Comprehensive Guide to Repairing Your John Deere Riding Mower

Proper upkeep of outdoor machinery is crucial for optimal performance and longevity. When issues arise, having access to comprehensive resources can make all the difference. This guide serves as a vital tool for enthusiasts and professionals alike, offering insights into troubleshooting and maintaining your equipment efficiently.

Understanding your machinery involves familiarizing yourself with its components and functions. Whether you are facing minor inconveniences or major malfunctions, knowing how to address these challenges can enhance your overall experience. This resource aims to empower users with knowledge, ensuring they can handle repairs and maintenance confidently.

In the following sections, we will delve into common issues, maintenance tips, and detailed instructions to keep your equipment running smoothly. With the right approach, even the most daunting tasks can be managed effectively, allowing you to enjoy your outdoor spaces to the fullest.

Understanding John Deere Riding Mowers

This section delves into the essential characteristics and functionalities of a popular type of lawn care equipment. Knowing how these machines operate and the components involved can significantly enhance your experience and maintenance efforts.

Key Features

- Durable construction designed for longevity.

- User-friendly controls for ease of operation.

- Variety of cutting widths to suit different yard sizes.

- Powerful engines providing efficient performance.

- Advanced technology for better handling and comfort.

Common Components

- Engine: The heart of the machine, providing the necessary power.

- Deck: The part that houses the cutting blades, crucial for achieving an even cut.

- Transmission: Responsible for power transfer, allowing for different speed settings.

- Wheels: Designed for stability and traction on various terrains.

- Controls: Interface for the operator to adjust settings and maneuver effectively.

Common Issues with Riding Mowers

When maintaining your outdoor equipment, it’s essential to recognize the frequent challenges that can arise during operation. Identifying these problems early can save time and effort, ensuring that your machinery runs smoothly throughout the season.

Engine Problems

One of the most prevalent issues involves the engine, which may not start due to fuel supply problems or battery failures. Additionally, irregular engine performance can stem from clogged air filters or spark plug malfunctions. Regular maintenance checks can help mitigate these concerns.

Transmission Difficulties

Transmission troubles often manifest as difficulty in shifting gears or a complete inability to move. These issues may arise from low fluid levels or worn components. Ensuring proper lubrication and timely replacements can greatly enhance functionality and prolong the life of the equipment.

Essential Tools for Repairs

Having the right instruments at your disposal is crucial for successful maintenance tasks. These implements not only streamline the process but also enhance efficiency and safety. Understanding what tools are necessary can make any undertaking significantly easier and more effective.

Basic Hand Tools

Every enthusiast should possess a set of fundamental hand tools. Wrenches, screwdrivers, and pliers are indispensable for various adjustments and fixes. Socket sets are also vital for accessing hard-to-reach fasteners.

Power Equipment

For more extensive work, power tools can be a game changer. Drills and impact wrenches save time and effort, while grinders are perfect for shaping and smoothing components. Investing in quality equipment will ultimately enhance your capability to tackle any challenge.

Step-by-Step Maintenance Guide

Proper upkeep of your outdoor equipment is essential for optimal performance and longevity. This comprehensive guide provides a structured approach to ensure your machine remains in top condition throughout its lifespan.

1. Regular Cleaning: Begin by removing dirt and debris from the exterior and undercarriage. Use a soft brush or cloth to avoid scratching surfaces. A clean machine not only looks better but also functions more efficiently.

2. Check Fluid Levels: Inspect all essential fluids, including oil, fuel, and coolant. Maintaining proper levels ensures smooth operation and prevents potential damage. Always refer to the specifications for the correct types and amounts.

3. Blade Maintenance: Inspect blades for sharpness and damage. Dull blades can lead to uneven cutting and strain the engine. Sharpen or replace blades as necessary to maintain cutting performance.

4. Battery Care: Keep the battery terminals clean and free of corrosion. Ensure a secure connection and check the charge level regularly. Replace the battery as needed to avoid starting issues.

