Comprehensive Guide to Repairing John Deere Gator 825i

When it comes to keeping your utility vehicle in optimal condition, having a comprehensive reference is essential. This resource offers valuable insights into the essential upkeep, troubleshooting, and enhancement of your machine. Understanding how to navigate common issues can significantly prolong the lifespan of your vehicle and improve its performance.

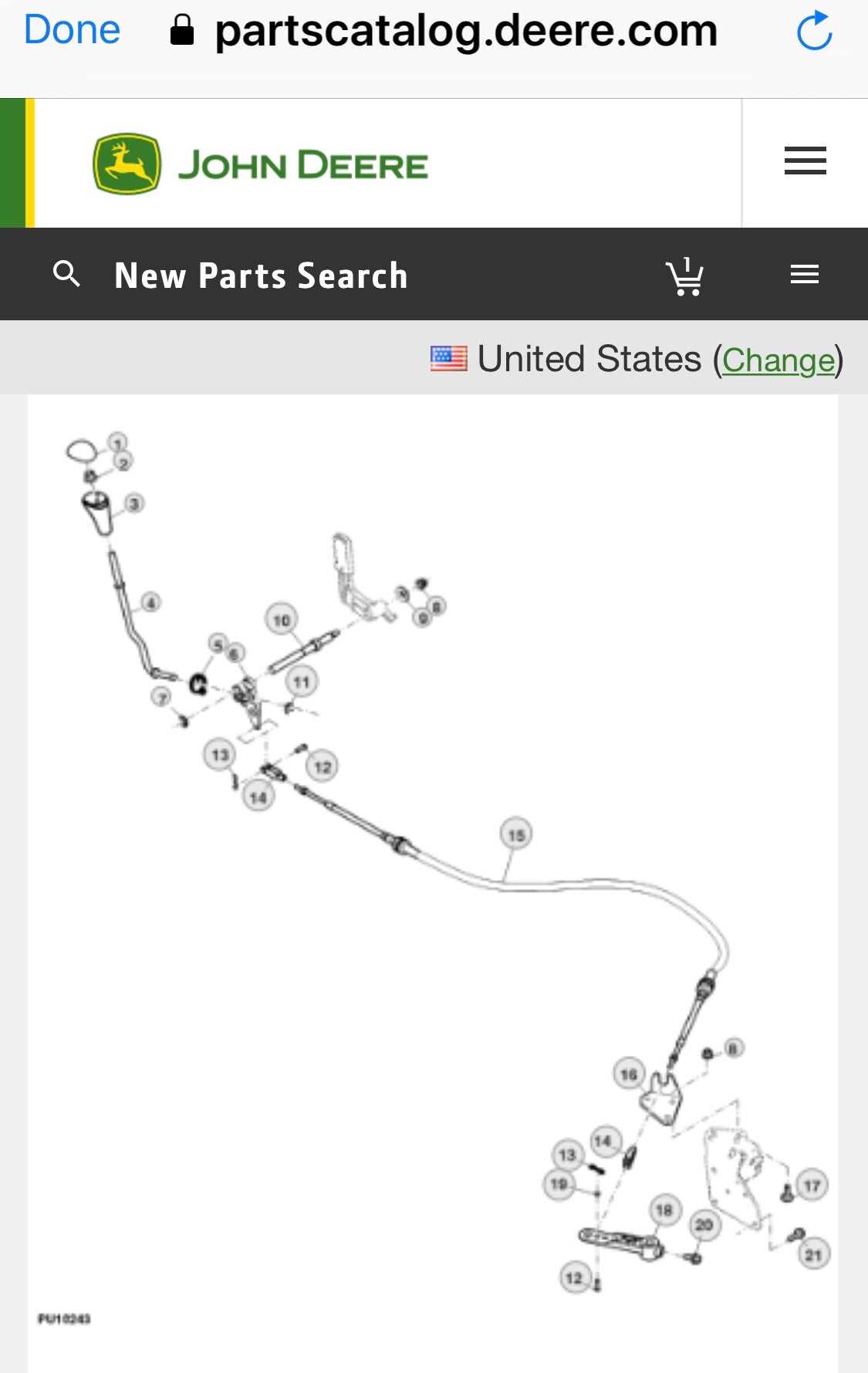

Within these pages, you will find step-by-step instructions tailored to assist users in addressing various mechanical challenges. From routine inspections to intricate repairs, the guidance provided ensures that even those with minimal experience can effectively manage their vehicle’s needs. With detailed diagrams and practical tips, maintaining efficiency becomes a manageable task.

Emphasizing the importance of regular care, this guide aims to empower operators to take control of their maintenance journey. By arming yourself with knowledge, you can ensure that your vehicle remains reliable and ready for any task, enhancing both safety and functionality on every adventure.

Overview of John Deere Gator 825i

This section provides an insight into a versatile utility vehicle designed for various tasks, from work to recreation. Known for its rugged performance and reliability, this machine is well-suited for demanding environments. It combines functionality with comfort, making it an excellent choice for both agricultural and leisure activities.

Equipped with a powerful engine, this vehicle offers impressive towing capacity and stability, enabling users to transport heavy loads with ease. Its design features a spacious cargo area, allowing for the convenient transport of tools, equipment, or recreational gear.

| Feature | Description |

|---|---|

| Engine | Robust engine that ensures high performance in various conditions. |

| Towing Capacity | Significant towing capability suitable for heavy-duty tasks. |

| Cargo Space | Ample storage area designed for versatility and ease of access. |

| Comfort | Ergonomically designed seating for a comfortable ride. |

| Terrain Capability | Ability to navigate through rough terrains with stability. |

Overall, this utility vehicle exemplifies a blend of strength and adaptability, making it an ideal companion for various outdoor and agricultural activities.

Common Issues with Gator 825i

