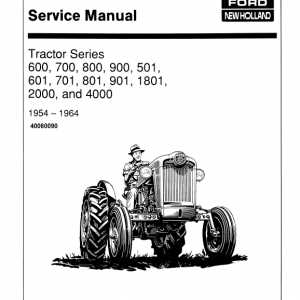

Comprehensive Guide to Repairing the Ford 1715 Tractor

The intricacies of maintaining essential farming equipment are vital for optimal performance and longevity. Understanding the components and systems that keep these machines operational can significantly impact productivity in agricultural practices. This section delves into the nuances of upkeep and troubleshooting for various models in this category.

Proper knowledge and techniques can prevent minor issues from escalating into major failures. With a focus on practical advice, this guide provides insights into systematic approaches for ensuring that your machinery remains in top condition. Whether you are a seasoned operator or a newcomer, the information presented here aims to empower you with the skills needed to manage maintenance effectively.

Emphasizing the importance of routine checks, this resource also highlights common problems and their solutions, enabling you to respond swiftly to potential setbacks. By familiarizing yourself with these practices, you can ensure that your equipment not only performs well but also supports your agricultural endeavors for years to come.

Overview of Ford 1715 Tractor

This section provides a comprehensive look at a popular piece of agricultural equipment known for its reliability and versatility. The machine is designed to handle various tasks, making it an essential tool for many farming operations. Understanding its features and capabilities can greatly enhance its effectiveness in the field.

Key Features

The equipment boasts a robust engine that delivers impressive power while maintaining fuel efficiency. Its compact design allows for maneuverability in tight spaces, making it suitable for various applications, from tilling to transporting goods. Additionally, the intuitive controls and user-friendly interface facilitate ease of operation, ensuring that even less experienced operators can work efficiently.

Maintenance Considerations

Regular upkeep is crucial to ensure longevity and optimal performance. Simple checks and routine servicing can prevent significant issues down the line. Familiarity with common maintenance tasks, such as oil changes and filter replacements, can save time and resources. It is advisable to consult specific guidelines tailored to this model for the best practices.

Common Issues Faced by Owners

Many individuals encounter a range of challenges when maintaining their agricultural machinery. Understanding these frequent problems can significantly aid in troubleshooting and prolonging the life of the equipment. Common concerns often revolve around performance, efficiency, and mechanical failures.

One prevalent issue involves starting difficulties, which can stem from battery malfunctions or fuel system blockages. Owners may also notice irregular operation, such as stalling or poor acceleration, often attributed to clogged filters or ignition system failures. Additionally, hydraulic system leaks can cause substantial operational setbacks, leading to decreased functionality and potential damage.

Regular maintenance neglect is another factor that can exacerbate these issues. Without timely servicing, components may wear out prematurely, resulting in costly repairs. Addressing these common problems promptly not only ensures smoother operation but also enhances the longevity of the machinery.

Essential Tools for Repairs

Having the right equipment is crucial for effective maintenance and troubleshooting of machinery. A well-equipped toolkit not only enhances efficiency but also ensures that tasks are completed safely and correctly. Understanding which instruments are necessary can significantly ease the process of restoration and upkeep.

Basic Hand Tools are fundamental for any repair task. Items such as wrenches, pliers, and screwdrivers form the backbone of any toolkit. These tools allow for the loosening and tightening of various components, making them indispensable for everyday fixes.

Specialized Instruments may also be required for specific tasks. For instance, torque wrenches ensure that bolts are tightened to the correct specifications, while diagnostic tools can help identify issues with electrical systems. Investing in these specialized devices can save time and prevent future complications.

Safety Equipment should never be overlooked. Protective goggles, gloves, and ear protection are essential to safeguard against potential hazards during maintenance work. Prioritizing safety not only protects the individual but also promotes a responsible working environment.

In summary, assembling a comprehensive collection of tools and safety gear is vital for successful machinery maintenance. Being prepared with the right equipment not only streamlines the repair process but also enhances overall performance and longevity of the equipment.

