Essential Guide to John Deere 260 Skid Steer Repair Manual

Maintaining heavy machinery is crucial for ensuring optimal performance and longevity. This guide focuses on essential procedures, troubleshooting tips, and preventive strategies that can enhance the functionality of compact construction vehicles. Proper understanding of these aspects can save both time and resources in the long run.

Familiarity with your equipment’s specifications and operational characteristics lays the groundwork for effective maintenance practices. Knowledge of the various components, their interactions, and common issues can empower operators and technicians to conduct thorough assessments. This, in turn, facilitates informed decision-making when it comes to upkeep and repairs.

Whether you are an experienced professional or a newcomer to the field, having access to detailed guidelines is invaluable. These resources provide insights into best practices, helping you navigate challenges confidently. By following a structured approach to maintenance, you can ensure that your machinery operates at peak efficiency, minimizing downtime and maximizing productivity.

Understanding John Deere 260 Skid Steer

This section explores the key features and functionalities of a versatile compact loader. These machines are essential in various industries for their ability to maneuver in tight spaces while offering robust lifting capabilities. By examining their components and operational principles, users can maximize efficiency and maintain optimal performance.

Key Features

Compact loaders are designed with a range of functionalities to cater to diverse tasks. Some of the notable attributes include:

| Feature | Description |

|---|---|

| Powerful Engine | Equipped with a high-performance engine that delivers significant power for demanding tasks. |

| Hydraulic System | A sophisticated hydraulic system allows for smooth operation and precise control over attachments. |

| Versatile Attachments | Compatible with various tools, enabling the machine to tackle different jobs effectively. |

| Compact Design | Small footprint allows for easy navigation in confined spaces without sacrificing capability. |

Maintenance Considerations

To ensure longevity and reliable operation, regular upkeep is essential. Users should focus on routine inspections, fluid changes, and monitoring wear on components. By adhering to a maintenance schedule, potential issues can be identified early, reducing downtime and repair costs.

Common Issues with Skid Steer Operation

Operating compact machinery can present various challenges that may hinder performance and efficiency. Understanding the typical problems faced by users can significantly enhance productivity and prolong the lifespan of the equipment.

- Hydraulic Issues:

- Insufficient power during operation

- Leaking fluid from hoses or connectors

- Slow response time from hydraulic controls

- Engine Performance:

- Difficulty starting the engine

- Unusual noises indicating mechanical failure

- Overheating due to inadequate cooling

- Electrical Problems:

- Faulty ignition system affecting startup

- Battery drainage issues

- Malfunctioning sensors leading to inaccurate readings

- Track and Tire Wear:

- Uneven wear patterns causing instability

- Punctures or damage from rough terrain

- Improper inflation leading to reduced traction

- Operational Errors:

- Poor maneuverability due to improper control usage

- Inaccurate load handling techniques

- Neglecting maintenance leading to preventable issues

By recognizing these common challenges, operators can take proactive measures to address them, ensuring optimal functionality and safety during use.

Essential Tools for Maintenance Tasks

Proper upkeep of machinery is crucial for optimal performance and longevity. Having the right instruments on hand not only simplifies maintenance procedures but also ensures safety and efficiency. This section outlines the key implements necessary for effective servicing and troubleshooting.

Basic Hand Tools

Every maintenance kit should include a set of fundamental hand tools. These typically encompass wrenches, screwdrivers, and pliers. Each tool serves a unique purpose, allowing for the tightening or loosening of bolts, screws, and various components. A reliable set of sockets can also enhance your ability to address mechanical issues promptly.

Diagnostic Equipment

In addition to basic hand tools, having diagnostic equipment is essential for identifying problems. Instruments such as multimeters and pressure gauges help in assessing electrical systems and fluid pressures. Furthermore, utilizing an oscilloscope can provide deeper insights into electronic malfunctions, ensuring a thorough evaluation of the machinery.

Step-by-Step Repair Process Overview

This section outlines a comprehensive guide to troubleshooting and fixing common issues with your equipment. By following a systematic approach, you can ensure that all aspects are thoroughly addressed, minimizing downtime and enhancing performance. Each phase of the process is designed to be clear and accessible, enabling even those with limited experience to effectively manage repairs.

| Step | Description |

|---|---|

| 1 | Identify the problem by conducting a visual inspection and noting any unusual sounds or behaviors. |

| 2 | Gather the necessary tools and replacement parts, ensuring you have everything required for the task. |

| 3 | Disassemble the relevant components, taking care to document the order of removal for easier reassembly. |

| 4 | Inspect the removed parts for wear and damage, deciding what needs to be repaired or replaced. |

| 5 | Reassemble the unit, following the documentation created during disassembly to maintain proper alignment and function. |

| 6 | Conduct a test run to ensure that the issue has been resolved and everything operates smoothly. |

By adhering to this structured method, you can efficiently tackle challenges and maintain the reliability of your machinery. Each step contributes to a thorough understanding of the system and enhances your ability to execute successful interventions.

