Comprehensive Guide to 2AR-FE Engine Repair

Maintaining optimal performance in a vehicle is essential for longevity and reliability. This guide aims to equip enthusiasts and professionals with the knowledge needed to address common issues and ensure smooth operation. By delving into the intricate workings of a specific powertrain unit, readers will gain insights into effective troubleshooting and restoration techniques.

Understanding the mechanics behind a high-performance system is crucial for anyone looking to extend the life of their automobile. This resource provides a step-by-step approach to addressing various complications, offering detailed explanations and illustrations. Whether you’re an experienced technician or a curious novice, this compilation serves as an invaluable reference.

With a focus on best practices and common pitfalls, this document emphasizes the importance of precision and care during the overhaul process. Proper techniques can significantly enhance efficiency and durability, allowing for a seamless driving experience. Prepare to immerse yourself in a wealth of information designed to foster both skill and confidence in the realm of automotive maintenance.

Overview of 2AR-FE Engine

This section provides a comprehensive examination of a specific power unit renowned for its reliability and efficiency. Known for its robust construction and advanced technology, it has gained popularity among automotive enthusiasts and manufacturers alike. Understanding its design and functionality is crucial for those seeking to maintain or enhance performance.

Designed primarily for compact and mid-size vehicles, this power unit features a four-cylinder layout that optimizes fuel consumption while delivering adequate power. Its architecture includes a dual overhead camshaft configuration, which enhances the engine’s breathing capabilities and improves overall performance.

Another significant aspect is the incorporation of advanced technologies, such as variable valve timing, which contributes to better efficiency and lower emissions. The engineering behind this power unit reflects a commitment to sustainable performance without sacrificing power output, making it a preferred choice for various applications.

In summary, the intricate design and innovative features of this power unit not only ensure dependable operation but also facilitate ease of maintenance, making it an ideal option for both everyday drivers and automotive professionals.

Common Issues with 2AR-FE Engine

Understanding the frequent problems associated with this power unit can help owners maintain optimal performance and longevity. Many of these concerns stem from wear and tear, as well as design aspects that may lead to specific challenges over time. Identifying these issues early can save both time and money in the long run.

Oil Consumption

One prevalent problem is excessive consumption of lubricating oil. This may result from worn piston rings or valve seals, leading to oil leaking into the combustion chamber. As a result, drivers might notice increased emissions and decreased fuel efficiency. Regular monitoring of oil levels is crucial to mitigate this issue.

Overheating

Another significant concern is overheating, which can stem from a variety of factors, including a malfunctioning thermostat, a clogged radiator, or issues with the water pump. Prolonged exposure to high temperatures can cause severe damage, such as warping of components. Ensuring the cooling system is in good condition is vital for preventing this issue.

Addressing these common problems promptly can greatly enhance the reliability and performance of the unit. Regular maintenance checks and being attentive to symptoms can make a considerable difference in the longevity of the vehicle.

Tools Required for Repairs

When undertaking maintenance tasks, having the right instruments is crucial for ensuring efficiency and effectiveness. The proper equipment not only facilitates the process but also helps in achieving the best results while minimizing the risk of damage.

Essential Tools

- Wrenches of various sizes

- Screwdrivers (flathead and Phillips)

- Socket set with ratchet

- Pliers (including needle-nose)

- Torque wrench for precise tightening

- Oil filter wrench

Additional Equipment

- Multimeter for electrical diagnostics

- Jack and jack stands for lifting

- Drain pan for fluids

- Work light to illuminate dark areas

- Gloves and safety glasses for protection

Investing in high-quality tools can enhance the overall experience, making the tasks at hand more manageable and safe. Proper preparation with the right gear leads to successful outcomes in any mechanical endeavor.

Step-by-Step Disassembly Process

This section outlines a detailed approach to dismantling a complex mechanical assembly. Following a systematic procedure is crucial to ensure that all components are handled with care, minimizing the risk of damage and facilitating a smoother reassembly later on.

Preparation: Before commencing, gather all necessary tools and equipment. A clean workspace will help maintain organization and prevent the misplacement of small parts.

Step 1: Documentation – Begin by documenting the assembly with photographs or notes. This visual reference will be invaluable during reassembly, ensuring each piece returns to its proper location.

Step 2: Disconnection – Carefully disconnect all electrical and fluid connections. Labeling each connection can help avoid confusion later. Use appropriate containers to collect fluids, preventing spills.

Step 3: Fasteners – Remove bolts and screws in a systematic order, following a pattern to avoid missing any. Keep fasteners organized by using magnetic trays or labeled bags.

Step 4: Component Removal – Start with external components, gradually moving inward. Gently pry apart any tightly fitted parts, taking care not to damage adjacent pieces.

