Comprehensive Guide to Repairing the Honda GCV160 Engine

Maintaining small motors is essential for ensuring their longevity and optimal performance. This guide delves into the various aspects of upkeep, offering insights and techniques to keep your machinery in peak condition. Whether you are a novice or an experienced user, understanding the fundamentals can save you time and money while enhancing the efficiency of your equipment.

Every machine has its nuances, and recognizing the specific needs of your model can significantly impact its functionality. By familiarizing yourself with common issues and preventative measures, you can tackle problems before they escalate. This resource will equip you with the knowledge to handle maintenance tasks with confidence and precision.

From troubleshooting to routine upkeep, this guide covers a range of topics aimed at empowering users. Clear explanations and practical tips will help demystify the maintenance process, making it accessible and manageable for everyone. Embrace the opportunity to enhance your skills and ensure that your small motor operates smoothly for years to come.

Understanding the Honda GCV160 Engine

This section delves into the fundamentals of a popular small power unit known for its reliability and efficiency. This machine is widely utilized in various outdoor applications, making it a favorite among enthusiasts and professionals alike. An understanding of its components, functionality, and maintenance is essential for maximizing performance and longevity.

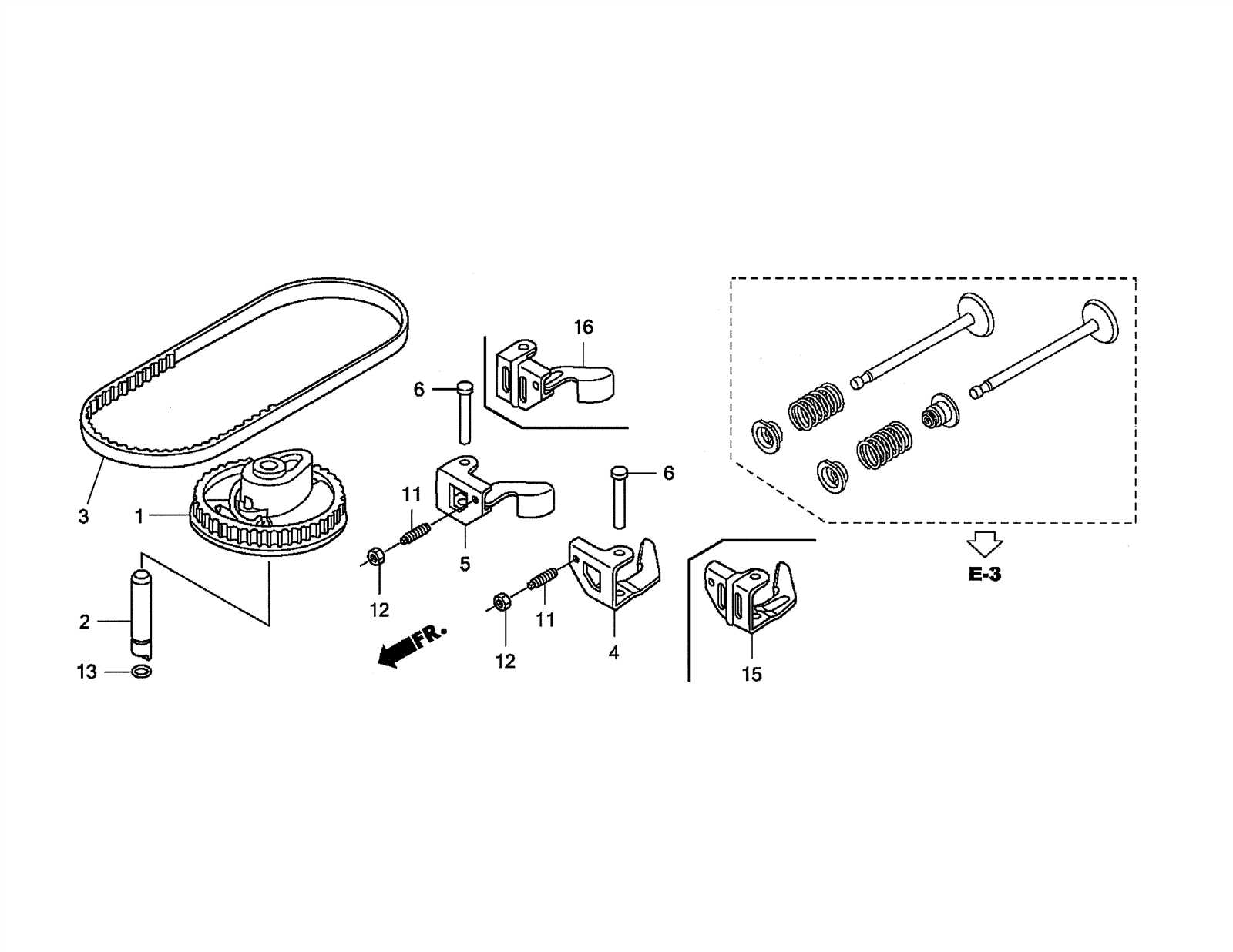

Key Components

The heart of this power unit consists of several crucial parts, each playing a significant role in its operation. The combustion chamber, fuel system, and ignition mechanism work in unison to provide the necessary power output. Familiarity with these components enables users to troubleshoot common issues and ensure optimal performance.

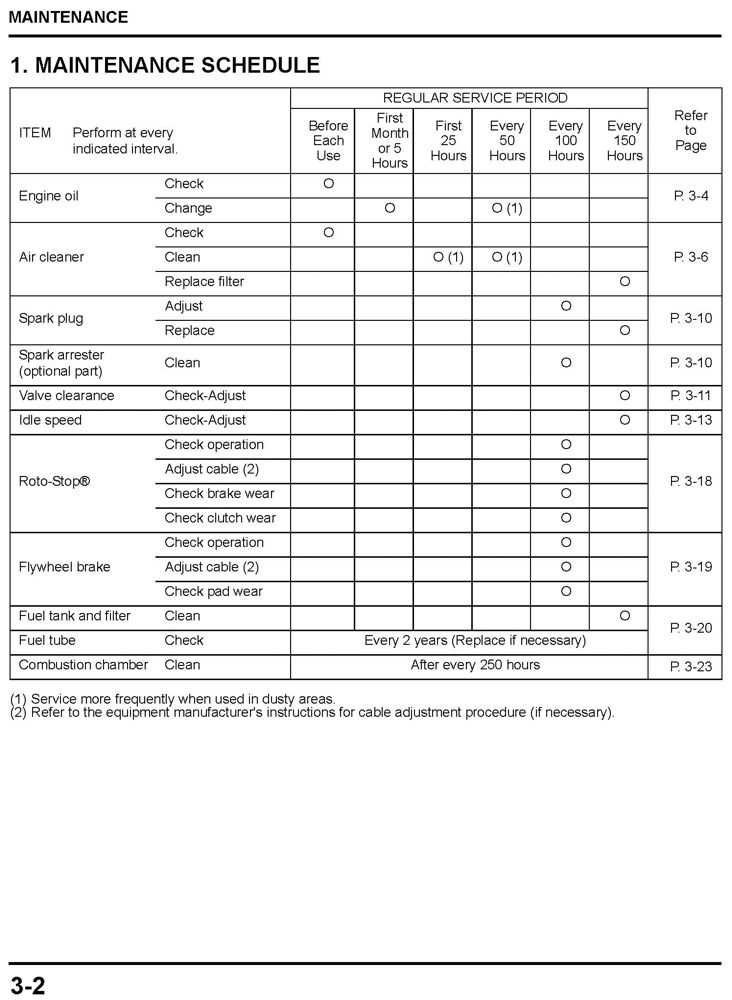

Maintenance Tips

Common Issues and Symptoms

When working with small machinery, it’s essential to recognize frequent problems that can hinder performance. Understanding these challenges allows for timely troubleshooting and helps maintain efficiency. Various signs may indicate underlying issues, which, if addressed promptly, can prevent further complications.

