Complete Repair Manual for 1986 Yamaha Moto 4 225

Understanding the intricacies of all-terrain vehicle upkeep is vital for enthusiasts and casual riders alike. Proper maintenance not only ensures optimal performance but also extends the lifespan of your machine. In this section, we will explore comprehensive insights into effective practices and troubleshooting techniques.

Mastering the basics is crucial for any owner looking to enhance their riding experience. From engine checks to tire care, every aspect contributes to a smoother journey. Diving deep into the specifics allows for a better grasp of what your vehicle needs to thrive.

Whether you’re an experienced mechanic or a novice, having access to detailed information can prove invaluable. Emphasizing routine inspections and timely interventions is the ultimate key to maintaining the integrity of your vehicle. Let’s embark on this journey of knowledge together.

Overview of the 1986 Yamaha Moto 4 225

This section provides a comprehensive look at a notable all-terrain vehicle that gained popularity for its reliability and performance. Designed for both recreational and utility purposes, this model offers a robust construction suitable for various terrains and conditions. Its engineering emphasizes durability and ease of use, making it a preferred choice for enthusiasts and casual riders alike.

Equipped with a powerful engine, this vehicle delivers impressive torque and speed, allowing for smooth handling and maneuverability. The design incorporates features that enhance rider comfort and safety, including ergonomic controls and a stable chassis. Maintenance of this model is straightforward, ensuring longevity and consistent performance over time.

In summary, this all-terrain vehicle exemplifies a blend of functionality and innovation, appealing to a wide range of users. Whether navigating through rugged landscapes or tackling everyday tasks, it stands out as a reliable companion for adventures and work alike.

Common Issues with the Yamaha Moto 4

ATVs can experience a variety of problems that affect their performance and reliability. Understanding these common issues can help owners troubleshoot and maintain their vehicles more effectively. Regular inspections and preventive measures are key to ensuring a long lifespan and optimal functionality.

Engine Performance Problems

One of the most frequent concerns involves engine performance. Riders may notice a lack of power or difficulty starting the engine. These symptoms can often be attributed to fuel system issues, such as clogged filters or old fuel. Regular maintenance, including changing the oil and checking spark plugs, can mitigate these problems and enhance overall performance.

Electrical System Failures

Electrical failures are another common headache for ATV owners. Problems with the battery, wiring, or ignition system can lead to starting issues or intermittent power loss. It’s essential to routinely inspect the battery connections and wiring harness for corrosion or wear. Addressing these concerns promptly can prevent more significant issues down the line.

Essential Tools for Repairing the ATV

Maintaining an all-terrain vehicle requires a variety of equipment to ensure optimal performance and longevity. Having the right instruments on hand not only simplifies the maintenance process but also enhances safety and efficiency. Below is a guide to the indispensable tools that every ATV enthusiast should consider for effective upkeep.

Basic Hand Tools

- Wrenches: Adjustable and socket wrenches are crucial for loosening and tightening various fasteners.

- Screwdrivers: A set of flathead and Phillips screwdrivers will assist in handling different types of screws.

- Pliers: Needle-nose and standard pliers are versatile tools for gripping and bending materials.

- Torque Wrench: Ensures that bolts are tightened to the manufacturer’s specifications, preventing damage from over-tightening.

Specialized Equipment

- Oil Change Kit: Includes a drain pan, funnel, and appropriate tools for replacing engine oil.

- Lift Stand: A sturdy stand raises the vehicle for easy access during inspections or repairs.

- Tire Repair Kit: Essential for fixing punctures and maintaining tire pressure, ensuring safe riding conditions.

- Diagnostic Tools: Digital multimeters and diagnostic scanners can help identify electrical issues and system malfunctions.

Equipping yourself with these essential tools will not only facilitate routine maintenance but also empower you to tackle unforeseen issues with confidence.

Step-by-Step Maintenance Guide

Regular upkeep of your all-terrain vehicle is crucial for optimal performance and longevity. This guide provides a comprehensive approach to maintaining your machine, ensuring it operates smoothly and reliably over time. By following these detailed steps, you can enhance the lifespan of your vehicle while minimizing the risk of unexpected issues.

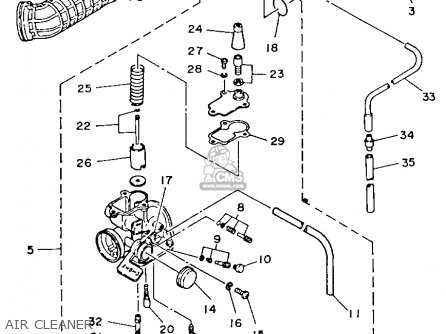

Start by performing routine inspections. Check fluid levels, including oil and coolant, and top them up as necessary. Inspect the air filter and clean or replace it if it appears dirty, as proper airflow is vital for engine efficiency. Ensure that the spark plug is in good condition and replace it if needed to maintain ignition performance.

