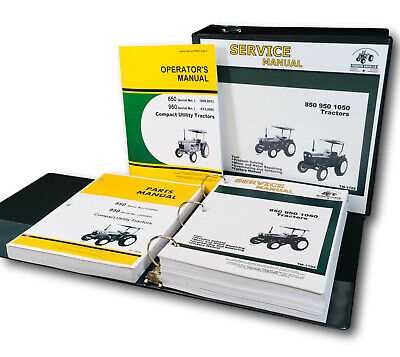

Comprehensive Guide to John Deere 850 Tractor Repair Manual

Understanding the intricacies of agricultural machinery is vital for efficient operations and longevity. This guide delves into the various aspects of maintaining and troubleshooting specific models, ensuring that users can achieve optimal performance and reliability. Whether you are a seasoned professional or a newcomer to the field, having access to comprehensive insights can make all the difference.

From identifying common issues to implementing effective solutions, this resource serves as a valuable reference. Each section is designed to equip users with the necessary knowledge, empowering them to handle challenges with confidence. Regular upkeep not only enhances functionality but also minimizes downtime, allowing for seamless productivity in demanding environments.

With a focus on practical tips and systematic approaches, readers will find themselves well-prepared to tackle maintenance tasks. The emphasis on detailed processes ensures that even the most complex issues can be approached with clarity. Embrace the journey of understanding your machinery, and unlock its full potential through informed care and attention.

Understanding the John Deere 850 Tractor

Exploring the functionality and design of this powerful agricultural machine reveals its importance in various farming tasks. Built for durability and efficiency, it stands out in its class, providing reliable performance in diverse conditions.

Key Features: This machine is equipped with a robust engine that ensures ample power for challenging jobs. Its compact size allows for maneuverability in tight spaces, making it an ideal choice for both large-scale operations and small farms. Operators appreciate the ease of use, which minimizes the learning curve for new users.

Maintenance Considerations: Regular upkeep is crucial to maintaining optimal performance. Understanding the components and their functions can significantly enhance longevity and efficiency. A proactive approach to maintenance not only prevents breakdowns but also improves overall productivity.

In summary, gaining a comprehensive understanding of this agricultural vehicle’s capabilities and maintenance requirements is essential for maximizing its utility on the field.

Common Issues Faced by Users

Owners of agricultural machinery often encounter a variety of challenges that can hinder performance and efficiency. Understanding these common problems is essential for maintaining optimal functionality and ensuring longevity of the equipment.

Engine Performance Problems

One of the most prevalent concerns involves engine efficiency. Users frequently report issues such as difficulty starting or stalling during operation. These symptoms may stem from inadequate fuel delivery, air intake blockages, or worn components. Regular inspections and timely replacements of parts can mitigate these issues.

Hydraulic System Failures

Another significant challenge lies within the hydraulic system. Users often face problems such as slow or unresponsive hydraulics, which can impede the overall productivity of the machinery. Common causes include leaks, air in the system, or low fluid levels. Addressing these problems promptly can enhance operational effectiveness and reduce downtime.

Importance of a Repair Manual

A comprehensive guide is essential for anyone looking to maintain and troubleshoot machinery effectively. Such documentation serves as a crucial resource, providing detailed instructions and insights that empower users to address issues confidently. Having access to this information not only enhances the understanding of the equipment but also promotes safe and efficient operations.

Facilitating Knowledge and Skills

One of the primary benefits of a well-structured guide is the knowledge it imparts. Users can familiarize themselves with various components, functionalities, and common issues. This familiarity not only builds confidence but also equips operators with the skills needed to perform maintenance tasks independently, ultimately extending the lifespan of the machinery.

Cost Efficiency

Investing in a detailed reference can lead to significant cost savings over time. By enabling individuals to diagnose and resolve problems without needing professional assistance, users can avoid costly repairs and service calls. Moreover, understanding the machinery encourages proactive maintenance, which further minimizes the likelihood of severe issues arising in the future.