Safety Precautions During Repairs

Ensuring a secure environment while conducting maintenance tasks is crucial for both efficiency and well-being. Proper protocols not only protect the individual performing the work but also safeguard the equipment and surroundings. Adhering to safety measures minimizes the risk of accidents and enhances overall productivity.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is essential. This includes items such as gloves, goggles, and helmets. Gloves protect hands from sharp edges and chemicals, while goggles shield the eyes from debris and harmful substances. Helmets can prevent serious head injuries in case of falling objects. Always ensure that your PPE is in good condition and fits properly.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Remove any unnecessary tools or materials that could cause tripping hazards. Ensure that the area is well-lit, and check for potential electrical hazards. Proper ventilation is also important, especially when working with chemicals. By creating a safe working environment, you enhance your ability to focus and perform tasks efficiently.

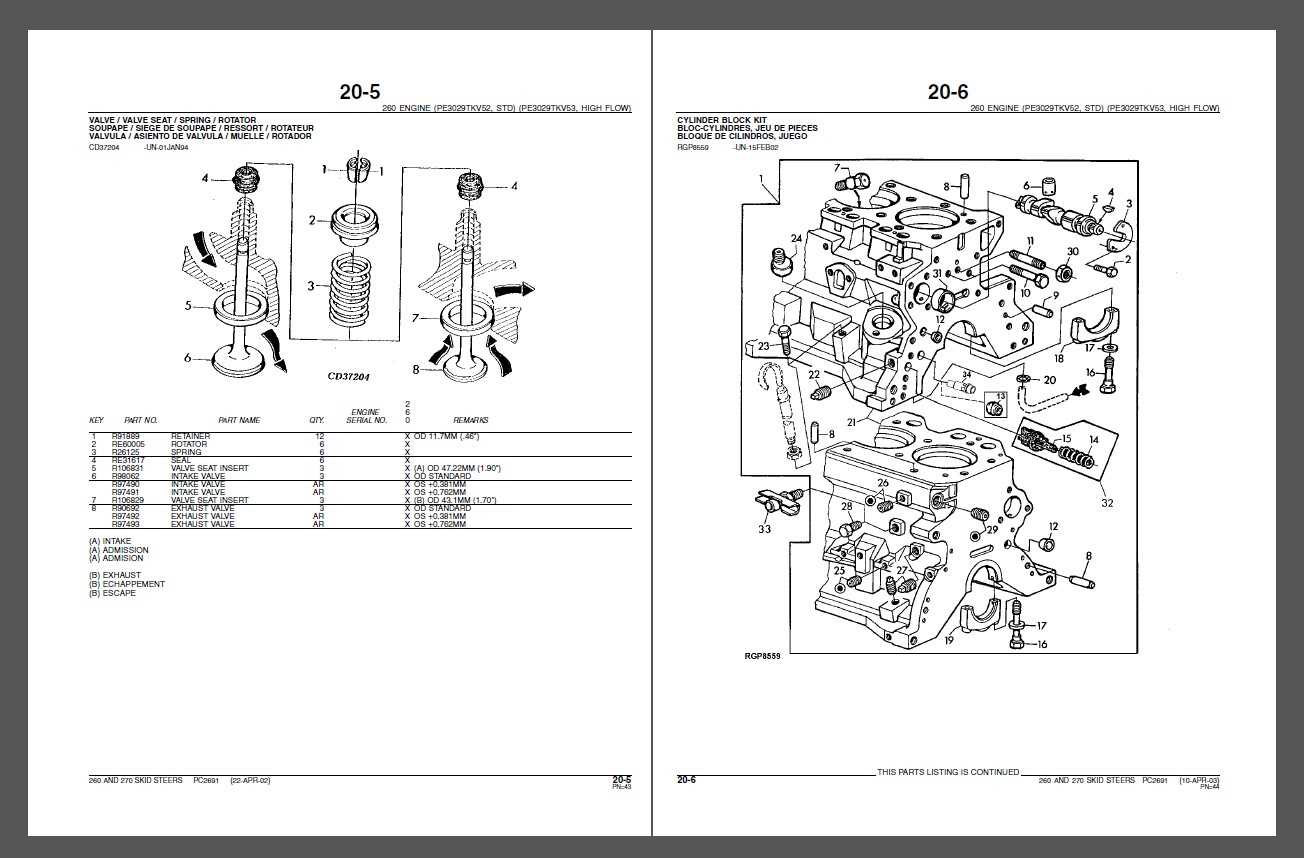

Replacing Key Components Effectively

Maintaining machinery involves the careful replacement of essential parts to ensure optimal performance. Understanding the process and utilizing appropriate techniques can significantly enhance the longevity and functionality of equipment.

Preparation Steps

Before starting any replacement task, gather all necessary tools and components. A well-organized workspace contributes to efficiency and safety.

Step-by-Step Replacement Process

| Step | Description |

|---|---|

| 1 | Power down the machinery and ensure all safety measures are in place. |

| 2 | Carefully remove the damaged component, taking note of its connections. |

| 3 | Install the new part, ensuring all connections are secure and correctly aligned. |