Owning a utility vehicle can bring great convenience, but it also comes with its own set of challenges. Understanding frequent problems can help owners maintain performance and extend the lifespan of their machines. This section explores typical concerns faced by users and offers insights for troubleshooting.

Engine Performance Problems

One of the most prevalent issues is engine performance. Users often report difficulties starting the vehicle or experiencing sluggish acceleration. These symptoms can stem from fuel system malfunctions, such as clogged filters or fuel pump failures. Regular inspections and maintenance can mitigate these issues, ensuring smooth operation.

Transmission and Drive Issues

Transmission and drive-related challenges are also commonly observed. Owners may encounter difficulties with gear shifting or unusual noises while in motion. These problems could arise from worn-out components or insufficient fluid levels. Addressing these concerns promptly can prevent further damage and enhance overall functionality.

Essential Tools for Repairs

When tackling maintenance and troubleshooting tasks, having the right equipment is crucial for efficiency and effectiveness. The appropriate tools not only enhance your ability to complete tasks but also ensure safety and longevity of the machinery. Below is a curated list of must-have implements for successful maintenance endeavors.

- Wrenches: A variety of wrenches, including adjustable and socket types, are essential for loosening and tightening nuts and bolts.

- Screwdrivers: Both flathead and Phillips screwdrivers are necessary for handling various screws found in machinery.

- Pliers: These versatile tools are useful for gripping, twisting, and cutting wires or other small components.

- Torque Wrench: This tool ensures that bolts are tightened to the correct specifications, preventing damage and ensuring safety.

- Multimeter: An invaluable tool for electrical diagnostics, helping to troubleshoot wiring and electrical systems.

- Jack and Jack Stands: Essential for lifting equipment safely to access undercarriages and perform maintenance tasks.

- Toolbox: A sturdy storage solution to keep all your tools organized and easily accessible.

Having these tools on hand will streamline your maintenance processes and provide you with the confidence needed to address any issues that arise.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to keeping your utility vehicle in optimal condition. Regular upkeep not only enhances performance but also extends the lifespan of your equipment. Follow these systematic instructions to ensure every aspect of maintenance is addressed effectively.

