Comprehensive Guide to Mcculloch Chainsaw Repair

Ensuring the longevity and efficiency of your power equipment is crucial for any enthusiast or professional. Proper upkeep not only enhances performance but also ensures safety during use. This guide offers essential insights into common issues and solutions, empowering users to tackle challenges confidently.

From minor adjustments to more complex tasks, understanding the inner workings of your equipment can save time and money. Armed with the right knowledge, you can identify problems early and implement effective strategies to maintain optimal functionality. Follow these guidelines to keep your device running smoothly and efficiently.

Whether you’re a seasoned expert or a novice, having access to comprehensive support can make all the difference. This resource aims to provide you with valuable information to navigate through maintenance tasks, ensuring that your equipment remains reliable for years to come. Let’s dive into the specifics and enhance your understanding of essential upkeep practices.

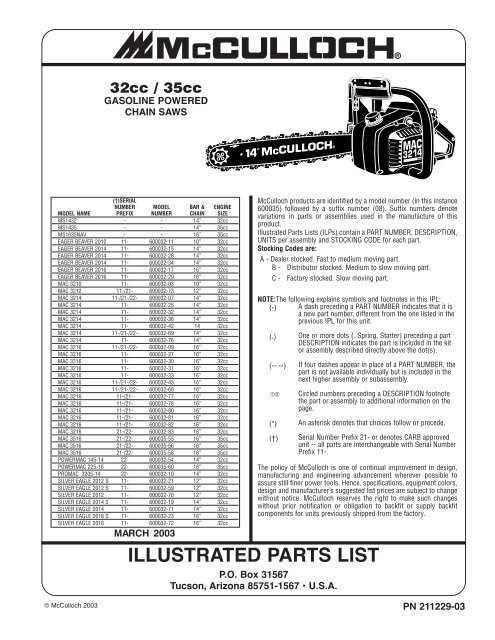

Mcculloch Chainsaw Repair Manual Overview

This section provides an overview of essential guidelines and insights for maintaining and troubleshooting your cutting tool effectively. Proper understanding of the components and functions can significantly enhance the longevity and performance of your equipment.

- Understanding key components

- Identifying common issues

- Step-by-step maintenance procedures

- Safety precautions during service

By familiarizing yourself with these aspects, you can ensure your device remains in optimal condition, allowing for efficient operation and reduced downtime.

Essential Tools for Chainsaw Maintenance

Proper upkeep of cutting equipment is crucial for ensuring longevity and optimal performance. Having the right instruments on hand simplifies this process and enhances efficiency. Here are some indispensable tools that every user should consider for effective maintenance.

