John Deere 4100 Maintenance Guide

Ensuring the longevity and efficiency of your agricultural machinery is crucial for optimal performance. This section delves into essential practices for keeping your equipment in peak condition. By understanding the intricacies of maintenance, users can enhance the lifespan and functionality of their machines.

In-depth knowledge of various components and their specific care requirements is vital for anyone looking to perform upkeep independently. This guide provides valuable insights into common issues, preventive measures, and effective solutions that can save time and resources.

Whether you’re a seasoned operator or a newcomer, grasping these concepts will empower you to tackle challenges confidently. Emphasizing the importance of regular checks and adjustments can lead to improved productivity and a smoother operation.

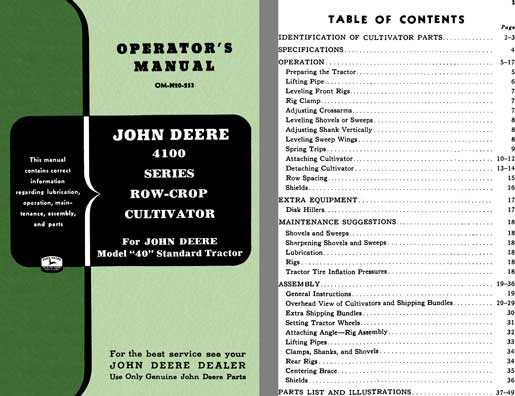

Understanding the 4100 Model

This section provides an overview of the essential features and specifications of the 4100 series, focusing on its functionality and design. Recognizing its components and capabilities is crucial for effective maintenance and operation.

Key Features of the Series

The 4100 model is equipped with various advanced features that enhance its performance and usability. Familiarity with these attributes will assist operators in maximizing the efficiency of their equipment.

Specifications Overview

Understanding the technical specifications of this model is vital for troubleshooting and repairs. Below is a summary of key specifications:

| Feature | Details |

|---|---|

| Engine Type | 4-Cylinder Diesel |

| Horsepower | Approx. 20 HP |

| Transmission | Hydrostatic |

| Weight | 1,400 lbs |

| Fuel Capacity | 6.5 gallons |

Common Issues and Solutions

Maintaining machinery can often lead to encountering various challenges that require effective troubleshooting. Understanding frequent problems and their corresponding remedies can significantly enhance operational efficiency and prolong the equipment’s lifespan.

Frequent Challenges

- Engine performance issues

- Hydraulic system failures

- Electrical malfunctions

- Unusual noises during operation

Solutions to Common Problems

-

Engine Performance Issues:

Check the fuel quality and ensure proper filtration. Regular maintenance of air filters can also prevent many performance-related concerns.

-

Hydraulic System Failures:

Inspect hoses for leaks and ensure fluid levels are adequate. Replacing worn seals and ensuring connections are secure can resolve many issues.

-

Electrical Malfunctions:

Examine wiring for any signs of damage and ensure all connections are clean and tight. Testing fuses and relays can identify faulty components quickly.

-

Unusual Noises:

Identify the source of the noise and check for loose components or worn parts. Regular lubrication can help reduce friction and noise.

Tools Required for Repairs

When undertaking maintenance or troubleshooting tasks on your machinery, having the right instruments is essential for efficiency and effectiveness. A well-equipped workspace not only facilitates smoother operations but also enhances safety during the process.

Basic tools that are commonly needed include wrenches, screwdrivers, and pliers, which are fundamental for disassembling components. Additionally, specialized equipment like diagnostic tools and torque wrenches can provide precise adjustments and accurate assessments. Always ensure that your toolkit is complete and organized to minimize downtime during repairs.

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your equipment. This guide provides a clear and structured approach to maintaining your machine, helping to prevent potential issues and extend its operational life.

Routine Checks

Start with frequent inspections of critical components. Look for signs of wear or damage, such as leaks or unusual noises. Checking fluid levels and replacing filters as needed is crucial for smooth functioning.

Seasonal Maintenance Tasks

During each season, specific maintenance tasks should be prioritized. For example, before winter, ensure that the battery is charged and the fuel system is treated. This proactive approach can significantly reduce downtime and enhance reliability.

Engine Troubleshooting Techniques

Identifying and resolving issues within an engine can significantly enhance its performance and longevity. This section provides insights into effective methods for diagnosing common problems, enabling users to systematically address various symptoms that may arise during operation.

Common Symptoms and Initial Checks

When experiencing engine difficulties, start by observing typical signs such as unusual noises, poor acceleration, or excessive emissions. Conduct a thorough inspection of the fuel system, air intake, and electrical components to pinpoint potential sources of the malfunction. Regular maintenance can prevent many issues from escalating.

Advanced Diagnostic Techniques

For persistent problems, consider utilizing specialized tools such as diagnostic scanners and pressure gauges. These instruments can provide valuable data, allowing for a more in-depth analysis of engine performance. Understanding the relationship between various systems can lead to more accurate conclusions and effective solutions.

