Essential Guide to Repairing Craftsman YS4500

In the realm of machinery and tools, understanding how to properly maintain and troubleshoot your devices is crucial for longevity and optimal performance. This section serves as a comprehensive resource for individuals seeking guidance on the upkeep of their outdoor equipment, ensuring that it remains functional and efficient for years to come.

The importance of routine servicing cannot be overstated. From minor adjustments to more intricate repairs, being informed about your equipment’s components and functions can save time and prevent costly damages. This guide will provide step-by-step instructions, practical tips, and insights into common issues that users may encounter.

Whether you are a seasoned user or a newcomer, having a reliable reference at your disposal will enhance your confidence in managing your tools. Emphasizing a proactive approach to maintenance, this resource will empower you to tackle challenges head-on and enjoy a smoother, more enjoyable experience with your equipment.

Craftsman YS4500 Overview

This section provides a comprehensive look at a versatile outdoor equipment model designed for efficiency and ease of use. It combines functionality with user-friendly features, making it a preferred choice among homeowners.

Key Features

- Powerful engine for robust performance

- Easy-to-navigate controls

- Durable construction for longevity

- Comfortable seating for extended use

Benefits

- Enhances productivity in lawn maintenance

- Offers a smooth and efficient mowing experience

- Reduces fatigue with ergonomic design

- Provides reliable operation across various terrains

Common Issues with YS4500

When it comes to outdoor equipment, certain problems tend to arise frequently, impacting performance and usability. Understanding these typical challenges can help users maintain their devices and extend their lifespan. Here are some prevalent concerns to be aware of.

Starting Difficulties: One of the most frequent complaints involves trouble initiating the engine. This can stem from issues such as a drained battery, faulty spark plug, or fuel delivery problems. Regular checks of these components can prevent such frustrating experiences.

Uneven Cutting: Users often report inconsistent cutting results. This can be attributed to dull blades, improper height settings, or even unbalanced wheels. Ensuring the blades are sharp and the machine is calibrated correctly is essential for optimal performance.

Overheating: Equipment can sometimes overheat during operation. This issue may be linked to low oil levels or a clogged air filter. Keeping an eye on these factors can help avoid severe damage and ensure smooth functioning.

Vibration and Noise: Excessive vibrations or unusual sounds can indicate underlying problems. Loose parts or worn-out components often cause these symptoms. Regular inspections and maintenance can help identify and rectify these issues before they escalate.

Fuel Leaks: Fuel leaks are a serious concern that can lead to safety hazards. Cracked fuel lines or damaged gaskets are common culprits. Timely replacement of these parts is crucial to maintaining a safe and efficient device.

By being aware of these common challenges, users can take proactive measures to address them, ensuring their equipment remains reliable and effective for years to come.

Tools Required for Repairs

When addressing maintenance tasks on machinery, having the right equipment is essential for achieving effective results. A well-equipped toolkit not only streamlines the process but also enhances safety and efficiency. Below is a selection of essential implements that can assist in various restoration efforts.

1. Wrenches: A variety of wrenches, including adjustable and socket types, are crucial for loosening and tightening bolts and nuts. They provide the necessary grip to handle different sizes and ensure secure fittings.

2. Screwdrivers: Both flathead and Phillips screwdrivers are indispensable for removing and securing screws. Having a set with varying lengths and widths allows for versatility in handling different components.

3. Pliers: Pliers, particularly needle-nose and slip-joint types, are useful for gripping, bending, and cutting wires or small parts. Their design offers better control and accessibility in tight spaces.

4. Socket Set: A comprehensive socket set enables quick and efficient fastening of fasteners in hard-to-reach areas. Ratchet handles enhance ease of use, making it easier to work on intricate assemblies.

5. Torque Wrench: To ensure that bolts are tightened to specific specifications, a torque wrench is vital. This tool prevents over-tightening, which can lead to damage.

6. Safety Gear: Protective eyewear, gloves, and appropriate clothing should always be worn. Safety gear protects against potential hazards associated with mechanical work.

Having these tools at your disposal can significantly simplify the process of maintaining and restoring equipment, leading to a more successful and efficient experience.

