Comprehensive Guide to Repairing Honda Outboard Motors

For enthusiasts and professionals alike, ensuring optimal performance of aquatic propulsion systems is crucial. Understanding the intricacies of these mechanisms not only enhances their longevity but also elevates the overall experience on the water. This guide serves as a resource for troubleshooting, maintenance, and fine-tuning various components essential for smooth operation.

With the right knowledge and techniques, tackling issues that arise in these machines can become a manageable task. From diagnosing performance glitches to executing routine checks, a systematic approach is key. This section will delve into methods and best practices for upkeep, allowing users to maximize efficiency and reliability.

Emphasizing hands-on learning and practical solutions, this guide aims to empower readers with the confidence to handle maintenance tasks independently. Whether you are a seasoned technician or a newcomer eager to learn, the insights provided here will serve as a valuable asset in mastering your craft.

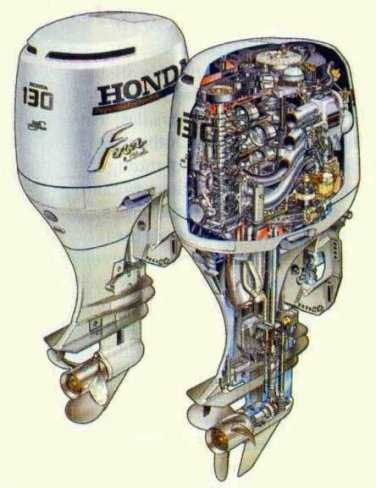

Understanding Honda Outboard Motors

This section delves into the intricacies of marine propulsion systems designed for recreational and professional use. These engines play a crucial role in ensuring reliable performance on the water, offering both efficiency and power. Familiarity with their components and functions enhances the user experience and maintenance practices.

Key Components

At the heart of these propulsion systems lie several essential parts that contribute to their overall functionality. The engine block, fuel system, and cooling mechanism work in unison to deliver optimal performance. Understanding how these elements interact helps users troubleshoot issues effectively.

Maintenance Essentials

Regular upkeep is vital for longevity and performance. Key practices include checking fluid levels, inspecting electrical connections, and ensuring the integrity of the propeller. Adhering to these guidelines not only maximizes efficiency but also prevents potential failures during operation.

Common Issues with Honda Engines

Engines, regardless of their brand, can encounter various challenges over time. Understanding these potential problems is crucial for maintaining performance and longevity. This section highlights frequent concerns associated with a popular engine brand, helping users identify and address them effectively.

Overheating Problems

One of the most prevalent issues faced by engine owners is overheating. This can result from several factors, including coolant leaks, blocked waterways, or faulty thermostats. Addressing overheating promptly is essential to prevent severe damage.

Fuel System Complications

Another common area of concern involves the fuel system. Issues such as clogged filters, contaminated fuel, or malfunctioning injectors can lead to poor engine performance. Regular maintenance and checks can help mitigate these problems.

| Issue | Symptoms | Possible Causes |

|---|---|---|

| Overheating | High temperature readings, steam | Coolant leaks, blocked waterways |

| Fuel Starvation | Stalling, poor acceleration | Clogged filters, contaminated fuel |

| Starting Difficulties | Engine won’t start, slow cranking | Weak battery, faulty starter |

Essential Tools for Repairs

When tackling maintenance and troubleshooting tasks, having the right instruments at your disposal is crucial. The effectiveness of your efforts largely depends on the quality and appropriateness of your tools. This section outlines key implements that will facilitate efficient servicing and ensure optimal performance of your equipment.

| Tool | Purpose |

|---|---|

| Socket Set | Used for tightening and loosening fasteners. |

| Screwdriver Set | Essential for handling various screws and components. |

| Pliers | Useful for gripping, twisting, and cutting wires or parts. |

| Wrench Set | Ideal for adjusting and securing nuts and bolts. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

| Multimeter | Measures electrical values for troubleshooting electrical systems. |

| Fuel Line Wrench | Facilitates the removal and installation of fuel components. |

| Cleaning Tools | Includes brushes and cloths for maintaining cleanliness and performance. |

Step-by-Step Maintenance Guide

Regular upkeep is essential for ensuring optimal performance and longevity of your aquatic propulsion device. This guide provides a structured approach to maintaining your equipment, helping you avoid potential issues and enhancing reliability during use.

