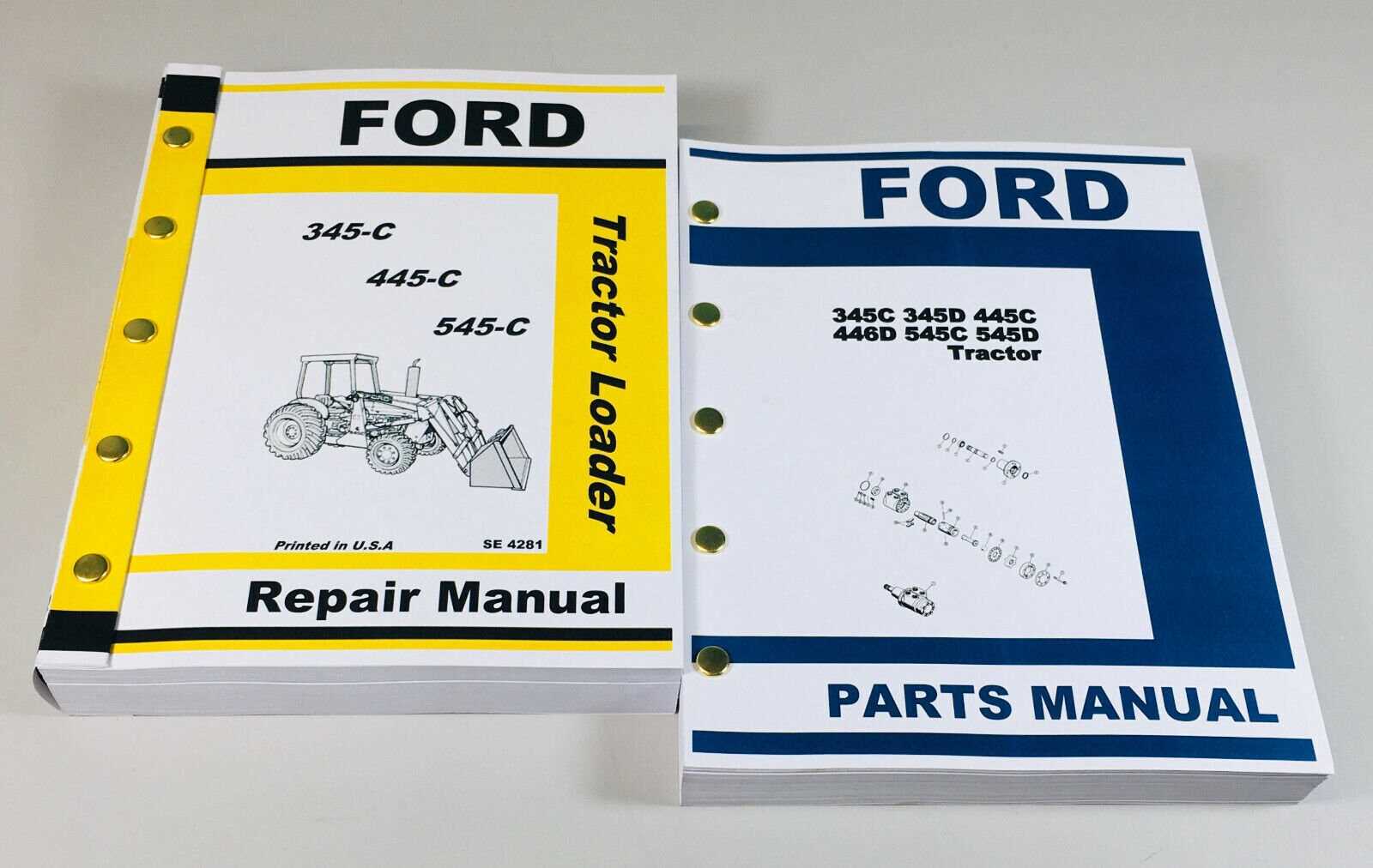

Comprehensive Guide to Repairing the Ford 445 Tractor

In the realm of farming equipment, understanding the intricacies of upkeep is vital for ensuring longevity and efficiency. This section delves into essential practices and guidelines that can help maintain and optimize the performance of heavy machinery. By focusing on systematic approaches, operators can enhance the reliability of their equipment.

