Essential Guide to Repairing the 1920 Ford Tractor

In the world of classic farming equipment, understanding the intricacies of maintenance is crucial for longevity and optimal performance. This guide aims to provide comprehensive insights into the upkeep and restoration of vintage machines that have played a significant role in agricultural history. With the right knowledge, enthusiasts can ensure their beloved implements continue to operate smoothly for years to come.

The nuances of vintage machinery demand a meticulous approach. From troubleshooting common issues to executing specific techniques, each aspect requires attention to detail and a thorough understanding of mechanical principles. This resource will empower owners with the information needed to tackle various challenges and keep their equipment in peak condition.

Whether you are a seasoned collector or a newcomer to the world of classic agricultural tools, the information contained here serves as a vital companion in your journey. Embracing the history and technology of these machines not only preserves their legacy but also enhances your skills as a caretaker of farming heritage.

Overview of the Ford 1920 Tractor

This section provides an insight into a notable piece of machinery renowned for its versatility and efficiency. Designed for various agricultural tasks, this compact powerhouse has earned a reputation among farmers and landowners alike.

Key features that contribute to its popularity include:

- Compact size, making it suitable for small to medium-sized farms.

- Reliable engine performance, ensuring consistent power for demanding tasks.

- User-friendly controls, which enhance operability for both seasoned users and novices.

- Durable construction, built to withstand the rigors of outdoor work.

This model excels in a range of applications, such as:

- Plowing and tilling soil for planting.

- Hauling materials and equipment across fields.

- Maintaining landscaping and managing properties.

- Operating various attachments, broadening its functionality.

With its blend of strength and adaptability, this equipment remains a valuable asset in the agricultural sector, supporting productivity and efficiency in various operations.

Common Issues with Ford 1920 Models

Owners of certain agricultural machines often encounter a range of frequent challenges that can affect performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity. Here are some of the most prevalent concerns faced by operators of these models.

Engine Problems

One of the primary difficulties reported involves the engine. Common symptoms include difficulty starting, unusual noises, and excessive exhaust emissions. These issues may stem from various factors, such as fuel contamination or wear in internal components. Regular maintenance and timely inspections can help mitigate these concerns.

Hydraulic System Failures

The hydraulic system is another area where users often experience complications. Symptoms like sluggish operation or leaks can significantly hinder productivity. Factors contributing to these failures may include fluid degradation or damaged seals. Regularly checking fluid levels and ensuring the integrity of components are vital for preventing these issues.

Essential Tools for Tractor Repairs

When maintaining and servicing heavy machinery, having the right instruments at your disposal is crucial for effective work. The right toolkit not only enhances efficiency but also ensures that tasks are completed safely and accurately. Below are some indispensable items that every technician should consider incorporating into their arsenal.

Basic Hand Tools

At the foundation of any toolkit are basic hand instruments. Wrenches, screwdrivers, and pliers are vital for loosening and tightening various components. Investing in a high-quality set will provide versatility and durability. Additionally, having torque wrenches ensures that bolts and nuts are fastened to the manufacturer’s specifications, preventing damage or failures during operation.

Diagnostic Equipment

In modern machinery, technology plays a pivotal role in troubleshooting issues. Diagnostic scanners are essential for identifying faults in electronic systems, allowing for prompt resolution. Moreover, multimeters can measure voltage and current, making it easier to assess electrical components. Having these advanced tools not only saves time but also enhances the quality of service provided.

Step-by-Step Repair Procedures

This section provides a detailed guide to assist you in the restoration and maintenance of your equipment. By following these outlined processes, you can ensure optimal performance and longevity, addressing common issues that may arise during use.

Preparation and Safety

Before starting any work, it’s crucial to prepare adequately and prioritize safety. Follow these steps:

- Gather all necessary tools and materials.

- Ensure a clean and organized workspace.

- Wear appropriate safety gear, such as gloves and goggles.

- Disconnect the power source to prevent accidents.

Diagnostic Procedures

Identifying the issue is key to effective troubleshooting. Use the following steps to diagnose the problem:

- Conduct a visual inspection for any obvious signs of damage.

