Comprehensive Guide to John Deere 6081 Repair Manual

In the realm of heavy machinery, ensuring optimal performance and longevity of the engine is crucial. A comprehensive understanding of maintenance procedures not only enhances efficiency but also prevents costly downtimes. This section delves into vital aspects of engine upkeep, equipping operators and technicians with the necessary knowledge to tackle various challenges.

Thorough insights into troubleshooting and service procedures can empower users to address issues effectively. By familiarizing oneself with the intricacies of the engine’s functionality, individuals can mitigate risks associated with neglect and wear. The importance of regular checks and proactive measures cannot be overstated, as they form the backbone of reliable machinery operation.

Additionally, this guide provides step-by-step instructions that serve as a roadmap for routine servicing tasks. Whether dealing with common malfunctions or routine maintenance, having access to detailed information can significantly improve problem-solving capabilities. The objective is to create a seamless experience for those engaged in engine management, fostering both confidence and competence in their skills.

Overview of John Deere 6081

This section provides a comprehensive look at a specific model renowned for its robust performance and reliability in agricultural applications. With a design that emphasizes durability and efficiency, this engine has become a popular choice among professionals in the field.

Key Features

Featuring advanced technology, this unit is equipped with systems that enhance fuel efficiency and reduce emissions. Its engineering excellence ensures that it meets the demands of various tasks, making it an ultimate solution for heavy-duty operations.

Applications

This engine is ideal for use in a range of machinery, from tractors to industrial equipment. Its versatility allows it to excel in multiple environments, providing users with reliable power for both agricultural and commercial tasks.

Common Issues with John Deere 6081

Engines of this type often experience a range of typical problems that can affect performance and reliability. Understanding these issues can aid in preventive maintenance and timely interventions, ensuring optimal operation and longevity.

Frequent Problems

Owners may encounter various concerns that arise during regular use. Identifying symptoms early can prevent more severe damage and costly repairs.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Overheating | High temperature readings, steam from the engine | Low coolant level, faulty thermostat |

| Starting Difficulties | Engine cranks slowly, failure to start | Weak battery, faulty starter motor |

| Unusual Noises | Knocking or grinding sounds | Worn bearings, loose components |

| Excessive Smoke | Visible smoke from exhaust | Fuel issues, worn piston rings |

Maintenance Tips

Regular inspections and maintenance can significantly reduce the risk of encountering these common issues. Staying proactive will help maintain performance and extend the lifespan of the engine.

Essential Tools for Repairs

When it comes to maintaining heavy machinery, having the right equipment is crucial for effective upkeep. Whether tackling minor adjustments or major overhauls, a well-stocked toolkit can make all the difference in ensuring smooth operations and longevity of the machine.

Here are some fundamental instruments that every technician should consider having on hand:

- Wrenches: A variety of sizes, including adjustable and socket wrenches, are essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types in various sizes are necessary for accessing different components.

- Pliers: These are useful for gripping, twisting, and cutting wires or small parts.

- Torque wrench: This tool ensures that bolts are tightened to the manufacturer’s specified torque, preventing damage from overtightening.

- Diagnostic tools: Multimeters and other testing devices help troubleshoot electrical issues.

- Jack stands: Safe lifting equipment is vital for accessing the undercarriage or replacing tires.

- Safety gear: Gloves, goggles, and masks protect against debris and hazardous materials during work.

By equipping yourself with these basic tools, you can enhance your ability to perform necessary tasks efficiently and safely, ensuring your equipment remains in top condition.

Step-by-Step Repair Instructions

This section provides a comprehensive guide to troubleshooting and fixing common issues encountered with agricultural engines. Following these structured steps will help ensure efficient operation and longevity of the machinery.

-

Identify the Issue: Begin by observing the performance. Common signs include unusual noises, leaks, or loss of power. Take note of any error codes displayed on the dashboard.

-

Gather Necessary Tools: Assemble the required tools for the task. This may include:

- Socket set

- Wrenches

- Screwdrivers

- Torque wrench

- Multimeter

-

Consult Documentation: Review any available technical documents or guidelines specific to your engine model for detailed specifications and procedures.

-

Access the Engine: Safely remove any coverings or panels to gain full access to the engine components. Ensure the machinery is powered down and secured.

-

Perform Diagnostic Checks: Utilize diagnostic tools to assess electrical systems. Check for proper connections and voltage levels.

-

Replace or Repair Components: Based on the findings, proceed with replacing faulty parts or making necessary adjustments. Ensure all components meet the manufacturer’s specifications.

-

Reassemble and Test: Once repairs are completed, carefully reassemble the engine. Conduct a series of tests to verify that the issue has been resolved and the engine operates smoothly.

-

Document the Process: Record all findings, repairs made, and parts replaced for future reference. This helps maintain a history of maintenance for the engine.

By following these detailed instructions, you can effectively address many typical problems that arise in agricultural engine maintenance, ensuring reliable performance and reducing downtime.