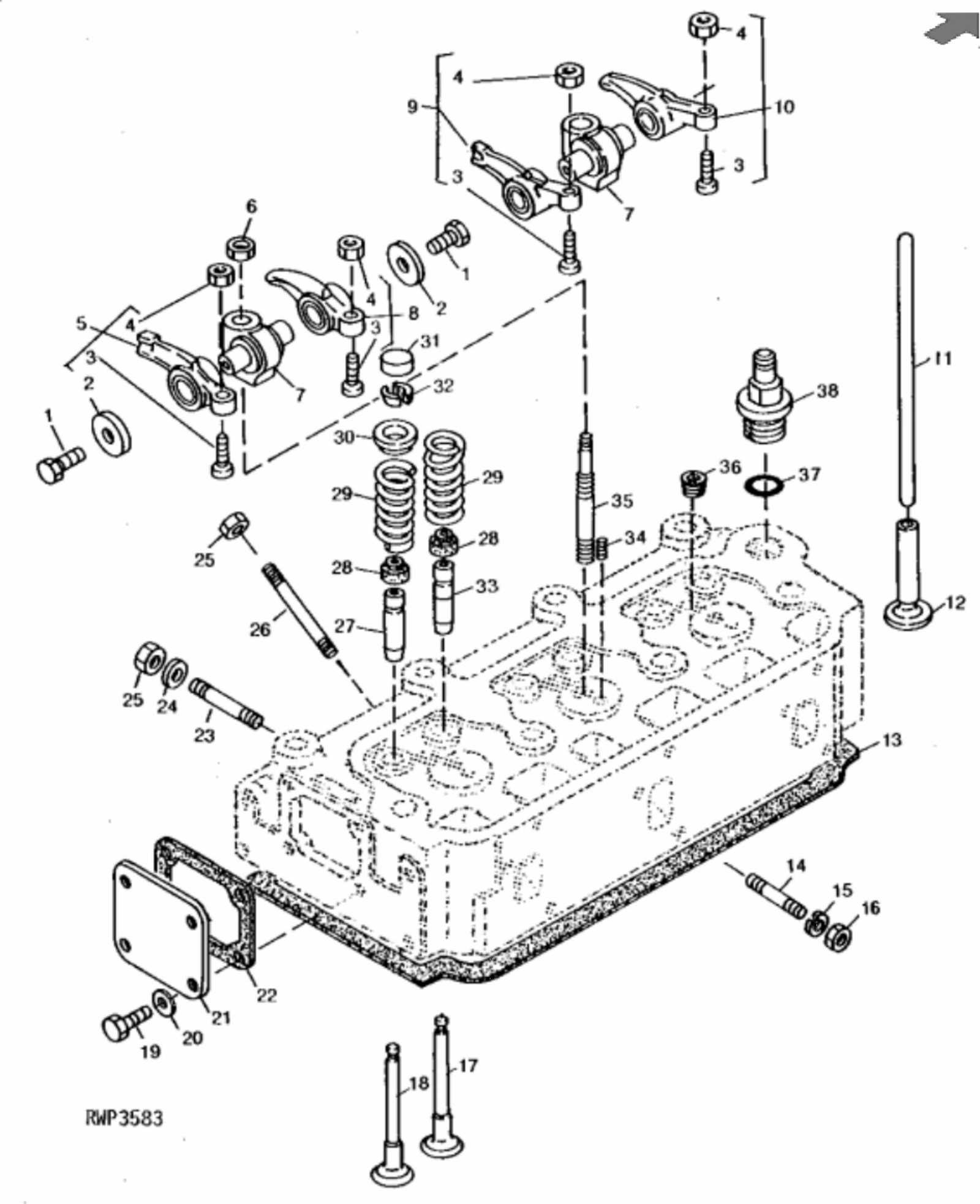

Key Components of the 850 Model

The efficiency and functionality of this agricultural machine largely depend on its fundamental elements. Understanding these components is crucial for ensuring optimal performance and longevity.

- Engine: The powerhouse of the equipment, providing the necessary torque and horsepower to handle various tasks.

- Transmission: This system allows for smooth gear shifting, enabling operators to adjust speed and power as needed.

- Hydraulic System: Essential for operating attachments and implements, the hydraulic setup enhances versatility and ease of use.

- Chassis: The frame supports all components, ensuring stability and durability during operation in diverse terrains.

- Wheels and Tires: Designed for traction and maneuverability, these components are critical for navigating different landscapes.

- Electrical System: Powers various features, including lighting and starting mechanisms, ensuring reliability in all conditions.

Each of these parts plays a vital role in the overall functionality, making familiarity with them important for effective operation and maintenance.

Step-by-Step Repair Techniques

This section aims to provide a comprehensive guide to effectively addressing issues with agricultural machinery. By following a systematic approach, operators can enhance their understanding of various components, leading to more efficient maintenance and troubleshooting. Each step is designed to build on the previous one, ensuring a clear path to resolving common challenges.

Begin by gathering the necessary tools and equipment. Ensure that you have everything within reach to avoid interruptions during the process. This includes wrenches, screwdrivers, and diagnostic devices, all of which are crucial for effective intervention.

Next, conduct a thorough inspection of the machinery to identify visible signs of wear or malfunction. Pay close attention to belts, hoses, and fluid levels, as these are often the first indicators of potential issues. Document any findings for reference.

Once you’ve pinpointed the problem areas, consult relevant resources or guides that provide insights specific to the identified components. Familiarize yourself with the suggested procedures and safety precautions, as these will ensure a safe working environment.

Proceed with the disassembly of the affected parts, taking care to keep track of all components. Organize screws and small items systematically to avoid misplacement. This organization will facilitate a smoother reassembly process.

After addressing the necessary repairs or replacements, clean all parts thoroughly before reassembling. This step not only ensures optimal performance but also prolongs the lifespan of the machinery. Pay special attention to lubrication points as you reassemble.

Finally, conduct a comprehensive test of the machinery to confirm that all issues have been resolved. Monitor its operation for any irregularities and be prepared to make further adjustments if needed. By adhering to this structured approach, operators can maintain their equipment in peak condition, ready for the demands of agricultural work.