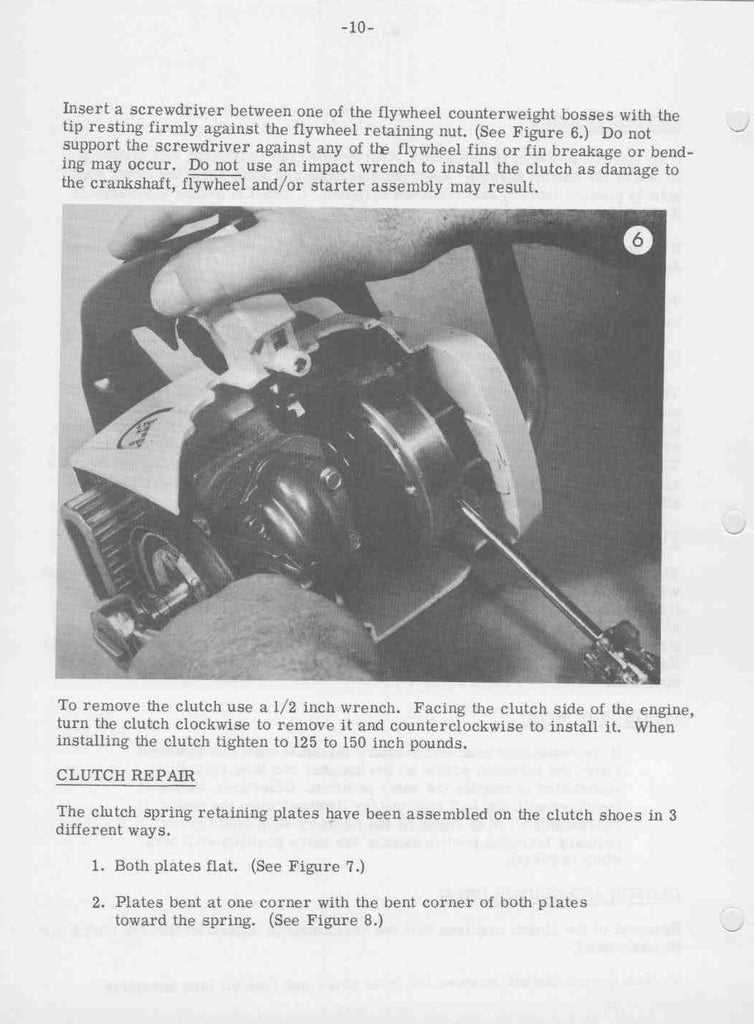

1. Wrench Set: A versatile wrench set is essential for loosening and tightening various components. This allows for adjustments and replacements as needed.

2. Screwdrivers: A good collection of screwdrivers, including flathead and Phillips, will help in securing parts and performing detailed adjustments.

3. File: A quality file is vital for maintaining sharpness on the cutting edge. Regular sharpening ensures clean cuts and reduces wear on the equipment.

4. Chain Breaker: This tool is critical for safely and effectively repairing or replacing links in the cutting chain, ensuring safety and functionality.

5. Oil Can: Lubrication is key to the smooth operation of moving parts. A dedicated oil can allows for precise application of lubricant where needed.

6. Safety Gear: Protective equipment such as gloves, goggles, and ear protection should always be part of the maintenance routine, ensuring safety during work.

Investing in these tools not only promotes efficient upkeep but also extends the life of your equipment, making them a worthwhile addition to any user’s toolkit.

Common Issues with Mcculloch Models

Many users encounter various challenges when operating their cutting tools. Understanding these frequent problems can help in maintaining optimal performance and prolonging the lifespan of the equipment. Below are some of the typical difficulties faced by owners of specific models.

| Issue | Description | Possible Solution |

|---|---|---|

| Starting Problems | Difficulty in initiating the engine can stem from various factors such as fuel blockage or spark plug issues. | Check fuel levels and ensure the spark plug is clean and functioning properly. |

| Fuel Leaks | Leaks from the fuel system can lead to safety hazards and decreased efficiency. | Inspect hoses and connections for cracks or wear, and replace any damaged parts. |

| Overheating | Excessive heat can result from inadequate lubrication or a dirty air filter. | Regularly clean or replace the air filter and ensure proper lubrication levels. |

| Inconsistent Cutting | Uneven performance during use may indicate dull blades or incorrect tension settings. | Sharpen the blades and adjust tension as necessary for smooth operation. |

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to diagnosing common issues that may arise with your cutting tool. By following these methodical steps, you can identify and resolve problems effectively, ensuring optimal performance and longevity of your equipment.

Identifying Common Issues

Conducting Basic Checks

How to Replace Chainsaw Chain

Replacing the cutting loop of your power tool is essential for maintaining its performance and ensuring safe operation. This guide will walk you through the necessary steps to efficiently install a new cutting loop, enhancing your tool’s efficiency and longevity.

-

Gather Required Tools and Parts:

- New cutting loop

- Screwdriver

- Wrench

- Protective gloves

- Safety goggles

-

Ensure Safety: Before starting, disconnect the power source to prevent accidental activation. Wear protective gear to safeguard against any potential injuries.

-

Remove the Old Loop: Open the guide bar cover using the screwdriver or wrench. Carefully take off the old cutting loop from the guide bar and sprocket.

-

Install the New Loop: Position the new cutting loop around the guide bar. Ensure it fits correctly around the sprocket. The cutting edges should face in the direction of rotation.

-

Reassemble the Tool: Securely replace the guide bar cover. Make sure all screws are tightened appropriately to avoid any loose parts during operation.

