Honda GXV160 Repair Manual Guide

In the world of small engines, keeping machinery in peak condition is essential for both performance and longevity. Understanding how to care for your equipment ensures smooth operation and helps avoid costly issues over time. This guide offers insights into effectively maintaining and troubleshooting your engine, from cleaning and inspecting key components to recognizing early signs of wear.

Regular upkeep can make a significant difference in engine efficiency, allowing machinery to operate at its best. We’ll explore practical steps for routine checks, covering essentials like air filters, fuel systems, and ignition components. With a proactive approach, small issues can be addressed before they become larger concerns.

Beyond maintenance, knowing how to address common technical challenges will empower you to handle unexpected situations with confidence. This guide provides a foundation for both new and experienced users, equipping them with the knowledge needed to keep engines running smoothly under various conditions. Each section is crafted to deliver clear, actionable advice, making it easy to maintain machinery with minimal hassle.

Honda GXV160 Repair Manual

Understanding the maintenance essentials for small engine upkeep can significantly prolong the equipment’s operational life and ensure smooth functionality. This guide provides a clear and structured approach to common service tasks, including cleaning, adjustments, and part replacements. Regular care aids in identifying early signs of wear, allowing timely intervention before larger issues develop.

Key points in servicing involve regular inspections of critical engine components, such as the fuel system, air filters, and spark plugs. Each part plays a role in optimal performance and should be checked periodically. Proper adjustments to throttle settings and carburetor calibration are also essential for peak efficiency, enhancing power output and reducing fuel consumption.

When performing detailed upkeep, attention to lubrication schedules is crucial, as it minimizes friction and prevents excessive wear. Following guidelines on oil types and intervals ensures engine longevity. The importance of tightening bolts, checking connections, and keeping the engine clean cannot be overstated, as these steps form the foundation of reliable equipment performance.

Engine Overview and Specifications

This section provides a concise description of the key features and design elements of the engine, focusing on its core characteristics that enhance performance and reliability. The goal is to give a general understanding of the engine’s structure and capabilities without delving into technical minutiae.

Engine dimensions are crafted to support efficient power output while maintaining compactness. This design prioritizes fuel efficiency and smooth operation, ensuring that the engine performs consistently under various operating conditions.

The unit’s power characteristics are achieved through a combination of durable materials and precise engineering, tailored for long-lasting performance. The layout includes features to minimize vibration and maximize power transfer, balancing power with operational stability.

Additional elements in the design support ease of maintenance, providing accessible components and straightforward servicing points. The engine construction focuses on high thermal efficiency and resistance to wear, ensuring an extended operational lifespan with minimal maintenance requirements.

Maintenance Tools and Equipment

Regular upkeep of any engine requires having the correct tools and essential equipment. This section focuses on the key items that make routine maintenance smoother and ensure tasks are completed safely and efficiently.

Basic Hand Tools: Essential hand tools such as wrenches, screwdrivers, and pliers are vital for performing most maintenance tasks. Using high-quality tools not only improves efficiency but also minimizes the risk of damaging components.

Specialty Tools: Some tasks may require specific tools, like torque wrenches, to ensure precise adjustments. These are particularly useful for tasks that demand accurate tension, helping maintain reliable performance over time.

Cleaning Supplies: Cleanliness is key in maintaining smooth operation. Common cleaning tools include brushes, compressed air, and safe cleaning agents to remove dirt, oil, and grime from surfaces and components.

Protective Gear: Safety during maintenance is crucial. Gloves, eye protection, and appropriate clothing safeguard against potential hazards, providing a safer work environment and reducing injury risk.

Maintaining access to these essential tools and equipment enables more efficient, thorough, and safe maintenance practices, prolonging the lifespan of the machine and enhancing its overall performance.

Initial Troubleshooting Steps

Understanding basic problem-solving steps can help identify and resolve common issues efficiently. By focusing on fundamental checks, users can quickly narrow down potential causes and determine if simple fixes are possible before seeking further assistance.

First, examine the power source. Ensure there is adequate fuel, clean and fresh, and that the battery, if applicable, is charged and properly connected. Fuel levels or a disconnected battery are frequent reasons for start-up challenges.

Next, inspect the air filter. A dirty or clogged filter can restrict airflow, making it difficult for the engine to run smoothly. If needed, clean or replace the filter to promote optimal performance.

