Comprehensive Guide to Repairing the John Deere 1023E

This section serves as a comprehensive resource for individuals seeking guidance on the upkeep and troubleshooting of a specific compact utility vehicle. It emphasizes the importance of regular maintenance practices to enhance performance and longevity. By understanding the mechanics and components involved, users can ensure optimal functionality and prevent common issues.

Within these pages, you will find detailed information on various operational aspects, including troubleshooting techniques and preventive measures. Each entry aims to empower users with the knowledge necessary to tackle challenges effectively, ensuring smooth operation throughout the equipment’s lifecycle.

Furthermore, this guide offers insights into the significance of following proper procedures during maintenance tasks. By adhering to recommended practices, users can avoid costly repairs and extend the working life of their machinery. Ultimately, this resource is designed to support and enhance the ownership experience through informed decision-making and proactive care.

Overview of John Deere 1023E

This section provides a comprehensive look at a compact utility vehicle designed for versatility and efficiency. It is particularly suited for a range of tasks, from landscaping to agricultural applications, making it an ideal choice for both residential and professional use.

Key Features

The vehicle boasts a powerful engine coupled with advanced transmission systems, ensuring smooth operation across various terrains. Additionally, its compact size allows for easy maneuverability in tight spaces, enhancing productivity.

Applications

This model excels in multiple applications, including gardening, property maintenance, and light construction work. Its adaptability is further supported by a variety of attachments that can be utilized for specialized tasks, increasing overall functionality.

In summary, this compact utility machine combines performance and versatility, making it a valuable asset for those seeking efficiency in their work.

Key Features of the Model

This section highlights the significant characteristics that define this compact utility vehicle. Its design and functionality are tailored to meet the diverse needs of users, making it a versatile choice for various tasks.

Power and Performance

- Equipped with a robust engine that delivers reliable power for a range of applications.

- Efficient fuel consumption ensures prolonged operation without frequent refueling.

- Advanced transmission system for smooth handling and maneuverability in different terrains.

Versatility and Attachments

- Compatible with a variety of implements and accessories to enhance productivity.

- Compact size allows for easy navigation in tight spaces, ideal for landscaping and agricultural tasks.

- Quick-connect features facilitate fast changes between attachments, saving time on the job.

Maintenance Schedule for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. Adhering to a well-structured timetable not only enhances functionality but also minimizes unexpected breakdowns. A proactive approach to maintenance guarantees that all components operate smoothly, leading to increased productivity and reduced costs over time.

Routine Checks

Implementing frequent inspections can help identify potential issues before they escalate. Focus on examining fluid levels, filters, and belts, ensuring everything is in optimal condition. Lubrication of moving parts should be performed as per the guidelines to prevent wear and tear.

Seasonal Maintenance

Adapting your maintenance routine according to the seasons can significantly improve performance. Before winter, it is crucial to prepare the machinery for colder temperatures, while spring should focus on cleaning and servicing after heavy usage. Documenting each service will provide a useful reference for future upkeep.

Common Issues and Solutions

This section addresses typical challenges faced by operators of compact tractors, offering practical solutions to enhance performance and reliability. Understanding these frequent problems can help in maintaining optimal functionality and extending the lifespan of the equipment.

Engine Troubles

- Starting Difficulties: Ensure the battery is fully charged and connections are secure. If the engine still won’t turn over, check the starter motor and ignition system.

- Overheating: Regularly inspect the coolant level and radiator for blockages. Clean the air filter to ensure proper airflow.

Transmission Issues

- Slipping Gears: Inspect the transmission fluid level and quality. Low or dirty fluid can lead to gear slippage.

- Noisy Operation: Check for proper fluid levels and listen for unusual sounds that may indicate worn components. Regular maintenance is essential to prevent major repairs.