Essential Pre-Use Checks

Before heading out on the water, it’s crucial to conduct a thorough inspection. Start by examining the fuel system; ensure there are no leaks and that the fuel is fresh. Next, check the battery charge and connections for corrosion. Inspect the propeller for any signs of damage, as a compromised propeller can affect performance significantly.

Routine Maintenance Tasks

Establish a regular maintenance schedule that includes the following tasks:

- Fluid Replacement: Change the lubricant and coolant as recommended to prevent overheating and wear.

- Filter Cleaning: Clean or replace the air and fuel filters to maintain efficiency.

- Electrical System Inspection: Regularly check wires and connections for signs of wear or corrosion.

By adhering to these practices, you can ensure that your device remains in peak condition and ready for any adventure on the water.

Electrical System Troubleshooting Tips

Ensuring optimal performance of any aquatic propulsion system involves a thorough understanding of its electrical components. Issues within this domain can lead to significant operational challenges. Identifying and resolving these problems requires a systematic approach and a keen eye for detail.

Common Issues and Symptoms

Below is a table summarizing frequent electrical complications along with their indicative symptoms:

| Issue | Symptoms |

|---|---|

| Dead Battery | No start, dim lights |

| Corroded Connections | Intermittent power, flickering instruments |

| Faulty Ignition Switch | No response when turning the key |

| Blown Fuse | Loss of electrical function in specific circuits |

| Damaged Wiring | Unexpected shutdowns, unusual noises |

Troubleshooting Steps

To address electrical challenges effectively, follow these recommended procedures:

- Begin with a visual inspection of all components and connections.

- Utilize a multimeter to check voltage levels and continuity.

- Test the battery under load to ensure it retains sufficient charge.

- Replace any damaged or corroded parts promptly.

- Consult wiring diagrams to trace and verify circuit integrity.

Fuel System Cleaning Procedures

Maintaining the cleanliness of the fuel delivery system is crucial for optimal performance and longevity of marine engines. Regular cleaning helps prevent the buildup of contaminants that can impair fuel flow and reduce efficiency. This section outlines essential steps for ensuring that the fuel system remains in top condition.

Preparation and Safety

Before starting the cleaning process, ensure that the work area is well-ventilated and free of any flammable materials. Gather all necessary tools and supplies, including cleaning solvents, brushes, and safety gear. Personal protective equipment, such as gloves and goggles, is essential to safeguard against hazardous chemicals.

Cleaning Steps

Begin by draining any residual fuel from the system. Carefully disconnect fuel lines and inspect filters for debris. Use a non-corrosive solvent to clean all accessible components, including the fuel tank, lines, and injectors. A soft brush can assist in removing stubborn deposits. After cleaning, thoroughly rinse all parts and allow them to dry completely before reassembling the system.

Once everything is reconnected, it’s advisable to run the engine at idle for a short period to ensure proper fuel flow and to check for leaks. Regular maintenance and cleaning of the fuel system will help in achieving smooth operation and prolonging the life of your engine.

Replacing Outboard Motor Components

Maintenance and restoration of watercraft propulsion units are essential for optimal performance and longevity. This section focuses on the process of swapping out key elements within these systems. Whether addressing wear and tear or upgrading for improved efficiency, understanding the replacement procedures is crucial for any operator.

Before beginning, ensure you have the necessary tools and parts at hand. Familiarize yourself with the specific components that may require attention. The following table outlines common elements that may need replacement, along with their symptoms and recommended replacement intervals.

| Component | Symptoms of Failure | Recommended Replacement Interval |

|---|---|---|

| Propeller | Dents, chips, or vibrations | Every 2 years or as needed |

| Fuel Filter | Engine sputtering or stalling | Annually or 100 hours of operation |

| Water Pump Impeller | Overheating or poor water flow | Every 2 years |

| Gear Oil | Water contamination or discoloration | Annually |

| Spark Plugs | Hard starting or poor acceleration | Every 100 hours or annually |

Following proper procedures ensures safety and efficiency during component changes. Consult specific guidelines for each part, and always verify the compatibility of replacement items with your unit.

