Repair Guide for the 2003 Grand Marquis

This section offers an extensive overview of essential information related to the upkeep and troubleshooting of a specific model of automobile. Understanding the intricacies of your vehicle’s systems is crucial for ensuring optimal performance and longevity.

By delving into the various components and functions, you will gain insights into effective practices for maintenance and problem resolution. Whether you are a novice or an experienced enthusiast, this guide is designed to enhance your knowledge and empower you to tackle challenges with confidence.

Essential tips and techniques are provided to assist in diagnosing issues and implementing solutions. Familiarizing yourself with these aspects not only promotes a smoother driving experience but also contributes to the overall health of your automobile.

Explore the following sections to uncover valuable information that will aid in your journey of maintaining your vehicle in top condition.

Understanding Your 2003 Mercury Grand Marquis

Owning a full-size vehicle from the early 2000s offers a blend of comfort and performance that remains appealing. This section will guide you through the key features and components of this model, ensuring you maximize its potential and enjoy a smooth driving experience.

Engine and Performance: The robust powertrain is designed to deliver reliable acceleration and responsiveness. Familiarizing yourself with the engine specifications can help you understand its capabilities and maintenance needs.

Comfort and Interior Features: Spacious interiors with high-quality materials provide a welcoming environment for both the driver and passengers. Learning about the various comfort features can enhance your travel experience.

Safety and Reliability: This vehicle includes several safety mechanisms that contribute to a secure ride. Understanding these systems is essential for ensuring safety on the road.

Maintenance Tips: Regular upkeep is vital for long-term performance. Recognizing common maintenance tasks will help you keep the vehicle in optimal condition.

Common Issues with the Vehicle

This section outlines some prevalent challenges encountered by owners of this full-sized sedan. Understanding these issues can help in proactive maintenance and informed decision-making.

- Electrical Problems: Many users report issues with the electrical system, including malfunctioning lights and faulty window mechanisms.

- Transmission Concerns: Transmission delays and rough shifting are common complaints, often requiring attention to prevent more serious damage.

- Suspension Wear: Premature wear of suspension components can lead to an uncomfortable ride and handling difficulties.

- Engine Performance: Some vehicles exhibit reduced power and efficiency, often attributed to fuel system issues or sensor malfunctions.

- Cooling System Failures: Overheating can occur due to radiator leaks or thermostat failures, which necessitate prompt action to avoid engine damage.

Addressing these concerns promptly can significantly enhance the longevity and performance of the vehicle, ensuring a smoother driving experience.

Essential Tools for Repairs

Having the right equipment is crucial when it comes to maintaining and servicing vehicles. A well-equipped workspace can significantly enhance efficiency and ensure that tasks are completed accurately. Below is a list of necessary instruments that every automotive enthusiast should consider for their toolkit.

Basic Hand Tools

- Wrenches: A variety of sizes is essential for loosening and tightening bolts.

- Screwdrivers: Both flathead and Phillips types are necessary for different fasteners.

- Pliers: Useful for gripping and manipulating various components.

Specialized Equipment

- Jack and Stands: Critical for lifting the vehicle safely.

- Oil Filter Wrench: Designed to remove oil filters with ease.

- Torque Wrench: Ensures fasteners are tightened to manufacturer specifications.

Step-by-Step Brake Maintenance Guide

Regular upkeep of braking systems is essential for ensuring safe driving and optimal vehicle performance. This guide outlines the fundamental procedures for maintaining and inspecting brake components, helping to prevent costly repairs and enhance overall safety on the road.

Tools and Materials Needed

- Jack and jack stands

- Brake cleaner

- Wrenches and sockets

- Brake pads and rotors (if replacement is needed)

- Torque wrench

- Protective gear (gloves and safety glasses)

Inspection Process

- Begin by lifting the vehicle with a jack and securing it on jack stands.

- Remove the wheel to access the braking assembly.

- Check the brake pads for wear; they should be at least 1/4 inch thick. If they are thinner, replacement is necessary.

- Examine the brake rotors for grooves or cracks. Smooth, even surfaces are ideal.

- Inspect brake lines and fluid levels for any signs of leaks or contamination.

By adhering to this guide, you can maintain the effectiveness of your vehicle’s braking system and ensure a safer driving experience.