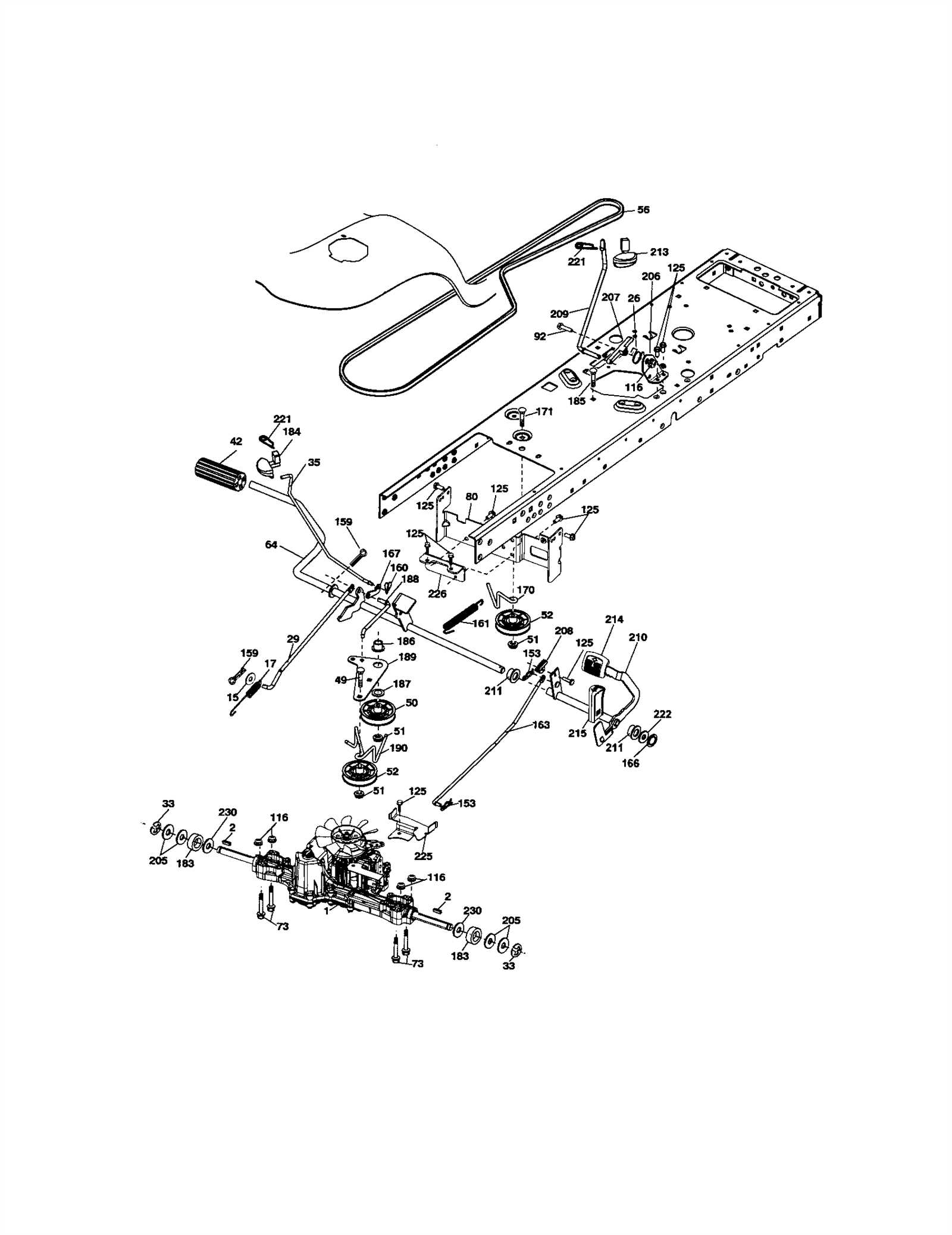

Step-by-Step Repair Guide

This section provides a comprehensive approach to restoring your equipment effectively. Following a structured process will ensure that each step is addressed methodically, helping you achieve optimal functionality once again.

1. Preparation: Begin by gathering all necessary tools and replacement parts. Ensure that you have a clean workspace to facilitate a smooth workflow.

2. Safety Measures: Before starting any work, disconnect the power source. Wearing protective gear such as gloves and goggles is essential to prevent any accidents.

3. Disassembly: Carefully take apart the components of your device. Keep track of screws and small parts by organizing them in containers to avoid misplacement.

4. Inspection: Examine each part for signs of wear or damage. Look for cracks, rust, or any other issues that may affect performance.

