Comprehensive Guide to Repairing John Deere LX277

Maintaining a lawn tractor is essential for ensuring its longevity and optimal performance. Regular upkeep not only enhances the efficiency of the machine but also prevents costly breakdowns in the future. A detailed understanding of its components and functions allows users to address common issues effectively, leading to a more rewarding gardening experience.

In this section, we will delve into essential practices and insights that can aid in the upkeep of your equipment. Whether you are facing minor challenges or major repairs, having a structured approach will empower you to tackle any situation with confidence. With the right knowledge at your disposal, you can maximize the lifespan of your machine while maintaining a pristine lawn.

Equipped with the necessary information and techniques, anyone can learn to navigate through the intricacies of their equipment. This guide serves as a valuable resource, providing step-by-step instructions and practical tips to simplify maintenance tasks. As you familiarize yourself with the inner workings of your lawn tractor, you’ll find that many repairs can be accomplished with just a few tools and a little patience.

Understanding the John Deere LX277

This section delves into the features and functionalities of a popular lawn care equipment model designed for efficient outdoor maintenance. With a robust construction and user-friendly design, it has become a go-to choice for homeowners seeking reliable performance in their landscaping tasks.

Key Features

- Powerful engine for effective cutting performance.

- Ergonomic controls for enhanced user comfort.

- Versatile attachment options for various gardening needs.

- Compact size for easy maneuverability in tight spaces.

Maintenance Tips

- Regularly check and replace the air filter to ensure optimal engine performance.

- Inspect the blades frequently and sharpen as needed to maintain cutting efficiency.

- Keep the exterior clean to prevent rust and deterioration.

- Follow the manufacturer’s guidelines for seasonal storage to extend longevity.

Common Issues with LX277 Models

Many users of this popular lawn care machine encounter a variety of challenges during operation. Understanding these frequent problems can aid in efficient troubleshooting and maintenance, ensuring a smoother experience.

- Starting Difficulties: One of the most reported issues involves trouble with ignition. Factors can include:

- Weak battery

- Faulty ignition switch

- Clogged fuel lines

- Engine Performance Problems: Users often experience irregular engine behavior, which may stem from:

- Dirty air filters

- Old or contaminated fuel

- Worn spark plugs

- Cutting Issues: Uneven grass cutting can be frustrating. This may be due to:

- Dull blades

- Improper deck height adjustment

- Obstructions under the mower deck

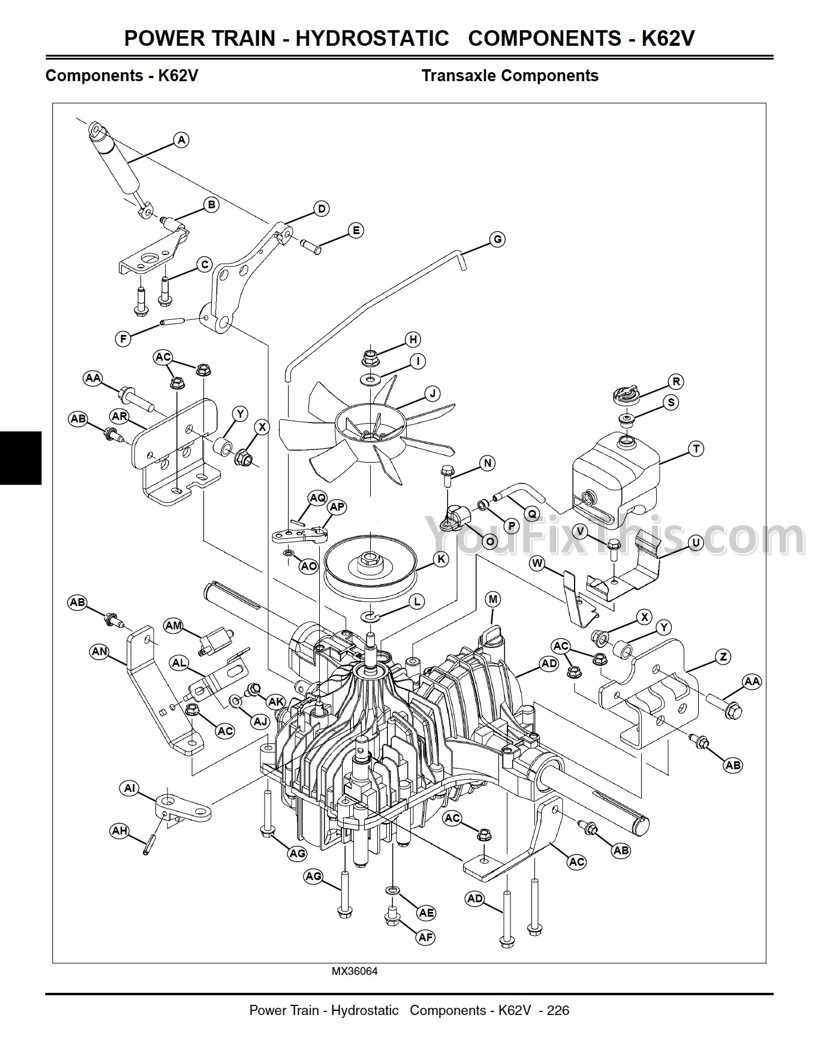

- Transmission Concerns: Problems with the drive system can lead to difficulty in movement. Common causes include:

- Low fluid levels

- Worn belts

- Damaged pulleys

lessCopy code

Regular maintenance and awareness of these potential issues can significantly enhance the longevity and performance of this equipment.

Essential Tools for LX277 Repairs

When it comes to maintaining and fixing your equipment, having the right tools is crucial for ensuring efficient and effective work. A well-equipped toolkit not only facilitates easier troubleshooting but also enhances the longevity of the machinery. Understanding which implements are necessary can significantly simplify the process of upkeep.

Wrenches are fundamental for loosening and tightening various fasteners. A set of both metric and imperial sizes is recommended to accommodate different components. Screwdrivers, including both flathead and Phillips, are essential for accessing covers and panels. Additionally, having a socket set allows for better torque application and can reach tighter spaces.

For those intricate tasks, a multimeter is invaluable for diagnosing electrical issues. This tool helps you test voltage, current, and resistance, ensuring all electrical systems function correctly. Furthermore, a jack or lift is necessary for safely elevating the unit, providing easier access to the underside for inspection and maintenance.

Lastly, a good supply of lubricants and cleaning agents is essential for proper maintenance. Keeping parts clean and well-lubricated prevents premature wear and ensures smooth operation. By assembling these essential tools, you’ll be well-prepared to tackle any maintenance challenge that arises.

Step-by-Step Repair Process Overview

This section provides a detailed approach to maintaining and fixing your equipment, ensuring optimal performance and longevity. By following a systematic method, you can efficiently address various issues that may arise during use. Each step is designed to be clear and concise, allowing for easy understanding and execution.

Preparation and Assessment

Begin by gathering all necessary tools and materials before starting the task. Conduct a thorough evaluation of the machinery to identify any visible problems. Make notes of unusual sounds or malfunctions, as these observations will guide you through the subsequent steps. Safety first: always ensure that the equipment is turned off and disconnected from power sources to prevent accidents.

Execution and Testing

After identifying the issue, proceed with the disassembly of relevant components, taking care to document the order of removal. Replace or fix the faulty parts, ensuring that all connections are secure. Once reassembly is complete, conduct tests to confirm that the machine operates smoothly. Regular maintenance post-repair is crucial to prevent future breakdowns and to maintain efficiency.

Maintaining Your John Deere LX277

Proper upkeep of your lawn care equipment is essential for ensuring its longevity and optimal performance. Regular maintenance tasks can prevent minor issues from escalating into significant problems, allowing you to enjoy a well-maintained landscape.

Routine Checks should be a part of your schedule. Inspect key components such as the engine, belts, and blades. Look for signs of wear and tear, and address any concerns promptly. Keeping these parts in good condition will enhance efficiency and reduce the likelihood of unexpected breakdowns.

Fluid Levels are crucial for smooth operation. Regularly check the oil, coolant, and fuel levels. Replacing oil and filters at recommended intervals will contribute to the overall health of your machine. Clean or replace air filters to maintain optimal airflow and engine performance.

Cleaning is often overlooked but vital. Remove grass clippings and debris from under the chassis and around the cutting deck. This practice not only prevents rust but also promotes better airflow and cutting efficiency.