Step 5: Inspection – As you disassemble, inspect each part for wear or damage. Document any issues for reference during reassembly or potential replacement.

Step 6: Storage – Place disassembled components in a labeled container, ensuring they are protected from dirt and physical harm. A systematic storage method will facilitate a more efficient reassembly process.

Following these steps will enhance the disassembly experience, making the subsequent tasks easier and more organized.

Inspecting Engine Components

Thorough examination of key parts is crucial for ensuring optimal performance and longevity of the power unit. Regular assessments help identify wear and damage, enabling timely interventions and maintenance.

Visual Inspection: Start with a careful visual check for any signs of leaks, cracks, or corrosion. Look for irregularities in surfaces that may indicate underlying issues.

Measuring Clearances: Utilize precise tools to measure tolerances between moving parts. This step is essential to prevent excessive wear and maintain efficiency during operation.

Checking for Wear: Assess surfaces of components like bearings and pistons for any signs of degradation. Uneven wear patterns can signal problems that may require further attention.

Testing for Functionality: Conduct functional tests to ensure that all parts operate as intended. This includes checking the responsiveness of moving components and the effectiveness of seals and gaskets.

Monitoring Fluid Quality: Analyze fluids for contamination or degradation. Clean, quality fluids are vital for the smooth operation of various mechanisms within the assembly.

Implementing these inspection techniques systematically can significantly enhance reliability and performance, ultimately extending the lifespan of the assembly.

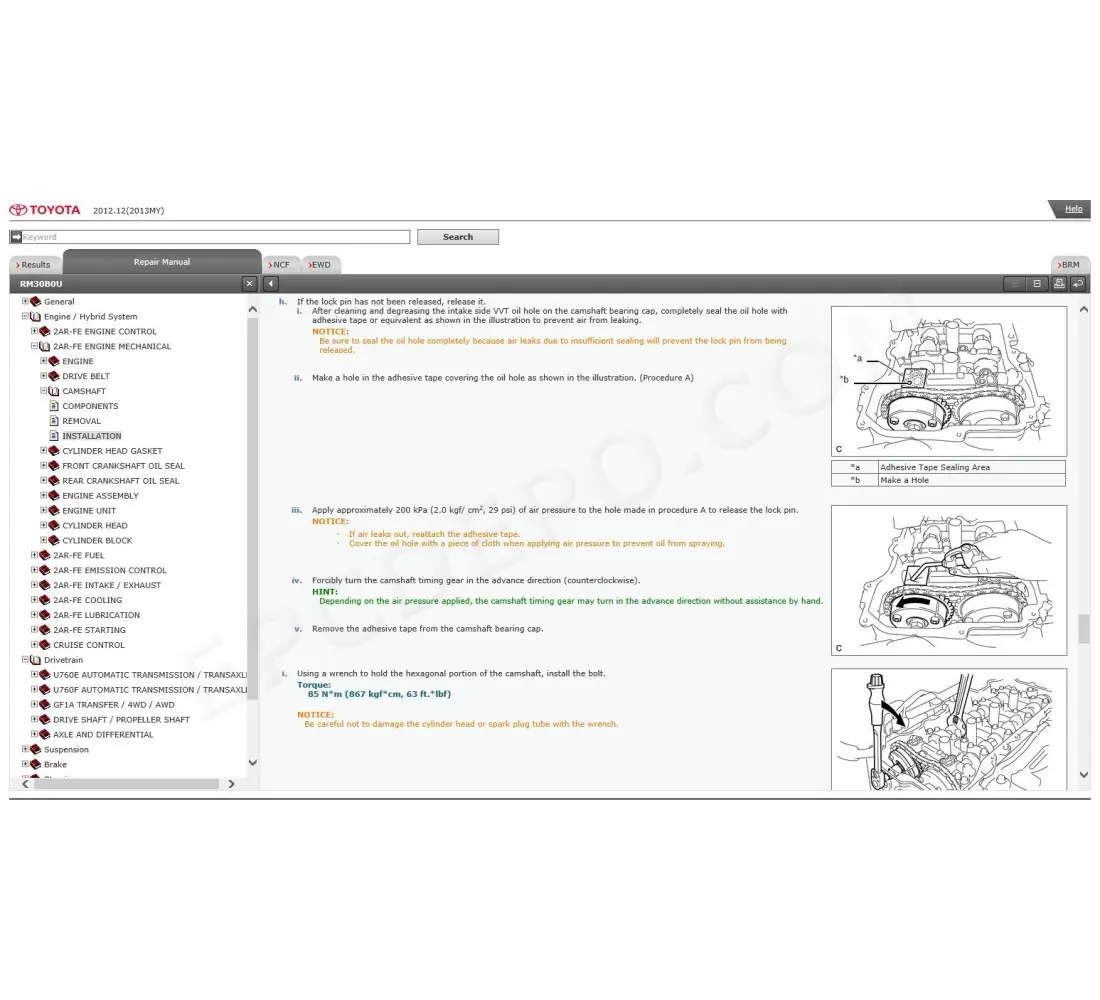

Replacing Timing Chain and Gears

Maintaining the timing components is crucial for optimal performance and longevity. This process involves the careful removal and installation of various parts, ensuring everything aligns correctly for proper functionality.