Essential Maintenance Tasks

To maintain peak functionality, focus on the following critical areas:

| Task | Frequency | Details |

|---|---|---|

| Oil Change | Every 100 hours | Replace oil and filter to ensure proper engine lubrication. |

| Air Filter Inspection | Every 50 hours | Clean or replace air filter to maintain airflow and performance. |

| Tire Pressure Check | Monthly | Ensure tires are inflated to the recommended PSI for optimal traction. |

| Battery Maintenance | Every 6 months | Inspect battery connections and clean terminals to prevent corrosion. |

Seasonal Maintenance Tips

In addition to routine checks, pay attention to seasonal requirements to prepare your vehicle for varying conditions:

- Before winter, store in a dry place and disconnect the battery.

- In spring, inspect belts and hoses for wear and tear.

- During summer, check the cooling system for efficiency.

Electrical System Troubleshooting

Troubleshooting the electrical system of your utility vehicle involves a systematic approach to identify and resolve issues that may affect performance. Understanding the components and their interconnections is crucial for efficient diagnosis. This section provides essential guidance to help you address common electrical concerns.

Begin by inspecting the battery, as it is the heart of the electrical system. Ensure that connections are tight and free of corrosion. A multimeter can be a valuable tool to measure voltage and determine if the battery is functioning correctly. Below is a table outlining common electrical issues and potential solutions:

| Issue | Possible Cause | Solution |

|---|---|---|

| No Power | Dead Battery | Charge or replace the battery. |

| Dim Lights | Weak Battery or Bad Connection | Check battery health and clean connections. |

| Starter Won’t Engage | Faulty Starter or Relay | Test and replace starter or relay as necessary. |

| Fuses Keep Blowing | Short Circuit | Inspect wiring for damage and repair. |

By following these steps and utilizing the table as a reference, you can systematically diagnose and rectify electrical system issues, ensuring your vehicle operates reliably.

Engine Performance Enhancements

Improving the functionality and efficiency of an engine can significantly enhance overall performance. Various techniques can be employed to boost power output, increase fuel efficiency, and ensure a smoother operation. These enhancements not only elevate driving experience but also contribute to the longevity of the vehicle.

Here are some key strategies for optimizing engine performance:

- Upgrade Air Intake Systems: Installing a high-flow air filter or a cold air intake can increase airflow, resulting in better combustion and increased horsepower.

- Enhance Exhaust Flow: Replacing the stock exhaust system with a performance exhaust can reduce back pressure, allowing for a more efficient expulsion of gases.

- Tune Engine Management: Adjusting the engine’s control unit settings can optimize fuel-to-air ratios, leading to improved performance and responsiveness.

- Use Higher-Quality Fuels: Switching to premium fuels can provide more energy, enhancing engine output and efficiency.

- Regular Maintenance: Keeping the engine well-maintained by changing oil and filters regularly helps to sustain optimal performance.

Incorporating these enhancements can lead to noticeable improvements in power and efficiency, making the overall driving experience more enjoyable and effective.

Replacing the Fuel System Components

Ensuring optimal performance of your vehicle’s fuel system is crucial for maintaining efficiency and reliability. Over time, components such as fuel pumps, filters, and injectors may wear out or become clogged, necessitating their replacement. This section outlines the steps involved in replacing these essential elements, allowing for a smooth and effective process.

Tools and Materials Needed

Before beginning the replacement procedure, gather the necessary tools and materials:

- Wrenches and sockets

- Screwdrivers (flathead and Phillips)

- Replacement fuel pump

- Fuel filter

- Fuel injectors

- Fuel line connectors

- Rags or towels

- Safety goggles and gloves

Steps for Replacement

- Prepare the Vehicle: Ensure the engine is off and cool. Disconnect the battery to prevent any electrical issues.

- Drain the Fuel: Safely drain any remaining fuel from the tank to minimize spills.