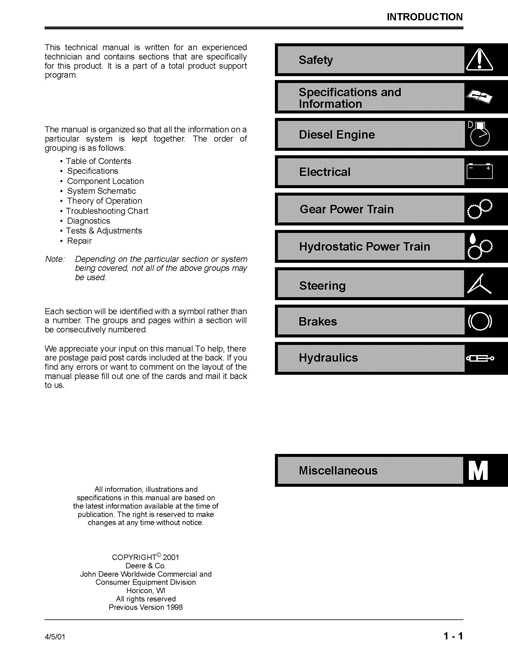

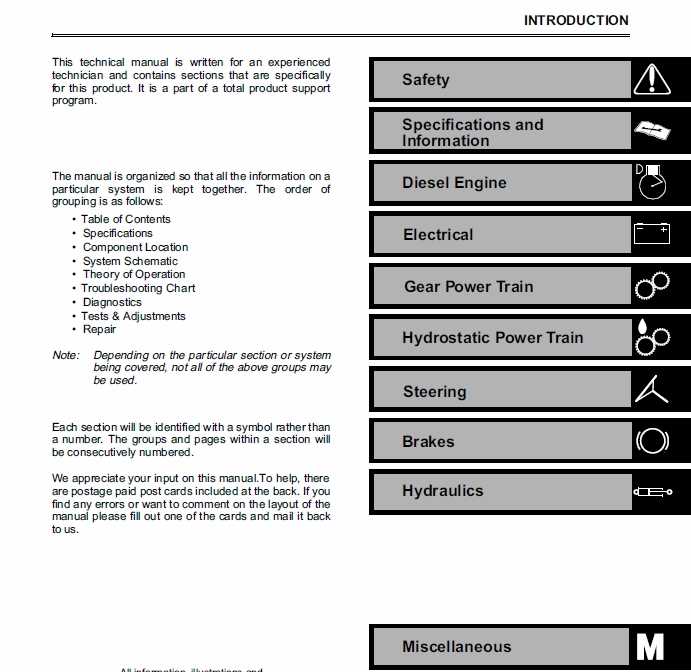

Electrical System Diagnostics

The assessment of electrical systems is crucial for ensuring optimal performance and reliability in machinery. This process involves a systematic approach to identify potential issues within the electrical circuits and components. By employing various diagnostic techniques, one can effectively troubleshoot malfunctions and enhance the overall functionality of the equipment.

Start by inspecting the battery and its connections, as they are fundamental to the electrical framework. Next, utilize multimeters to measure voltage and continuity across different components. This helps in pinpointing any faulty parts, such as relays or switches. Additionally, visual checks for damaged wiring or loose connections can uncover hidden problems that might disrupt the system.

Finally, it’s essential to consult the specific guidelines provided for electrical diagnostics, as they offer valuable insights into the expected values and test procedures. Thorough evaluation and regular maintenance of the electrical system can significantly prolong the life of the machinery and prevent unexpected failures.

Hydraulic System Overview

The hydraulic system is a crucial component in various machinery, enabling efficient operation through fluid power. Understanding its functionality and design is essential for maintenance and troubleshooting.

Key Components

- Pump: Generates hydraulic pressure to facilitate movement.

- Reservoir: Stores hydraulic fluid, ensuring a steady supply.

- Actuators: Convert hydraulic energy into mechanical motion.

- Valves: Control fluid flow and pressure within the system.

System Operation

This system operates by circulating hydraulic fluid through various components. The pump draws fluid from the reservoir and pressurizes it, directing it to the actuators via the valves. This process allows for precise control over machinery functions.

Regular inspection and maintenance of the hydraulic system are vital for optimal performance and longevity. Ensuring fluid levels are adequate and checking for leaks will help prevent potential failures.

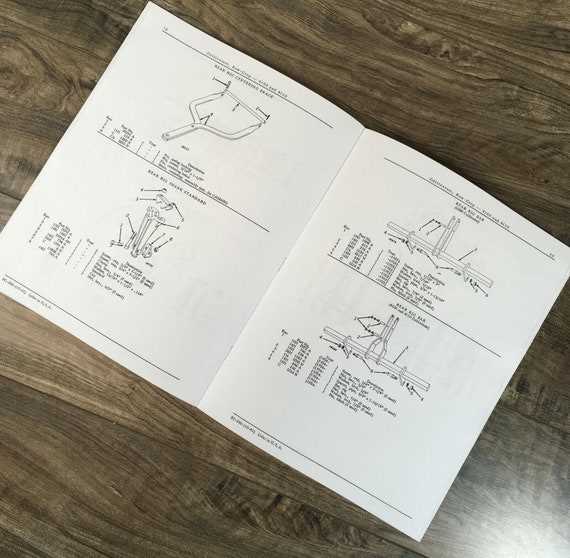

Parts Replacement Procedures

This section outlines essential methods for replacing components in machinery. Proper procedures ensure optimal performance and longevity of the equipment, minimizing downtime and enhancing reliability. Understanding the correct techniques for part substitution is vital for maintaining operational efficiency.