Identifying Engine Noise Problems

Understanding unusual sounds from a propulsion unit is essential for maintaining optimal performance and longevity. Different types of noises can indicate various issues, ranging from minor adjustments needed to significant mechanical failures. Recognizing these sounds early can help in diagnosing potential problems and preventing further damage.

Types of Noises and Their Meanings

Engine noise can manifest in several forms, including knocking, whining, and rattling. A knocking sound may suggest loose components or issues with the crankshaft, while a whining noise could be related to gear problems or insufficient lubrication. Rattling noises often indicate loose parts or misalignment. Each type of noise can provide valuable clues about the underlying issues that require attention.

Steps to Diagnose the Source

To effectively identify the source of the noise, start by observing when the sounds occur. Pay attention to whether they happen during acceleration, idling, or at higher speeds. Additionally, inspect the unit for any visible signs of wear or damage. Listening closely while varying the throttle can also help isolate the issue, allowing for a more accurate assessment of the problem.

Cooling System Inspection Techniques

Proper maintenance of the cooling mechanism is crucial for optimal performance and longevity of marine engines. Regular checks ensure that the system is functioning efficiently, preventing overheating and potential damage. This section outlines essential methods for examining the cooling components effectively.

Visual Inspection

Begin with a thorough visual assessment. Check for any signs of leaks, corrosion, or damage around hoses and connections. Look for discoloration or buildup, which may indicate a blockage or inadequate flow. Ensure that all components are securely attached and free of cracks or wear.

Flow Test

Conducting a flow test is vital for assessing the efficiency of the cooling system. Disconnect the water intake hose and place it into a bucket. Start the engine and observe the water discharge. A steady, strong flow indicates that the system is functioning correctly. If the flow is weak or inconsistent, further investigation may be required to identify clogs or obstructions.

Incorporating these inspection techniques into regular maintenance routines will help ensure the cooling system operates smoothly, contributing to the overall health of the engine.

Recommended Lubricants for Longevity

Proper maintenance of mechanical equipment is crucial for ensuring its durability and optimal performance. One of the key aspects of this maintenance involves the selection of appropriate lubricants, which can significantly influence the lifespan and efficiency of the components. Understanding the right products to use can make a substantial difference in reducing wear and tear, thus enhancing the overall reliability of the machinery.

Types of Lubricants are varied, and each serves a specific purpose. Greases are typically used for applications requiring a thicker consistency to adhere to surfaces and provide lasting protection. In contrast, oils are often preferred for their ability to flow easily, penetrating tight spaces and offering comprehensive coverage. Selecting the correct type based on the equipment’s requirements is essential.

When considering performance, look for products that are formulated with high-quality base oils and advanced additives. These formulations can enhance resistance to oxidation, corrosion, and thermal degradation, ensuring that the machinery operates smoothly under various conditions. Additionally, paying attention to the viscosity ratings will help in choosing a lubricant that maintains its effectiveness across different temperatures.

Regularly checking and replacing lubricants according to the manufacturer’s recommendations is vital. Timely maintenance not only prevents potential failures but also ensures that the equipment runs efficiently. Keeping a record of lubricant changes and monitoring performance can lead to better insights into when to schedule service and which products yield the best results.

Preparing for Seasonal Storage

As the boating season comes to an end, it is crucial to ensure that your equipment is properly prepared for its off-season rest. Taking the time to perform essential maintenance tasks will help protect your investment and ensure smooth performance when the next season begins.

Thorough Cleaning is the first step in the storage process. Remove any debris, salt, or grime that may have accumulated during use. Pay special attention to hard-to-reach areas, as moisture can lead to corrosion and mold growth.

Next, consider draining all fluids. This includes fuel, oil, and cooling liquids. Fuel left in the tank can deteriorate and cause starting issues, while oil that sits can break down and become less effective. Replacing these fluids before storage will maintain optimal conditions.

Inspecting components is another important task. Check for any signs of wear or damage, such as frayed wires or cracked hoses. Addressing these issues now can prevent more significant problems later on.