Starting Difficulties

A common symptom is trouble initiating the operation. This can manifest as the unit refusing to start or stalling shortly after ignition. Possible causes include insufficient fuel supply, clogged filters, or issues with the ignition system. Checking these components can often resolve the problem.

Unusual Noises and Vibrations

Abnormal sounds or excessive vibrations during operation can signal deeper concerns. Rattling or grinding noises may indicate loose parts or wear on internal components. It’s advisable to conduct regular inspections to identify and rectify such issues early, ensuring smoother operation.

Tools Required for Repairs

Performing maintenance and restoration tasks on machinery requires a selection of essential instruments to ensure efficiency and effectiveness. Having the right tools on hand not only facilitates the process but also enhances safety and precision during the work. Below is an overview of the necessary items that will help you achieve successful outcomes.

Basic Tools

Start with these fundamental implements that form the backbone of any maintenance project:

| Tool | Purpose |

|---|---|

| Screwdrivers | Used for removing and tightening screws. |

| Wrenches | Essential for loosening and tightening bolts and nuts. |

| Pliers | Helpful for gripping and twisting various components. |

| Socket Set | Provides versatility for working with different fasteners. |

Specialized Instruments

In addition to basic tools, some specific instruments may be required for more intricate tasks:

| Tool | Purpose |

|---|---|

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Compression Gauge | Measures the compression levels for diagnostics. |