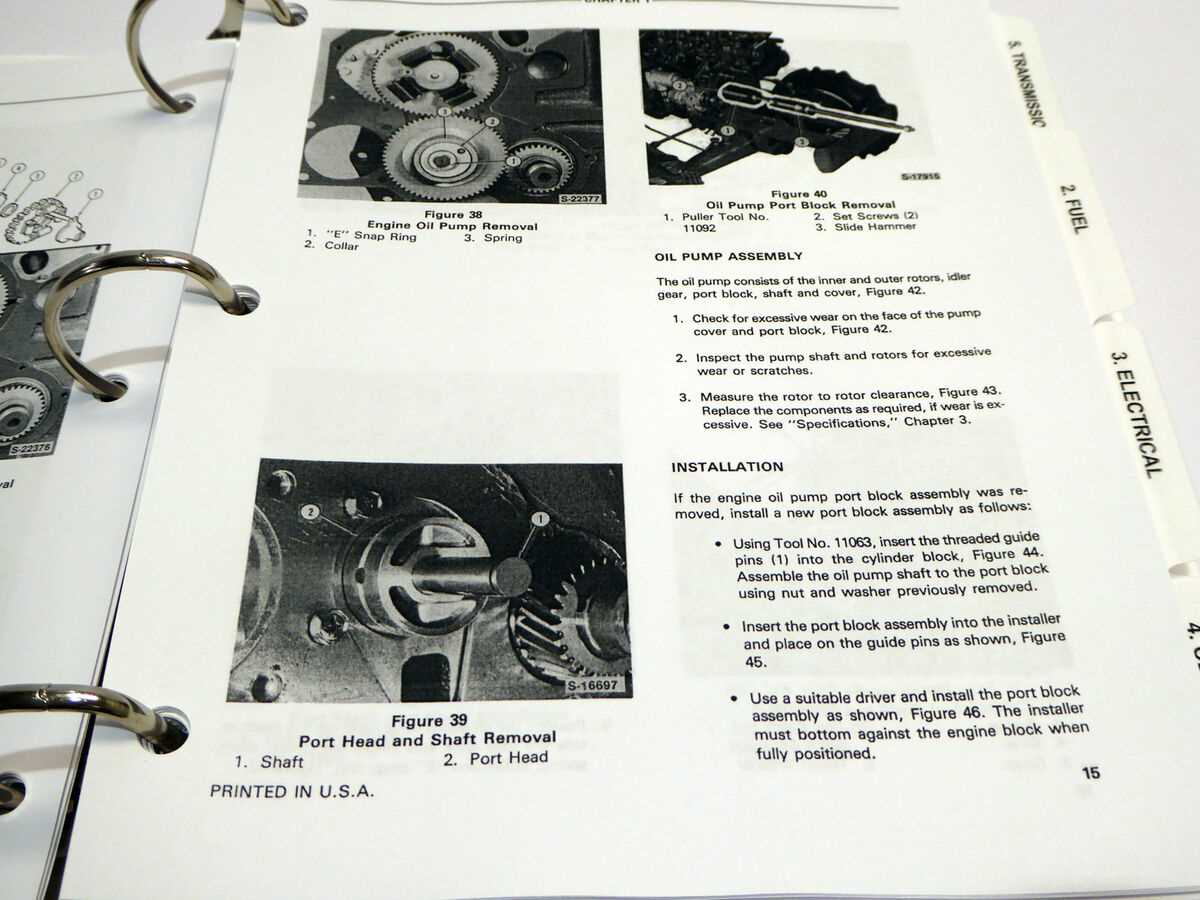

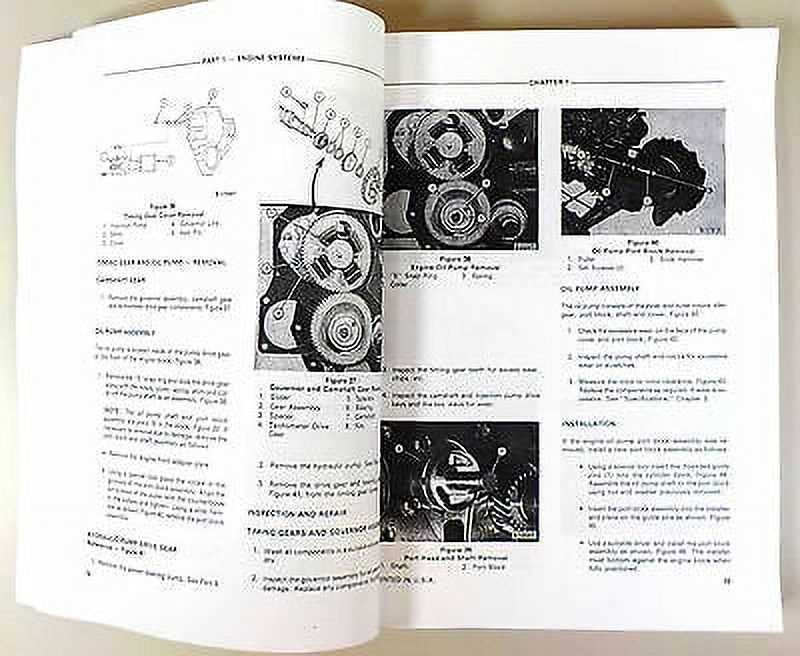

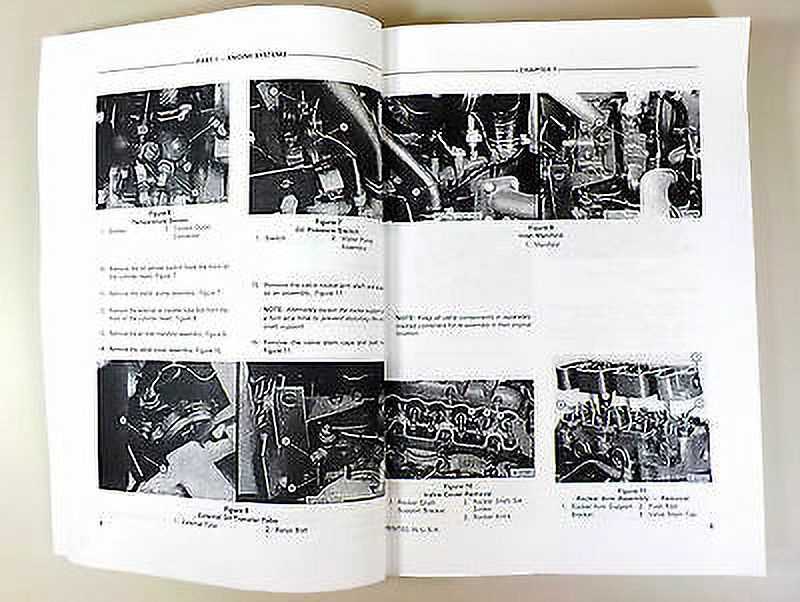

Engine Maintenance Procedures

Regular upkeep of the engine is essential for ensuring optimal performance and longevity. Implementing a systematic approach to maintenance can prevent unexpected failures and costly repairs. Below are key procedures to maintain engine health effectively.

- Oil Changes:

- Check the oil level regularly using the dipstick.

- Change the oil based on manufacturer recommendations or every 100 hours of operation.

- Replace the oil filter during oil changes to ensure clean oil circulation.

- Cooling System Maintenance:

- Inspect coolant levels frequently and top off as necessary.

- Flush the cooling system annually to remove debris and prevent overheating.

- Check hoses and connections for leaks or wear and replace if needed.

- Air Filter Inspection:

- Examine the air filter regularly for dirt and blockages.

- Clean or replace the filter based on usage and environmental conditions.

- Ensure proper sealing to prevent unfiltered air from entering the engine.

- Fuel System Care:

- Keep the fuel tank clean and free from contaminants.

- Use high-quality fuel to reduce the risk of deposits forming.

- Replace the fuel filter as per the maintenance schedule.

- Belt and Hose Checks:

- Inspect belts for cracks or fraying and replace if necessary.

- Check hoses for signs of wear, leaks, or bulges.

- Ensure all connections are secure and tight.

Adhering to these procedures will enhance engine reliability and efficiency, ultimately contributing to better performance and reduced downtime.

Hydraulic System Troubleshooting

Troubleshooting a hydraulic system involves identifying and resolving issues that affect performance and efficiency. Understanding the common symptoms and causes can significantly enhance the troubleshooting process, leading to effective solutions and improved functionality.

Common Symptoms

Several indicators may suggest that the hydraulic system is not functioning correctly. These can include:

- Loss of power: Inadequate lifting or pushing force.

- Unusual noises: Grinding or whining sounds during operation.