Preparation for Component Replacement

Before beginning the substitution process, it is crucial to gather all necessary tools and replacement parts. Ensure the equipment is powered down and secured to prevent accidental activation. Reviewing the specifications of the new components can help avoid compatibility issues and ensure a seamless installation.

Step-by-Step Replacement Process

Begin by removing any covers or barriers that obstruct access to the component. Carefully detach the old part, taking note of any connections or fasteners. Install the new piece by reversing the removal steps, ensuring all connections are secure. Finally, conduct a thorough inspection to verify that the installation meets operational standards.

Safety Precautions During Repairs

Ensuring safety during maintenance tasks is essential for preventing accidents and injuries. Proper precautions can significantly reduce risks associated with mechanical work.

Always wear appropriate protective gear, including gloves, goggles, and sturdy footwear. This equipment shields against potential hazards such as sharp objects and chemicals.

Additionally, maintaining a clean workspace helps avoid slips and falls. Remove any unnecessary items and ensure tools are organized and easily accessible.

It is also crucial to follow operational guidelines provided by the manufacturer. Familiarizing yourself with the equipment’s specifications and recommended practices promotes a safer working environment.

Lastly, disconnect power sources before starting any servicing tasks. This simple step can prevent unintentional activation, which could lead to serious injuries.

Service Interval Recommendations

Regular maintenance is crucial for optimal performance and longevity of machinery. Following specific timeframes for service tasks ensures that all components function efficiently and safely.

- Daily Checks: Inspect fluids, filters, and belts before operation.

- Weekly Maintenance: Clean air filters and check tire pressure.

- Monthly Inspections: Assess battery condition and tighten bolts.

- Quarterly Servicing: Change oil and replace worn parts as necessary.

- Annual Overhaul: Conduct a comprehensive inspection of all systems.

Adhering to these intervals not only enhances performance but also minimizes the risk of unexpected breakdowns.

Owner’s Manual Insights

The insights provided in the owner’s guide are essential for maximizing the performance and longevity of your equipment. This resource offers comprehensive information that helps operators understand the functionalities and maintenance requirements, ensuring smooth operation and reducing the risk of potential issues.

Key Features and Benefits

This resource highlights various features that enhance usability and efficiency. By familiarizing yourself with these aspects, you can make informed decisions during operation and upkeep. Additionally, the guide emphasizes the importance of routine maintenance, which plays a crucial role in sustaining performance levels.

Understanding Maintenance Recommendations

Maintenance recommendations are critical for preserving the integrity of your machine. Following these guidelines will not only prevent premature wear but also ensure that the equipment functions optimally. Regular checks and timely interventions can lead to significant cost savings and extend the lifespan of your investment.

FAQs About the 4100 Series

This section addresses common inquiries related to the 4100 series, providing helpful insights for users seeking guidance on various aspects of their machinery. Whether you are new to this line of equipment or looking to deepen your understanding, the following questions and answers can assist in navigating typical concerns.

What are the main features of this series?

The 4100 series is known for its robust construction and versatility. Users appreciate its ease of use, efficient performance, and compatibility with a wide range of attachments. These attributes make it suitable for various tasks, from landscaping to agricultural applications.

How can I troubleshoot common issues?

When facing challenges, it’s essential to start with basic checks. Look for any signs of wear on components, ensure proper fluid levels, and consult the troubleshooting guide for systematic approaches. Regular maintenance plays a crucial role in preventing problems and ensuring longevity.

Resources for Further Assistance

When seeking additional guidance for maintenance and troubleshooting, various platforms can provide valuable insights. Engaging with community forums and expert websites can enhance your understanding and facilitate effective solutions.

Online Forums: Participating in dedicated discussion groups allows users to exchange experiences and solutions. These platforms often feature threads covering a wide range of topics, enabling you to ask questions and receive responses from knowledgeable individuals.

Video Tutorials: Visual aids can significantly simplify complex tasks. Numerous video-sharing platforms host tutorials that demonstrate step-by-step procedures, catering to both novices and seasoned users.

Manufacturer’s Support: Many manufacturers offer customer service and technical support. Accessing these resources can provide you with expert advice tailored to your specific situation.

Local Workshops: Consider reaching out to nearby repair shops or community workshops. Many offer classes or one-on-one sessions, allowing you to gain hands-on experience and learn from professionals in the field.