and engine damage. Additionally, consider checking the battery and cleaning terminals to ensure reliable starts.

Every 60,000 Miles: Replace the timing belt if applicable, as a failure in this component can lead to severe engine damage. Also, check the transmission fluid and replace it as necessary to maintain smooth gear shifts.

Following these guidelines can significantly enhance the performance and reliability of your vehicle. Regular checks and timely interventions not only save money in the long run but also provide peace of mind while driving.

Safety Features and Their Repair

Ensuring the well-being of occupants is a paramount concern for vehicle manufacturers. Advanced mechanisms designed to enhance protection in case of an incident are integral to modern automobiles. These systems require regular assessment and, when necessary, maintenance to function optimally. Understanding their components and the common issues that may arise can help maintain a high level of safety.

Key elements of safety systems include airbags, anti-lock braking systems, and stability control. Each feature plays a significant role in accident prevention and minimizing injury. Timely attention to these systems can prevent malfunctions that might compromise safety.

| Feature | Common Issues | Recommended Action |

|---|---|---|

| Airbags | Warning light activation | Diagnostics to check sensors and connections |

| Anti-lock Braking System | Loss of braking efficiency | Inspection of hydraulic components and sensors |

| Stability Control | Indicator light on dashboard | System recalibration and sensor checks |

Regular inspections by a qualified technician can ensure these systems operate as intended. Proactive measures can significantly reduce the risk of malfunction, enhancing overall vehicle safety.

Where to Find Replacement Parts

Locating components for your vehicle can be a straightforward process if you know where to look. Various resources are available to help you find high-quality alternatives that suit your needs. Whether you prefer online shopping or local stores, understanding your options will streamline the replacement process.

One of the most convenient places to start your search is online marketplaces. Websites specializing in automotive parts often provide extensive inventories, detailed descriptions, and customer reviews, making it easier to compare different items. Additionally, manufacturer websites can offer direct access to genuine parts, ensuring compatibility and reliability.

For those who prefer a hands-on approach, local auto parts stores are a great option. Staff members at these establishments can provide valuable advice and assistance in finding the right components. Salvage yards can also be a cost-effective alternative, offering a variety of used parts that may be in excellent condition.

Finally, forums and online communities dedicated to car enthusiasts can be invaluable. Members often share recommendations for trustworthy suppliers, and you might even find second-hand parts available for sale from fellow enthusiasts. By exploring these diverse avenues, you can efficiently secure the components necessary for your automotive projects.