5. Tire Pressure: Regularly check the pressure in all tires to ensure stability and control. Proper inflation enhances traction and prolongs tire life. Adjust pressure according to the manufacturer’s recommendations.

6. Seasonal Checks: Before and after each season, perform a thorough inspection. This includes checking belts, cables, and filters. Addressing minor issues early can prevent larger problems later on.

7. Storage Tips: If storing for an extended period, ensure the machine is cleaned, serviced, and stored in a dry location. Use a cover to protect it from dust and moisture.

Following these steps will help maintain your equipment in peak condition, ensuring reliable performance and extending its service life.

Troubleshooting Engine Problems

Identifying and resolving issues related to the power unit can significantly enhance performance and prolong the lifespan of your equipment. Addressing these challenges requires a systematic approach to isolate the root cause of the malfunction. Below are some common problems and their potential solutions.

- Engine Won’t Start

- Check the fuel level and ensure there is a sufficient supply.

- Inspect the battery connections for corrosion or loose wires.

- Examine the ignition system for faulty spark plugs or wires.

- Rough Idle

- Ensure the air filter is clean and unobstructed.

- Inspect the fuel lines for clogs or leaks.

- Verify that the carburetor is functioning properly and is not dirty.

- Overheating

- Check the coolant levels and add if necessary.

- Inspect the radiator for blockages or damage.

- Examine the fan and belt for proper operation.

- Excessive Vibration

- Ensure all bolts and screws are tightened securely.

- Inspect the blades for damage or imbalance.

- Check for any loose components in the engine compartment.

By following these steps, you can effectively diagnose and address engine-related issues, ensuring optimal functionality and reliability. Regular maintenance is key to preventing future complications.

Repairing the Cutting Deck

The cutting assembly of any lawn maintenance machine is essential for achieving a clean and efficient finish. Over time, wear and tear can lead to decreased performance, necessitating attention to various components to ensure optimal functionality. This section provides an overview of common issues and maintenance practices to restore the cutting platform to its prime condition.

Before starting any work, it is crucial to gather the necessary tools and materials. Here’s a quick reference table to help you prepare:

| Tool/Material | Purpose |

|---|---|

| Wrench Set | To loosen and tighten bolts |

| Screwdriver | For adjusting screws and fasteners |

| Replacement Blades | To ensure effective cutting |

| Lubricant | To reduce friction in moving parts |

| Cleaning Brush | To remove debris and buildup |

Regular inspection of the cutting apparatus is vital. Look for signs of damage or excessive wear on blades, belts, and other attachments. A well-maintained deck not only enhances performance but also prolongs the lifespan of the entire unit. If issues are identified, it’s important to address them promptly, following the manufacturer’s guidelines for replacement or adjustment.

