Guide to Repairing Your Necchi Sewing Machine

Understanding how to care for your crafting tools is essential for ensuring their longevity and optimal performance. Whether you are a hobbyist or a professional, having a solid foundation in maintenance practices can enhance your creative process. This section will provide insights into effectively managing your equipment.

Every tool has its unique features and requirements, making it crucial to familiarize yourself with the specific needs of your equipment. By adopting a proactive approach, you can prevent common issues that may arise during usage. This knowledge will empower you to address challenges with confidence and keep your tools in peak condition.

From regular cleaning to troubleshooting minor problems, mastering these techniques will allow you to maximize the functionality of your equipment. Embracing these practices will not only improve your experience but also foster a deeper appreciation for the craftsmanship involved in your creative endeavors.

Every user may encounter a range of typical problems while working with textile devices. Understanding these frequent challenges can help in maintaining optimal functionality and ensuring smooth operation. Below are some of the most commonly observed difficulties and their potential causes.

| Issue | Description | Possible Solutions |

|---|---|---|

| Skipped Stitches | Occurs when the needle fails to catch the thread properly. | Check needle type and size, ensure proper threading, and adjust tension settings. |

| Thread Bunching | Results in tangled threads under the fabric. | Re-thread the device, check for thread tension issues, and clean the bobbin area. |

| Fabric Jamming | Happens when the material gets stuck, preventing movement. | Remove the fabric, check for obstructions, and ensure proper feed dog engagement. |

| Uneven Stitch Length | Leads to inconsistent stitches, affecting the final look. | Adjust the stitch length settings and ensure the presser foot is properly engaged. |

Essential Tools for Repairs

To effectively address issues with your device, having the right set of instruments is crucial. These tools not only facilitate the process but also ensure precision and safety while you work. Understanding which items are necessary can help streamline your tasks and lead to successful outcomes.

Basic Toolkit

- Screwdrivers (flathead and Phillips)

- Pliers (needle-nose and standard)

- Wire cutters and strippers

- Scissors for trimming threads

- Measuring tape for accurate dimensions

Specialized Equipment

- Lubricants to maintain smooth operation

- Cleaning brushes for dust removal

- Replacement parts as needed

- Protective gear like gloves and goggles

Step-by-Step Troubleshooting Guide

This guide provides a systematic approach to identifying and resolving common issues that may arise during operation. Following these steps can help enhance performance and ensure smooth functionality.

Initial Checks

- Verify power supply and connections.

- Ensure that all components are securely in place.

- Examine the settings for correct adjustments.

Common Issues and Solutions

- *Problem: Inconsistent Performance*

- Check for any obstructions in the pathways.

- Clean the parts to remove dust or debris.

- *Problem: Unusual Noises*

- Inspect for loose components that may be causing vibrations.

- Lubricate moving parts as necessary to reduce friction.

How to Clean Your Machine Properly

Regular maintenance is essential for ensuring longevity and optimal performance of your equipment. A thorough cleaning routine helps prevent dust and debris from causing operational issues, allowing for smoother functionality and enhanced precision.

Gathering Your Supplies

Before starting the cleaning process, it’s important to have the right tools at hand:

- Soft cloths or microfiber rags

- Small brush or toothbrush

- Vacuum with a brush attachment

- Lubricating oil specific for the type of device

- Cleaning solution suitable for delicate surfaces

Step-by-Step Cleaning Process

- Unplug the device to ensure safety during cleaning.

- Wipe the exterior surfaces with a soft cloth dampened with a mild cleaning solution.

- Use a small brush to remove any lint or dust from hard-to-reach areas.

- Carefully vacuum the interior, ensuring that no loose particles remain.

- Apply a few drops of lubricating oil to the designated points as per the guidelines.

Replacing Worn-Out Parts

Over time, components in any device can become worn, affecting overall performance and functionality. Addressing these issues promptly is crucial to maintain efficiency and prolong the life of the equipment. This section will guide you through the process of identifying and replacing these essential elements.

Identifying Worn Components

The first step in the replacement process is to assess which parts are showing signs of wear. Common indicators include unusual noises, decreased efficiency, or visible damage. Regular inspections can help you catch these issues early, ensuring a smoother transition when it’s time for replacements.

Steps for Replacement

Once you’ve identified the components that need attention, gather the necessary tools and suitable replacements. Follow manufacturer guidelines for proper installation, ensuring each part fits securely. Take your time during this process to avoid potential mistakes that could lead to further complications.