Various components require attention to prevent wear and tear, ensuring smooth operation during demanding tasks. Regular inspections and timely interventions are crucial in identifying potential issues before they escalate. This proactive strategy not only minimizes downtime but also extends the lifespan of valuable machinery.

Furthermore, this guide aims to equip users with practical insights into troubleshooting and resolving common challenges faced by operators. Whether you are a seasoned professional or a newcomer, the information provided here will empower you to tackle maintenance tasks with confidence and efficiency.

Essential Tools for Tractor Repair

Having the right equipment is crucial for maintaining and fixing machinery effectively. This section outlines the key instruments needed to ensure optimal functionality and longevity of your agricultural machinery.

Basic Hand Tools

- Wrenches: Various sizes to accommodate different fasteners.

- Screwdrivers: Flathead and Phillips for diverse applications.

- Pliers: Essential for gripping and twisting tasks.

- Socket Set: Allows for quick adjustments and replacements.

Specialized Equipment

- Diagnostic Tools: For identifying issues and assessing performance.

- Grease Gun: Necessary for lubrication of moving parts.

- Jack Stands: Ensure safety when lifting heavy components.

- Torque Wrench: Important for applying precise force to fasteners.

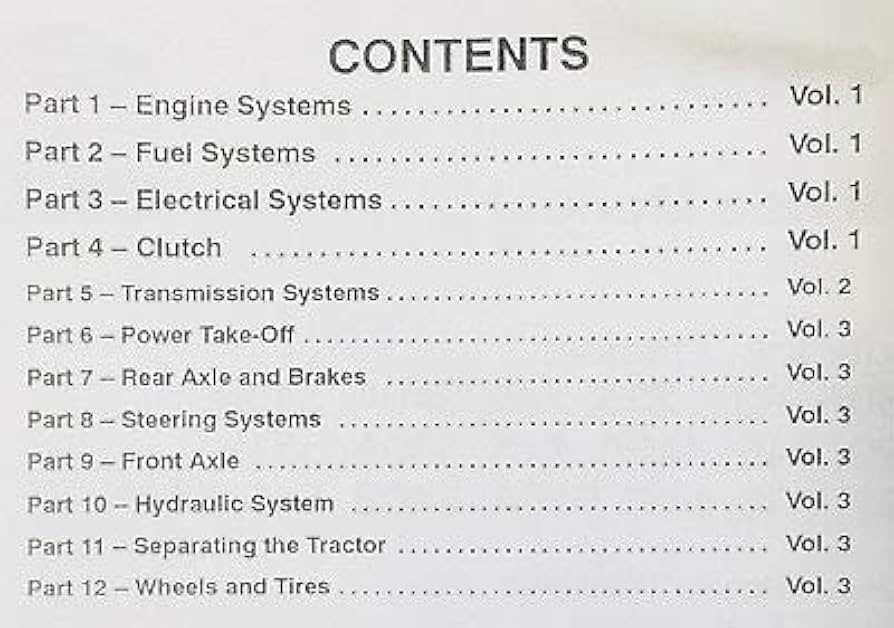

Understanding the Ford 445 System

This section delves into the intricate workings of a renowned agricultural machine, focusing on its essential components and their interactions. Grasping the functionality of this system is crucial for optimal performance and maintenance.

Core Components: At the heart of this machinery lies a well-coordinated assembly of parts that work together seamlessly. Understanding these elements helps users identify potential issues and enhances overall efficiency.

Operational Insights: Familiarity with the operational dynamics allows for informed decisions during usage. Knowledge of how various subsystems contribute to the overall functionality aids in troubleshooting and performance enhancement.

Maintenance Practices: Regular attention to the key elements ensures longevity and reliability. Implementing recommended procedures will not only safeguard the equipment but also maximize productivity in the field.