Check the spark plug for any visible damage or deposits. A fouled or worn plug can disrupt ignition, affecting the engine’s reliability. Cleaning or replacing the spark plug can often restore functionality.

Lastly, verify that all safety switches and controls are in the correct position. Sometimes, minor adjustments to settings or ensuring that components are securely attached can resolve the issue. These straightforward steps are key to diagnosing the most common operational problems efficiently.

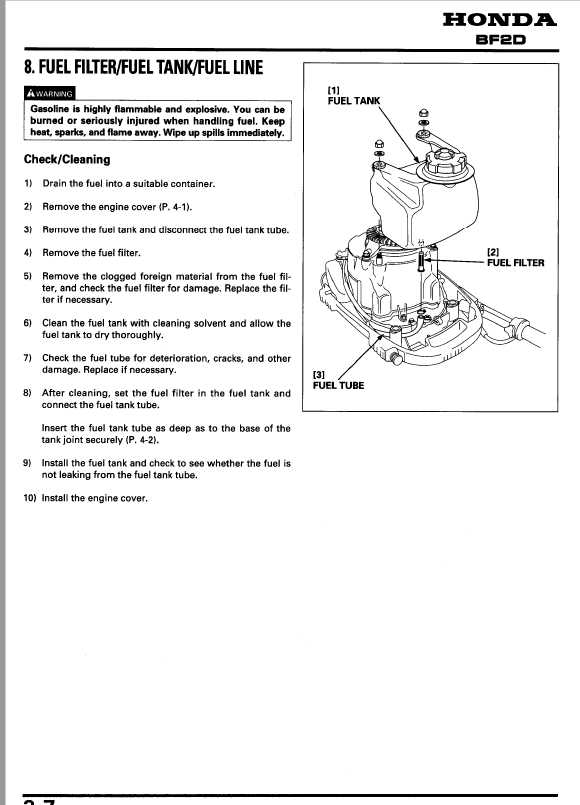

Fuel System Inspection Guide

Examining the fuel system regularly is essential for reliable and efficient performance. This guide outlines the key areas to assess and maintain for a smooth-running engine.

- Fuel Tank and Lines: Begin by inspecting the fuel tank and lines for any visible damage, leaks, or wear. Look for cracks, loose connections, or corrosion, which may hinder fuel flow.

- Fuel Filter: Check the fuel filter to ensure it’s free of debris or blockages. A clean filter allows fuel to reach the engine without impurities, supporting optimal combustion.

- Fuel Cap and Vent: Examine the fuel cap and vent to confirm they’re functioning properly. The vented cap allows air to enter the tank, preventing a vacuum that could restrict fuel flow.

- Carburetor: Inspect the carburetor for signs of wear or residue buildup. Clean any deposits around the jets and passages, which could disrupt the air-fuel mixture and impact efficiency.

- Drain Fuel: Before long storage, drain the fuel to prevent clogging and ensure a fresh start when restarting.

- Replace Worn Components: Regularly replace any worn or damaged parts, including fuel lines, filters, or gaskets, to maintain peak performance and prevent future issues.

Performing these checks and addressing issues as they arise will help maintain a dependable and efficient fuel system.