-

Check Tension: Before use, adjust the tension of the new cutting loop according to the manufacturer’s specifications. Proper tension is crucial for optimal performance.

-

Test the Tool: Once everything is in place, reconnect the power source and conduct a brief test run to ensure everything is functioning correctly.

Fuel System Cleaning Techniques

Maintaining the fuel delivery system is crucial for optimal performance and longevity of your equipment. Regular cleaning ensures that the components remain free from debris and contaminants, allowing for efficient operation. This section outlines effective methods for cleaning the fuel system, enhancing reliability and performance.

Cleaning with Specialized Solutions

Utilizing commercial cleaning agents specifically designed for fuel systems can effectively dissolve gum, varnish, and other deposits. These solutions are typically added to the fuel tank in a diluted form, allowing them to circulate through the entire system. Following the manufacturer’s instructions is essential to achieve the best results and avoid any potential damage.

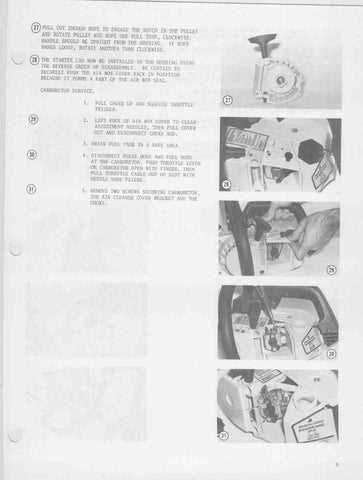

Manual Disassembly and Inspection

For a thorough cleaning, manual disassembly of components such as the fuel filter and carburetor is often necessary. This process allows for direct access to internal parts, enabling a more detailed inspection and cleaning. Using a soft brush and appropriate solvents can help remove stubborn residues. Reassembling the system correctly is vital to ensure proper function and avoid leaks.

Replacing the Spark Plug Safely

Ensuring optimal performance of your cutting tool often involves maintenance tasks, including the replacement of the ignition component. This procedure is essential for enhancing efficiency and reliability.

Before starting, it’s crucial to prepare adequately to ensure safety throughout the process. Follow these steps to perform the task effectively:

| Step | Description |

|---|---|

| 1 | Disconnect the power source to prevent accidental starts. |

| 2 | Locate the ignition component carefully, ensuring you have the right tools ready. |

| 3 | Use a socket wrench to remove the old part, being cautious not to damage surrounding areas. |

| 4 | Inspect the new item for any defects before installation. |

| 5 | Install the new part securely, ensuring it is fitted correctly. |

| 6 | Reconnect the power source and perform a test to verify functionality. |

By following these steps, you can ensure that the ignition component is replaced safely and effectively, maintaining the performance of your equipment.

Bar and Chain Lubrication Tips

Proper lubrication of the cutting components is essential for maintaining optimal performance and extending the life of your equipment. Adequate oiling reduces friction and heat buildup, which can lead to premature wear and tear. Here are some effective strategies for ensuring that the bar and chain receive the necessary lubrication.

Choosing the Right Lubricant

Using the correct type of lubricant is crucial for effective performance. Select a high-quality oil specifically designed for the intended application. These products are formulated to adhere to the surfaces, providing a protective layer that minimizes wear. Avoid using non-specific oils, as they may not offer the same level of protection.

Regular Maintenance Practices

Incorporate regular checks of the oil reservoir and ensure it is filled to the appropriate level. During use, monitor the lubrication system for any signs of blockage or malfunction. Cleaning the bar groove and oil holes frequently will help maintain a consistent flow of lubricant. Additionally, always remember to apply oil before starting work, especially after long periods of inactivity.