- Check fluid levels and look for leaks.

- Listen for unusual noises during operation.

- Test key components systematically to isolate the issue.

By following these procedures, you can tackle problems methodically, ensuring a successful outcome for your maintenance tasks.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring that your machinery remains in optimal condition for years to come. Regular attention not only enhances performance but also significantly extends the lifespan of your equipment. Here are some valuable suggestions to keep your vehicle functioning smoothly and efficiently.

Routine Inspections

- Check fluid levels frequently, including oil, coolant, and hydraulic fluids.

- Inspect belts and hoses for signs of wear and tear.

- Examine tires for proper inflation and tread depth.

Cleaning Practices

- Clean air filters regularly to ensure efficient airflow.

- Remove debris from exterior surfaces to prevent corrosion.

- Wash the undercarriage to avoid buildup that can lead to rust.

By following these simple yet effective maintenance practices, you can maximize the reliability and longevity of your machinery, ultimately leading to better performance and lower operational costs.

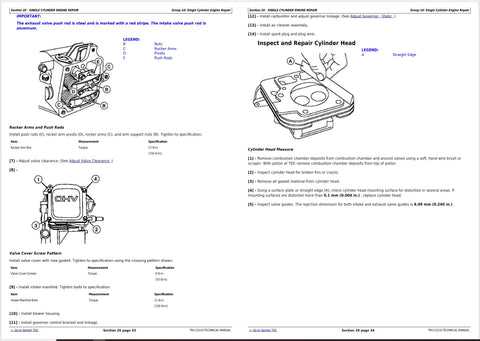

Engine Troubleshooting Techniques

Identifying and resolving issues within an engine can be a challenging yet rewarding process. Effective troubleshooting requires a systematic approach, allowing one to diagnose problems accurately and implement appropriate solutions. By understanding the common symptoms and applying strategic techniques, you can restore functionality and enhance performance.

Observation is the first step in diagnosing engine malfunctions. Pay attention to unusual noises, vibrations, or performance irregularities. These indicators often provide valuable clues regarding underlying issues. Make detailed notes of any symptoms, as this information will assist in further analysis.

Next, visual inspection plays a critical role. Check for leaks, worn components, or damaged hoses. Look for signs of overheating, such as discolored engine parts. Inspecting electrical connections and wiring for corrosion or fraying can also reveal potential problems.

Utilizing diagnostic tools can greatly enhance your troubleshooting efforts. Tools like multimeters, pressure gauges, and scan tools help measure various parameters and detect faults. Understanding how to interpret the data these instruments provide is essential for accurate diagnosis.

Once you have gathered information, elimination techniques can be employed. This involves systematically ruling out potential causes by testing components individually. Start with the most likely sources of trouble and work through the list, focusing on one issue at a time to avoid confusion.

Finally, maintain a methodical approach throughout the troubleshooting process. Document each step taken and the results observed. This practice not only aids in current repairs but also serves as a valuable reference for future maintenance and problem-solving endeavors.

