1997 Honda Odyssey Repair Guide for Maintenance and Fixes

Ensuring the smooth operation and longevity of your vehicle requires a solid understanding of essential upkeep and diagnostic practices. With the right insights, routine care and troubleshooting can be a straightforward, rewarding process that not only extends the life of the vehicle but also enhances safety and performance.

In-depth maintenance knowledge is invaluable, particularly for older models where wear and tear may require more attention. Regular inspections and adjustments help address minor issues before they evolve into larger, costlier problems. Familiarity with common adjustments, part replacements, and regular checks can make a significant difference in the overall driving experience.

This guide provides step-by-step approaches for diagnosing and resolving various mechanical and technical concerns, tailored for those looking to better understand and care for their vehicle independently. From basic engine care to detailed component checks, this resource is designed to be both informative and user-friendly.

1997 Honda Odyssey Repair Guide

Taking care of your vehicle ensures its longevity and reliable performance. This guide provides essential steps for keeping your minivan in prime condition, from routine maintenance to more advanced adjustments. Focusing on critical areas of upkeep can help you address potential issues early and maintain smooth operation on the road.

Routine Maintenance Tips

Regularly inspecting the primary systems and components is key. Pay attention to areas like fluid levels, tire condition, and brake functionality. Routine oil changes, fluid top-ups, and filter replacements are simple yet impactful measures to prevent wear. These actions contribute to smoother rides and can reduce long-term repair costs.

Addressing Common Issues

Older models often face wear in areas like the suspension, exhaust system, and electrical wiring. Promptly attending to unusual sounds, changes in handling, or electrical glitches can help prevent more extensive fixes. For instance, if you notice irregular engine sounds or dimming lights, checking the battery or alternator can sometimes resolve the issue before it escalates. Regular attention to these elements helps ensure dependable performance.

Engine Maintenance Essentials

Regular upkeep of your vehicle’s engine is crucial for ensuring its longevity and optimal performance. This section covers key maintenance tasks that help keep the engine running smoothly and efficiently, reducing the likelihood of breakdowns and expensive repairs.

Oil and Fluid Levels

Maintaining the right levels of oil and other essential fluids is fundamental to engine health. Low or old oil can lead to friction and wear, potentially damaging key components. Regular checks of engine oil, coolant, and transmission fluid help ensure smooth functioning and prevent overheating.

- Oil Check: Regularly inspect the oil level and change it according to the vehicle’s requirements.

- Coolant Level: Ensure the coolant is topped up to avoid overheating, especially during long drives.

- Transmission Fluid: Check and replace as needed to maintain smooth gear shifts.

Air Filter Replacement

An essential part of engine maintenance is keeping the air filter clean and free from debris. A clogged air filter can restrict airflow, causing the engine to work harder and consume more fuel. Regular replacement or cleaning of the filter ensures proper air intake and improves fuel efficiency.

- Inspect the air filter every few months or according to the maintenance schedule.

- Replace the filter if it appears dirty or damaged to maintain optimal airflow.

Following these simple engine maintenance steps can significantly enhance the performance and lifespan of the vehicle, making every drive smoother and more reliable.

Transmission Troubleshooting Tips

Effective transmission troubleshooting is crucial for maintaining a smooth and responsive driving experience. This guide provides key pointers to help identify common issues and possible solutions related to transmission performance.

Signs of Transmission Issues

- Unusual noises: Grinding, clunking, or whining sounds may indicate internal problems within the transmission system.

- Gear slippage: If the vehicle unexpectedly shifts gears or struggles to stay in gear, this can signal potential issues.

- Delayed response: A delay when shifting into drive or reverse could hint at transmission troubles.

Basic Troubleshooting Steps

- Check fluid levels: Low or dirty fluid can affect transmission performance. Ensure fluid is at the proper level and inspect for leaks.

- Inspect for warning lights: Dashboard indicators can often reveal specific issues. A diagnostic scan can provide more detail if a light is illuminated.

- Monitor shifting patterns: Irregular shifting, like hard shifts or hesitation, might suggest a need for transmission service or inspection.

Regular attention to these warning signs and troubleshooting steps can help keep the transmission functioning optimally and extend its lifespan.

Brake System Repair Steps

Understanding the essential processes for maintaining and restoring a vehicle’s braking system ensures reliable performance and safety. This section provides a structured approach to servicing the brakes, guiding through each stage of inspection and component replacement.

1. Initial Inspection

- Check brake fluid levels in the reservoir to ensure they are within the recommended range.

- Inspect brake lines for any visible signs of wear, cracks, or leaks.

- Assess the brake pads for thickness; thin or worn pads may require replacement to maintain efficiency.

2. Removing Old Components

- Lift the vehicle securely to access the wheel area.

- Remove the wheels to expose the braking elements.