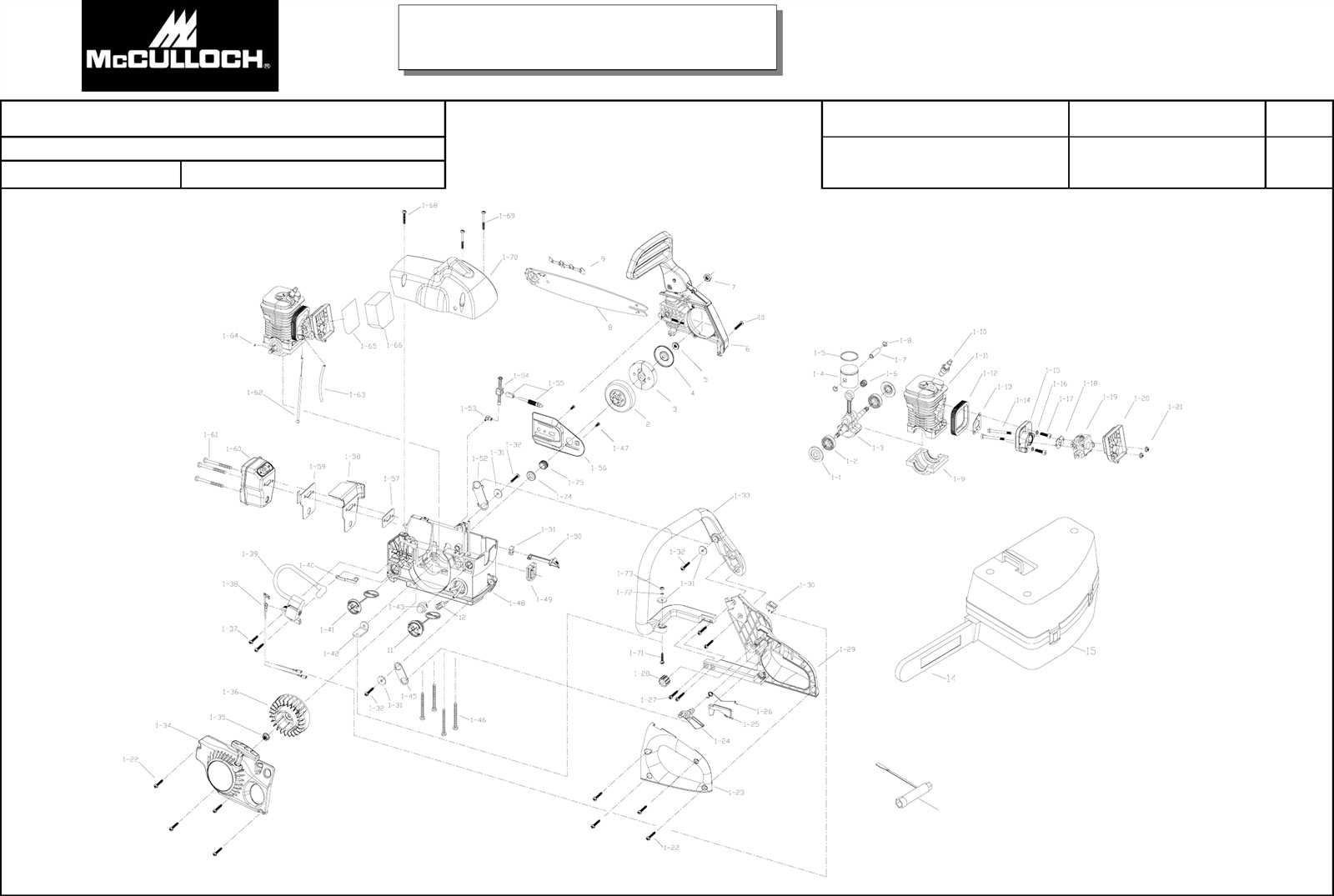

Understanding Engine Components

Grasping the various elements that make up a small engine is essential for effective maintenance and troubleshooting. Each part plays a crucial role in the overall performance and longevity of the equipment.

Fuel System: The fuel system is responsible for delivering the right mixture of fuel and air to the engine. It typically consists of a fuel tank, lines, and a carburetor, which ensures optimal combustion.

Ignition System: This system ignites the fuel-air mixture, initiating the power cycle. Key components include the spark plug and ignition coil, which work together to produce the necessary spark for ignition.

Crankshaft: The crankshaft converts the linear motion of the pistons into rotational motion, powering the entire mechanism. Its design and material significantly affect the engine’s efficiency and durability.

Cylinder: The cylinder is where the combustion takes place. The shape and size of the cylinder can influence performance, torque, and fuel efficiency, making it a critical aspect of engine design.