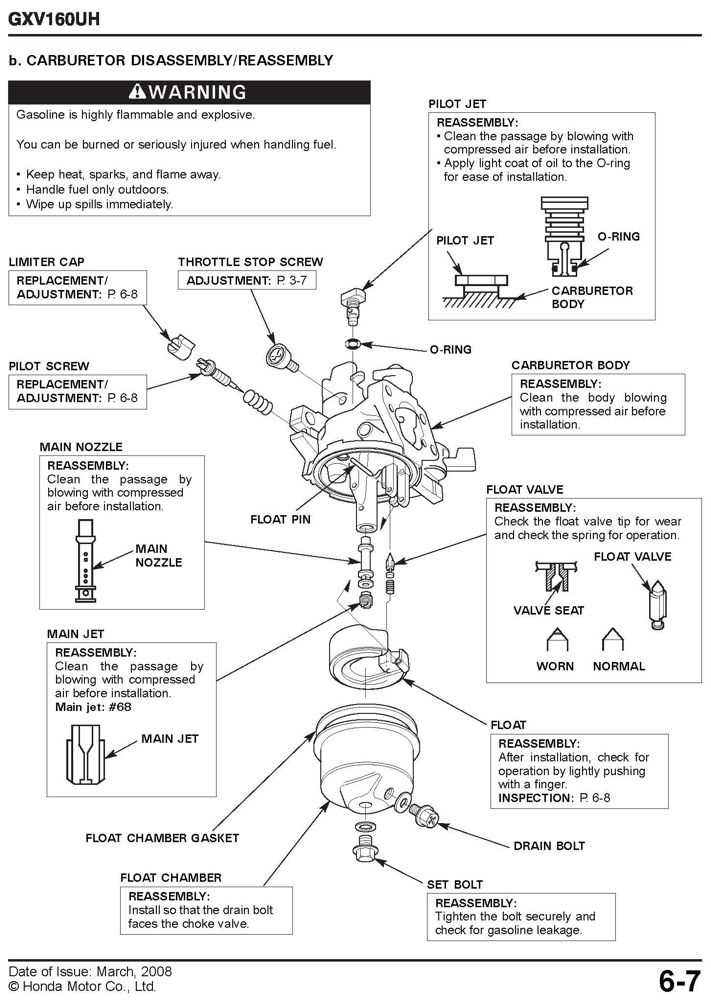

Carburetor Cleaning and Adjustment

Maintaining optimal performance of small engines often involves thorough cleaning and precise adjustment of the carburetor. This critical component plays a vital role in mixing air and fuel, ensuring efficient combustion. Regular care can prevent common issues such as poor starting, uneven idling, and reduced power output.

Follow these steps for effective cleaning and adjustment:

- Gather Necessary Tools:

- Wrench set

- Screwdrivers (flathead and Phillips)

- Carburetor cleaner

- Compressed air

- Cleaning brush

- Safety goggles and gloves

- Prepare the Engine:

Ensure the engine is cool before beginning. Disconnect the spark plug to prevent accidental ignition during the cleaning process.

- Remove the Carburetor:

Detach the carburetor from the engine carefully. Take note of the connections and components for reassembly.

- Clean the Carburetor:

Using the carburetor cleaner, spray all surfaces thoroughly. Pay special attention to the jets and passages. Use the cleaning brush to remove any stubborn deposits. Rinse with compressed air to clear out any remaining debris.

- Inspect for Damage:

Check for any cracks or wear in the carburetor body and gaskets. Replace any damaged parts to ensure a proper seal and function.

- Adjust Settings:

Reattach the carburetor and adjust the mixture settings according to the manufacturer’s specifications. This typically involves adjusting the idle speed and air-fuel mixture screws.

- Test the Engine:

Reconnect the spark plug and start the engine. Observe its performance, checking for smooth operation and proper idling. Make further adjustments as necessary.

By following these steps, you can ensure that the carburetor operates efficiently, promoting better engine performance and longevity.

Air Filter Replacement Process

Maintaining optimal performance of your engine requires regular attention to key components, one of which is the air filter. This part plays a crucial role in ensuring that clean air enters the engine, which is essential for efficient combustion. Over time, air filters can become clogged with dirt and debris, leading to decreased performance and potential engine damage. Understanding how to replace this component effectively is vital for sustaining the longevity and efficiency of your equipment.

Steps for Removing the Old Filter

To begin the replacement, first ensure the engine is turned off and cool. Locate the air filter housing, which is typically secured with clips or screws. Carefully remove these fasteners and take off the housing cover. Once exposed, gently pull out the old air filter, taking care not to let any debris fall into the intake. Inspect the filter for any signs of damage or excessive dirt, as this will help determine the necessity of a timely replacement.

Installing the New Filter

After removing the old filter, it’s time to install the new one. Place the new air filter into the housing, ensuring it fits snugly and seals properly. Replace the housing cover and secure it with the clips or screws previously removed. Once everything is reassembled, start the engine to check for any unusual sounds or issues. Regularly inspecting and replacing the air filter will contribute to the overall efficiency and reliability of your engine.

Ignition System Diagnosis

This section provides essential insights into diagnosing issues related to the ignition system of small engines. A well-functioning ignition system is crucial for ensuring that the engine starts efficiently and operates smoothly. Understanding the components involved and recognizing potential problems can greatly enhance troubleshooting efforts.