Next, focus on the wheels and tires. Inspect them for wear and tear, ensuring proper inflation levels. Rotate the tires periodically to promote even wear and enhance traction. Pay attention to the brakes; check the pads and fluid levels, and replace components if they show signs of significant wear.

Don’t overlook the battery. Clean the terminals and ensure it is securely mounted. Test the battery’s charge and replace it if it’s not holding a charge effectively. Additionally, examine the electrical system for any frayed wires or loose connections that could lead to malfunctions.

Finally, perform a thorough cleaning of your vehicle. Remove dirt and debris from all surfaces, paying special attention to the undercarriage. A clean machine not only looks better but also helps prevent rust and corrosion. Following this guide will help maintain your all-terrain vehicle, ensuring it remains ready for your next adventure.

Understanding the Engine Components

Engines are intricate systems composed of various elements that work together to convert fuel into mechanical energy. Each part plays a vital role in ensuring optimal performance and efficiency. Grasping the function of these components is essential for effective maintenance and troubleshooting.

| Component | Function |

|---|---|

| Cylinder | Houses the piston and allows for combustion. |

| Piston | Moves up and down within the cylinder to create power. |

| Crankshaft | Transforms linear motion of the piston into rotational motion. |

| Valves | Regulate the intake of air and fuel and the expulsion of exhaust gases. |

| Camshaft | Controls the timing of the valves’ opening and closing. |

| Fuel Injector | Delivers the precise amount of fuel into the combustion chamber. |

| Ignition System | Ignites the air-fuel mixture for combustion. |

Familiarity with these components enhances the understanding of how an engine operates and aids in identifying potential issues that may arise during its use.

Electrical System Troubleshooting Tips

Understanding the electrical system of your vehicle is crucial for effective maintenance and repair. Identifying issues early can save you time and prevent more significant problems down the line. Here are some practical tips to help you diagnose and resolve electrical faults.

- Check the Battery:

- Ensure the battery terminals are clean and tightly connected.

- Test the voltage; a healthy battery should read around 12.6 volts.

- Look for signs of corrosion on the terminals.

- Inspect Fuses:

- Locate the fuse box and examine all fuses for damage.

- Replace any blown fuses with the correct amperage rating.

- Examine Wiring and Connectors:

- Look for frayed or damaged wires that may cause shorts.

- Check connectors for rust or looseness.

- Ensure all connections are secure and free from debris.

- Test Switches and Relays:

- Use a multimeter to check the functionality of switches.

- Test relays for continuity and proper operation.

- Assess Ground Connections:

- Ensure all ground points are clean and securely fastened.

- Look for any rust or paint that may disrupt the connection.

- Use Diagnostic Tools:

- Consider using a multimeter or an automotive scanner for precise diagnostics.

- Follow the manufacturer’s guidelines for troubleshooting specific issues.

By following these troubleshooting steps, you can systematically identify and resolve electrical problems, ensuring your vehicle remains in optimal condition.

Transmission Repair Techniques Explained

Maintaining the functionality of a vehicle’s transmission system is crucial for optimal performance and longevity. This section delves into various strategies and methods employed to address issues within the transmission, ensuring smooth operation and reliability.

Diagnosis is the first step in addressing transmission problems. Identifying symptoms such as unusual noises, slipping gears, or fluid leaks helps pinpoint the underlying issues. Utilizing diagnostic tools can provide valuable insights, enabling a more accurate assessment.

Once the problem is identified, disassembly of the transmission is often necessary. Careful removal of components allows for a thorough inspection. It’s essential to document the order of disassembly to facilitate reassembly. During this phase, parts should be cleaned and assessed for wear and damage.

After inspection, replacement of faulty components is crucial. Sourcing high-quality parts ensures compatibility and durability. When reinstalling components, following the manufacturer’s specifications is vital to prevent future issues.

Reassembly involves meticulous attention to detail. Each part must be aligned correctly, and fasteners should be tightened to the specified torque. It’s advisable to perform a final inspection before the transmission is reinstalled in the vehicle.

Lastly, testing the transmission after reassembly is critical. Conducting a series of tests, including fluid checks and operational trials, ensures that all components function as intended. This step verifies the effectiveness of the repairs and helps identify any remaining issues.