Adjusting Tension Settings Correctly

Achieving the perfect balance in thread tightness is crucial for optimal stitching results. Proper adjustment can prevent issues such as puckering or uneven seams. By understanding how to fine-tune these settings, one can enhance the quality of their creations significantly.

Begin by identifying the recommended tension levels for the threads being used. Each type of thread may require different settings to function effectively. Once the initial setting is established, conduct a few test stitches on a scrap piece of fabric to observe the results.

If the stitches appear too loose, increase the tension slightly and re-test. Conversely, if the threads are overly tight and create bunching, reduce the tension accordingly. It may take several adjustments to find the ideal balance, but patience is key to achieving flawless results.

Dealing with Thread Jamming Problems

Thread jamming can be a frustrating issue that many face when using their textile equipment. It often occurs due to various factors that disrupt the smooth flow of thread, causing interruptions during the crafting process. Understanding the common causes and solutions can help restore functionality and improve overall experience.

Identifying the Causes

One of the primary reasons for thread jamming is incorrect threading. If the filament is not properly aligned through the guides and tension discs, it can lead to tangles. Additionally, using the wrong type of filament for the fabric being worked on can contribute to this problem. Ensure that the thread matches the requirements for the project at hand.

Effective Solutions

To resolve thread jams, start by removing the tangled thread and re-threading the equipment carefully. Check for any lint or debris that might obstruct the path and clean the area as needed. Adjusting the tension settings can also help prevent future issues. Regular maintenance and using high-quality materials are essential for smooth operation.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment requires a proactive approach to care and upkeep. By following some simple guidelines, you can enhance performance and minimize the risk of issues over time.

- Regular Cleaning: Dust and debris can accumulate, so it is essential to clean components frequently to prevent blockages and ensure smooth operation.

- Lubrication: Proper lubrication of moving parts is crucial. Use recommended oils to reduce friction and wear, helping to maintain efficiency.

- Inspection: Periodically inspect all components for signs of wear or damage. Early detection can prevent more significant problems down the line.

- Proper Storage: Store your equipment in a cool, dry place. Avoid exposure to extreme temperatures and humidity to protect materials.

- Follow Guidelines: Always adhere to the manufacturer’s recommendations for maintenance and care to ensure optimal performance.

By implementing these practices, you can enjoy reliable operation and prolong the functionality of your device for years to come.

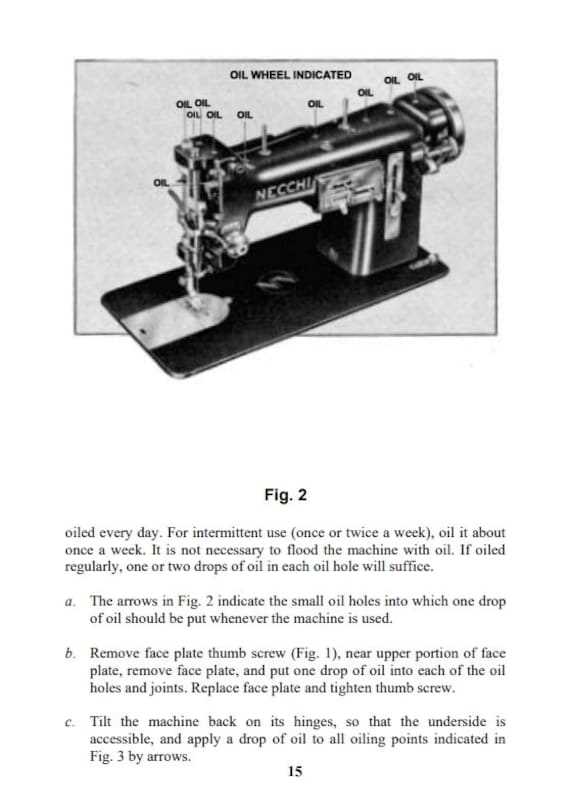

How to Oil Your Sewing Machine

Regular maintenance is essential for ensuring the longevity and smooth operation of your equipment. Proper lubrication reduces friction, minimizes wear, and enhances performance. Understanding how to effectively apply oil is crucial for keeping your device in optimal condition.

Begin by selecting a high-quality lubricant specifically designed for your type of apparatus. Before starting, ensure the device is unplugged to prevent any accidental activation. Locate the designated points for oil application, which are often specified in the guidelines provided with your equipment.