5. Replacement: If any components are found to be defective, replace them with new parts. Ensure that the replacements match the specifications of the original components.

6. Reassembly: Once all necessary replacements are made, reassemble the unit in the reverse order of disassembly. Make sure all screws and connections are secure.

7. Testing: After reassembly, reconnect the power source and conduct a test run. Monitor the equipment for any unusual sounds or behaviors.

8. Final Adjustments: If issues persist, revisit specific components to ensure everything is functioning as intended. Make any additional adjustments as needed.

By following these steps, you can effectively restore your device to its full potential, ensuring reliable performance for future use.

Maintenance Tips for Longevity

Proper upkeep is essential to ensure the extended lifespan and optimal performance of your equipment. By adhering to a consistent maintenance routine, you can prevent potential issues and enhance efficiency. Here are some vital practices to consider:

- Regular Cleaning: Keep the machine free from debris and dirt. Use a soft brush and cloth to clean surfaces after each use.

- Inspect Components: Routinely check belts, blades, and other key parts for signs of wear and tear. Address any issues promptly to avoid further damage.

- Lubrication: Apply the appropriate lubricant to moving parts as specified in the guidelines. This helps reduce friction and prevents overheating.

- Fuel Quality: Use high-quality fuel and replace old fuel regularly. Contaminated fuel can lead to engine problems.

- Air Filter Maintenance: Clean or replace air filters as needed. A clean filter ensures proper airflow and improves performance.

- Storage Conditions: Store the equipment in a dry, sheltered location to protect it from environmental factors such as moisture and extreme temperatures.

By following these straightforward maintenance tips, you can significantly enhance the durability and reliability of your machinery.

Engine Troubleshooting Techniques

Identifying and resolving issues with your machinery’s power unit requires a systematic approach. Understanding common symptoms and applying targeted methods can significantly enhance performance and longevity. This section will explore effective strategies to diagnose engine problems, ensuring smooth operation and minimizing downtime.

Common Symptoms and Their Causes

| Symptom | Possible Cause |

|---|---|

| Engine won’t start | Empty fuel tank, faulty ignition system, or blocked air filter |

| Rough idling | Dirty fuel injectors, improper air-fuel mixture, or worn spark plugs |

| Overheating | Low coolant levels, malfunctioning thermostat, or blocked radiator |

| Loss of power | Clogged air filter, exhaust blockage, or fuel delivery issues |

Basic Troubleshooting Steps

Begin by conducting a visual inspection of the unit. Check for leaks, loose connections, and any signs of wear or damage. Next, verify that the fuel supply is adequate and that filters are clean. If issues persist, consult diagnostic tools to assess electrical components and performance metrics, allowing for a more detailed analysis of the situation.

Replacing the Battery Safely

Changing the power source of your equipment is an essential task that ensures optimal performance and longevity. However, this process must be carried out with caution to avoid any potential hazards. This section provides guidance on how to safely replace the energy unit, highlighting necessary precautions and steps to follow.

Preparation Steps

Before beginning the replacement, ensure you have the appropriate tools and a new power unit compatible with your device. Always wear protective gear, such as gloves and safety goggles, to minimize the risk of injury. Disconnect the device from any power supply to prevent accidental activation during the process.

Replacement Procedure

Start by locating the battery compartment, usually secured with screws or clips. Carefully remove these fasteners and take out the old power source, observing any specific orientation. Insert the new unit in the same position, ensuring secure connections. Finally, reassemble the compartment, double-checking that everything is in place before reconnecting to a power source.

By following these steps, you can effectively replace the energy unit while minimizing risks, ensuring that your equipment continues to operate smoothly.

Inspecting and Changing Blades

Regular examination and replacement of cutting edges are vital for maintaining optimal performance and ensuring safety during operation. Dull or damaged blades can lead to poor cutting results and increased strain on the equipment. This section outlines the necessary steps for inspecting and changing blades effectively.

Before starting the inspection process, gather the required tools, including safety gloves, a wrench, and a blade sharpener or replacement blades. Always prioritize safety by disconnecting the power source before working on the machinery.

Inspection Steps

- Examine the blades for any visible signs of wear, such as chips, cracks, or rust.

- Check the sharpness of the edges; a simple touch test can help determine if they feel dull.

- Ensure that the blades are properly secured and not loose.