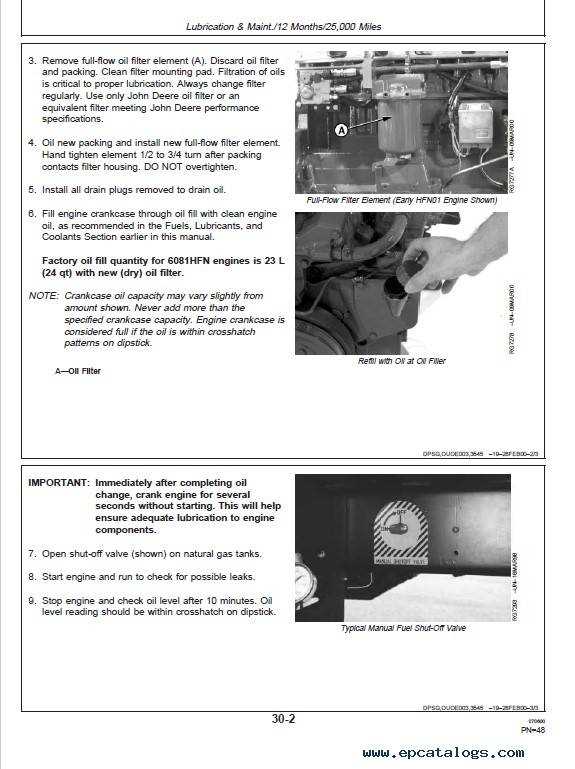

Preventative Maintenance Tips

Routine upkeep is essential for prolonging the lifespan of machinery and ensuring optimal performance. Implementing a structured maintenance schedule can help identify potential issues before they escalate, ultimately saving time and resources. Below are key strategies to maintain equipment effectively.

Regular Inspections

Conducting consistent evaluations of your machinery allows for the early detection of wear and tear. Focus on critical components such as filters, belts, and hoses. Documenting these inspections not only aids in tracking maintenance history but also facilitates timely repairs when necessary.

Fluid Management

Proper management of fluids is crucial for the efficient operation of any equipment. Regularly check and replace oils, coolants, and other essential fluids as per manufacturer recommendations. Maintaining appropriate fluid levels helps prevent overheating and ensures that all parts function smoothly, reducing the risk of breakdowns.

Parts Replacement Guidelines

Replacing components in machinery is essential for maintaining optimal performance and longevity. Following a structured approach ensures that replacements are done efficiently and correctly, minimizing downtime and preventing further issues.

Preparation Steps

- Identify the component that requires replacement.

- Gather the necessary tools and equipment.

- Refer to specifications for compatible parts.

- Ensure safety measures are in place before starting the procedure.

Replacement Process

- Turn off the machine and disconnect the power supply.

- Carefully remove the faulty part, taking note of the installation process.

- Install the new component, ensuring it fits securely and aligns with existing parts.

- Reconnect any electrical or hydraulic connections as needed.

- Conduct a thorough inspection to confirm everything is in place.

- Power on the machine and run a test to verify proper functionality.