| Fuel Line Wrench | Facilitates access to fuel system components. |

| Multi-meter | Used for electrical diagnostics and troubleshooting. |

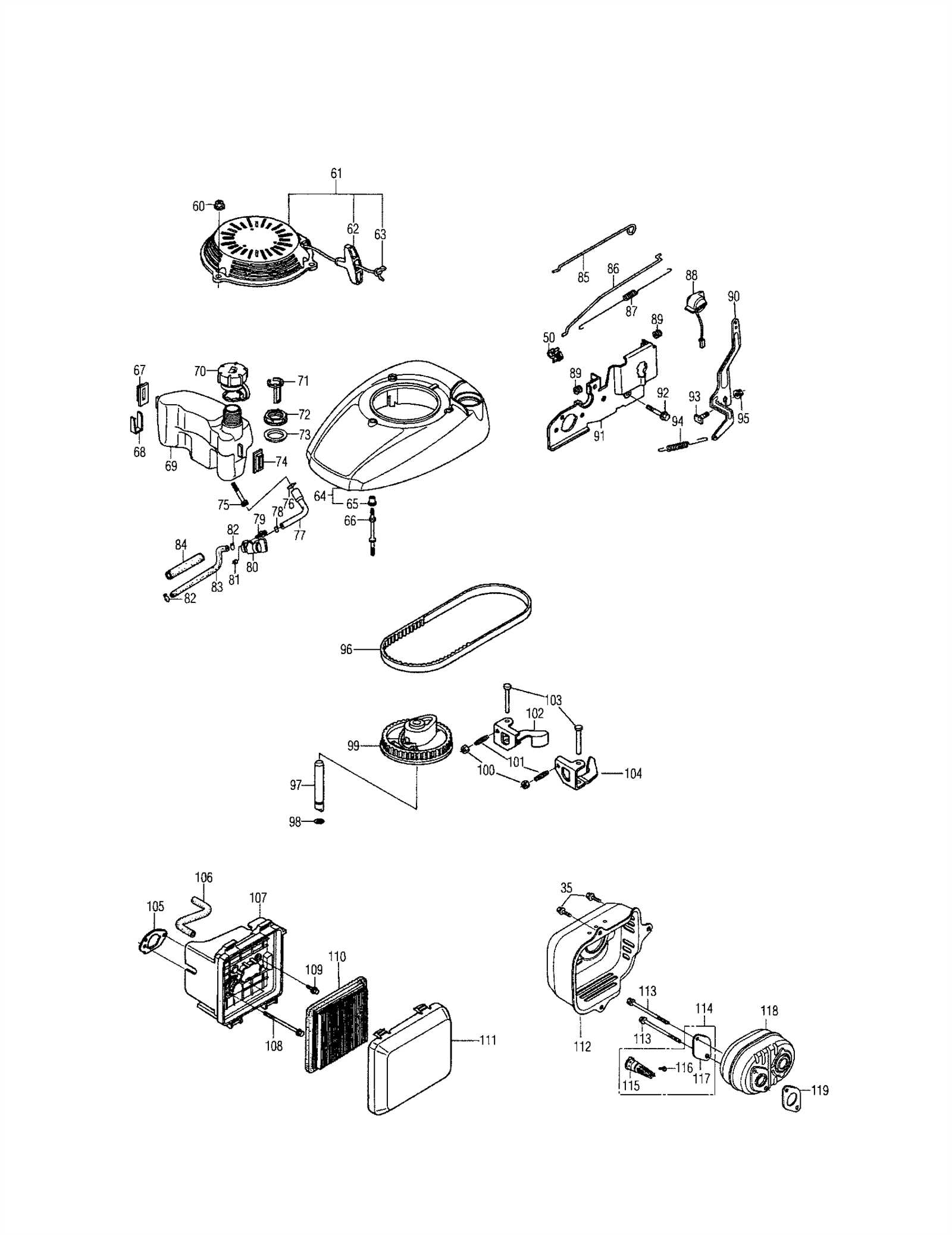

Step-by-Step Disassembly Guide

This section provides a detailed approach to taking apart a small motor system for maintenance and troubleshooting. Understanding the correct sequence and techniques is crucial for ensuring that each component is handled with care, minimizing the risk of damage during the process.

Tools and Materials Required

- Socket set

- Screwdriver set

- Wrench

- Pliers

- Container for small parts

- Cleaning cloths

- Safety glasses

Disassembly Steps

- Ensure the motor is turned off and cool to the touch.

- Remove the outer casing by unscrewing all visible screws. Keep them organized for reassembly.

- Detach the air filter cover and set it aside.

- Carefully take off the air filter, inspecting it for any damage.