| 4 | Test the equipment to confirm that the replacement was successful and everything functions properly. |

Electrical System Troubleshooting Tips

Tackling issues within the electrical framework of machinery can often seem daunting. However, understanding common problems and knowing how to approach them systematically can lead to effective solutions. This section offers practical advice for diagnosing and resolving electrical concerns efficiently.

- Check Battery Condition:

- Inspect for corrosion on terminals.

- Ensure battery is charged adequately.

- Test with a multimeter to verify voltage levels.

- Examine Fuses and Relays:

- Identify blown fuses and replace them.

- Check relays for proper function.

- Make sure connections are secure and clean.

- Inspect Wiring and Connections:

- Look for frayed or damaged wires.

- Ensure all connectors are tight and free from dirt.

- Use a continuity tester to find breaks in the circuit.

- Test Switches and Sensors:

- Verify the operation of control switches.

- Check that sensors are functioning correctly.

- Look for any signs of wear or malfunction.

- Utilize Diagnostic Tools:

- Employ a multimeter for precise measurements.

- Consider using diagnostic software if available.

- Review any error codes to guide your troubleshooting.

By following these steps, you can systematically identify and resolve issues within the electrical system, ensuring smooth operation and extending the lifespan of your equipment.

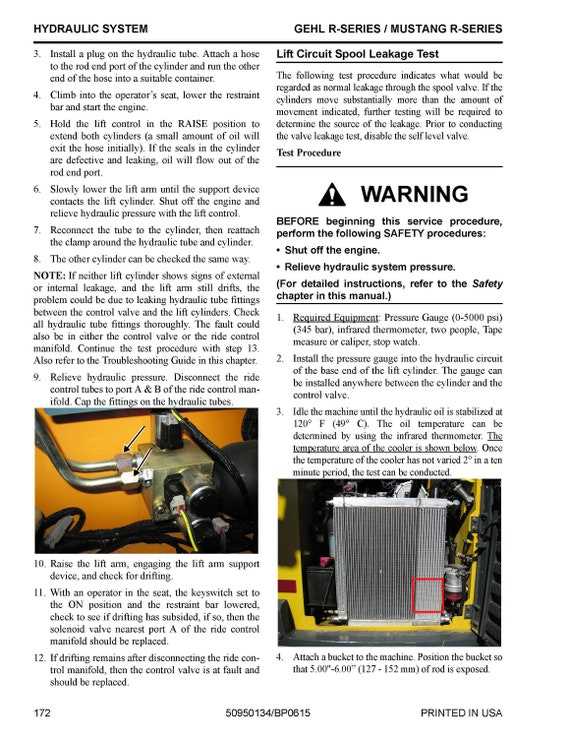

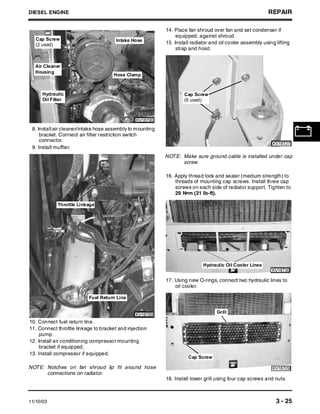

Hydraulic System Maintenance Guidelines

Maintaining the hydraulic system is essential for ensuring optimal performance and longevity of the machinery. Regular attention to this critical component not only enhances efficiency but also prevents costly breakdowns. Adhering to systematic maintenance practices can significantly extend the lifespan of hydraulic equipment.