- Access the Components: Depending on your model, remove any panels or covers to access the fuel system components.

- Remove Old Parts: Carefully disconnect and remove the old fuel pump, filter, and injectors. Take note of the orientation and connections for proper installation.

- Install New Components: Position the new fuel pump, filter, and injectors in their respective locations. Ensure all connections are secure.

- Reconnect the Fuel System: Attach the fuel lines and ensure there are no leaks. Double-check all connections.

- Test the System: Reconnect the battery and start the engine. Monitor for proper operation and any signs of leakage.

Following these steps will help ensure your vehicle’s fuel system is functioning optimally, enhancing overall performance and reliability.

Upgrading Suspension and Tires

Enhancing the suspension and tires of your utility vehicle can significantly improve its performance, handling, and comfort. By investing in high-quality components, you can achieve a smoother ride, better traction, and increased stability across various terrains. This upgrade not only boosts the vehicle’s capabilities but also prolongs its lifespan, making it a worthwhile consideration for any enthusiast.

Choosing the Right Suspension Components

When selecting suspension upgrades, consider options that offer adjustable settings for ride height and stiffness. Upgraded shocks can provide improved damping, while coil springs designed for off-road conditions can enhance overall handling. Look for kits that are compatible with your model to ensure a seamless installation and optimal performance.

Selecting Tires for Optimal Performance

Choosing the right tires is crucial for achieving the best performance in various conditions. Opt for all-terrain tires that provide excellent grip on both muddy and rocky surfaces. Consider the tread pattern, which should offer a balance between traction and durability. Additionally, pay attention to the size; larger tires can improve ground clearance, but make sure they fit within the vehicle’s wheel wells without causing rubbing.

By carefully selecting and installing high-quality suspension and tire upgrades, you can transform your vehicle into a more capable and enjoyable machine for any adventure.

Cooling System Checks and Fixes

The efficiency of any vehicle largely depends on its cooling mechanism, which prevents overheating and ensures optimal performance. Regular inspection and maintenance of this system are crucial for longevity and reliability. Below are some essential checks and solutions for common issues that may arise within the cooling setup.

- Fluid Levels:

Start by checking the coolant level in the reservoir. Low fluid can lead to overheating. Top it up with the appropriate mixture if necessary.

- Leaks:

Inspect hoses and connections for any signs of leakage. Look for wet spots or puddles beneath the vehicle. Tightening loose connections or replacing damaged hoses may resolve this issue.

- Radiator Condition:

Examine the radiator for blockages, corrosion, or damage. Cleaning the exterior and ensuring the fins are not bent can improve airflow. If significant damage is found, replacement might be necessary.

- Thermostat Functionality:

Check the thermostat for proper operation. If the engine is running too hot or not reaching the optimal temperature, replacing the thermostat could be the solution.

- Fan Operation:

Ensure that the cooling fan engages when needed. A malfunctioning fan can lead to overheating, so testing its operation and replacing it if necessary is vital.

By regularly conducting these checks and addressing issues promptly, you can maintain an effective cooling system, ensuring your vehicle operates smoothly and efficiently.

Transmission Repair Techniques

Maintaining the functionality of a vehicle’s transmission is crucial for optimal performance and longevity. Understanding various methods for addressing common issues can significantly enhance reliability. This section outlines essential approaches and practices for effectively managing transmission challenges.

Common Issues and Diagnostics

- Unresponsive shifting

- Slipping gears

- Fluid leaks

- Strange noises during operation

Identifying symptoms is the first step toward resolving transmission difficulties. Utilizing diagnostic tools and performing thorough inspections will aid in pinpointing the source of problems.

Repair Techniques

- Fluid Change: Regularly replacing transmission fluid ensures optimal lubrication and cooling.

- Filter Replacement: Changing the filter prevents contaminants from damaging internal components.

- Seal Repair: Addressing leaks by replacing worn seals is essential for maintaining fluid levels.