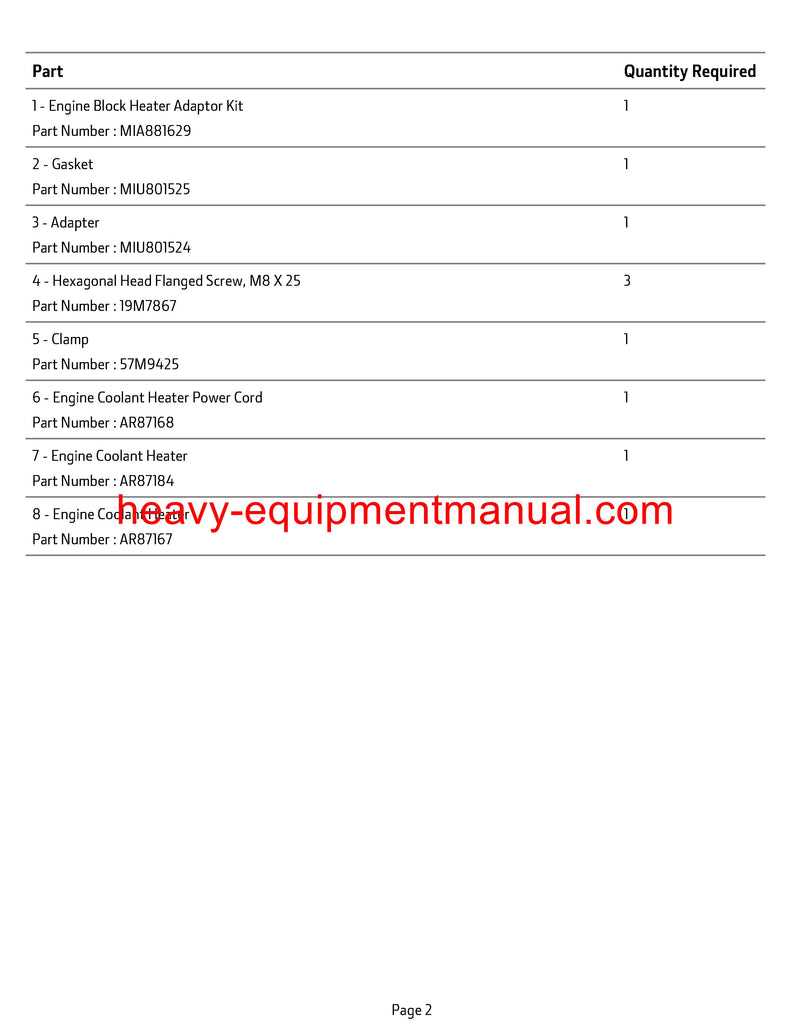

Parts Replacement Guide

This section provides essential information for maintaining and upgrading your equipment through effective component substitution. Understanding when and how to replace parts can enhance performance and extend the lifespan of your machinery.

Before proceeding with any replacements, it’s crucial to identify the specific components that require attention. Referencing manufacturer specifications and guidelines will help ensure compatibility and optimal functionality.

| Part Name | Description | Replacement Frequency |

|---|---|---|

| Air Filter | Essential for maintaining clean airflow to the engine. | Every 200 hours of operation |

| Oil Filter | Helps to keep engine oil free from contaminants. | Every 100 hours of operation |

| Fuel Filter | Prevents impurities in fuel from entering the engine. | Every 500 hours of operation |

| Belt | Transfers power from the engine to various components. | Inspect regularly; replace as needed |

| Battery | Provides electrical energy to start the engine. | Every 2-3 years, depending on usage |

By adhering to this replacement guide, you can ensure your equipment remains in optimal condition, ready to tackle any task effectively.

Tools Needed for Repairs

Effective maintenance of equipment requires a selection of essential instruments that facilitate various tasks. Understanding the types of tools available can significantly enhance the efficiency and accuracy of the work performed.

| Tool Type | Purpose |

|---|---|

| Wrenches | For tightening and loosening bolts and nuts. |

| Screwdrivers | For driving screws into place. |

| Pliers | For gripping, twisting, and cutting wire. |

| Socket Set | For accessing hard-to-reach fasteners. |

| Torque Wrench | For applying a specific torque to fasteners. |

Safety Precautions During Maintenance

Ensuring a secure environment while performing upkeep on machinery is crucial. Adhering to safety guidelines not only protects the individual working on the equipment but also enhances the longevity and performance of the unit. By prioritizing safety, operators can effectively mitigate risks and avoid accidents.