Routine Inspection

Performing routine inspections is vital for identifying potential issues before they escalate. Check for signs of leaks, corrosion, or wear in hoses and fittings. Additionally, ensure that the hydraulic fluid levels are adequate and that the fluid itself is clean and free from contaminants. Regular monitoring helps maintain system integrity and performance.

Fluid Management

Proper management of hydraulic fluid is crucial. Use the recommended type and grade as specified by the manufacturer. Change the fluid at the intervals suggested in the guidelines to prevent degradation and contamination. Keeping the hydraulic fluid clean not only protects the components but also enhances overall efficiency and reliability.

Engine Care and Performance Optimization

Maintaining optimal engine functionality is crucial for enhancing the overall performance and longevity of your equipment. Proper care routines and adjustments can significantly improve efficiency and reduce the risk of unexpected failures.

To ensure your engine operates at its best, consider the following key practices:

- Regular Oil Changes: Frequent oil replacements help to maintain lubrication and prevent wear. Follow the recommended intervals for your specific model.

- Air Filter Maintenance: A clean air filter allows for better airflow, enhancing combustion and fuel efficiency. Check and replace it as needed.

- Fuel Quality: Using high-quality fuel prevents deposits from building up in the engine, promoting smoother operation. Always choose fuels that meet the manufacturer’s specifications.

- Cooling System Checks: Regularly inspect the cooling system for leaks or blockages. Keeping the engine at an optimal temperature is vital for performance.

- Belt and Hose Inspections: Check belts and hoses for signs of wear or damage. Replacing them promptly prevents larger issues from arising.

In addition to routine maintenance, consider the following optimization strategies:

- Tuning the Engine: Periodic tuning can enhance performance by adjusting fuel-air mixtures and ignition timing.

- Upgrading Components: Consider aftermarket upgrades for filters, exhaust systems, or performance chips that can boost horsepower and efficiency.

- Regular Diagnostics: Utilize diagnostic tools to identify any underlying issues early, ensuring that your engine runs smoothly.

By adhering to these maintenance and optimization practices, you can ensure your engine performs efficiently, ultimately saving time and reducing costs associated with repairs and fuel consumption.

Finding Quality Replacement Parts

When it comes to maintaining machinery, sourcing high-quality components is essential for optimal performance and longevity. Reliable parts not only enhance functionality but also ensure safety during operation. Here are key considerations to help you find the best replacements for your equipment.

- Identify Specifications: Understand the precise requirements of the part you need. Check dimensions, materials, and compatibility with your equipment.

- Research Suppliers: Look for reputable suppliers who specialize in parts for your specific machinery type. Online reviews and testimonials can provide insights into their reliability.

- Evaluate Quality: Always prioritize quality over cost. Cheaper alternatives may lead to frequent replacements and increased downtime.

- Check Warranty: A solid warranty often indicates a manufacturer’s confidence in their product. It also provides you with peace of mind in case of defects.

- Consider OEM vs. Aftermarket: Original equipment manufacturer (OEM) parts generally guarantee compatibility and quality, while aftermarket options may offer cost savings but vary in reliability.

- Consult Experts: Seek advice from professionals or experienced users who can recommend reliable sources and parts based on their own experiences.

By following these guidelines, you can ensure that you procure the best components for your machinery, ultimately enhancing its efficiency and lifespan.

Best Practices for Long-Term Care

Ensuring the longevity and optimal performance of machinery requires consistent attention and a proactive approach. By implementing a series of best practices, operators can significantly extend the life of their equipment while minimizing the need for extensive repairs. These strategies focus on regular maintenance, proper usage, and timely interventions, all of which contribute to a more reliable and efficient operation.

Regular Maintenance and Inspections

Establishing a routine maintenance schedule is crucial. Routine inspections allow operators to identify potential issues before they escalate. Check fluid levels, filters, and belts frequently to ensure everything is functioning correctly. Keeping the machinery clean, especially from dirt and debris, can prevent premature wear and tear.

Proper Operation Techniques

Understanding and following the manufacturer’s guidelines for operation can greatly affect performance. Avoiding excessive loads and abrupt maneuvers can reduce stress on components, promoting smoother functioning. Additionally, using the right attachments and tools for specific tasks helps in maintaining overall efficiency and effectiveness.