Here’s a step-by-step guide to facilitate the replacement:

- Preparation:

- Gather necessary tools: wrenches, sockets, and timing tools.

- Ensure you have the replacement chain and gears on hand.

- Disconnect the battery to avoid any electrical issues.

- Accessing the Timing Components:

- Remove any covers obstructing access to the timing area.

- Take off the front accessory components if needed.

- Removal:

- Align the marks on the crankshaft and camshaft to maintain timing.

- Carefully unbolt and remove the old chain and gears.

- Installation:

- Position the new gears and chain, ensuring alignment with the timing marks.

- Tighten all bolts to the manufacturer’s specifications.

- Reassembly:

- Reattach any covers and components removed during access.

- Reconnect the battery.

- Final Checks:

- Inspect the installation for any loose parts.

- Start the vehicle and listen for any unusual noises.

Following these steps ensures a successful transition to new timing components, promoting efficiency and reliability.

Rebuilding Cylinder Head Procedures

The process of restoring the upper component of a combustion chamber involves several critical steps that ensure optimal performance and longevity. Proper attention to detail during this procedure can significantly enhance the efficiency and reliability of the entire system.

Preparation and Disassembly

Before beginning the rebuild, it is essential to gather all necessary tools and components. Follow these steps for effective preparation:

- Gather tools: wrenches, sockets, torque wrench, and cleaning supplies.

- Ensure a clean workspace to prevent contamination.

- Document the assembly for reference during reinstallation.

Next, proceed with disassembly:

- Remove the cylinder head from the block, taking care to avoid damage.

- Detach all components attached to the head, including valves, springs, and camshafts.

- Inspect each part for wear and tear; replace any damaged components.

Cleaning and Inspection

Thorough cleaning is vital for ensuring proper function and longevity. Follow these guidelines:

- Use a suitable solvent to clean the head and its components.

- Inspect for cracks, warping, or other imperfections using a straight edge.

- Check valve seats and guides for wear; replace as necessary.

Once cleaned, evaluate the components for any needed repairs or replacements, ensuring each part meets the required specifications for reassembly.

Checking Fuel System Integrity

Ensuring the reliability of the fuel delivery system is essential for optimal performance and efficiency. Regular assessments help identify potential issues that could lead to malfunctions or decreased efficiency. This section outlines the key steps to evaluate the system’s condition effectively.

Begin the assessment by inspecting the entire setup for visible signs of wear or damage. Check for leaks, corrosion, and loose connections that may affect performance. It is crucial to ensure that all components are securely fitted and functioning correctly.

| Component | Inspection Method | Notes |

|---|---|---|

| Fuel Lines | Visual check for cracks or leaks | Replace if damaged |

| Fuel Filter | Check for clogging | Change if necessary |

| Fuel Pump | Listen for unusual sounds | Inspect electrical connections |

| Injectors | Check spray pattern | Clean or replace if faulty |

Next, conduct a pressure test to measure the system’s ability to maintain proper fuel pressure. This test can reveal leaks or blockages that might not be visible during a visual inspection. Ensure that all readings are within the specified range for optimal functionality.

Finally, reviewing the diagnostic codes can provide additional insights into the system’s performance. Utilize specialized tools to read these codes, which may indicate specific areas requiring attention. Regular monitoring and maintenance of the fuel delivery system contribute to the longevity and efficiency of the overall setup.

Reassembling the Engine Correctly

Putting components back together is a crucial phase in the overhaul process. It requires precision and attention to detail to ensure optimal performance and longevity. Each piece must be aligned and secured properly to avoid future complications.

Before starting the reassembly, it’s vital to have a clean workspace and all necessary tools at hand. Make sure to organize parts in the order they were removed, which simplifies the process and helps prevent any missing components. Following the original specifications and torque settings is essential for achieving the correct balance and function.

Begin with the foundation, reintroducing the block and ensuring all gaskets and seals are correctly placed. Pay close attention to any critical junctions, as these areas are prone to leaks. As you continue, incorporate all ancillary components, verifying that each is fitted according to the manufacturer’s guidelines.

Lastly, conduct a thorough inspection of your work before sealing everything up. Double-check that all fasteners are tightened to the specified torque and that there are no obstructions in the assembly. This diligence will pave the way for a successful operation once everything is back in place.

