Comprehensive Guide to Repairing the Cat 3054C Engine

Proper maintenance of heavy machinery is crucial for ensuring optimal performance and longevity. The intricacies of internal components require a comprehensive approach, including systematic checks and specific adjustments to avoid costly breakdowns. This guide delves into essential practices and detailed insights that empower operators and technicians alike to maintain their equipment effectively.

Mastering the nuances of mechanical systems can significantly enhance operational efficiency. Through careful examination of components and adherence to established protocols, users can mitigate risks associated with wear and tear. This resource provides a structured framework, offering valuable information tailored to facilitate informed decision-making and proactive care.

Equipped with the right knowledge, individuals can tackle common challenges that arise during usage. Understanding the functionality of various parts and how they interact is vital for diagnosing issues early. By embracing a methodical approach to upkeep, you can ensure that your machinery remains in peak condition, ready to perform its tasks reliably.

Overview of the Cat 3054C Engine

This section provides a comprehensive look at a specific model of a compact power unit, widely recognized for its efficiency and reliability. Understanding its features, applications, and maintenance needs is essential for anyone working with this machinery.

Key Features

The unit is designed with advanced technology to deliver robust performance while maintaining fuel efficiency. It boasts a compact design, making it suitable for various applications, from construction to agriculture. Its durability ensures long service life, which is crucial for operators seeking dependable machinery in challenging environments.

Applications

This versatile power source is utilized in numerous settings, ranging from small-scale equipment to larger industrial applications. Its adaptability makes it a preferred choice for operators looking to enhance productivity without compromising on reliability. The ability to work efficiently in tight spaces further underscores its value in diverse operational contexts.

Common Issues with Cat 3054C Engines

When it comes to machinery that relies on robust power sources, various challenges may arise during operation. Understanding these frequent complications can aid in effective troubleshooting and maintenance. Below are some of the most typical problems encountered with this specific model.

- Overheating: A prevalent issue that can stem from coolant leaks, a malfunctioning thermostat, or blocked radiators.

- Fuel Injection Problems: Clogged injectors or a faulty pump can lead to reduced performance and increased emissions.

- Oil Leaks: Commonly caused by worn gaskets or seals, leading to potential lubrication failures.

- Starting Difficulties: Issues with the starting system, such as a weak battery or faulty starter, can prevent proper ignition.

- Excessive Smoke: Black, blue, or white smoke can indicate issues ranging from poor combustion to oil burning.

Addressing these complications promptly can enhance the lifespan and reliability of the equipment, ensuring it continues to perform optimally in demanding conditions.

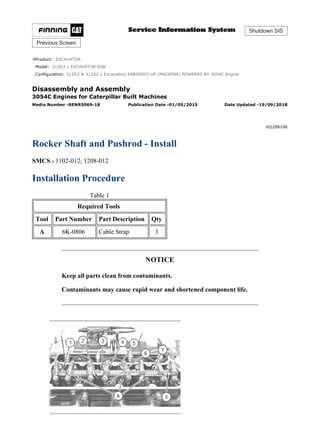

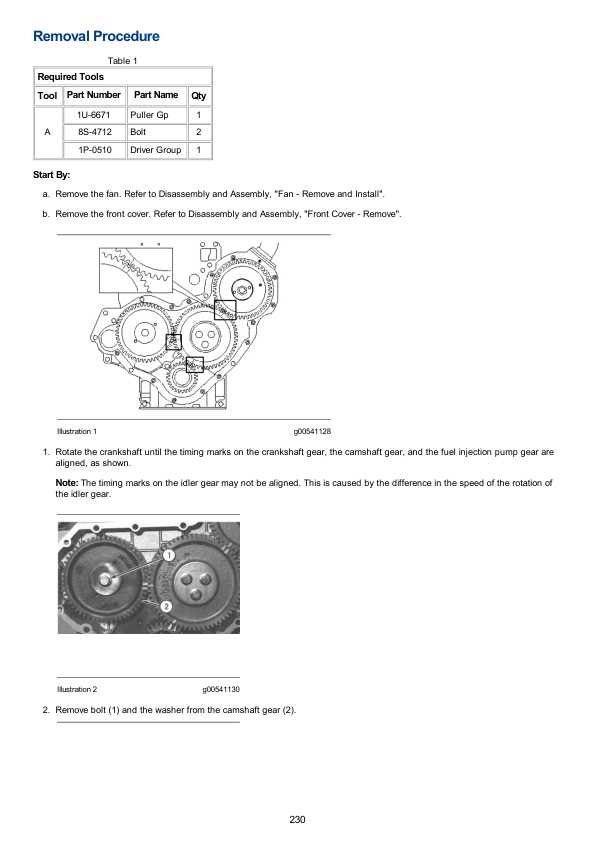

Tools Needed for Engine Repairs

When it comes to maintaining and fixing machinery, having the right instruments is essential for a successful outcome. The appropriate equipment not only enhances efficiency but also ensures safety during the process. Below is a detailed list of essential tools that will facilitate various tasks associated with overhauling mechanical systems.