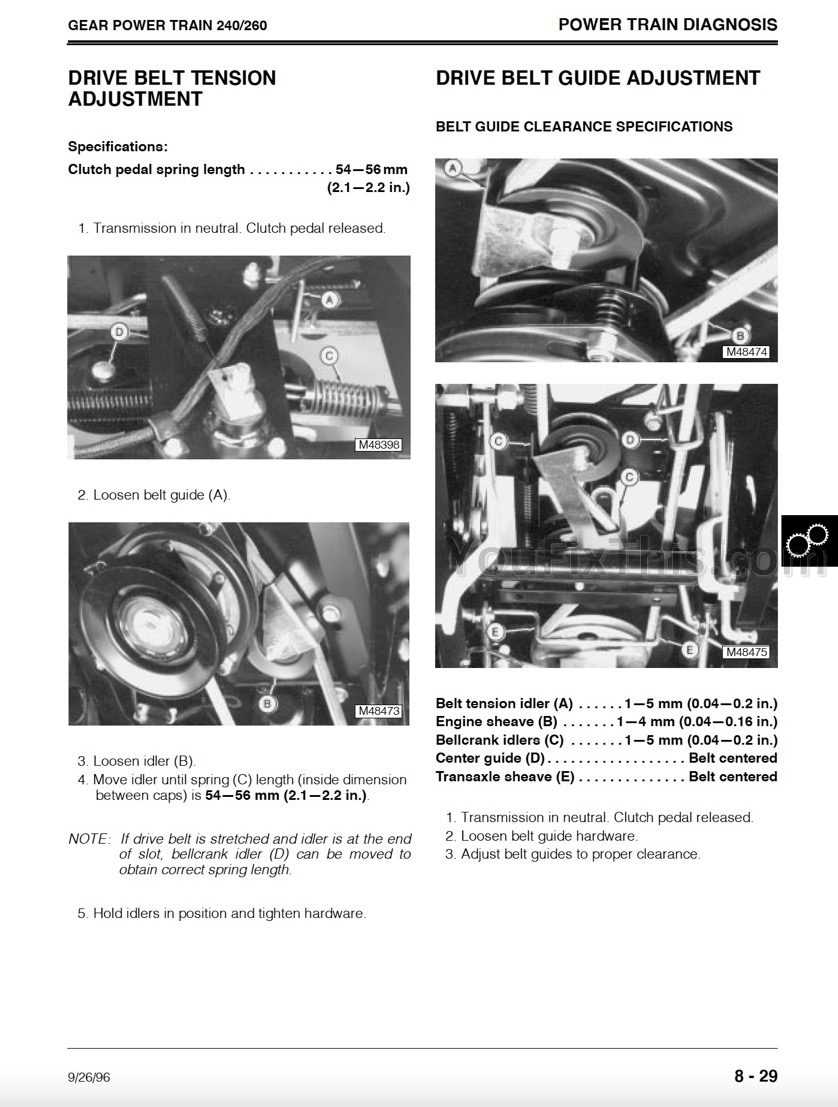

Adjusting the Drive System

Ensuring the optimal performance of the drive mechanism is essential for smooth operation. Proper adjustments can enhance efficiency, extend the lifespan of components, and provide a more enjoyable experience. This section covers the key steps involved in fine-tuning the drive system for peak functionality.

Understanding the Components

Before proceeding with adjustments, it is important to familiarize yourself with the main elements of the drive system:

- Transmission unit

- Belts and pulleys

- Drive wheels

- Throttle control

Adjustment Steps

Follow these steps to ensure proper alignment and performance of the drive system:

- Check Belt Tension: Inspect the belts for any signs of wear or looseness. Adjust the tension according to manufacturer specifications.

- Align Pulleys: Ensure that the pulleys are aligned properly. Misalignment can cause excessive wear and reduce efficiency.

- Inspect Drive Wheels: Examine the drive wheels for damage and ensure they are securely attached. Replace if necessary.

- Test Throttle Response: Verify that the throttle control is functioning correctly and making smooth adjustments to speed.

- Perform a Test Run: After making adjustments, conduct a test run to check for any irregularities in operation.

Regular maintenance and timely adjustments can significantly enhance the performance and reliability of the drive system. By following these steps, you can ensure a smoother operation and greater satisfaction in usage.

Battery Maintenance and Replacement

Maintaining and replacing the power source of your equipment is crucial for optimal performance and longevity. Proper care ensures that the battery operates efficiently and can prevent unexpected failures during use.

Routine Maintenance Tips

- Check terminals regularly for corrosion and clean them with a mixture of baking soda and water.

- Ensure connections are tight to prevent power loss.

- Inspect the battery case for cracks or damage, which could lead to leaks.

- Keep the battery charged according to manufacturer guidelines, especially during off-seasons.

Replacement Process

- Disconnect the old battery, starting with the negative terminal to avoid sparks.

- Remove the battery from its compartment carefully.

- Place the new battery in position and connect the positive terminal first, followed by the negative terminal.

- Secure the battery and ensure all connections are tight.

Following these guidelines will help maintain your power unit in peak condition, allowing for consistent performance when needed most.