Storage plays a significant role in maintaining your equipment. During off-seasons, store the machine in a dry, sheltered area. Ensure that the fuel system is treated with stabilizers to prevent degradation and that the battery is charged or disconnected to extend its lifespan.

By adhering to these maintenance practices, you will ensure that your lawn equipment remains reliable and performs at its best, providing you with a beautiful outdoor space year after year.

Replacing the Battery Safely

Ensuring a smooth and safe process during battery replacement is crucial for the longevity and performance of your equipment. This task requires attention to detail and adherence to safety protocols to prevent accidents or damage.

Preparation is Key: Before starting, gather necessary tools and materials. Make sure you have safety gloves and goggles to protect yourself. Disconnecting the power source is essential to avoid any electrical hazards.

Steps to Follow: Begin by removing the old power unit carefully. Inspect the connectors for corrosion or damage. Clean them if necessary. When installing the new unit, ensure it is securely fastened and connected to prevent any loose connections that could lead to operational issues.

Final Checks: Once the replacement is complete, double-check all connections and ensure everything is in place. Power on the device to test functionality. Keeping a regular maintenance schedule will enhance safety and performance in the future.

Troubleshooting Engine Problems

Identifying and resolving issues with an engine can significantly enhance the performance and longevity of your equipment. Common symptoms often indicate underlying problems that require careful examination and methodical approaches for effective solutions.

Before diving into specific troubleshooting steps, it’s crucial to recognize typical signs of engine malfunction:

- Unusual noises during operation

- Difficulty starting or failure to start

- Inefficient power output

- Excessive smoke from the exhaust

- Overheating

To systematically address these concerns, consider the following steps:

- Check Fuel Supply:

- Ensure there is adequate fuel in the tank.

- Inspect for clogs in the fuel lines.

- Examine the fuel filter for dirt and debris.

- Examine Electrical Components:

- Test the battery voltage and connections.

- Inspect fuses for any signs of damage.

- Check ignition system components for wear.

- Assess Air Intake:

- Ensure the air filter is clean and free of obstructions.

- Check for leaks in the intake manifold.

- Verify the carburetor is functioning properly.

- Inspect Engine Oil:

- Confirm oil levels are within the recommended range.

- Look for signs of contamination or burning oil.

- Change oil regularly to maintain optimal performance.

By following these troubleshooting guidelines, you can effectively diagnose and rectify engine issues, ensuring your machinery operates smoothly and efficiently.

Repairing the Mower Deck

Maintaining the cutting assembly of your lawn maintenance equipment is essential for optimal performance and longevity. Over time, wear and tear can lead to reduced efficiency, uneven cuts, and increased fuel consumption. Addressing these issues promptly can help restore functionality and ensure a smooth mowing experience.

Common Issues and Solutions

Several common problems can arise with the cutting deck, including blade dullness, damage to the housing, and misalignment. Below is a table summarizing these issues along with potential solutions:

| Issue | Solution |

|---|---|

| Dull Blades | Sharpen or replace the blades to ensure a clean cut. |

| Deck Damage | Inspect for cracks or dents; repair or replace as necessary. |

| Misalignment | Check the mounting and adjust as needed for proper alignment. |

| Rust Build-Up | Clean thoroughly and apply protective coating to prevent future rust. |

Preventive Maintenance Tips

To minimize issues with the cutting assembly, regular maintenance is crucial. Always clean the deck after each use to prevent grass buildup, and inspect for signs of wear periodically. Keeping the blades sharp and ensuring that all components are securely fastened will significantly enhance the longevity of your equipment.

Adjusting the Cutting Height

Achieving the perfect cutting height is essential for maintaining a healthy and attractive lawn. Proper adjustment ensures that grass is trimmed to an ideal length, promoting growth and preventing damage. This process involves familiarizing oneself with the equipment and making precise modifications to suit the specific requirements of your yard.

Understanding Cutting Height Settings

Most lawn care devices feature adjustable cutting height settings, allowing users to customize the blade’s position. Typically, these adjustments can be made using a lever or dial. Familiarizing yourself with these settings is crucial; lower heights may yield a clean finish but can stress the grass, while higher settings encourage resilience and deeper root growth.