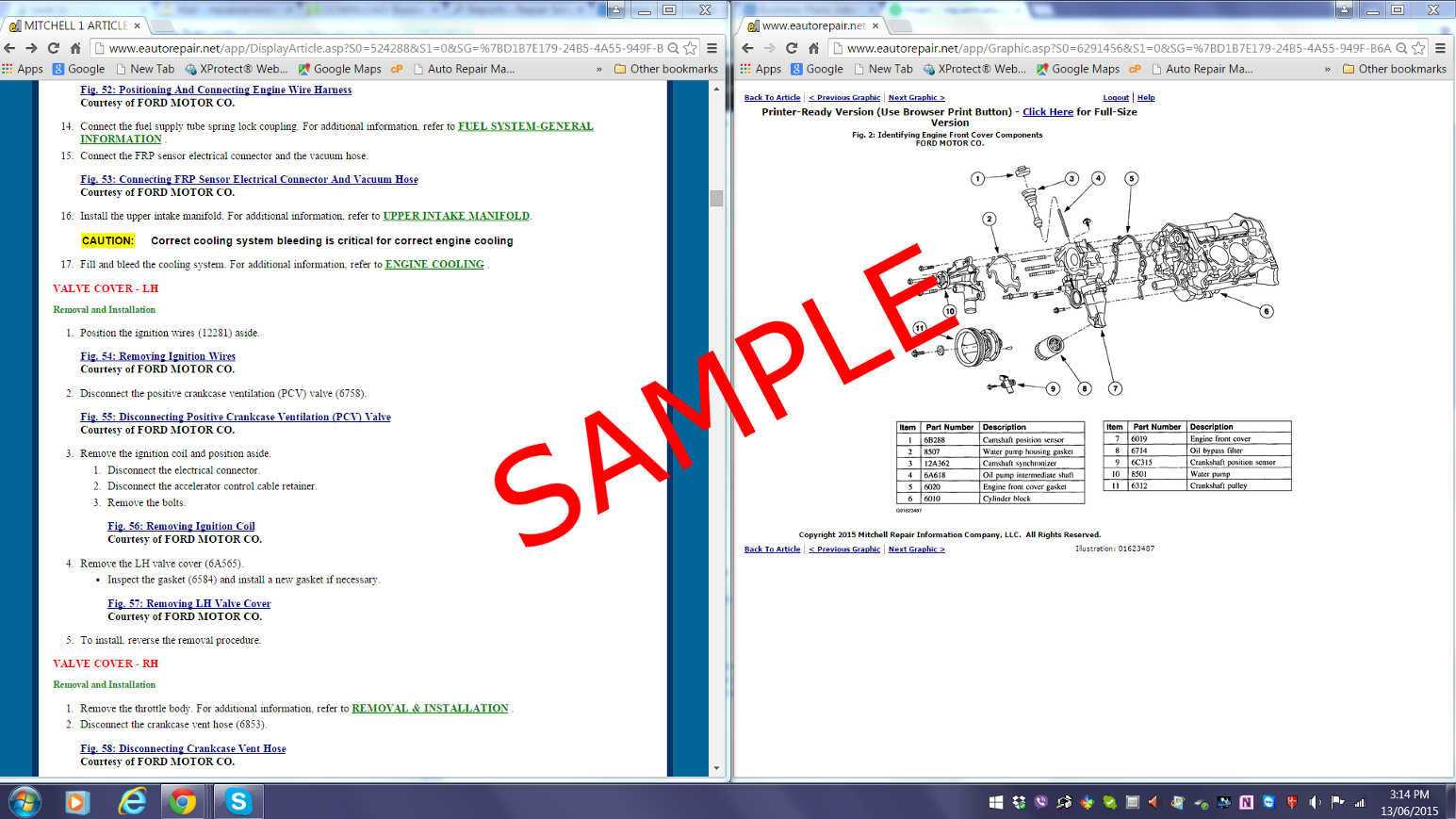

Engine Troubleshooting Techniques

Identifying and resolving issues within an automotive powertrain is essential for maintaining optimal performance. Various methods can be employed to diagnose problems effectively, ensuring that potential faults are addressed promptly.

One effective approach involves conducting a thorough visual inspection. Look for signs of wear, leaks, or damage to components such as hoses, belts, and electrical connections. Pay attention to any unusual noises or smells that may indicate underlying issues.

Next, utilize diagnostic tools to retrieve trouble codes from the vehicle’s computer system. These codes provide valuable insights into the specific areas that may require attention. Interpreting these codes accurately can save time and resources in the troubleshooting process.

Additionally, perform tests on various engine systems, including ignition, fuel delivery, and exhaust. Measuring parameters such as voltage and pressure can help pinpoint malfunctions. A systematic approach to testing ensures that no area is overlooked, leading to a comprehensive understanding of the situation.

Lastly, consulting technical resources and forums can provide additional guidance and shared experiences from other automotive enthusiasts. Engaging with a community can offer new perspectives and solutions to complex challenges.

Electrical System Diagnostics Explained

The process of evaluating the electrical framework in vehicles is crucial for maintaining optimal performance. Understanding how to assess various components can help identify issues before they escalate, ensuring a reliable driving experience.

Key aspects of electrical diagnostics include analyzing voltage levels, current flow, and resistance across circuits. This involves utilizing specialized tools and techniques to pinpoint discrepancies that could indicate malfunctioning parts.

Moreover, systematic troubleshooting methods enable technicians to isolate problems effectively. By following a logical sequence, it’s possible to trace faults back to their source, whether it’s a defective battery, faulty wiring, or a malfunctioning control module.

In summary, comprehensive knowledge of electrical diagnostics empowers vehicle owners and technicians alike to maintain and enhance vehicle reliability through timely interventions.