| Tool Type | Purpose |

|---|---|

| Socket Set | Used for tightening and loosening bolts and nuts of various sizes. |

| Wrenches | Essential for gripping and turning fasteners. |

| Torque Wrench | Ensures that fasteners are tightened to the manufacturer’s specifications. |

| Screwdrivers | Required for adjusting screws, available in various head types. |

| Pliers | Useful for gripping and bending components. |

| Oil Filter Wrench | Facilitates the removal and installation of oil filters. |

| Diagnostic Tools | Helps in identifying issues through readings and analysis. |

| Cleaning Supplies | Necessary for maintaining cleanliness and preventing contamination. |

Step-by-Step Repair Procedures

This section provides a comprehensive guide for addressing common issues in heavy machinery. By following a structured approach, you can ensure that all necessary tasks are completed efficiently and accurately. Each step is designed to facilitate a clear understanding of the process, enhancing both safety and effectiveness.

1. Preparation: Before starting any work, gather all required tools and materials. Ensure you have protective gear to maintain safety throughout the procedure. Review the specific model’s specifications to familiarize yourself with key components.

2. Diagnostics: Begin by identifying the symptoms of the malfunction. Utilize diagnostic tools to assess performance metrics and pinpoint the root cause of the issue. Document your findings for reference.

3. Disassembly: Carefully remove any covers or panels to access the necessary parts. Follow the recommended order of disassembly to avoid damaging components. Keep track of all fasteners and parts for reassembly.

4. Inspection: Examine all exposed components for wear, damage, or defects. Pay close attention to critical areas such as seals and connections. Replace any parts that do not meet operational standards.

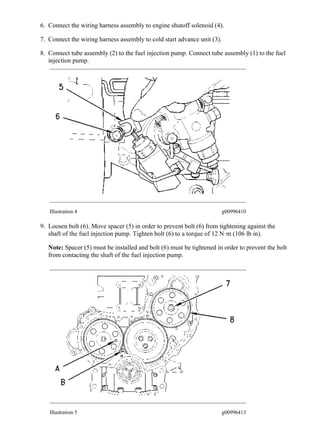

5. Cleaning: Thoroughly clean all parts using appropriate solvents. Remove any debris or buildup that may interfere with performance. Ensure that all surfaces are dry before proceeding to the next step.

6. Reassembly: Following the reverse order of disassembly, carefully reassemble the machinery. Use new gaskets and seals where necessary to prevent leaks. Torque all fasteners to the manufacturer’s specifications.

7. Testing: Once reassembly is complete, conduct a thorough test to ensure proper functionality. Monitor performance closely during initial operation and check for any irregularities.

8. Documentation: After completing the work, record all actions taken, parts replaced, and any observations. This documentation will be invaluable for future reference and maintenance planning.

By adhering to these structured procedures, you can enhance the reliability and longevity of your equipment, ensuring it operates at peak performance.

Engine Maintenance Best Practices

Regular upkeep of machinery is essential for optimal performance and longevity. Following a structured approach to care can prevent unexpected breakdowns and enhance efficiency. Understanding key practices can make a significant difference in the overall functionality of your equipment.

| Practice | Description | Frequency |

|---|---|---|

| Fluid Checks | Regularly inspect and replace lubricants and coolants to ensure proper operation. | Every 50 hours of operation |

| Filter Replacement | Change air and fuel filters to maintain clean airflow and fuel supply. | Every 200 hours of operation |

| Belt Inspection | Examine belts for wear and tension; replace any that show signs of damage. | Every 100 hours of operation |

| Visual Inspections | Conduct thorough checks for leaks, cracks, or any signs of wear on components. | Before each use |

| Battery Maintenance | Check battery charge levels and connections; clean terminals as needed. | Monthly |

By adhering to these essential practices, operators can significantly reduce the risk of failures and extend the service life of their machinery. Consistency in maintenance leads to improved reliability and efficiency, which ultimately saves time and costs in the long run.

Identifying Engine Performance Problems

Recognizing issues related to power unit efficiency is crucial for maintaining optimal functionality. Various symptoms can indicate underlying complications that may hinder performance. Addressing these signs promptly can prevent further damage and ensure reliable operation.

Common indicators of performance issues include:

- Unusual noises during operation

- Decreased power output

- Excessive fuel consumption

- Frequent stalling or difficulty starting

- Overheating

To diagnose these problems effectively, it is important to conduct a systematic assessment:

- Check the fluid levels and condition.

- Inspect filters for blockages or contamination.

- Examine connections for leaks or damage.

- Monitor performance under various loads.

- Utilize diagnostic tools to read error codes, if applicable.

By following these steps, operators can pinpoint issues and take corrective measures, ensuring that the unit operates efficiently and reliably.

Replacing Components in Cat 3054C

When it comes to maintaining high-performance machinery, understanding the process of component replacement is essential. This task not only enhances the longevity of the equipment but also ensures optimal functionality. By addressing worn or damaged parts, operators can significantly improve performance and reduce the risk of failures.