Steps for Adjustment

To adjust the cutting height, follow these steps:

- Park the Equipment: Ensure the machine is on a flat surface and turned off.

- Locate the Adjustment Mechanism: Identify the lever or knob responsible for height changes.

- Make the Adjustment: Move the lever or turn the knob to the desired height setting.

- Check the Height: Use a ruler to measure the grass height to ensure accuracy.

Regularly adjusting the cutting height based on seasonal changes and grass type will lead to a lush, well-maintained lawn.

Checking and Changing Fluids

Maintaining optimal performance in your machinery requires regular assessment and replacement of various fluids. This process ensures that all components operate smoothly and efficiently, reducing the risk of damage and extending the lifespan of the equipment. Proper fluid levels and conditions are essential for preventing overheating and minimizing wear and tear.

Start by identifying the different fluids involved, such as engine oil, coolant, hydraulic fluid, and fuel. Each type has specific requirements for checking levels and determining when it should be changed. Regular inspections will help you recognize signs of contamination or degradation, such as discoloration or unusual odors, prompting timely replacements.

When performing fluid changes, ensure you have the appropriate containers and tools ready. Always follow the manufacturer’s guidelines regarding the type and quantity of fluids to use. After draining the old fluid, carefully refill the system, checking for leaks and proper levels. This routine maintenance task is vital for keeping your equipment in peak condition.

Importance of Regular Maintenance

Routine upkeep is crucial for the longevity and efficiency of any equipment. Regular attention not only enhances performance but also helps prevent unexpected breakdowns. By adhering to a consistent maintenance schedule, operators can ensure that their machinery operates at optimal levels, thereby minimizing downtime and costly repairs.

Benefits of Consistent Upkeep

Implementing a structured maintenance routine yields numerous advantages. Regular inspections can identify potential issues early, allowing for timely interventions that can extend the life of the equipment. Additionally, well-maintained machinery often operates more efficiently, leading to better fuel economy and reduced operational costs.

Maintenance Checklist

| Task | Frequency | Notes |

|---|---|---|

| Oil Change | Every 50 hours | Ensure to use the recommended type of oil. |

| Filter Replacement | Every 100 hours | Check air and fuel filters for clogging. |

| Tire Inspection | Monthly | Look for wear and proper inflation. |

| Battery Check | Every season | Clean terminals and check for corrosion. |

| Belts and Cables | Every 50 hours | Inspect for wear and tension adjustments. |

By maintaining a proactive approach to equipment care, operators can significantly enhance reliability and performance, ensuring that their investment continues to serve them effectively for years to come.

Finding Replacement Parts Online

Locating suitable components for your equipment can be a straightforward process with the right approach. The internet offers a vast selection of resources and platforms where you can easily source necessary items, ensuring your machinery remains in optimal working condition. By utilizing specialized websites and forums, you can access a wealth of information and options tailored to your specific needs.

Utilizing Specialized Websites

Many websites cater specifically to machinery parts, providing comprehensive catalogs and search functions. These platforms often allow users to filter results by model, type, or even compatibility, making the search efficient. Additionally, customer reviews and ratings can guide you in selecting quality products.

Engaging with Online Communities

Joining forums and social media groups dedicated to equipment maintenance can be invaluable. Members often share insights on where to find the best deals, as well as recommendations for reliable suppliers. Engaging with these communities can lead to helpful tips and potential discounts on parts.

Owner Experiences and Tips

This section aims to share insights and practical advice gathered from individuals who have firsthand experience with their equipment. Their stories and tips can help others navigate common challenges, enhance performance, and ensure longevity.

Common Challenges

Owners often face several recurring issues. Here are some of the most mentioned:

- Maintenance frequency and procedures

- Identifying wear and tear

- Dealing with performance inconsistencies

Helpful Tips

To mitigate issues and improve overall functionality, consider the following recommendations:

- Establish a regular maintenance schedule, including oil changes and filter replacements.

- Keep an eye on tire pressure and tread wear to ensure stability.

- Store equipment in a dry place to prevent rust and deterioration.

- Utilize online forums and communities for troubleshooting advice.

- Document any modifications or repairs for future reference.

By learning from the experiences of others, owners can better equip themselves to tackle challenges and maximize their investment in quality machinery.