- Unbolt and carefully remove the brake calipers, allowing access to the brake pads and rotors.

- Inspect the rotors for any deep grooves or significant wear; if damaged, consider resurfacing or replacing them.

3. Installing New Brake Parts

- Install new brake pads, ensuring they align correctly with the calipers.

- If necessary, place new rotors or resurfaced ones onto the wheel hub.

- Reattach the brake calipers, securing them firmly over the new components.

- Cooling System Care and Upkeep

Maintaining the cooling system is essential for ensuring the engine remains at optimal temperature and operates smoothly under various conditions. Regular attention to this system helps prevent overheating and extends the overall lifespan of the engine.

Inspecting Coolant Levels: Frequently check the coolant reservoir and refill as necessary. Coolant levels should be kept within the recommended range to avoid issues with heat regulation.

Flushing and Replacing Coolant: Over time, coolant can become contaminated, reducing its effectiveness. Flushing the system and replacing the coolant periodically helps remove impurities, improving efficiency and preventing corrosion.

Examining Hoses and Connections: Hoses and connectors are vital components of the cooling system and should be examined regularly for signs of wear or leaks. Replace any damaged parts promptly to maintain the integrity of the system.

Monitoring Temperature Gauges: Keep an eye on the temperature gauge during operation. Any unusual rises in temperature could indicate issues within the cooling system that may require further inspection.

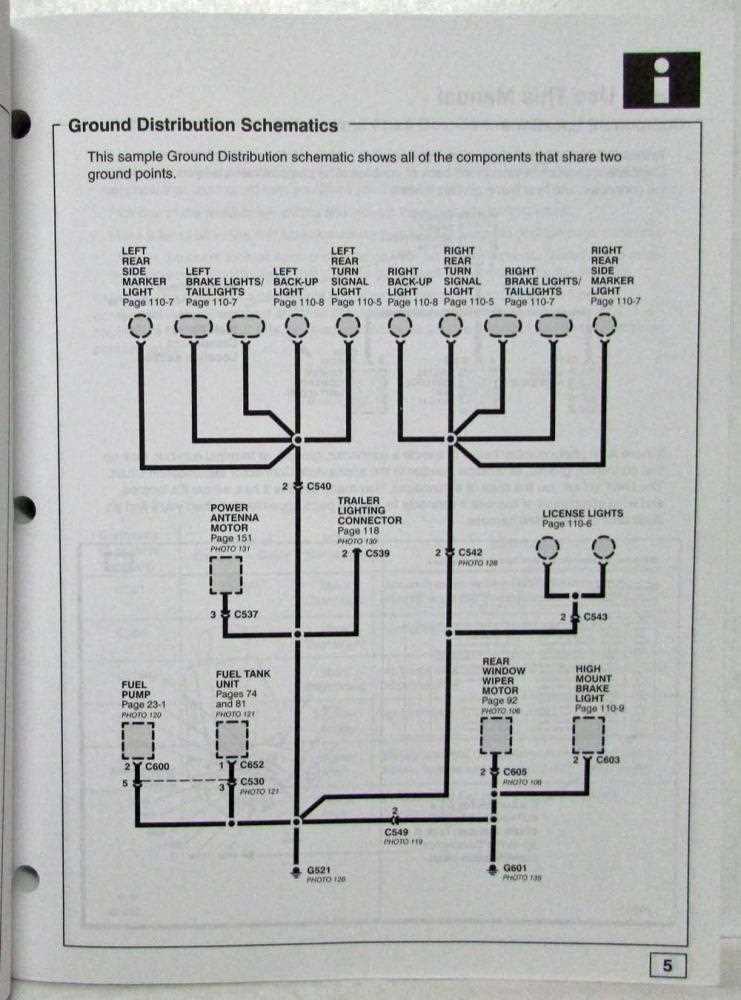

Electrical System Diagnostics

Evaluating the electrical components of a vehicle is crucial for maintaining optimal performance and safety. A thorough examination helps identify potential issues that could affect functionality and reliability. By understanding the key elements of the electrical system, one can effectively troubleshoot and resolve malfunctions.

Key Components to Inspect

The electrical system consists of several essential parts, including the battery, alternator, wiring, and fuses. Each of these components plays a significant role in ensuring proper power distribution throughout the vehicle. Regular checks of these elements can prevent unexpected failures and enhance overall performance.

Troubleshooting Techniques

When diagnosing electrical issues, utilizing a multimeter to measure voltage and resistance is invaluable. Additionally, visual inspections of wiring for signs of wear or damage can reveal hidden problems. Documenting any irregularities observed during these checks can aid in pinpointing specific areas that require attention.