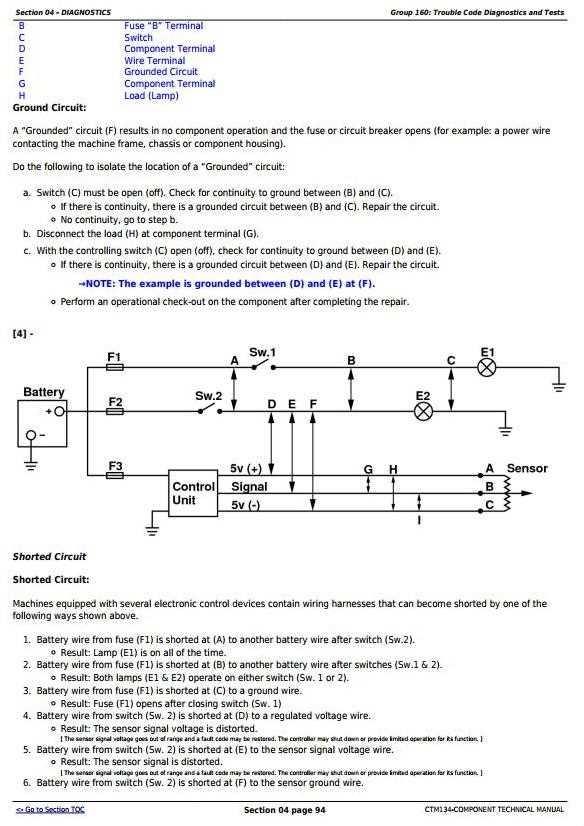

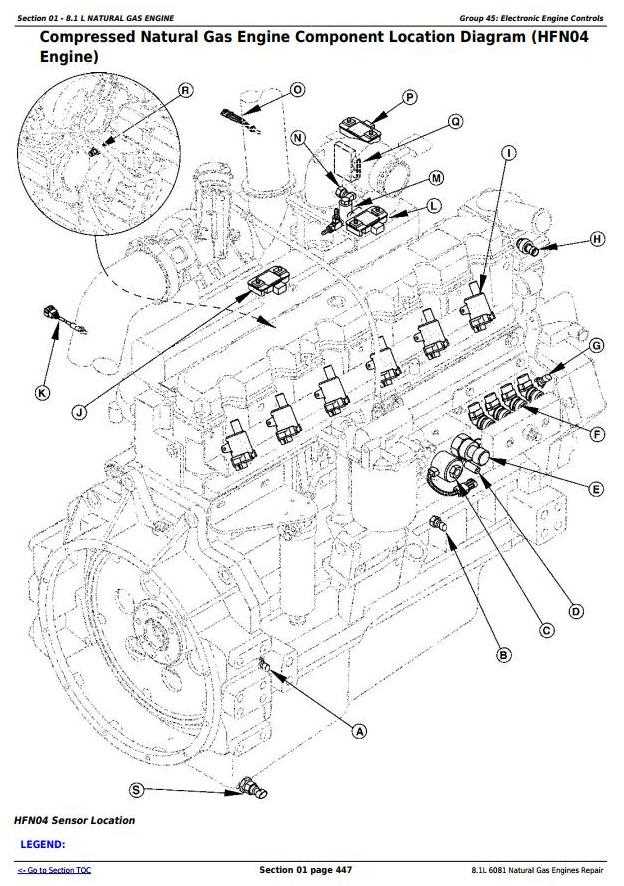

Electrical System Troubleshooting

Diagnosing issues within an electrical framework is essential for optimal performance. By systematically examining components and connections, one can identify malfunctions that impede functionality. A methodical approach will ensure that potential problems are addressed effectively.

Common Issues

Frequent challenges include faulty wiring, poor connections, and malfunctioning components. Inspecting the entire circuit for signs of wear or damage is crucial. Voltage fluctuations can also indicate underlying issues that need immediate attention.

Diagnostic Steps

Begin by checking battery health and ensuring proper voltage levels. Utilize a multimeter to assess continuity throughout the system. Thoroughly examine switches and relays for functionality, as these play vital roles in the overall operation.

Engine Overhaul Procedures

Performing an overhaul on an engine is a critical process aimed at restoring optimal functionality and efficiency. This procedure involves a series of systematic steps that address wear and tear, ensuring longevity and reliability. Proper execution not only enhances performance but also minimizes the risk of future malfunctions.

Preparation is essential before commencing the overhaul. Gather all necessary tools, equipment, and replacement components. Ensure a clean and organized workspace to facilitate smooth progress. Familiarity with the engine’s specifications and requirements will aid in achieving successful outcomes.

Once preparations are complete, disassembly begins. Carefully remove all external components, such as the intake and exhaust systems, to gain access to the engine block. Document the order of disassembly to simplify reassembly later. Inspect each part for damage or excessive wear, taking note of any necessary replacements.

After disassembly, cleaning the components is crucial. Use appropriate solvents and tools to remove grime, carbon deposits, and other contaminants. This step ensures that all parts are in optimal condition for reassembly and helps prevent potential issues during operation.

Next, inspection of critical components such as pistons, crankshaft, and cylinder head is vital. Measure tolerances and identify any signs of wear that may require machining or replacement. Attention to detail in this stage can significantly affect engine performance post-overhaul.

Once all components are assessed, proceed with reassembly. Follow the documented sequence carefully, using proper torque specifications for all fasteners. It is important to utilize new gaskets and seals to prevent leaks and ensure a tight fit. Each step should be executed with precision to maintain the integrity of the engine.

Finally, conduct a thorough testing phase post-assembly. Start the engine and monitor for unusual sounds or leaks. Allow the engine to reach operating temperature and check all systems for proper functionality. Address any issues immediately to avoid long-term damage.

Hydraulic System Maintenance

Regular upkeep of the hydraulic system is essential for ensuring optimal performance and longevity of machinery. Proper maintenance not only prevents costly repairs but also enhances efficiency, making it crucial for operators to understand and implement effective care strategies.

Inspection and Cleaning

Routine inspections play a vital role in identifying potential issues before they escalate. Check for leaks, wear, and tear on hoses and connections. Additionally, cleaning components regularly helps maintain fluid quality, reducing contamination and ensuring smooth operation.

Fluid Replacement and Levels

Maintaining the correct fluid level is critical for the hydraulic system’s performance. Regularly check and replace hydraulic fluid as per manufacturer guidelines. Using the recommended type of fluid enhances system efficiency and reduces the risk of damage to components.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring safety is paramount. Proper precautions not only protect the individual performing the work but also enhance the longevity of the equipment. Awareness of potential hazards and adherence to safety protocols can significantly reduce the risk of accidents.

- Always wear appropriate personal protective equipment (PPE), including gloves, goggles, and sturdy footwear.

- Ensure the machinery is turned off and isolated from power sources before beginning any work.

- Use tools that are suitable for the task and in good condition to prevent malfunctions.

Moreover, maintaining a clean and organized workspace is essential for preventing slips and falls.

- Clear away any debris or tools that may obstruct movement.

- Keep flammable materials away from the work area.

- Have a first aid kit readily available in case of emergencies.

Finally, always consult relevant guidelines or seek assistance when unsure about any procedures. Prioritizing safety ensures effective and secure maintenance practices.