- Fluid leaks: Visible signs of hydraulic fluid escaping from connections or components.

Troubleshooting Steps

To address the identified symptoms, follow these troubleshooting steps:

- Check fluid levels: Ensure that the hydraulic fluid is at the recommended level, as low fluid can cause a multitude of issues.

- Inspect hoses and fittings: Look for cracks, wear, or loose connections that may lead to leaks.

- Examine filters: Clogged filters can restrict fluid flow, leading to poor system performance. Replace if necessary.

- Test pressure: Use a gauge to check system pressure against manufacturer specifications.

By systematically following these steps, operators can efficiently identify and rectify issues within the hydraulic system, ensuring optimal performance and longevity.

Electrical Components Inspection Guide

Proper examination of electrical components is crucial for ensuring optimal performance and longevity of machinery. Regular inspections help identify potential issues before they escalate, enhancing both safety and efficiency. This guide outlines the essential steps for assessing the electrical systems effectively.

Preparation for Inspection

Before beginning the inspection, gather the necessary tools and equipment:

- Multimeter

- Wrenches

- Wire strippers

- Safety gloves and goggles

- Flashlight

Ensure that the equipment is powered off and disconnected from any power source to prevent accidents.

Steps for Inspection

- Visual Examination: Check for any signs of wear, corrosion, or damage on wires and connectors.

- Testing Connections: Use a multimeter to test voltage levels at various points. Ensure that connections are secure and free from debris.

- Assessing Components: Inspect fuses, relays, and switches for proper operation. Replace any faulty parts as necessary.

- Insulation Check: Examine wire insulation for cracks or deterioration, which could lead to short circuits.

- Ground Connections: Ensure that all ground connections are tight and free from rust or dirt.

Following these steps will help maintain the electrical integrity of the equipment, promoting safe and reliable operation.

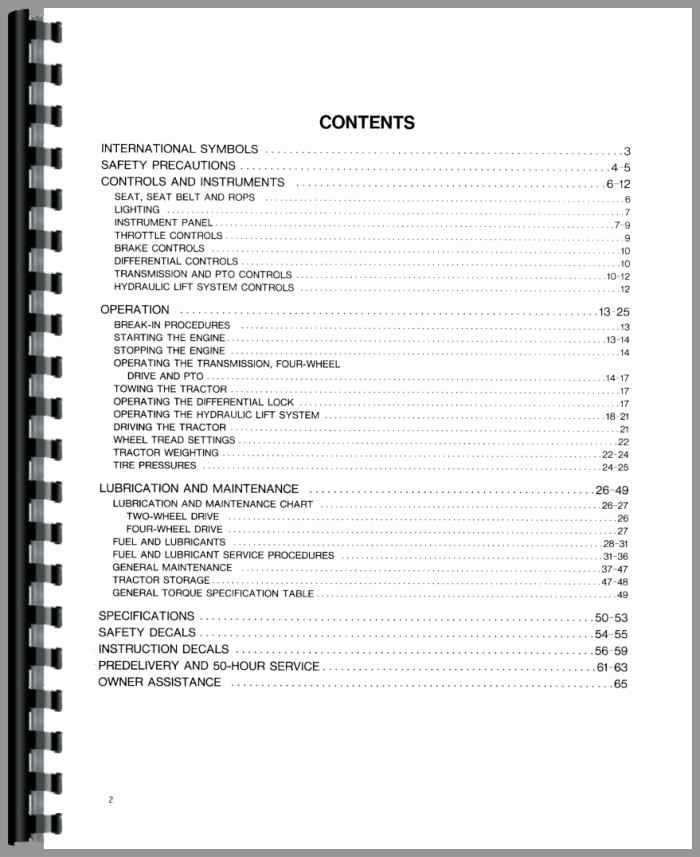

Transmission Fluid Change Steps

Changing the hydraulic fluid in your equipment is essential for maintaining optimal performance and prolonging its lifespan. This procedure involves draining the old fluid, replacing it with new, and ensuring that all components are functioning correctly. Follow these systematic steps to ensure a successful fluid change.