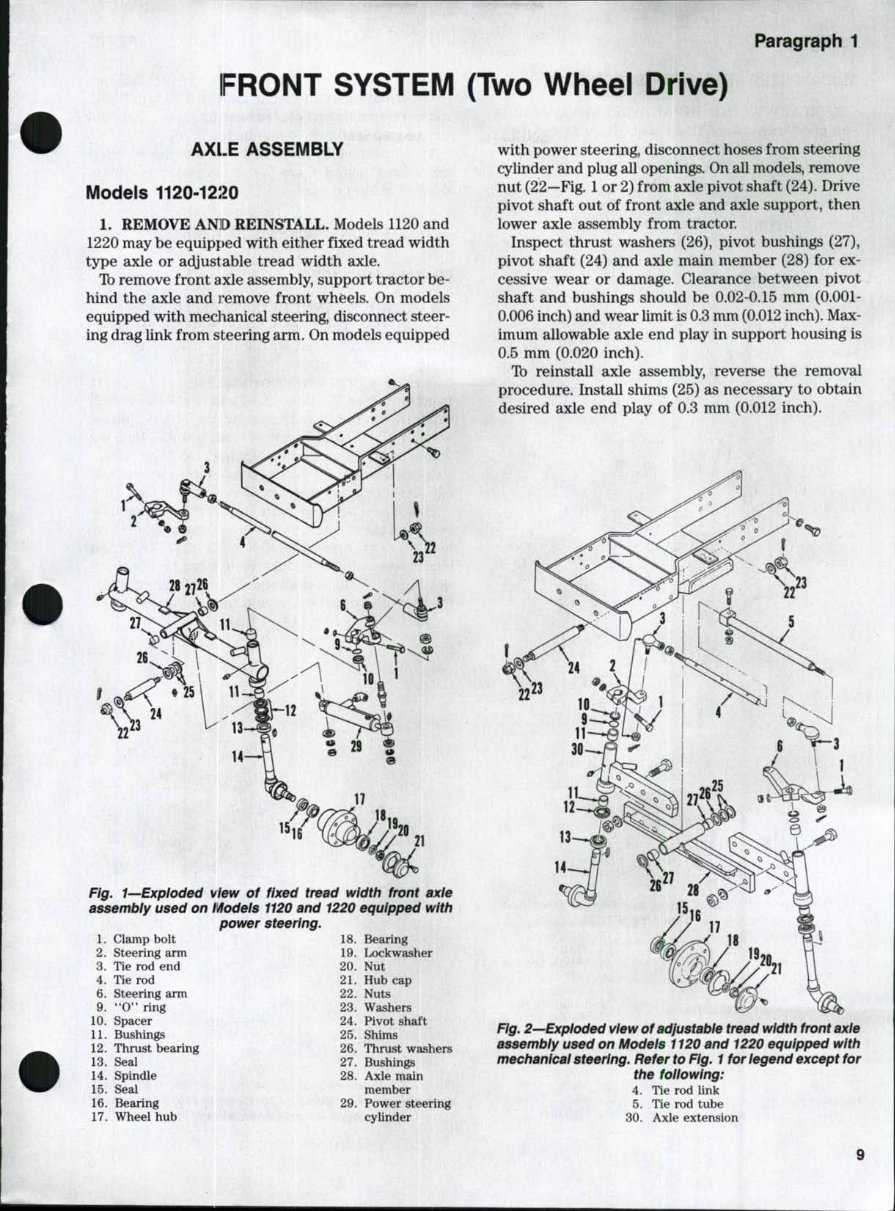

Hydraulic System Repair Guidelines

This section provides essential instructions for addressing issues within hydraulic systems, emphasizing systematic troubleshooting and component maintenance. Understanding the core mechanics involved is vital for effective diagnosis and resolution of any operational challenges.

Identifying Common Issues

Begin by observing any unusual behavior such as leaks, slow response times, or erratic movements. These symptoms often indicate potential faults in hoses, seals, or the pump. Conduct a thorough visual inspection to pinpoint the source of the problem.

Maintenance Practices

Regular upkeep is crucial for optimal functionality. Ensure that fluid levels are adequate and free from contamination. Replace filters as needed and inspect components periodically to prevent minor issues from escalating into major failures.

Electrical System Diagnostics

Understanding the functionality and potential issues of an electrical system is crucial for maintaining optimal performance in agricultural machinery. This section focuses on diagnosing common electrical faults, ensuring that all components work harmoniously and efficiently. Identifying problems early can save time and resources, leading to enhanced productivity.

Common Issues and Symptoms

Several symptoms may indicate electrical malfunctions. For instance, frequent blown fuses, erratic behavior of gauges, or failure to start can all point to underlying issues within the system. Corrosion at connections, worn wiring, or faulty switches are typical culprits that disrupt the flow of electricity.

Diagnostic Procedures

To effectively diagnose electrical issues, start with a thorough visual inspection of all wiring and connections. Look for signs of wear or damage. Utilize a multimeter to measure voltage, continuity, and resistance in circuits. Testing individual components such as batteries, alternators, and relays can help isolate the source of the problem. Documenting findings throughout the process is essential for future reference and troubleshooting.