Cooling System Maintenance Tips

Proper upkeep of the cooling system is crucial for ensuring optimal engine performance and preventing overheating. Regular maintenance can help extend the life of your vehicle and improve its efficiency. Here are some essential tips to keep in mind.

| Tip | Description |

|---|---|

| Check Coolant Levels | Regularly inspect the coolant levels in the reservoir to ensure they are within the recommended range. Low levels can lead to overheating. |

| Inspect Hoses | Examine hoses for signs of wear, cracking, or leaks. Replacing damaged hoses promptly can prevent coolant loss and system failure. |

| Flush the System | Periodically flushing the cooling system removes sediment and contaminants, which can hinder performance. Follow manufacturer guidelines for the recommended interval. |

| Check the Thermostat | A malfunctioning thermostat can disrupt the cooling process. Regularly testing and replacing it if necessary is vital for maintaining proper temperature regulation. |

| Monitor for Leaks | Be vigilant for any signs of coolant leaks under the vehicle. Addressing leaks immediately can prevent further damage and costly repairs. |

Suspension and Steering Overhaul Steps

This section outlines the essential procedures for addressing the suspension and steering systems in a vehicle. Proper maintenance and refurbishment of these components are critical for ensuring optimal handling, ride quality, and safety.

Preparation and Safety Measures

Before starting the overhaul process, it is crucial to follow safety protocols and prepare the workspace effectively:

- Gather necessary tools and equipment.

- Ensure the vehicle is on a flat, stable surface.

- Use jack stands to secure the vehicle once raised.

- Disconnect the battery to prevent electrical issues.

Steps for Overhaul

Follow these steps for a thorough overhaul of the suspension and steering systems:

- Inspect the existing components for wear and damage.

- Remove the wheels to access suspension parts.

- Detach the suspension assembly, including control arms and struts.

- Replace worn bushings, bearings, and other components as necessary.

- Reinstall the suspension assembly and ensure all fasteners are torqued to specifications.

- Address steering components, including the rack and pinion, ensuring proper alignment.

- Reattach the wheels and lower the vehicle carefully.

- Conduct a final inspection and road test to verify performance.

Transmission Fluid Change Procedure

Changing the fluid in a vehicle’s transmission is a crucial maintenance task that ensures smooth operation and longevity. This process helps in removing contaminants and old fluid, replacing it with fresh lubricant that supports optimal performance.

To begin, ensure the vehicle is parked on a level surface and the engine is turned off. Gather the necessary tools, including a socket set, fluid pump, and appropriate replacement fluid. It’s advisable to consult the specifications for the exact type and quantity needed.

Next, raise the vehicle using jack stands for safety and locate the transmission pan. Remove the bolts securing the pan and carefully lower it to allow the old fluid to drain into a container. Once drained, inspect the pan for debris or metal shavings, which may indicate wear.

After draining, clean the pan and replace the filter if applicable. Reinstall the pan, tightening the bolts to the manufacturer’s specifications. Fill the transmission with new fluid through the dipstick tube or designated fill port, using the pump for precision.

Finally, start the engine and let it run for a few minutes while cycling through the gears. Check the fluid level again and add more if necessary. Properly dispose of the old fluid and any materials used during the process.

Exhaust System Inspection Methods

Ensuring the proper functionality of an exhaust system is vital for vehicle performance and emissions control. This section outlines effective techniques for assessing the condition and integrity of exhaust components, enabling timely maintenance and repairs.

Visual Inspection: Begin with a thorough visual examination of the exhaust system. Look for any signs of rust, cracks, or corrosion on pipes, mufflers, and connections. A detailed inspection can reveal potential issues that may lead to larger problems if left unaddressed.

Sound Assessment: Pay attention to the sounds emitted from the exhaust while the engine is running. Unusual noises, such as loud rumbling or hissing, may indicate leaks or other malfunctions within the system that require further investigation.

Performance Testing: Evaluate the vehicle’s acceleration and overall performance. A decrease in power or sluggishness may signal exhaust restrictions or blockages that necessitate immediate attention. Monitoring these changes can help identify underlying issues.

Emission Testing: Conducting emissions tests can provide crucial information regarding the exhaust system’s efficiency. Elevated levels of harmful emissions may indicate a failing catalytic converter or other components, prompting necessary repairs or replacements.

Routine Maintenance Schedule Overview

Establishing a consistent maintenance plan is essential for ensuring the longevity and optimal performance of your vehicle. This section outlines key tasks that should be performed regularly to keep the automobile in excellent condition. Adhering to this schedule not only enhances reliability but also helps in preventing potential issues before they arise.

Regular inspections should include checking fluid levels, examining tire pressure, and ensuring the functionality of lights and signals. It is advisable to follow the recommended intervals for replacing filters and fluids to maintain engine efficiency.

Additionally, visual assessments of belts and hoses can prevent unexpected breakdowns. Tire rotation and alignment are also crucial for even wear and improved handling. Following these guidelines will contribute to a smoother driving experience and enhance overall safety.