Tools and Materials Needed

| Item | Purpose |

|---|---|

| Drain Pan | To collect old fluid |

| Socket Set | For removing bolts |

| New Fluid | To refill the system |

| Funnel | To avoid spills during filling |

| Rags | For cleaning up spills |

Step-by-Step Process

1. Start by parking the machine on a level surface and engaging the parking brake. This ensures safety during the fluid change.

2. Locate the drain plug, typically found at the lowest point of the system. Use the appropriate socket to remove the plug, allowing the old fluid to drain completely into the pan.

3. Once drained, inspect the drain plug and replace it if necessary. Clean the area around the plug to prevent contamination.

4. Refill the system with new hydraulic fluid using a funnel. Refer to the manufacturer’s specifications for the correct type and amount of fluid.

5. After filling, run the machine for a few minutes to circulate the new fluid. This helps to ensure that the fluid reaches all components.

6. Finally, check the fluid level and top off if necessary, then secure all plugs and clean up any spills.

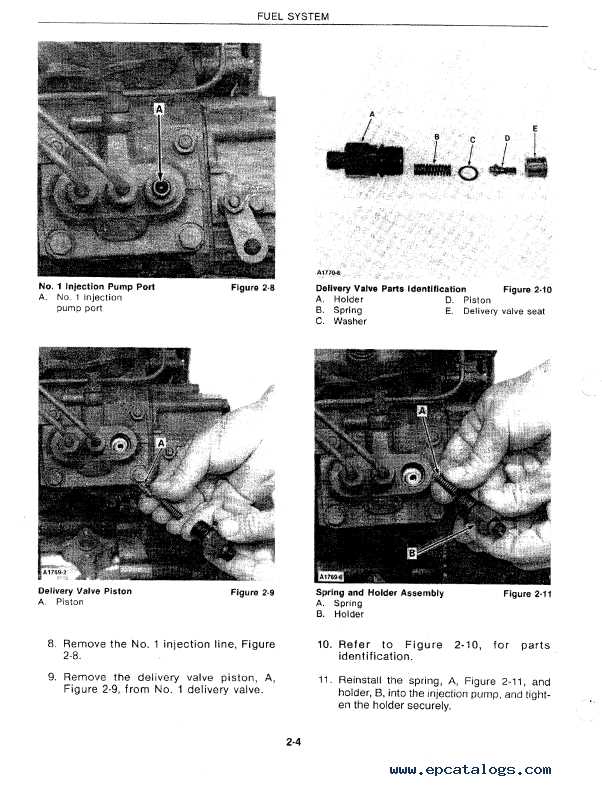

Fuel System Cleaning Techniques

Maintaining the cleanliness of a fuel system is crucial for optimal engine performance. Regular cleaning can prevent buildup and ensure that fuel flows freely through the various components. Various methods exist for achieving this, each with its own benefits and procedures. Understanding these techniques can help enhance the longevity and efficiency of the engine.

| Technique | Description | Benefits |

|---|---|---|

| Chemical Cleaning | Using specialized cleaning solutions to dissolve deposits. | Effective for removing stubborn contaminants. |

| Ultrasonic Cleaning | Employing ultrasonic waves in a cleaning solution to agitate and dislodge impurities. | Thorough and uniform cleaning of intricate parts. |

| Physical Inspection | Manually inspecting and cleaning fuel lines and filters. | Identifies potential issues and ensures clear pathways. |

| Pressure Flushing | Using pressurized fluid to clear obstructions in the system. | Quick and effective for removing loose debris. |

By implementing these techniques regularly, one can maintain an efficient fuel system that promotes smooth operation and extends the lifespan of the engine components.

Replacing Tires and Wheels

Maintaining optimal performance and safety requires periodic changes of the rubber components and rims. This process is crucial for ensuring proper traction, stability, and overall efficiency. Understanding the steps involved can help you execute the task with confidence and precision.

Preparation is key before beginning the replacement. Make sure you have the necessary tools at hand, including a jack, lug wrench, and new tires and wheels. Additionally, ensure that the work area is level and free of obstructions to prevent accidents.

To start, raise the vehicle using the jack, ensuring it is securely supported. Remove the lug nuts with the wrench in a star pattern to prevent warping of the rim. Carefully detach the old wheel and tire assembly, paying attention to any attached components that may need to be reattached later.

Once the old assembly is removed, it’s time to install the new tire and wheel. Align the holes of the rim with the hub, then gently slide it into place. Hand-tighten the lug nuts before lowering the vehicle back to the ground.