Maintenance Tips for Longevity

Ensuring the durability of your agricultural equipment requires consistent care and attention. By following a few essential practices, you can significantly extend the lifespan and efficiency of your machinery. Regular maintenance not only prevents unexpected breakdowns but also optimizes performance, making your investment more worthwhile.

Regular Inspection

Conducting frequent checks is vital for identifying potential issues before they escalate. Focus on the following areas during your inspections:

| Component | Inspection Frequency | Common Issues |

|---|---|---|

| Oil Levels | Every 50 hours | Low viscosity, contamination |

| Belts and Hoses | Monthly | Wear, cracks, leaks |

| Filters | Every season | Clogging, reduced airflow |

Proper Storage Practices

Storing your equipment correctly can prevent many common issues related to wear and environmental factors. Here are key storage tips:

- Keep the machinery in a sheltered area to protect it from harsh weather.

- Ensure that it is cleaned thoroughly before storage to remove dirt and debris.

- Use protective covers to guard against dust and moisture.

Tools Needed for Effective Repairs

Having the right equipment is essential for performing maintenance and restoration tasks efficiently. Proper tools not only facilitate the process but also enhance the quality of the outcome. A well-equipped workspace can make all the difference when addressing mechanical issues or performing upgrades.

| Tool | Description |

|---|---|

| Wrenches | Essential for loosening or tightening nuts and bolts. |

| Sockets | Provide better grip and leverage for various fasteners. |

| Jack Stands | Ensure safety while working under heavy equipment. |

| Screwdrivers | Vital for assembling and disassembling components. |

| Pliers | Useful for gripping, twisting, and cutting wires or small parts. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | Helps in diagnosing electrical issues by measuring voltage and resistance. |

| Grease Gun | Facilitates the application of lubricant to moving parts. |

Equipping yourself with these essential tools will streamline the process and improve your ability to address various mechanical challenges. Investing in high-quality equipment can lead to better performance and longer-lasting results.

Safety Precautions During Repairs

Ensuring a secure environment while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to safety measures not only protects the individual but also extends the lifespan of the machinery being serviced. Implementing best practices during these processes is essential for a successful outcome.

Proper Attire and Equipment

Wearing appropriate clothing is vital. Always opt for sturdy footwear and protective gear, such as gloves and safety glasses. These items provide a barrier against potential hazards, including sharp objects and chemical spills. Before beginning any task, ensure that you have all necessary tools on hand, reducing the need to reach for items while handling machinery.

Work Environment Considerations

Maintaining a tidy workspace significantly decreases the likelihood of mishaps. Remove any unnecessary items from the area, and ensure that the floor is free of debris. Adequate lighting is also essential; dimly lit areas can obscure hazards. Additionally, ensure that fire extinguishers are accessible, and always have a first-aid kit available in case of emergencies.

Resources for Troubleshooting Problems

When it comes to diagnosing issues with heavy machinery, having access to the right resources is essential. Whether you’re facing mechanical failures, electrical glitches, or performance inefficiencies, various tools and references can significantly aid in identifying and resolving these challenges. This section provides valuable information to guide you through the troubleshooting process effectively.

Online Forums and Communities

Engaging with online communities can be an invaluable resource for problem-solving. Many enthusiasts and professionals share their experiences, tips, and solutions for common issues. Websites dedicated to machinery discussions often contain threads that cover a range of topics, from minor adjustments to major overhauls.

Manufacturer Websites and Technical Bulletins

Official manufacturer websites often provide technical bulletins and updates that can clarify common issues and their fixes. Accessing these documents can help you stay informed about the latest developments and recommended practices, ensuring optimal performance and longevity of your equipment.

| Resource Type | Description |

|---|---|

| Online Forums | Platforms for discussion among users sharing troubleshooting tips and experiences. |

| Technical Bulletins | Documents from manufacturers outlining known issues and solutions. |

| Diagnostic Tools | Software and hardware designed to identify faults and performance issues. |

| Service Guides | Detailed instructions on maintenance and common repairs to aid in troubleshooting. |

When to Seek Professional Help

Understanding when to consult an expert can significantly enhance the longevity and performance of your machinery. While many tasks can be handled independently, there are specific situations that warrant professional assistance to ensure safety and efficacy.

Consider reaching out to a specialist if you encounter any of the following scenarios:

- Complex Issues: If the problem involves intricate systems or advanced technology that exceeds your expertise.

- Safety Concerns: When there is a risk of injury or damage to equipment, especially with electrical or hydraulic systems.

- Frequent Breakdowns: If equipment fails repeatedly despite your attempts to fix it, professional diagnostics may be necessary.

- Time Constraints: When you lack the time to adequately troubleshoot or perform necessary maintenance tasks.

- Warranty Considerations: If the machinery is still under warranty, repairs performed by unauthorized individuals could void it.

In these cases, enlisting the help of a qualified technician can save time, prevent further damage, and ensure that repairs are done correctly. Investing in professional services often pays off in the long run through improved reliability and performance.