- Component Inspection: Regular checks on gears, clutches, and bands help identify wear before it leads to significant issues.

By employing these techniques, operators can enhance transmission performance and extend the lifespan of their vehicles, ensuring reliable service in various conditions.

Body and Frame Restoration Tips

Restoring the body and structure of utility vehicles can significantly enhance their longevity and performance. This process not only improves aesthetics but also ensures safety and functionality. Here are some effective strategies to guide you through the restoration journey.

- Assess Damage: Before starting, thoroughly inspect the body and frame for dents, rust, and structural integrity. Make a list of areas needing attention.

- Gather Tools: Ensure you have the necessary tools on hand, including wrenches, screwdrivers, hammers, and sanders. Proper equipment simplifies the restoration process.

- Rust Treatment: Address any rust spots immediately. Use a wire brush to remove loose rust, then apply a rust inhibitor to prevent future corrosion.

- Frame Reinforcement: For frames with significant wear, consider reinforcing weak spots with additional metal plates or welding to improve durability.

Following these initial steps can set the foundation for a successful restoration project. As you progress, keep in mind the importance of patience and attention to detail.

- Painting: After repairs, clean the surface thoroughly before applying a primer. Choose a high-quality paint suitable for vehicles to ensure a long-lasting finish.

- Sealants: Apply sealants to vulnerable joints and seams to protect against moisture and debris, which can lead to deterioration over time.

- Final Inspection: Once the restoration is complete, conduct a comprehensive inspection to ensure all components are securely fitted and functioning properly.

Implementing these restoration tips can help maintain the utility vehicle in optimal condition, providing reliable service for years to come.

Utilizing the Repair Manual Effectively

Maximizing the benefits of a maintenance guide is essential for anyone looking to enhance the longevity and performance of their utility vehicle. By leveraging the comprehensive information provided, users can efficiently troubleshoot issues, perform routine upkeep, and tackle complex repairs with confidence.

To make the most of the resource, consider the following strategies:

- Familiarize Yourself with the Layout: Understand how the guide is organized. Knowing where to find specific sections can save time and reduce frustration.

- Utilize Visual Aids: Pay attention to diagrams and illustrations. They often provide crucial insights that written instructions may not fully convey.

- Follow Step-by-Step Instructions: Adhere closely to the outlined procedures. Skipping steps can lead to mistakes or further complications.

- Refer to the Troubleshooting Section: When faced with problems, consult the troubleshooting guide for quick solutions and diagnostic tips.

- Keep the Manual Accessible: Whether in print or digital form, having the guide within reach during maintenance activities can streamline the process.

By integrating these practices, users can effectively utilize the maintenance guide, ensuring their vehicle remains in peak condition and performs reliably over time.

Best Practices for Regular Maintenance

Maintaining your utility vehicle is essential for ensuring its longevity and optimal performance. Regular upkeep not only prevents unexpected breakdowns but also enhances safety and efficiency. By following a systematic approach, you can keep your machine in top condition and ready for any task.

Start with routine inspections to identify any signs of wear or damage. Check fluid levels, including oil, coolant, and fuel, ensuring they are at appropriate levels. Inspect the tires for proper inflation and tread wear, as well as the brakes and lights for functionality. Keeping a maintenance log can help track these checks and any repairs performed.

Cleaning is another critical aspect of upkeep. Regularly wash the exterior to remove dirt and debris that could lead to corrosion. Pay special attention to the undercarriage, where mud and grime can accumulate. Additionally, inspect and clean the air filter to maintain optimal engine performance.

Lubrication is vital for moving parts to function smoothly. Apply lubricant to joints and bearings as recommended in the guidelines. This practice reduces friction and prolongs the life of components.

Finally, adhere to the manufacturer’s recommendations for scheduled service intervals. This includes changing the oil and filters, inspecting belts and hoses, and addressing any specific needs unique to your vehicle. Staying proactive with these practices will ensure your utility vehicle remains reliable for years to come.