Finally, tighten the lug nuts securely, again using the star pattern. It is recommended to check the pressure of the new tires to ensure they are inflated to the manufacturer’s specifications. Regularly inspecting and maintaining your wheels will enhance longevity and performance.

Maintaining the Cooling System

The cooling system plays a vital role in ensuring optimal performance and longevity of your machinery. Regular upkeep is essential to prevent overheating and maintain efficient operation. Here are key aspects to consider for effective maintenance.

- Regular Fluid Checks: Monitor coolant levels consistently. Ensure that the mixture is appropriate for the operating conditions.

- Inspect Hoses and Clamps: Look for signs of wear, cracking, or leaks. Replace any damaged components promptly to avoid fluid loss.

- Clean Radiator: Remove debris and dirt from the radiator fins to ensure proper airflow. A clean radiator enhances cooling efficiency.

- Flush System Periodically: Conduct a complete flush to remove old coolant and contaminants. This should be done according to the manufacturer’s recommendations.

- Thermostat Functionality: Test the thermostat regularly to ensure it opens and closes at the correct temperatures, preventing overheating.

- Check Water Pump: Inspect for leaks or noise, as these can indicate failure. A functioning water pump is critical for circulation.

By following these steps, you can ensure that the cooling mechanism remains in optimal condition, ultimately enhancing the performance and reliability of your equipment.

Brake System Repair Tips

Ensuring optimal performance of your stopping mechanism is crucial for safety and efficiency. Regular maintenance and timely interventions can significantly enhance the functionality and longevity of this vital system. Below are essential suggestions to help you address common issues effectively.

Common Issues and Solutions

| Issue | Possible Causes | Suggested Solutions |

|---|---|---|

| Fading Brakes | Overheating, worn pads | Check for proper ventilation, replace pads |

| Noisy Brakes | Dirt accumulation, worn components | Clean system, inspect and replace parts |

| Pulling to One Side | Uneven wear, misaligned components | Inspect alignment, replace worn pads |

| Fluid Leaks | Deteriorated seals, loose fittings | Check and tighten connections, replace seals |

Maintenance Best Practices

Routine inspections are key to identifying potential concerns before they escalate. Regularly check the fluid levels and replace them as necessary to maintain effectiveness. Additionally, ensure all components are free from debris and corrosion, which can hinder performance.