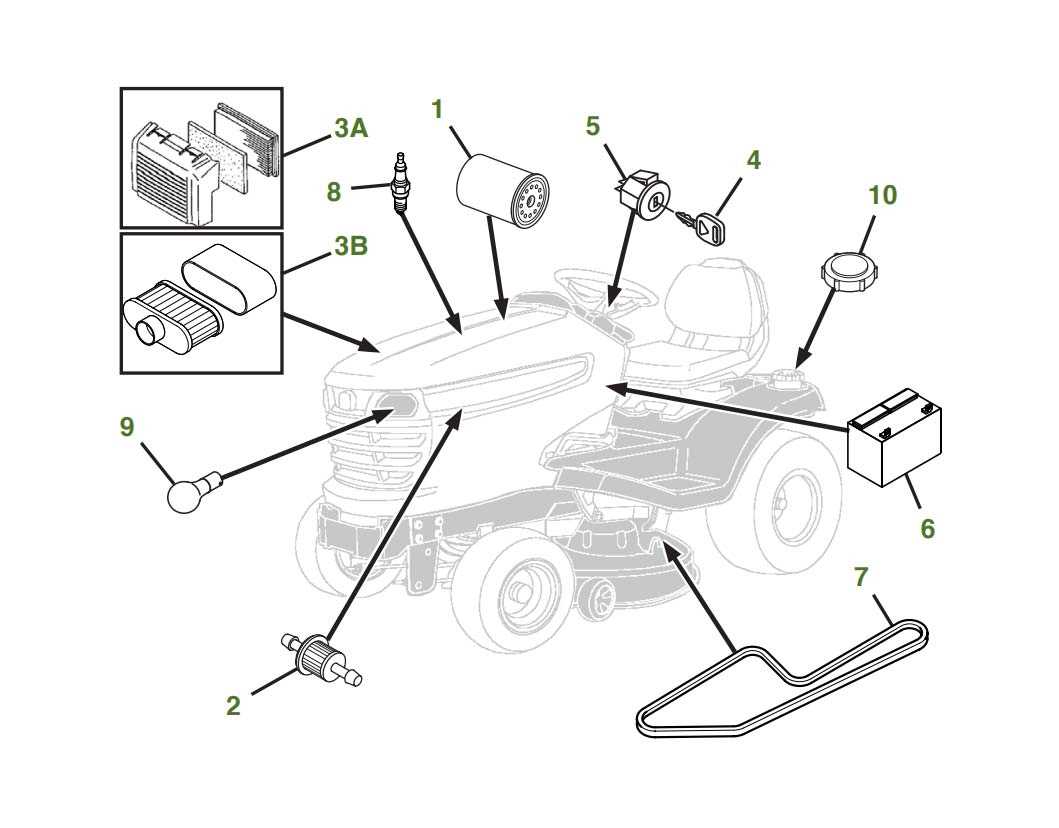

Changing Oil and Filters

Regular maintenance of your outdoor equipment is crucial for optimal performance and longevity. One of the most essential tasks is the replacement of lubricants and filtration systems, which helps ensure that the engine runs smoothly and efficiently. Neglecting this task can lead to a buildup of contaminants, potentially causing significant damage over time.

To begin, gather the necessary tools and materials, including fresh oil, new filters, and a container for waste. First, ensure the engine is cool before draining the old lubricant. Locate the drain plug, remove it, and allow the oil to completely empty into your container. After draining, replace the plug securely.

Next, proceed to the filter. Identify its location, usually near the engine, and remove it carefully. Install the new filter, ensuring a snug fit to prevent leaks. Once both the oil and filter have been changed, refill the engine with the appropriate amount of new oil, checking the dipstick to confirm proper levels. This straightforward procedure is vital for maintaining peak functionality and extending the life of your equipment.

Identifying Electrical Issues

Diagnosing electrical complications in outdoor machinery can be challenging yet crucial for maintaining optimal performance. Understanding the common symptoms of electrical failures enables users to troubleshoot effectively, ensuring that the equipment operates smoothly and safely. Recognizing these signs early can prevent more significant problems down the line.