Suspension and Steering Adjustments

Proper maintenance of the suspension and steering components is crucial for optimal performance and handling. Ensuring these systems are correctly adjusted can significantly enhance your riding experience, offering better stability, control, and comfort.

To achieve the best results, consider the following aspects:

- Suspension Setup: Regularly check the preload, compression, and rebound settings to match your weight and riding style.

- Steering Alignment: Ensure that the front end is aligned properly. Misalignment can lead to uneven tire wear and poor handling.

- Lubrication: Keep all moving parts well-lubricated to reduce friction and wear, which can affect both suspension and steering performance.

Here are some steps to guide you through the adjustment process:

- Begin by assessing the current setup of your suspension. Adjust the preload to accommodate your weight.

- Test the compression and rebound settings, making small adjustments and noting the differences in handling.

- For steering, check the tightness of the head bearings. They should be snug but not overly tight.

- After making adjustments, take the vehicle for a test ride to evaluate the changes. Pay attention to any handling issues or discomfort.

Regular checks and adjustments can prolong the lifespan of these components and improve your overall riding experience. Keeping everything in optimal condition will ensure safety and performance in various riding conditions.

Braking System Maintenance Insights

Proper upkeep of the braking mechanism is crucial for ensuring safety and performance. Regular checks and maintenance practices not only enhance responsiveness but also extend the lifespan of components. Understanding the fundamental aspects of this system is essential for any operator aiming to maintain optimal functionality.

Key components such as brake pads, discs, and fluid levels require attention. Each element plays a significant role in the overall effectiveness of the braking system. A well-maintained system not only prevents wear but also ensures reliable operation in various conditions.

| Component | Maintenance Tip | Signs of Wear |

|---|---|---|

| Brake Pads | Inspect thickness regularly and replace when worn. | Squeaking noises or reduced braking efficiency. |

| Brake Discs | Check for warping and scoring; resurface or replace as needed. | Vibrations during braking or visible grooves. |

| Brake Fluid | Replace fluid every 1-2 years and check for contamination. | Discoloration or a spongy brake pedal feel. |

By adhering to these maintenance insights, operators can ensure their braking system remains reliable and effective, promoting safe operation and enhanced performance. Regular attention to these elements is key to achieving long-lasting results.