Cooling System: To prevent overheating, the cooling system circulates air or liquid around the engine. Efficient cooling is vital for maintaining optimal operating temperatures and ensuring longevity.

Understanding these fundamental components enhances one’s ability to maintain and troubleshoot effectively, ensuring smooth operation and extended life of the equipment.

Tips for Starting Difficult Chainsaws

Starting a stubborn outdoor power tool can be frustrating, especially when you rely on it for various tasks. Understanding some effective strategies can make the process smoother and help you get back to work quickly.

Common Issues

Several factors can lead to starting difficulties. Here are some frequent culprits:

| Issue | Description |

|---|---|

| Fuel Problems | Old or contaminated fuel can prevent ignition. |

| Ignition System | A malfunctioning spark plug may not generate enough spark. |

| Air Filter | A clogged filter restricts airflow, affecting combustion. |

| Cold Weather | Low temperatures can thicken the lubricant and make starting harder. |

Effective Strategies

Implementing the following techniques can significantly improve your chances of a successful start:

- Ensure fresh, clean fuel is used and consider adding a fuel stabilizer.

- Check and replace the spark plug if it shows signs of wear.

- Clean or replace the air filter to allow for proper airflow.

- In cold weather, consider using a lighter oil or a starter spray designed for outdoor equipment.

Winterization Steps for Chainsaws

Preparing your cutting tool for the colder months is essential to ensure its longevity and optimal performance. Proper steps taken now can prevent issues and ensure readiness for the upcoming season. Here’s a guide to help you safeguard your equipment effectively.

Essential Preparation Tasks

- Clean the exterior thoroughly to remove dirt and debris.

- Inspect the bar and chain for wear and damage.

- Sharpen the cutting edges if necessary.

Fuel and Oil Management

- Drain the fuel tank completely.

- Run the engine until it consumes the remaining fuel.

- Fill the tank with fresh, appropriate fuel mixed with the recommended oil ratio.

By following these steps, you can ensure your equipment remains in peak condition during the off-season, ready for action when needed.

Regular Maintenance Schedule Suggestions

Establishing a consistent upkeep routine is essential for ensuring optimal performance and longevity of your equipment. By adhering to a scheduled maintenance plan, users can prevent potential issues and enhance the overall efficiency of their devices.

Daily Checks: Before each use, inspect the unit for any visible signs of wear or damage. Pay special attention to the sharpness of the cutting blade and ensure all components are securely attached. This quick assessment can help identify minor problems before they escalate.

Weekly Maintenance: Dedicate time each week to clean the air filter and check the fuel system. A clean filter promotes better airflow, while inspecting the fuel lines can prevent clogs that may hinder operation.

Monthly Servicing: Conduct a more thorough examination once a month. This should include checking the spark plug, tightening screws, and lubricating moving parts. These actions contribute to smoother functioning and reduced wear.

Seasonal Upkeep: At the start of each season, perform a comprehensive check-up. Replace worn-out parts, refresh lubricants, and ensure all safety features are functioning correctly. Preparing your equipment for seasonal changes can significantly impact its reliability and efficiency.

By following these structured maintenance suggestions, users can ensure that their tools remain in peak condition, ultimately leading to improved performance and satisfaction.

Resources for Further Chainsaw Help

When facing issues with your cutting equipment, having access to a variety of resources can be invaluable. Whether you need detailed instructions, troubleshooting advice, or community support, there are numerous platforms available to assist you. These resources can guide you through maintenance processes, provide insights into common challenges, and help you connect with other enthusiasts.

Online Forums and Communities

Participating in online forums can be a great way to learn from others’ experiences. Websites dedicated to outdoor equipment often feature discussion boards where users share tips, ask questions, and offer solutions. Engaging with fellow users can enhance your understanding and provide practical advice tailored to your specific model.

Video Tutorials

Visual learning can be particularly effective for complex tasks. Platforms like YouTube host a multitude of video guides demonstrating various maintenance and troubleshooting techniques. These tutorials can provide step-by-step instructions, making it easier to follow along and understand the process, regardless of your skill level.