Using a few drops of oil, apply it to the moving parts, focusing on areas such as the needle bar, feed dogs, and any other parts that exhibit motion. Be cautious not to over-oil, as excess lubricant can attract dust and lint, potentially leading to complications.

After oiling, run the equipment briefly to distribute the lubricant evenly. This practice not only enhances functionality but also helps in identifying any issues that may need attention. Following this simple routine can significantly extend the life of your valuable apparatus.

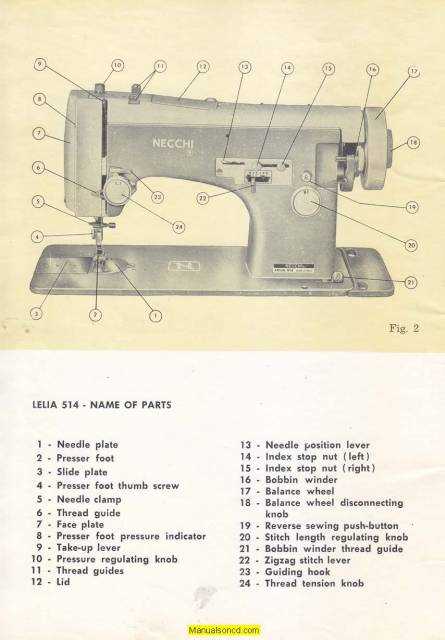

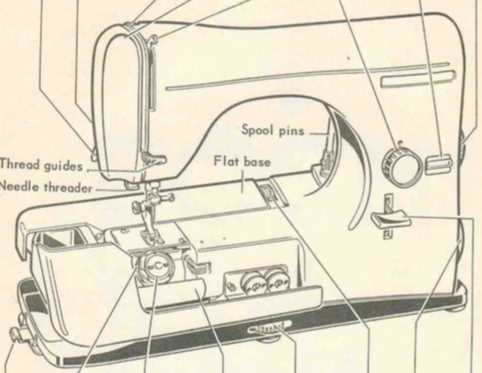

Understanding the Stitch Selection Mechanism

The process of choosing different types of stitching is crucial for achieving desired results in various fabric projects. This system enables users to customize their outcomes based on fabric characteristics and the intended purpose of the work. It plays a significant role in ensuring versatility and precision in crafting.

At the core of this functionality is a set of controls that allows individuals to switch between various patterns. These controls may be mechanical or electronic, providing options that cater to both novice and experienced users. The arrangement typically involves dials or buttons that activate specific stitch configurations, reflecting the user’s selection.

Moreover, understanding this system enhances the overall experience and empowers users to explore creative possibilities. By grasping how to effectively utilize this feature, one can unlock a broader range of techniques, contributing to more innovative and satisfying outcomes in textile projects.

Fixing Electrical Issues Safely

Addressing electrical malfunctions requires careful attention and a methodical approach to ensure safety and effectiveness. Understanding the potential hazards associated with electrical components is essential for anyone involved in maintenance tasks.

Before beginning any troubleshooting, always unplug the device to eliminate the risk of electric shock. This precaution is vital when inspecting wires or replacing components. Utilize appropriate tools such as insulated screwdrivers to further enhance safety during the process.

In situations where a fault is suspected, it is advisable to check for visible damage like frayed wires or burnt connectors. If any defects are found, it is crucial to replace the damaged parts before proceeding. Regular maintenance checks can help prevent issues from escalating, ensuring long-term functionality.

If problems persist after addressing obvious issues, consider consulting a professional. Electrical systems can be complex, and expert guidance is often necessary to avoid dangerous situations. Prioritizing safety and thoroughness will lead to successful resolutions in managing electrical concerns.

Resources for Further Assistance

When tackling issues with your equipment, it’s beneficial to explore various resources that can provide guidance and support. These tools and communities can enhance your understanding and help resolve common challenges effectively.

Online forums and dedicated websites often serve as valuable platforms where enthusiasts and experts share their experiences. Engaging with these communities can lead to discovering practical solutions and tips that might not be found in traditional literature.

Additionally, instructional videos and tutorials available on popular platforms can visually demonstrate techniques and fixes. These resources cater to different learning styles, ensuring that you can find the method that works best for you.

Don’t overlook the importance of local workshops and classes. Participating in hands-on sessions can deepen your knowledge and provide personalized assistance from seasoned professionals, making it easier to master your craft.