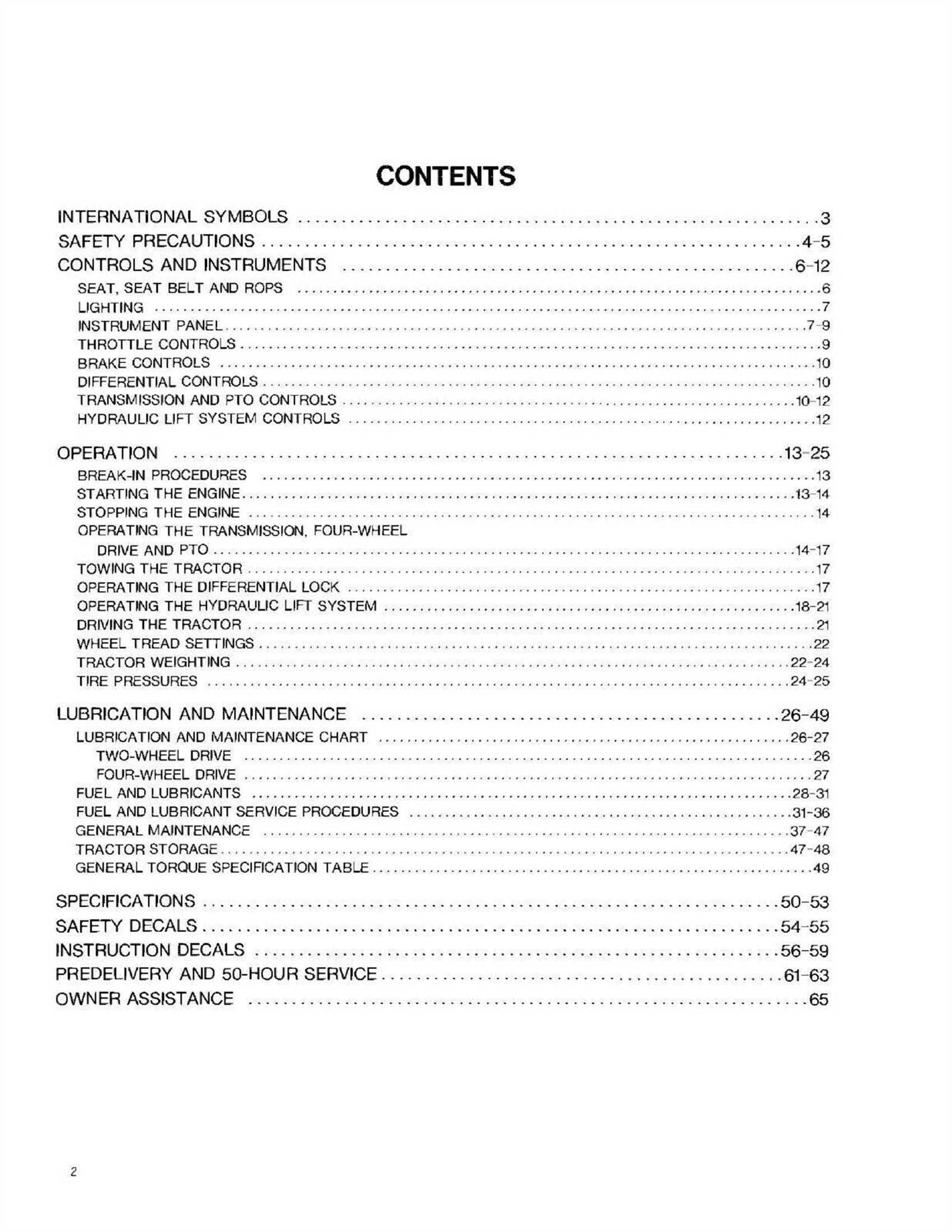

Seasonal Maintenance Checklist

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment throughout the year. By adhering to a seasonal maintenance schedule, you can prevent unexpected breakdowns and enhance overall efficiency. Below is a comprehensive checklist tailored to seasonal requirements.

Spring Maintenance

- Inspect and replace air filters if necessary.

- Check fluid levels and top off hydraulic fluid, engine oil, and coolant.

- Examine tires for wear and correct inflation pressure.

- Clean and lubricate all moving parts to ensure smooth operation.

- Test the battery and clean terminals to prevent corrosion.

Summer Maintenance

- Monitor coolant levels and inspect for leaks.

- Check belts and hoses for signs of wear or damage.

- Ensure that the cooling system is functioning effectively.

- Keep the exterior clean to prevent rust and corrosion.

- Verify that safety features are in working order.

Autumn Maintenance

- Change the engine oil and replace the oil filter.

- Inspect the ignition system and replace spark plugs if necessary.

- Clear any debris from air intakes and exhaust systems.

- Prepare for storage by cleaning and covering the equipment.

- Check and tighten all fasteners and connections.

Winter Maintenance

- Store in a dry place to prevent moisture buildup.

- Disconnect the battery to avoid drainage.

- Apply protective coatings to metal surfaces.

- Inspect and replace any damaged or worn parts.

- Review maintenance logs and plan for the upcoming season.

Following this seasonal checklist will help ensure that your machinery remains in peak condition, ready to tackle any task as the seasons change.

Finding Replacement Parts Easily

Locating suitable components for your machinery can be a straightforward process if you know where to look. With the right resources and strategies, you can ensure that you find high-quality parts that meet your specific needs.

Here are some effective methods to consider:

- Online Retailers: Many websites specialize in machinery parts. They often provide detailed descriptions and customer reviews.

- Local Dealers: Visiting local suppliers can give you immediate access to parts, along with expert advice.

- Salvage Yards: These can be a goldmine for hard-to-find items at a fraction of the cost.

- Manufacturer’s Websites: Often, the original makers will have a parts section where you can order directly.

Additionally, consider joining online forums or communities where enthusiasts share their experiences. This can lead to valuable recommendations and tips on sourcing parts effectively.

Finally, always keep a record of the part numbers you need. This can simplify the search process, whether you’re browsing online or speaking to a dealer.