- Inspect the mounting area for any debris or damage that could affect blade performance.

Changing Blades

When it becomes clear that replacement is necessary, follow these steps:

- Disconnect the power supply to prevent accidental start-up.

- Use a wrench to remove the fastening hardware securing the blade in place.

- Carefully lift the old blade off the mount and replace it with a new one.

- Secure the new blade tightly using the fastening hardware.

- Reconnect the power supply and perform a test run to ensure everything operates smoothly.

Maintaining sharp and well-functioning cutting edges not only enhances the quality of work but also prolongs the lifespan of the equipment. Regular checks and timely replacements are key to achieving these goals.

Checking Fuel System Efficiency

Assessing the performance of the fuel delivery system is essential for ensuring optimal operation of your equipment. A well-functioning fuel system contributes significantly to the overall efficiency and longevity of the engine. This section outlines the key steps for evaluating fuel system effectiveness.

To effectively check the fuel system, follow these essential guidelines:

- Inspect Fuel Lines:

- Look for any signs of wear, cracks, or leaks.

- Ensure connections are secure and free from corrosion.

- Examine the Fuel Filter:

- Replace the filter if it appears clogged or dirty.

- Check the manufacturer’s recommendations for maintenance intervals.

- Evaluate Fuel Quality:

- Use fresh fuel to avoid issues with degradation.

- Look for contamination or water in the fuel.

- Test Fuel Pump Operation:

- Listen for unusual noises that may indicate malfunction.

- Measure fuel pressure to ensure it meets specifications.

- Check for Air Leaks:

- Inspect gaskets and seals for proper sealing.

- Perform a visual check around connections for any signs of air intrusion.

By following these steps, you can ensure that your fuel system operates at peak performance, ultimately leading to a smoother and more efficient running engine.