Common Symptoms

Typical indicators of electrical problems include difficulties starting the engine, flickering lights, and unexpected shut-offs during operation. Additionally, abnormal noises or a complete lack of response when attempting to activate the machinery may signal underlying issues. Observing these symptoms promptly can help in identifying the source of the problem.

Troubleshooting Steps

Begin by checking the battery connections for any corrosion or loose wires. A multimeter can be used to measure voltage levels and ensure the battery is functioning correctly. Inspect fuses and relays for any signs of damage, as these components are often the first to fail. Lastly, reviewing the wiring harness for frays or breaks will help pinpoint any issues that may disrupt electrical flow.

Winterization Tips for Storage

Preparing your equipment for the colder months is essential to ensure its longevity and optimal performance. Proper winterization involves several steps that protect vital components and prevent damage during storage. Following these guidelines will help maintain the integrity of your machinery until it is needed again in the spring.

Here are some important steps to consider for effective winterization:

| Step | Description |

|---|---|

| Clean Thoroughly | Remove dirt, grass clippings, and debris to prevent rust and corrosion. |

| Drain Fluids | Empty the fuel tank and replace oil to avoid deterioration of components. |

| Check Batteries | Inspect and charge batteries, and store them in a cool, dry place to extend their life. |

| Inspect Belts and Cables | Look for wear and tear; replace any damaged parts to prevent future issues. |

| Cover Properly | Use a breathable cover to protect against moisture while allowing airflow. |

By following these winterization tips, you can ensure that your equipment remains in top condition and is ready for use when the seasons change.

Ordering Replacement Parts

When it comes to maintaining your outdoor equipment, acquiring the right components is crucial for optimal performance. This section provides guidance on how to efficiently obtain the necessary items for your machinery.

Here are some steps to follow when ordering parts:

- Identify the Required Part: Begin by determining the specific component you need. Check the model number and any relevant specifications.

- Consult the Manufacturer’s Website: Most manufacturers offer a dedicated section for parts. Navigate to the parts catalog for your equipment model.

- Contact Authorized Dealers: If you’re unsure, reach out to authorized retailers or service centers for assistance. They can provide expert advice and ensure you order the correct part.

Consider the following options for acquiring parts:

- Online Retailers: Many websites specialize in outdoor equipment components. Be sure to check for user reviews and return policies.

- Local Stores: Visiting a nearby shop can sometimes yield immediate availability, saving you shipping time.

- Second-Hand Markets: For older models, consider looking at resale platforms where you might find used parts at a reduced price.

Always verify the part numbers and compatibility with your specific equipment before making a purchase. This diligence helps prevent delays and ensures your machinery operates smoothly.

Best Practices for Safety

Ensuring safety during maintenance and operation of outdoor equipment is crucial for both the user and those nearby. Adhering to established guidelines not only minimizes the risk of accidents but also promotes a smoother working experience. This section outlines essential practices to follow, emphasizing the importance of caution and awareness.

1. Wear Appropriate Gear: Always don protective clothing, including gloves, safety glasses, and sturdy footwear. This minimizes the risk of injuries from debris or sharp objects that may arise during usage or servicing.

2. Read the Instructions: Familiarize yourself with the manufacturer’s guidelines before beginning any task. Understanding the equipment’s features and functions is vital for safe handling.

3. Keep Work Area Clear: Ensure the workspace is free of clutter and obstacles. This reduces the chances of tripping or losing control of the equipment.

4. Inspect Equipment Regularly: Before use, conduct thorough inspections to identify any wear or damage. Addressing potential issues early can prevent malfunctions during operation.

5. Use Caution with Fuel: When refueling, do so in a well-ventilated area, away from ignition sources. Allow any hot components to cool before attempting to add fuel.

6. Be Mindful of Surroundings: Always be aware of your environment and any bystanders. Maintain a safe distance from children and pets while operating equipment.

7. Turn Off When Not in Use: Shut down the machine and remove the key when taking breaks or finishing work. This prevents accidental startups and ensures the equipment is secure.

By implementing these safety measures, users can create a more secure environment while enjoying the benefits of outdoor maintenance tasks.