Lastly, covering your equipment with a protective tarp or dedicated cover will shield it from dust, moisture, and pests during its time in storage. Ensuring your vessel is properly sealed will provide an extra layer of protection against the elements.

By following these steps, you will set the stage for a successful return to the water, keeping your gear in top-notch condition for years to come.

Safety Practices During Repairs

Ensuring safety during maintenance tasks is crucial for both the technician and the equipment. By following proper guidelines, one can minimize risks and enhance the overall efficiency of the service process.

- Personal Protective Equipment (PPE): Always wear suitable gear such as gloves, goggles, and ear protection to shield against potential hazards.

- Work Environment: Maintain a clean and organized workspace. Clear any clutter that could cause trips or accidents.

- Ventilation: Ensure adequate airflow in the area to prevent the buildup of harmful fumes or gases during the service.

- Tool Inspection: Regularly check tools for wear and tear. Use only tools that are in good condition to avoid accidents.

- Electrical Safety: Disconnect power sources before starting any service. This reduces the risk of electric shock.

Implementing these practices creates a safer environment, ultimately leading to more effective maintenance and longevity of the equipment.

- Emergency Preparedness: Keep a first aid kit nearby and familiarize yourself with emergency procedures.

- Handling Fluids: Be cautious with oils and chemicals. Store them properly and dispose of waste in accordance with regulations.

- Documentation: Keep a record of all service activities. This helps in tracking maintenance history and addressing recurring issues.

Adhering to these safety measures not only protects the individual but also enhances the reliability of the equipment being serviced.

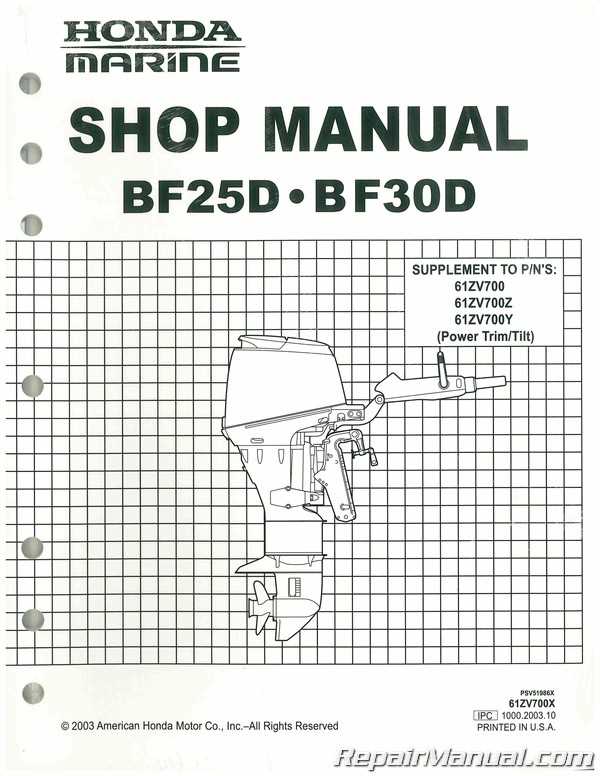

Resources for Honda Motor Manuals

Accessing comprehensive guides and references is essential for anyone involved in maintaining and servicing their aquatic propulsion systems. These resources provide crucial insights, detailed instructions, and troubleshooting tips that enhance the longevity and performance of the equipment.

Numerous websites offer digital copies of instructional documents that cover various models and specifications. These platforms often include user forums where enthusiasts and professionals exchange advice, experiences, and solutions to common issues. Additionally, manufacturers may provide official resources on their websites, including downloadable documents and video tutorials to assist users in their endeavors.

Local libraries and marine supply stores can also be valuable resources, as they may carry printed versions of essential guides or access to specialized databases. Joining community groups focused on boating can further enrich your knowledge, providing opportunities to connect with seasoned users who can share their insights and experiences.

Finally, online marketplaces often have a selection of printed guides and reference materials, allowing for the acquisition of hard-to-find editions that may not be available elsewhere. Utilizing these various resources ensures that individuals are well-equipped to tackle any challenges that may arise with their aquatic propulsion systems.