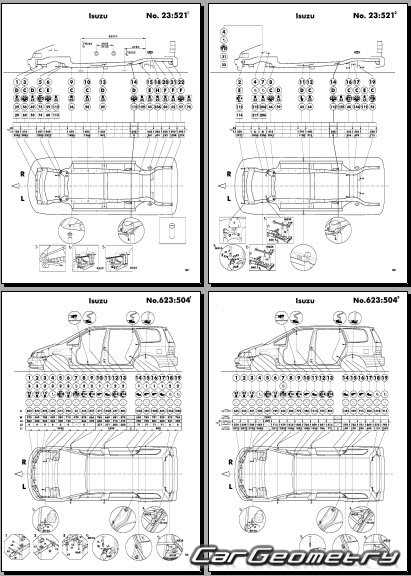

Suspension and Steering Checks

Regular examination of the suspension and steering systems is essential for maintaining optimal vehicle performance and safety. These components play a critical role in ensuring a smooth ride and effective handling. Neglecting their condition can lead to various issues, affecting overall driving experience.

Inspecting Suspension Components: Start by assessing the condition of shock absorbers and struts. Look for any signs of leakage or physical damage, which can compromise their ability to absorb bumps. Additionally, check the springs for any fractures or sagging, as this can affect vehicle height and stability.

Evaluating Steering Mechanism: The steering system should be examined for any unusual noises or play. Ensure that the steering fluid is at the appropriate level and free of contaminants. Inspect the tie rods and ball joints for wear, as these parts are crucial for precise steering control.

Alignment and Balance: Proper wheel alignment and balance are vital for even tire wear and vehicle stability. Schedule routine checks to ensure the wheels are aligned correctly, preventing unnecessary strain on the suspension and steering systems.

Maintaining the integrity of these systems will contribute to a safer driving experience and enhance the longevity of your vehicle.

Fuel System Maintenance

Proper upkeep of the fuel delivery system is essential for ensuring optimal performance and efficiency. Regular attention to this component can prevent issues related to fuel flow and combustion, ultimately enhancing the overall driving experience. This section outlines the key practices to maintain a reliable fuel system.

Regular Inspections

Conducting frequent inspections of the fuel system can help identify potential problems before they escalate. Check for any signs of leaks, corrosion, or damage to the fuel lines and connections. Additionally, ensure that the fuel filter is clean and free of debris to promote smooth operation.

Fuel Quality and Additives

Using high-quality fuel and appropriate additives can significantly impact the longevity and efficiency of the fuel system. Consider incorporating fuel system cleaners periodically to remove carbon deposits and improve injector performance. Always follow the manufacturer’s recommendations for fuel specifications to maintain optimal functionality.

Exhaust System Inspection

The exhaust system is a critical component of any vehicle, playing a vital role in managing emissions and ensuring optimal engine performance. Regular evaluation of this system is essential to identify potential issues that could affect functionality or lead to costly repairs.

During the inspection process, begin by examining the exhaust pipes for any signs of corrosion, cracks, or loose connections. Visual checks are important to ensure that all components are securely attached and free from leaks. Pay close attention to the joints and connections, as these areas are prone to wear over time.

Next, listen for any unusual noises while the engine is running. A loud rumble or hissing sound may indicate a leak within the exhaust system. Additionally, observe the exhaust fumes; a rich, black smoke can suggest a fuel mixture problem, while excessive white smoke might point to coolant leakage.

Lastly, it is crucial to check the mounting brackets and hangers that support the exhaust system. Loose or damaged mounts can lead to misalignment and further complications. Maintaining the integrity of these components ensures a secure installation and reduces the risk of future issues.

Battery Health and Replacement

Maintaining the vitality of your vehicle’s energy source is essential for optimal performance and longevity. Regularly assessing the condition of the power unit can prevent unexpected failures and ensure reliable operation.

Signs of Deterioration

Several indicators suggest that the energy unit may require attention:

- Difficulty starting the engine

- Dim or flickering lights

- Corrosion on terminals

- Unusual swelling or leaks

Replacement Process

When the time comes for a change, follow these steps for proper installation:

- Turn off the ignition and all electrical components.

- Disconnect the negative terminal first, followed by the positive.

- Remove the old power source carefully.

- Install the new energy unit, ensuring proper alignment.

- Reconnect the positive terminal first, then the negative.

- Test the vehicle to ensure everything functions correctly.