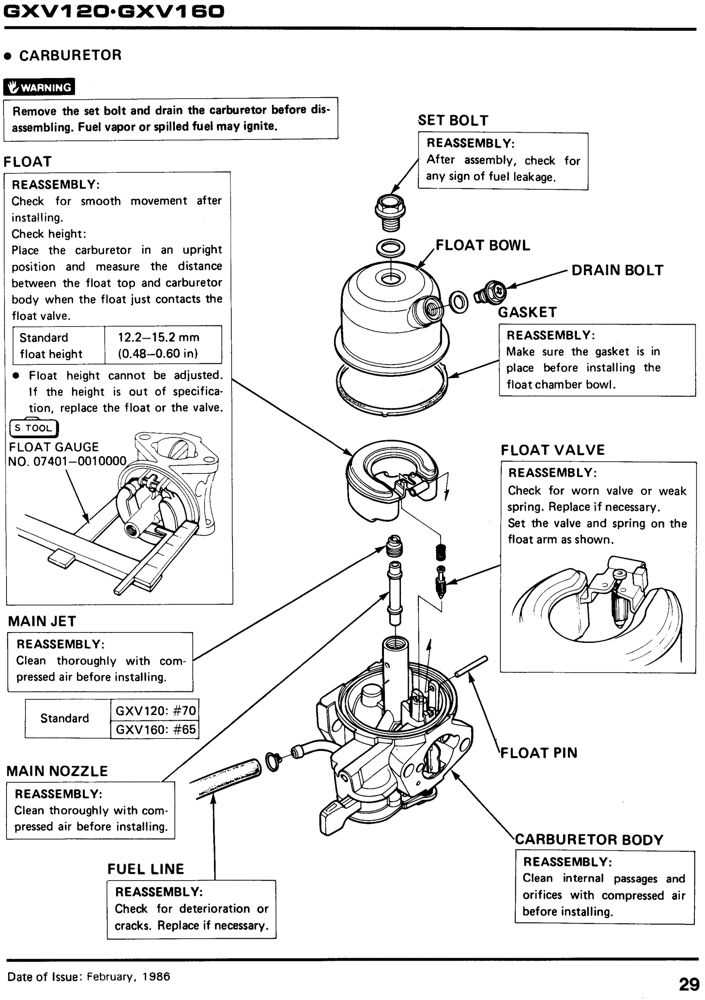

- Unscrew the carburetor from the intake manifold. Be gentle to avoid breaking any seals.

- Disconnect the fuel line, ensuring no spills occur.

- Remove the ignition coil by loosening its mounting screws.

- Carefully take out the spark plug using a spark plug socket.

- Take apart the crankcase cover by unscrewing the bolts, keeping track of their positions.

- Inspect all components for wear or damage as you disassemble.

After completing these steps, you’ll have a clear view of the internal parts, allowing for thorough inspection and necessary maintenance. Remember to document each step, which will assist during the reassembly process.

Replacing the Air Filter

Maintaining optimal performance in small machines often hinges on ensuring that components such as the air filtration system are clean and functional. Regularly changing the air filter is essential for promoting airflow and preventing contaminants from entering the internal mechanisms. This task is straightforward and can significantly enhance the efficiency and longevity of your equipment.

Tools and Materials Needed

Before starting the replacement process, gather the necessary tools and materials. You will typically need a new air filter, a screwdriver, and possibly some cleaning supplies. Ensuring you have everything ready will streamline the procedure and help avoid interruptions.

Steps for Replacement

Begin by turning off the machine and disconnecting any power source. Locate the air filter cover, which is usually secured by screws. Carefully remove the cover and take out the old filter, noting its orientation for the new one. Clean the area around the filter housing to remove any debris. Insert the new filter, ensuring it fits snugly in place, then reattach the cover securely. Finally, restore the power and perform a brief test to ensure everything is functioning correctly.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is crucial for optimal performance and longevity of small machinery. Regular attention to this area ensures efficient operation and prevents potential issues that could lead to costly repairs or reduced efficiency. Here are some essential tips for maintaining the fuel system.

Regular Fuel Inspection

- Check fuel quality regularly; use fresh fuel to avoid degradation.

- Inspect for any signs of contamination, such as water or dirt.

- Replace the fuel filter as recommended by the manufacturer.

Cleaning and Storage Practices

- Clean the fuel tank periodically to remove any buildup or residue.

- Store equipment in a cool, dry place to prevent condensation.

- Use a fuel stabilizer if the machinery will not be used for an extended period.

Following these guidelines will help maintain a well-functioning fuel system, ensuring reliable performance when you need it most.

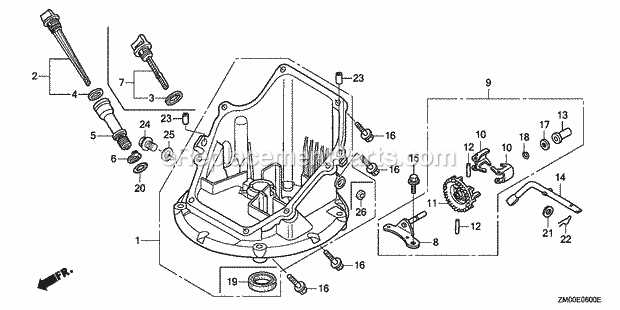

Inspecting and Changing the Oil

Regular examination and replacement of the lubricant are essential for ensuring optimal performance and longevity of your machinery. Clean oil facilitates smooth operation and prevents wear on internal components. Neglecting this task can lead to reduced efficiency and potential damage.