Always wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and steel-toed boots to shield against potential hazards. Additionally, ensure that hair is secured and loose clothing is tucked away to prevent entanglement in moving parts.

Before starting any maintenance tasks, it is essential to disconnect the power source. This precaution helps to prevent unintended operation while work is being carried out. It is also advisable to consult the specific guidelines for the equipment to understand any unique safety requirements.

Maintain a clean workspace. Clutter can lead to slips, trips, and falls. Ensure that tools are organized and that spills are promptly cleaned to minimize hazards. Keeping the area well-lit will also enhance visibility and reduce the risk of accidents.

Always use the correct tools for each task. Utilizing improper equipment can not only compromise safety but may also damage the machinery. Familiarize yourself with the tools required for various maintenance procedures to ensure efficiency and safety.

Finally, ensure proper lifting techniques are employed when handling heavy components. Bend at the knees, keep the load close to the body, and lift with the legs to prevent injury. Seeking assistance for particularly heavy or awkward items is always a wise choice.

Best Practices for Troubleshooting

Troubleshooting effectively requires a systematic approach to identify and resolve issues efficiently. By employing certain strategies, individuals can minimize downtime and enhance overall functionality.

Start with Observation: Carefully observe the situation and symptoms. Take note of any unusual sounds, vibrations, or behaviors, as these can provide crucial clues.

Consult Documentation: Review relevant technical resources and guidelines. These documents often contain valuable insights and troubleshooting steps tailored to specific equipment or systems.

Isolate the Problem: Narrow down the potential sources of the issue by testing one component at a time. This method helps identify faulty parts without the confusion of multiple variables.

Utilize Diagnostic Tools: Employ appropriate diagnostic equipment to assess the condition of various components. Multimeters, pressure gauges, and software diagnostics can aid in pinpointing malfunctions.

Keep a Log: Document your findings, tests performed, and solutions attempted. A detailed record can help track recurring issues and facilitate future troubleshooting efforts.

Seek Expert Assistance: When in doubt, don’t hesitate to consult a professional or experienced technician. Their expertise can save time and prevent further complications.

Owner’s Manual Utilization Tips

Maximizing the benefits of a vehicle guidance document can enhance the ownership experience significantly. Understanding its contents and applying the recommendations can lead to better maintenance, increased longevity, and overall satisfaction with your equipment.

Here are some practical tips for effectively using your guidance document:

- Familiarize Yourself: Spend time reviewing the entire document to understand its structure and locate vital sections.

- Regular Reference: Keep the document accessible and consult it regularly for maintenance schedules and operation procedures.

- Highlight Key Information: Mark important sections that you frequently need, such as troubleshooting steps or safety guidelines.

Additionally, consider the following strategies:

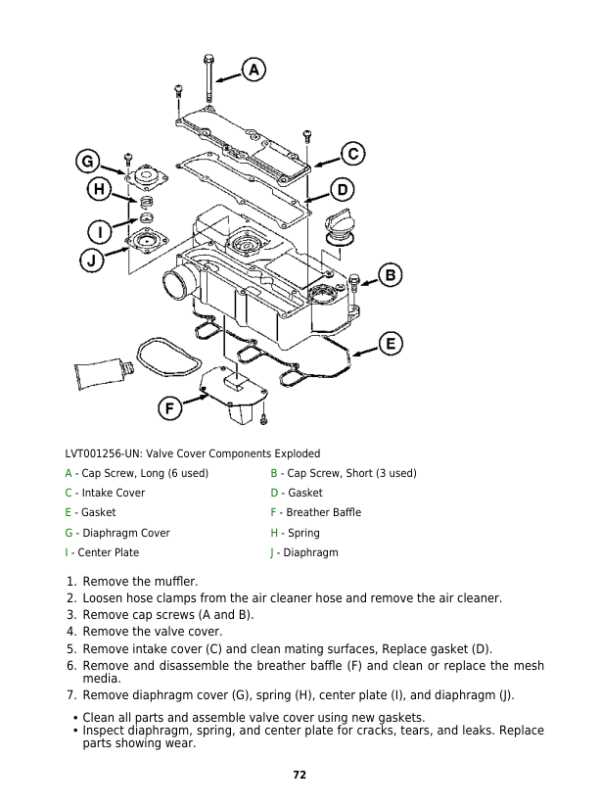

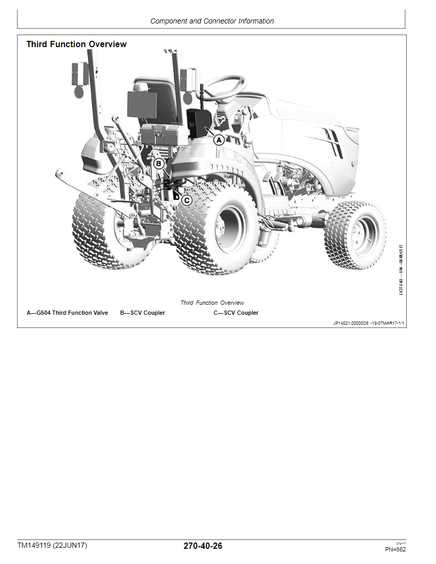

- Use Visual Aids: Diagrams and images can clarify complex instructions. Refer to these visuals to better understand components and procedures.

- Note Personal Observations: Jot down any unique observations or experiences that may not be included in the document, enhancing your personal reference.

- Engage with Online Communities: Join forums or groups where fellow owners share insights and tips, further expanding your knowledge beyond the written text.

By adopting these practices, you can ensure that your equipment remains in optimal condition while enhancing your overall understanding and capability as an owner.

Local Repair Shops and Resources

Accessing nearby service centers and support networks is essential for maintaining machinery efficiently. Local establishments often offer specialized knowledge and hands-on assistance, ensuring optimal performance and longevity of equipment. Understanding available resources can significantly enhance the user experience.

Finding Trusted Service Centers

When seeking assistance, look for facilities with positive reviews and recommendations from fellow users. These locations typically provide a variety of services, including diagnostics and routine maintenance. Additionally, engaging with local agricultural communities can yield valuable insights and referrals.

Utilizing Online Platforms

Digital resources can also be beneficial. Websites and forums dedicated to machinery enthusiasts often feature troubleshooting guides, parts suppliers, and community discussions. Leveraging these platforms can enhance understanding and facilitate effective problem-solving.

Understanding Warranty Coverage

Warranties play a crucial role in providing assurance and support for machinery owners. These agreements serve as a promise from the manufacturer, ensuring that specific repairs or replacements will be handled under defined conditions. Understanding the nuances of warranty coverage can help owners make informed decisions and protect their investments.

Typically, warranty coverage includes various aspects, such as the duration of the protection, the types of failures covered, and any exclusions that may apply. It is essential for users to familiarize themselves with these details to ensure they are adequately protected against unforeseen issues.

| Aspect | Description |

|---|---|

| Duration | The length of time the warranty remains valid. |

| Coverage | Types of defects or failures that are eligible for repair or replacement. |

| Exclusions | Specific conditions or damages not covered under the warranty. |

| Transferability | Whether the warranty can be transferred to a new owner if the equipment is sold. |

By understanding these elements, owners can better navigate the terms of their warranties and utilize them effectively when necessary.

Upgrades and Modifications Options

Enhancing the performance and versatility of your compact utility vehicle can significantly improve its functionality for various tasks. Whether you aim to increase power, improve comfort, or expand capabilities, numerous options are available to suit diverse needs and preferences.

Performance Enhancements

One of the most popular upgrades involves boosting engine efficiency through modifications like an improved air intake system or a high-performance exhaust. These changes can lead to enhanced power output and better fuel efficiency, allowing for more efficient operation in demanding conditions.

Accessory Additions

Consider integrating accessories such as additional lighting, upgraded seating, or enhanced towing equipment. These additions can enhance safety and convenience, making your vehicle more adaptable for specific tasks. Always ensure that any modifications comply with safety regulations and manufacturer guidelines to maintain optimal performance.