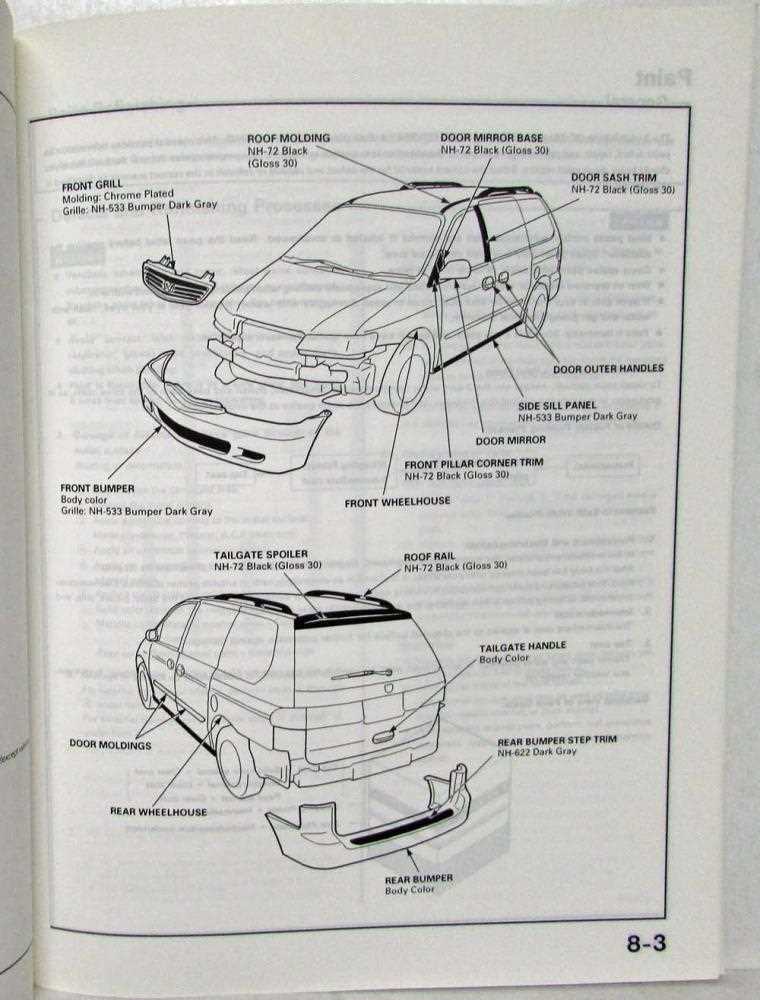

Interior Components Fixes

Maintaining the interior elements of a vehicle is essential for both functionality and comfort. Over time, various components can experience wear and tear, leading to the need for repairs or replacements. This section discusses common issues found in the interior parts and how to address them effectively.

Common Issues

- Worn upholstery that requires patching or replacing.

- Malfunctioning switches that may need cleaning or replacement.

- Loose trim that requires reattachment or securing.

- Faulty speakers that may need inspection or replacement.

Repair Steps

- Assess the condition of the affected components to determine necessary repairs.

- Gather the required tools and materials for the fixes.

- Carefully disassemble any parts if needed, ensuring not to damage surrounding elements.

- Make the necessary repairs, such as reupholstering seats or replacing faulty switches.

- Reassemble the components, ensuring all parts are secure and functioning properly.

Lighting System Adjustments

The proper alignment and functionality of the illumination system are crucial for ensuring optimal visibility and safety while driving. This section will guide you through the essential steps to adjust the lighting components effectively, enhancing both performance and reliability.

Adjustment Type Procedure Tools Required Headlight Aim Park the vehicle on a level surface facing a wall. Measure the height of the headlight centers and mark this height on the wall. Adjust the headlights until the top of the beam is aligned with the mark. Tape measure, screwdriver Turn Signal Functionality Test the operation of the turn signals by activating them and ensuring they flash at a consistent rate. Replace any bulbs that are malfunctioning. Replacement bulbs, basic hand tools Taillight Brightness Check the intensity of the taillights during both day and night conditions. Replace any dim bulbs and clean the lens for improved visibility. Replacement bulbs, cleaning cloth Basic Tools for DIY Repairs

Having the right equipment is essential for anyone looking to handle their own vehicle maintenance and enhancements. A well-equipped toolbox not only simplifies the process but also enhances the efficiency and effectiveness of various tasks. Understanding which tools are necessary can make a significant difference in the outcome of your projects.

Start with fundamental hand tools such as wrenches, sockets, and screwdrivers. These versatile instruments allow you to tackle a wide range of tasks, from tightening bolts to replacing components. Additionally, consider including pliers and hammers, which can be invaluable for gripping, bending, and adjusting parts as needed.

Power tools can also greatly increase your capabilities. Drills, impact wrenches, and grinders are just a few examples that can expedite projects and provide more precise results. However, it’s crucial to familiarize yourself with the proper use and safety precautions associated with these devices to ensure a safe working environment.

Finally, don’t forget specialty tools that may be specific to certain jobs. Items like torque wrenches, diagnostic scanners, and fluid extractors can provide additional support, helping to streamline tasks that require more specialized knowledge. By equipping yourself with these tools, you will be well-prepared for any undertaking.