Before starting, gather the necessary tools: an oil container, a funnel, and a dipstick. Begin by checking the oil level to determine if a change is needed. It’s best to perform this task when the unit is on a level surface and has cooled down.

| Step | Action |

|---|---|

| 1 | Remove the dipstick and wipe it clean. |

| 2 | Reinsert the dipstick to check the oil level. |

| 3 | If low, add the recommended type of lubricant. |

| 4 | To change, drain the old lubricant into a suitable container. |

| 5 | Fill with fresh oil using a funnel, ensuring not to overfill. |

| 6 | Check the level again with the dipstick. |

Following these steps will help maintain the health of your equipment and enhance its operational efficiency. Regular attention to lubricant quality and level is a simple yet vital part of maintenance.

Diagnosing Electrical Problems

Identifying issues within an electrical system can be a challenging yet crucial task. Proper diagnosis helps in pinpointing the source of malfunctions, ensuring efficient operation and longevity of the machinery. This section outlines the essential steps and techniques to systematically troubleshoot and resolve electrical anomalies.

Begin with Visual Inspection: Start by examining all visible components, including wiring, connectors, and switches. Look for signs of wear, corrosion, or loose connections. Any physical damage can be a clear indicator of underlying problems.

Utilize a Multimeter: A multimeter is an indispensable tool for diagnosing electrical issues. Measure voltage, resistance, and continuity in various parts of the system. Check for expected values against the specifications to determine if components are functioning correctly.

Test the Battery: Ensure that the power source is fully charged and in good condition. A weak or faulty battery can lead to erratic behavior and should be tested regularly to avoid unnecessary complications.

Inspect the Fuses: Fuses serve as protective devices, preventing damage from overloads. Check for blown fuses and replace them as necessary. Understanding the circuit’s load can help avoid future failures.

Analyze the Wiring Diagram: Consulting the wiring diagram specific to the system can provide insights into the electrical layout and help locate potential problem areas. Following the diagram ensures that each component is correctly assessed.

Check for Ground Issues: Proper grounding is essential for electrical stability. Inspect ground connections for integrity and ensure they are clean and secure. A poor ground can lead to inconsistent performance and safety hazards.

By methodically following these steps, one can effectively diagnose and resolve electrical issues, ensuring optimal functionality and performance of the equipment.

Reassembling the Engine Components

Reassembling the internal machinery requires meticulous attention to detail and a systematic approach. Each part must be carefully fitted together to ensure optimal performance and longevity. This process not only involves aligning components accurately but also verifying that all fasteners are secured properly and that lubrication is applied where necessary.

Step-by-Step Assembly Process

Begin by laying out all components in the order they will be assembled. Start with the base structure, ensuring that any gaskets are correctly placed to prevent leaks. Gradually add components such as the piston and crankshaft, making sure to adhere to specified torque settings for all bolts. This careful progression helps to avoid misalignment and ensures that the assembly functions smoothly.

Final Checks and Adjustments

After all parts are in place, conduct a thorough inspection. Check for any loose fittings and verify that all connections are tight. Rotate the assembled unit manually to confirm smooth operation. If any resistance is felt, re-evaluate the alignment and clearances. Proper final adjustments can significantly impact overall performance and reliability.

Final Testing and Troubleshooting

After completing maintenance or modifications, it’s essential to ensure that the unit operates effectively and efficiently. This section outlines key procedures to verify functionality and diagnose potential issues. Conducting thorough tests not only confirms repairs but also enhances longevity and performance.

Conducting Performance Tests

Start with a visual inspection of all components. Look for any signs of wear or improper assembly. Once confirmed, proceed to power the unit and listen for any unusual noises. Vibration and excessive smoke can indicate underlying problems that need addressing. Run the unit under typical load conditions to evaluate responsiveness and stability. If the performance deviates from expected standards, further investigation may be required.

Troubleshooting Common Issues

In the event of malfunctions, systematically isolate potential causes. Begin with the fuel system; ensure that fuel is fresh and that the supply is unobstructed. Next, check the ignition system for any faults. Testing spark plugs and electrical connections can reveal crucial insights. If the problem persists, delve into the cooling and lubrication systems, as these are vital for optimal operation. Document any findings to streamline future diagnostics.