Common Issues and Solutions

This section explores frequent challenges faced by users of specific agricultural machinery and provides practical solutions to address them. Understanding these common problems can enhance the efficiency and longevity of your equipment.

Engine Performance Problems

Many operators encounter issues related to engine performance, which can manifest as reduced power or difficulty starting. These problems often stem from fuel system malfunctions or air intake blockages.

Hydraulic System Failures

Another prevalent concern involves the hydraulic system, where users may experience leaks or insufficient lifting capacity. Regular maintenance and timely troubleshooting are key to resolving these issues.

| Issue | Possible Causes | Recommended Solutions |

|---|---|---|

| Reduced Engine Power | Clogged fuel filters, air intake issues | Replace filters, check air intake |

| Starting Difficulties | Weak battery, faulty ignition | Test battery, inspect ignition system |

| Hydraulic Leaks | Worn seals, loose connections | Replace seals, tighten connections |

| Insufficient Lifting Capacity | Low fluid levels, clogged filters | Check fluid levels, replace filters |

Step-by-Step Maintenance Guide

Proper upkeep is essential for ensuring the longevity and efficiency of your equipment. This section provides a structured approach to regular care, allowing you to maintain optimal performance. Following these guidelines will help you address common issues and enhance the functionality of your machinery.

Routine Inspections

Begin with frequent evaluations of your equipment. Check fluid levels, examine hoses for wear, and inspect components for any signs of damage. Regular monitoring can help identify potential problems early, preventing more significant repairs down the line.

Essential Servicing Tasks

Perform key servicing activities, such as oil changes and filter replacements, at recommended intervals. Keeping these elements in top condition minimizes wear and keeps your machinery operating smoothly. Don’t overlook the importance of cleaning parts and ensuring all connections are secure.

Engine Troubleshooting Techniques

Identifying and resolving issues within an engine requires a systematic approach. By employing effective diagnostic strategies, operators can pinpoint the root causes of malfunctions, ensuring optimal performance and longevity.

Begin by examining the fuel system, checking for blockages or leaks that may hinder proper flow. Inspect the air intake components for any obstructions that could affect combustion efficiency. Additionally, reviewing the electrical connections and battery health can reveal potential problems with starting and power delivery.

Listening for unusual sounds while the engine is running can also provide clues. Rattling or knocking noises might indicate mechanical wear or misalignment, while excessive vibrations could signal mounting issues. Regular monitoring of fluid levels and conditions helps to detect leaks or contamination early, preventing further complications.

Utilizing diagnostic tools, such as pressure gauges and multimeters, allows for more precise evaluations of system performance. By following these techniques, operators can effectively troubleshoot and maintain engine functionality.

Hydraulic System Repairs Explained

The hydraulic system is a crucial component that facilitates efficient operation in various machinery. Understanding the common issues that can arise within this system is essential for maintaining optimal performance. This section delves into the intricacies of diagnosing and addressing these concerns to ensure reliable functionality.

Common Issues

Leaks are often the primary problem encountered in hydraulic systems. These leaks can occur at connections, seals, or hoses, leading to a significant loss of fluid and reduced efficiency. Identifying the source of the leak is vital, as it allows for targeted solutions.

Diagnosis Techniques

To effectively troubleshoot, one must employ various techniques such as visual inspections and pressure tests. Using a pressure gauge can help ascertain whether the system is functioning within the required parameters. If the pressure is too low, it may indicate blockages or worn-out components.

Maintenance Tips

Regular maintenance is key to preventing major failures. This includes checking fluid levels, replacing filters, and inspecting hoses for signs of wear. Keeping the hydraulic fluid clean is essential to ensure the longevity of the system’s components.

Repair Procedures

When it comes to fixing leaks, replacing damaged seals and hoses is often necessary. In cases of more severe damage, components may need to be replaced entirely. It is crucial to follow proper procedures during these repairs to avoid further complications.