Common symptoms of ignition system failures may include difficulty starting the engine, intermittent power loss, or stalling during operation. It is important to systematically assess each component to pinpoint the source of the problem.

| Component | Possible Issues | Diagnosis Steps |

|---|---|---|

| Spark Plug | Wear or fouling | Inspect for damage, check gap, replace if necessary |

| Ignition Coil | Weak spark or no spark | Test with a multimeter, replace if faulty |

| Flywheel Magnet | Improper alignment | Check alignment with the stator, adjust if needed |

| Stator | Electrical shorts | Inspect wiring for damage, perform continuity tests |

By following the outlined steps and examining the listed components, users can effectively diagnose ignition system problems and ensure optimal engine performance.

Oil Change and Lubrication Tips

Regular maintenance is essential for ensuring optimal performance and longevity of your engine. One of the key aspects of this maintenance is changing the oil and ensuring proper lubrication. This process not only keeps the engine running smoothly but also helps prevent potential issues that could arise from neglected oil levels or quality.

Steps for Oil Change

Begin by gathering the necessary tools and materials, including fresh oil, an oil filter, a wrench, and a drain pan. Start the engine for a few minutes to warm up the oil, as this makes it easier to drain. Once warmed, turn off the engine and carefully remove the drain plug to allow the old oil to flow into the pan. After the oil has completely drained, replace the drain plug and proceed to remove and replace the oil filter. Finally, refill the engine with new oil, ensuring you use the recommended type and quantity for optimal performance.

Importance of Lubrication

Proper lubrication is crucial for minimizing friction and wear on moving parts. Check oil levels regularly and top off as needed, ensuring that the oil remains clean and free from contaminants. Consider using high-quality oil designed for your specific engine type to enhance protection and efficiency. Regular checks and timely changes will significantly contribute to the overall health of the engine.

Engine Cooling System Check

Ensuring the efficiency of the cooling system is vital for the longevity and performance of the engine. Regular inspection helps identify potential issues that could lead to overheating or reduced operational efficiency. This section outlines the key components to examine and the steps to take for a thorough assessment of the cooling system.

| Component | Inspection Steps | Notes |

|---|---|---|

| Radiator | Check for blockages, leaks, or damage. Ensure fins are clean. | A clogged radiator can hinder cooling efficiency. |

| Coolant Level | Verify that the coolant is at the appropriate level and top off if necessary. | Low coolant can lead to overheating. |

| Hoses | Inspect for cracks, wear, or loose connections. | Worn hoses can lead to leaks and cooling loss. |

| Water Pump | Check for any signs of leakage and ensure it operates smoothly. | A faulty pump can disrupt coolant circulation. |

| Thermostat | Test for proper opening and closing at specified temperatures. | A malfunctioning thermostat can cause overheating or underheating. |

By following these steps and maintaining the cooling system, one can significantly enhance the reliability and performance of the engine, preventing overheating and ensuring optimal functionality during operation.

Common Issues and Solutions

When working with small engines, various challenges can arise that may affect their performance and reliability. Understanding these common problems and knowing how to address them can greatly enhance the longevity and efficiency of the equipment. Below, we explore frequent issues encountered and offer practical solutions for effective troubleshooting.

Starting Difficulties

One of the most prevalent problems users face is difficulty in starting the engine. This can often be attributed to a lack of fuel, a clogged air filter, or spark plug issues. To resolve this, ensure that the fuel tank is filled with fresh gasoline, clean or replace the air filter, and check the spark plug for wear or damage. Cleaning or replacing the spark plug can significantly improve ignition performance.

Overheating

Overheating is another common issue that can lead to severe damage if not addressed promptly. This may result from low oil levels, debris blocking the cooling fins, or a malfunctioning cooling system. Regularly check the oil level and top it up as needed, clear any obstructions around the engine, and ensure the cooling system is functioning properly. Maintaining these components can prevent overheating and extend the engine’s lifespan.

Storage and Long-Term Care

Proper storage and maintenance are essential for ensuring the longevity and reliability of small engines. By following recommended procedures, you can protect your equipment from damage and preserve its performance over time.

Preparation for Storage

- Clean the exterior to remove dirt and debris.

- Drain or stabilize the fuel to prevent gumming and corrosion.

- Change the oil to eliminate contaminants that can harm internal components.

- Inspect and replace any worn or damaged parts before storage.

Long-Term Maintenance Practices

- Store the equipment in a dry, sheltered area to protect it from the elements.

- Check periodically for any signs of leaks or wear.

- Run the engine for a few minutes every few months to keep parts lubricated.

- Keep the owner’s guide handy for reference on maintenance schedules and procedures.