Testing Engine Performance After Repair

Evaluating the functionality of a power unit post-restoration is crucial to ensure optimal operation and reliability. This process involves a series of assessments to confirm that all systems are working as intended and that the unit meets performance standards. Proper testing can help identify any lingering issues that may affect efficiency or longevity.

Before conducting tests, it’s essential to prepare the vehicle. This includes checking fluid levels, ensuring all components are properly connected, and inspecting for any visible leaks or damages. Once preparations are complete, various tests can be performed to gauge performance.

| Test Type | Description | Purpose |

|---|---|---|

| Idle Check | Observe the unit while idling to assess stability and smoothness. | Identifies irregularities in operation at low RPMs. |

| Acceleration Test | Measure the time taken to reach specific speed benchmarks. | Evaluates responsiveness and power delivery. |

| Load Test | Operate the unit under various loads to assess performance. | Determines capability under real-world conditions. |

| Fuel Efficiency Assessment | Monitor fuel consumption during a standard drive cycle. | Checks for optimal efficiency and potential issues. |

| Noise and Vibration Check | Listen for unusual sounds and assess vibration levels. | Highlights potential mechanical issues. |

Post-assessment, analyzing the collected data is vital to understanding performance characteristics. Any deviations from expected results should prompt further investigation to ensure reliability and satisfaction. This thorough approach not only guarantees a well-functioning unit but also enhances the overall driving experience.

Regular Maintenance Tips for Longevity

Consistent upkeep is essential for enhancing the lifespan of any mechanical system. By adhering to a structured routine, users can ensure optimal performance and reduce the likelihood of unexpected issues. This section offers practical advice for maintaining your unit effectively.

Key Maintenance Practices

Regularly implementing these practices will help in preserving the efficiency and durability of your machinery:

| Maintenance Task | Frequency | Description |

|---|---|---|

| Fluid Check | Every 3,000 miles | Inspect and replenish necessary fluids to ensure proper functioning. |

| Filter Replacement | Every 6 months | Change filters to maintain cleanliness and prevent contamination. |

| Belts and Hoses Inspection | Quarterly | Check for wear and tear, and replace if necessary. |

| Battery Maintenance | Every 6 months | Clean terminals and ensure connections are secure. |

| Tire Pressure Check | Monthly | Verify and adjust tire pressure for optimal handling and fuel efficiency. |

Benefits of Regular Upkeep

Routine maintenance not only prolongs the life of your apparatus but also enhances safety and performance. By committing to these practices, users can avoid costly repairs and enjoy a smoother operation overall.

Common Mistakes to Avoid

When undertaking maintenance or refurbishment tasks, certain pitfalls can lead to significant setbacks or even damage. Recognizing and avoiding these common errors can enhance the overall success of the project and prolong the lifespan of the machinery involved.

1. Neglecting Pre-Inspection

Failing to thoroughly inspect components before starting work can lead to oversight of critical issues. Ensure to:

- Check for signs of wear or damage.

- Examine seals and gaskets for leaks.

- Review fluid levels and conditions.

2. Using Incorrect Tools

Utilizing the wrong instruments can result in improper handling and potential harm. To avoid this, make sure to:

- Refer to specifications for necessary tools.

- Invest in quality tools that are suited for the task.

- Always double-check compatibility before use.

Resources for Further Learning

Expanding your knowledge in automotive technology can significantly enhance your skills and understanding. Whether you are a novice or an experienced enthusiast, numerous resources are available to deepen your expertise. From books and online courses to forums and workshops, each avenue offers valuable insights into the intricacies of vehicle systems.

Books: Look for comprehensive texts that cover the fundamentals of vehicle mechanics. Titles that focus on specific systems or general maintenance can provide a solid foundation. Check local libraries or bookstores for updated editions that reflect the latest advancements in the field.

Online Courses: Various platforms offer structured learning experiences tailored to different skill levels. Websites like Coursera, Udemy, and Khan Academy provide courses that range from introductory principles to advanced diagnostic techniques. These courses often include interactive elements and quizzes to reinforce learning.

Forums and Community Groups: Engaging with online communities can be incredibly beneficial. Platforms such as Reddit and specialized automotive forums allow you to ask questions, share experiences, and connect with other learners. Participating in discussions can enhance your understanding and expose you to diverse perspectives.

Workshops and Hands-On Training: Practical experience is crucial. Seek out local workshops or community colleges that offer hands-on training sessions. These opportunities allow you to apply theoretical knowledge in a controlled environment, building confidence and competence.

Continuously seeking knowledge through these diverse resources will not only improve your skills but also foster a greater appreciation for the complexity of automotive technology.