Choosing Replacement Parts Wisely

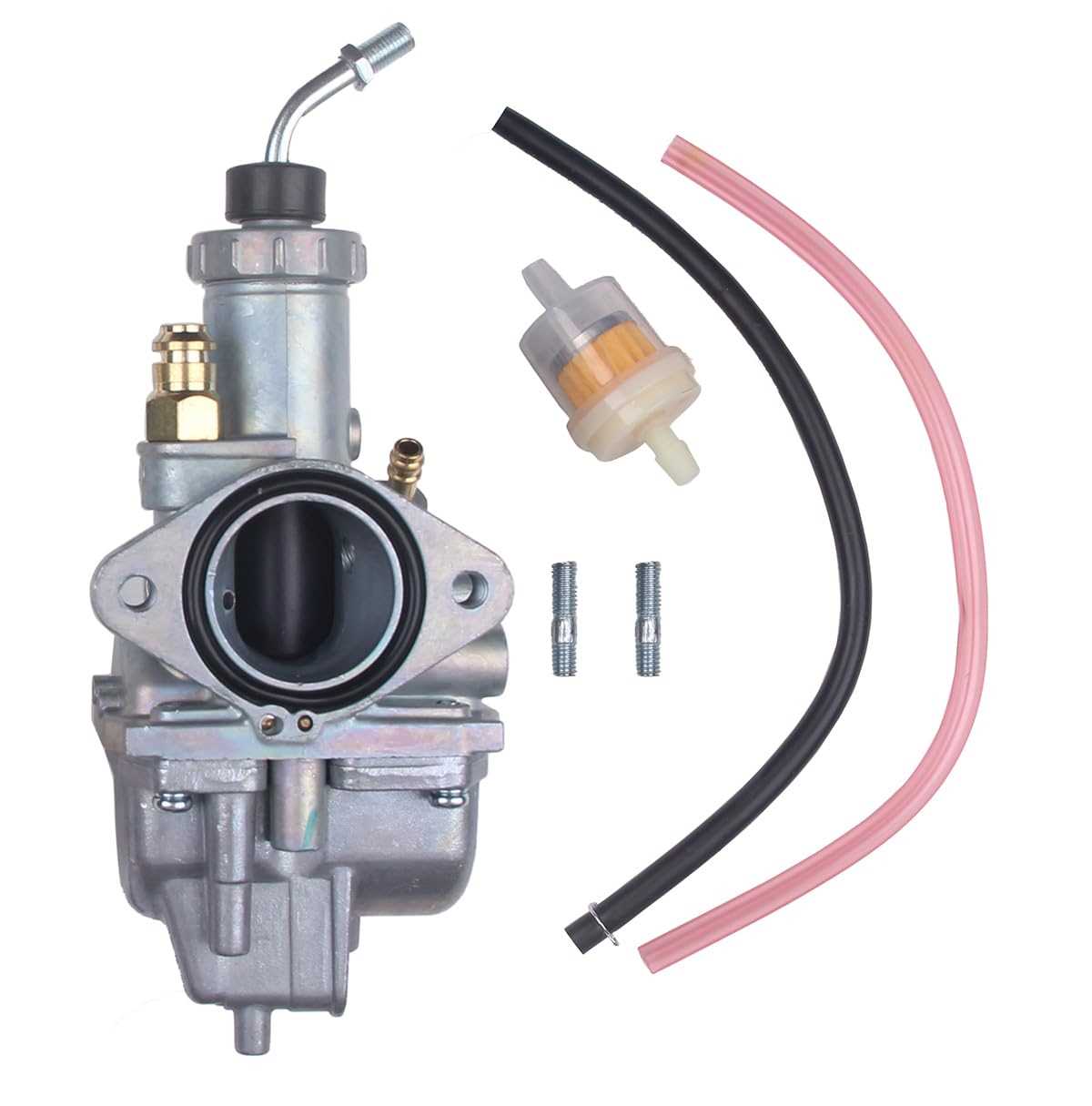

Selecting the right components for your vehicle is crucial for maintaining its performance and longevity. The process requires careful consideration of quality, compatibility, and cost to ensure you make informed decisions that enhance your machine’s reliability.

Understanding Quality and Compatibility

When searching for new parts, prioritize those made from durable materials. High-quality components not only last longer but also function more effectively. Always verify that the parts are compatible with your specific model. Referencing manufacturer specifications or consulting with knowledgeable professionals can prevent costly mistakes.

Balancing Cost and Value

While it may be tempting to opt for the cheapest options available, remember that lower prices often come at the expense of quality. Consider the long-term value of the investment. Sometimes, spending a bit more on superior parts can save you money over time by reducing the frequency of replacements and repairs.

In summary, taking the time to choose the right parts with attention to quality and compatibility will ultimately enhance the performance and lifespan of your vehicle. By balancing cost with value, you can ensure your investment pays off in the long run.

Safety Precautions During Repairs

When undertaking maintenance tasks on your vehicle, ensuring personal safety and preventing damage are paramount. Proper precautions not only protect the individual performing the work but also contribute to the longevity and functionality of the machine. Understanding the necessary steps can lead to a smoother and safer experience.

Personal Protective Equipment

Utilizing appropriate personal protective equipment (PPE) is essential. Always wear gloves to shield your hands from sharp objects and hazardous materials. Safety goggles are crucial for protecting your eyes from debris and chemical splashes. Additionally, sturdy footwear helps prevent injuries from heavy parts that may fall during the process.

Work Environment Safety

Creating a safe workspace is equally important. Ensure that the area is well-lit and free from clutter to minimize the risk of accidents. Maintain a clean environment by promptly removing any spills or debris. If using tools, inspect them beforehand to confirm they are in good condition, and store them properly to avoid hazards.

By adhering to these guidelines, you can significantly reduce the risks associated with maintenance activities, allowing for a more efficient and secure working process.

Resources for Further Assistance

When working on your vehicle, having access to reliable information and support can significantly enhance your experience. Whether you need specific guidance, troubleshooting tips, or detailed specifications, various resources are available to help you navigate any challenges that may arise. This section outlines valuable avenues for obtaining further assistance.

Online Forums and Communities

Engaging with fellow enthusiasts can provide insights and shared experiences that may be crucial for your project. Numerous online platforms allow you to ask questions, share solutions, and learn from others who have encountered similar issues.

Technical Resources

For in-depth information, consider utilizing various technical documents and resources. These can range from official publications to user-generated content that offers detailed instructions and schematics.

| Resource Type | Description | Website |

|---|---|---|

| Forums | Online communities for discussion and advice. | www.exampleforum.com |

| Technical Guides | Comprehensive manuals and schematics. | www.technicalresources.com |

| Video Tutorials | Visual guides demonstrating repairs and maintenance. | www.videotutorials.com |

| Local Workshops | Hands-on assistance and expert advice. | www.localworkshops.com |