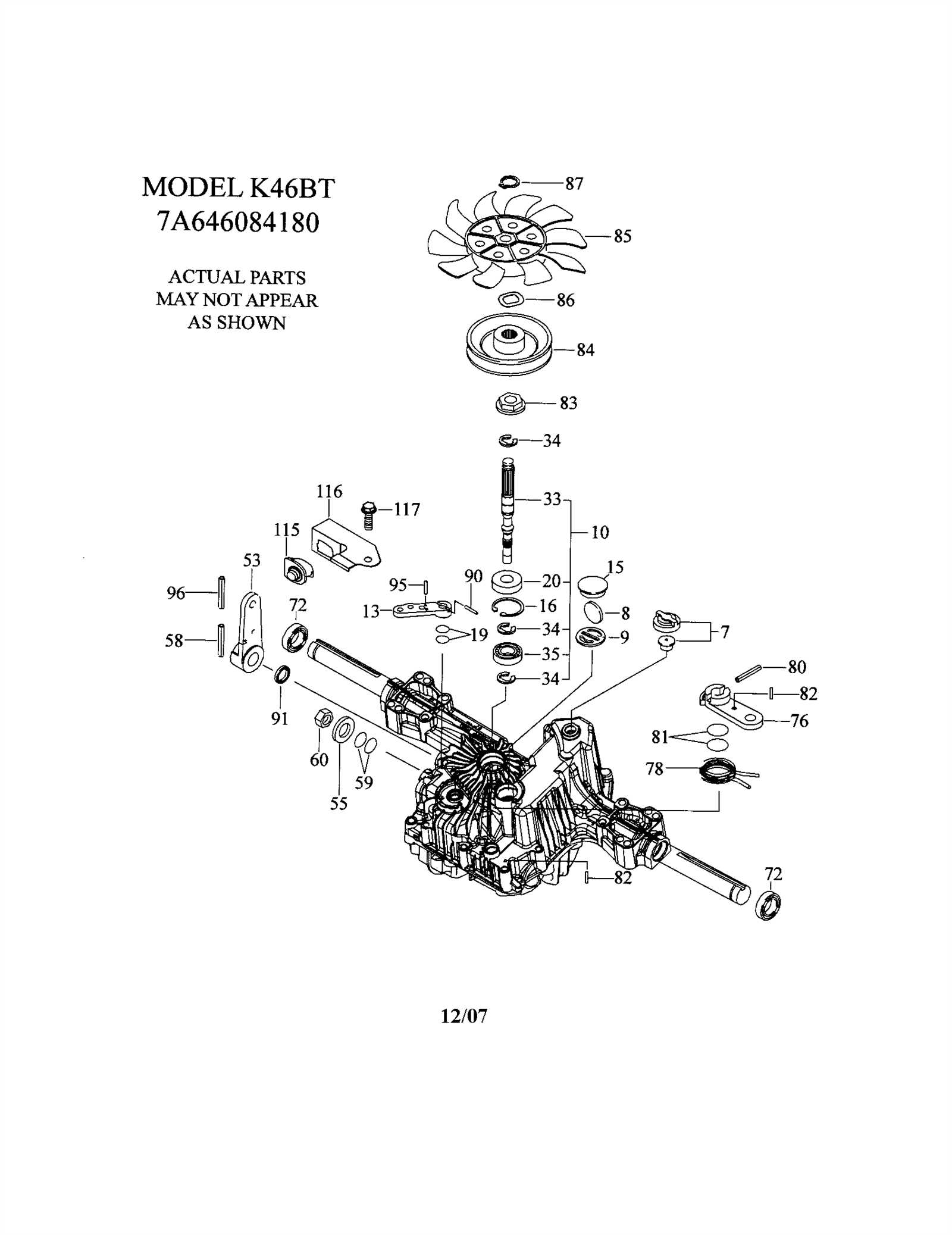

Transmission and Gear Issues

Understanding the mechanics behind a vehicle’s transmission and gear system is crucial for ensuring smooth operation and longevity. Common complications in these systems can lead to significant performance drawbacks, affecting everything from acceleration to fuel efficiency. Recognizing and addressing these issues promptly can prevent more extensive damage and costly repairs.

Common Symptoms of Transmission Problems

- Unusual noises during shifting

- Delayed engagement when shifting gears

- Slipping gears or unexpected changes in gear

- Fluid leaks under the vehicle

- Warning lights on the dashboard

Potential Causes of Gear Malfunctions

- Low transmission fluid levels

- Worn or damaged gears

- Faulty shift linkage

- Overheating due to excessive strain

- Electrical issues affecting the transmission control unit

Identifying these signs early and understanding their root causes can help in maintaining optimal performance and avoiding further complications. Regular maintenance checks are essential for keeping the transmission and gear systems in top condition.

Electrical System Diagnostics

Diagnosing the electrical framework of outdoor equipment is crucial for ensuring optimal performance and longevity. An efficient assessment can help identify issues such as shorts, open circuits, or component failures. This section outlines key methods and tools necessary for effective troubleshooting, allowing users to maintain the reliability of their machinery.

Common Symptoms and Initial Checks

Recognizing the signs of electrical problems is the first step in the diagnostic process. Symptoms may include inconsistent starting, dim lights, or complete electrical failure. Begin by inspecting the battery connections for corrosion and ensuring they are secure. A multimeter can be invaluable in measuring voltage levels, confirming whether the battery is functioning correctly.

Advanced Diagnostic Techniques

For more complex issues, a thorough examination of the wiring harness and individual components is necessary. Check for frayed wires or damaged connectors that could disrupt the circuit. Utilize circuit testers to verify the integrity of switches and relays. If specific components are suspected to be faulty, refer to manufacturer specifications for resistance values and operational parameters to guide your troubleshooting efforts.

When to Seek Professional Help

Understanding when to enlist the expertise of a professional is crucial for ensuring the longevity and efficiency of your equipment. While many issues can be addressed independently, certain situations require specialized knowledge and tools to prevent further complications.

Signs That Indicate Professional Intervention

Recognizing the warning signs that suggest it’s time to consult an expert can save you time and money. Below are common indicators:

| Indicator | Description |

|---|---|

| Persistent Issues | If a problem recurs despite attempts to fix it, professional evaluation is advisable. |

| Strange Noises | Unusual sounds during operation may indicate internal damage that requires expert assessment. |

| Performance Decline | A noticeable drop in functionality can suggest underlying issues that are best addressed by a specialist. |

| Safety Concerns | If any aspect poses a risk to safety, immediate professional assistance is necessary. |

Benefits of Professional Assistance

Seeking help from a qualified technician offers numerous advantages. They bring a wealth of experience and can diagnose issues accurately, ensuring that repairs are conducted effectively and safely. Additionally, professionals often provide warranties on their work, giving you peace of mind.