Identifying Components: Before initiating the replacement, it’s crucial to identify which parts require attention. Regular inspections can help pinpoint issues, allowing for timely interventions.

Tools and Preparation: Having the right tools at hand simplifies the process. Ensure that you gather all necessary instruments and prepare a clean workspace to facilitate efficient replacements.

Replacement Process: Follow a systematic approach when removing old components. Carefully detach the part, inspect surrounding areas for damage, and clean any debris. Install the new part, ensuring it fits securely and is aligned correctly.

Testing and Validation: After installation, conduct thorough tests to confirm that the new component functions as intended. Monitoring performance metrics can help detect any irregularities early on.

Safety Precautions During Repairs

When undertaking maintenance tasks on machinery, ensuring a safe working environment is paramount. Adopting proper safety measures not only protects the individual performing the work but also safeguards the equipment and surrounding personnel. Awareness and preparedness are key components in minimizing risks associated with mechanical servicing.

Always wear appropriate personal protective equipment (PPE). This includes gloves, safety goggles, and steel-toed boots, which help shield against potential hazards such as sharp edges or hot surfaces. The selection of suitable clothing can also prevent entanglement with moving parts.

Ensure proper ventilation. When working in enclosed spaces, adequate airflow is essential to avoid inhaling harmful fumes or vapors. Consider using exhaust fans or opening doors and windows to facilitate air circulation, especially when dealing with substances that emit noxious gases.

Keep your workspace organized and free of clutter. A tidy environment reduces the chances of accidents and makes it easier to locate tools and materials. Always store equipment in designated areas and promptly clean up spills to prevent slips and falls.

Disconnect power sources before starting any maintenance. This simple step is crucial to prevent accidental activation of machinery. Always double-check that all energy sources, whether electrical or hydraulic, are securely disengaged.

Familiarize yourself with emergency procedures. Knowing the location of fire extinguishers, first aid kits, and emergency exits can make a significant difference in critical situations. Regularly review these procedures to ensure that everyone involved is aware of the appropriate actions to take in case of an emergency.

By implementing these safety measures, individuals can effectively minimize risks and create a secure environment conducive to successful mechanical work. Prioritizing safety fosters not only personal well-being but also enhances the efficiency of the tasks at hand.

Common Replacement Parts and Costs

When maintaining heavy machinery, understanding the frequently needed components and their associated expenses is crucial for effective budgeting and planning. Regular upkeep often involves replacing key parts that can wear out over time due to rigorous use. This section highlights typical components that may require replacement and provides insights into their estimated costs.

Key Components

Among the most commonly replaced items are filters, gaskets, and fuel injectors. Filters, including air and oil variants, are essential for ensuring optimal performance and preventing contaminants from causing damage. Gaskets play a critical role in sealing joints, and over time, they can deteriorate, leading to leaks and inefficiencies. Additionally, fuel injectors can become clogged, impacting fuel delivery and overall performance.

Cost Overview

The costs for these parts can vary widely depending on the brand and specifications. For instance, air filters may range from $20 to $50, while oil filters typically cost between $10 and $30. Gaskets can range from $15 to $100, depending on the complexity of the design. Lastly, fuel injectors usually fall within the $100 to $300 range each. Understanding these prices can help operators prepare for maintenance expenses and ensure their machinery runs smoothly.

Troubleshooting Electrical Systems

Diagnosing issues within electrical circuits is crucial for maintaining optimal performance in machinery. Understanding the components and their interactions can help identify problems that may arise due to faulty wiring, connectors, or devices. This section will guide you through systematic approaches to effectively troubleshoot electrical systems.

Common Symptoms of Electrical Issues

- Inconsistent power supply

- Unresponsive controls

- Frequent blown fuses

- Overheating components

- Erratic performance of electrical devices

Diagnostic Steps

- Start by inspecting the power source to ensure it is functioning correctly.

- Examine all wiring for visible damage or wear.

- Use a multimeter to check for continuity in circuits.

- Test connectors for secure fittings and proper contact.

- Evaluate individual components for operational integrity.

- Document findings and symptoms to establish a pattern that may indicate the root cause.

By following these guidelines, you can methodically address electrical concerns and enhance the reliability of your systems.

Resource Recommendations for Further Learning

Exploring additional resources can significantly enhance your understanding and skills in maintenance and troubleshooting. Whether you are a beginner or an experienced technician, the right materials can provide valuable insights and practical knowledge to refine your abilities.

Books and Publications

- Technical handbooks focused on mechanical systems

- Industry journals that cover advancements and best practices

- Field guides detailing specifications and service techniques

Online Courses and Tutorials

- Websites offering courses on machinery operation and diagnostics

- YouTube channels featuring detailed video guides

- Forums where professionals share experiences and solutions

Utilizing these resources will deepen your expertise and help you stay updated with the latest trends and technologies in the field.