Transmission and Gear Maintenance

Ensuring optimal performance of the drive system is essential for smooth operation. Regular upkeep of the transmission and gears not only prolongs their lifespan but also enhances efficiency and reliability. Understanding the components and their functions is crucial for effective maintenance.

- Check fluid levels frequently to maintain proper lubrication.

- Inspect seals and gaskets for signs of wear or leaks.

- Clean or replace filters as needed to prevent contamination.

Implementing a routine inspection schedule can help identify issues before they escalate. Below are key practices to consider:

- Conduct regular fluid changes according to the manufacturer’s recommendations.

- Monitor gear engagement for any unusual noises or vibrations.

- Examine the shift linkage for proper adjustment and smooth operation.

In addition, addressing any signs of slippage or difficulty in shifting promptly can prevent more severe damage. Keeping a detailed log of maintenance activities can also aid in tracking performance over time.

Ultimately, consistent attention to these elements will ensure a dependable and efficient power transmission system, allowing for seamless functionality in various tasks.

Safety Precautions During Repairs

Ensuring safety while performing maintenance tasks is crucial to prevent accidents and injuries. Adhering to specific guidelines can help create a secure working environment and promote efficient handling of machinery components. Always prioritize protective measures to safeguard yourself and those around you.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves, goggles, and steel-toed boots, which help protect against potential hazards. Below is a table summarizing the recommended gear:

| Type of Gear | Purpose |

|---|---|

| Gloves | Protect hands from sharp objects and chemicals |

| Goggles | Shield eyes from dust and debris |

| Steel-toed Boots | Prevent foot injuries from heavy equipment |

| Ear Protection | Reduce noise exposure in loud environments |

Work Environment Considerations

Creating a safe workspace is equally important. Ensure the area is well-lit, free of clutter, and equipped with proper ventilation. Regularly inspect tools and equipment for any signs of wear or malfunction. These steps can significantly reduce the risk of accidents during maintenance tasks.

Parts Replacement: What You Need

When it comes to maintaining machinery, knowing when and how to replace components is crucial for optimal performance. Regular updates and replacements not only enhance functionality but also prolong the lifespan of the equipment. Understanding the essentials of parts replacement is key for any operator or enthusiast looking to ensure their machine runs smoothly.

Identifying Components for Replacement

Before initiating any changes, it’s important to accurately identify which parts require attention. Common indicators include unusual noises, decreased efficiency, or visible wear. Consult the specifications for your equipment to determine the correct parts, ensuring compatibility and reliability. Always opt for high-quality replacements to avoid further issues down the line.

Tools and Materials Required

Equipping yourself with the right tools is essential for successful replacement. Basic tools such as wrenches, screwdrivers, and pliers should be readily available. Additionally, you may need specific items tailored to particular components. Gather all necessary materials beforehand to streamline the process and minimize downtime. Taking the time to prepare will make the task more efficient and effective.

Resources for Ford 1920 Owners

Maintaining and enhancing your agricultural equipment requires access to reliable information and resources. Whether you are looking for guidance on upkeep, troubleshooting, or performance optimization, various tools and materials can assist you in your journey. This section outlines key resources tailored to owners of this specific model, ensuring you have the support needed to keep your machinery in top condition.

Online Forums and Communities

Engaging with fellow enthusiasts and professionals can provide invaluable insights. Consider exploring the following platforms:

- Dedicated Forums: Join specialized online forums where users share their experiences, tips, and solutions.

- Social Media Groups: Participate in Facebook groups or other social networks focused on agricultural machinery for real-time advice.

- Local Clubs: Look for nearby clubs or associations that host events and workshops.

Publications and Literature

Accessing printed and digital materials can enhance your knowledge significantly. Recommended resources include:

- Technical Books: Search for literature that covers operation and maintenance best practices.

- Magazines: Subscribe to industry-specific magazines that feature articles, reviews, and how-to guides.

- Newsletters: Sign up for newsletters from manufacturers and equipment specialists for the latest updates and tips.