Conclusion

A thorough understanding of the hydraulic system’s workings enables effective maintenance and troubleshooting. By addressing issues promptly and adhering to best practices, one can ensure the longevity and reliability of the machinery.

Electrical Components and Diagnostics

This section delves into the essential elements of the electrical system, focusing on their functionality and methods for assessment. Understanding these components is vital for effective troubleshooting and ensuring optimal performance of machinery.

Key Elements of the Electrical System

The electrical framework encompasses various parts, including the battery, alternator, and wiring harnesses. Each component plays a significant role in the overall operation. The battery provides the necessary power to start the engine, while the alternator recharges it and powers the electrical accessories. Proper functioning of these elements is crucial for reliability.

Diagnostic Techniques

To maintain efficiency, implementing systematic diagnostic approaches is essential. Regular inspections can help identify issues such as voltage drops or short circuits. Utilizing diagnostic tools, such as multimeters and circuit testers, aids in pinpointing faults accurately. Regular maintenance and checks contribute to extending the lifespan of the electrical system.

Restoring Performance and Efficiency

Enhancing the functionality and productivity of agricultural machinery is crucial for optimal operation. By focusing on key aspects, one can ensure that these machines perform at their best and maintain efficiency over time.

Key Areas to Address

- Regular Maintenance: Consistent checks and servicing are vital to keep machinery running smoothly.

- Fluid Levels: Ensuring that all fluids are at proper levels can significantly affect performance.

- Component Replacement: Timely substitution of worn-out parts helps prevent larger issues.

Practical Steps for Improvement

- Inspect filters and replace them as necessary to ensure proper airflow and fluid flow.

- Clean or replace spark plugs to enhance ignition and fuel efficiency.

- Check tire pressure and tread for better traction and handling.

- Calibrate settings and controls for optimal performance tailored to specific tasks.

By following these steps, one can significantly enhance the overall operation and longevity of the equipment, ultimately leading to better productivity and reduced downtime.

Safety Precautions During Repairs

When undertaking maintenance tasks on heavy machinery, adhering to safety measures is crucial to ensure both personal well-being and the integrity of the equipment. Prioritizing these precautions helps to mitigate risks associated with mechanical work and enhances overall efficiency.

Before commencing any work, it is essential to wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. This gear protects against potential hazards such as sharp objects and heavy components. Additionally, maintaining a clean workspace minimizes the likelihood of accidents and allows for a smoother workflow.

Always consult the relevant guidelines and instructions to familiarize yourself with the machinery’s specific requirements. Ensuring proper tool usage and handling not only improves safety but also promotes effective task completion. It is advisable to work in a well-ventilated area to prevent exposure to harmful fumes or dust.

In the event of an emergency, having a first aid kit readily available can be a lifesaver. Moreover, it is wise to inform others of your work plans, particularly if you are operating in isolated locations. This step ensures that help is accessible should an incident occur.

By prioritizing safety through these practices, individuals can confidently engage in the maintenance of heavy machinery, reducing the risk of injury and ensuring a productive experience.

Resources for Parts and Accessories

Finding the right components and add-ons is essential for maintaining optimal performance and extending the lifespan of your equipment. This section provides valuable insights into where you can source quality parts and accessories that meet your needs.

Here are some recommended sources to consider:

- Online Retailers: Numerous websites specialize in providing a wide range of components for various machinery. Look for reputable suppliers that offer customer reviews and return policies.

- Local Dealers: Authorized dealerships often carry original parts and can provide expert advice on compatibility and installation.

- Aftermarket Suppliers: Many companies produce alternative options that may be more affordable while still meeting performance standards. Ensure they are well-reviewed.

- Salvage Yards: These can be excellent places to find used components at a fraction of the cost. Inspect items carefully for wear and functionality.

- Online Marketplaces: Platforms such as eBay or specialized forums can offer new and used items from various sellers, allowing for comparison shopping.

When sourcing parts, always verify the compatibility with your specific model and consider reaching out to experts for guidance to ensure a successful maintenance or enhancement project.