Comprehensive Guide to Repairing the Mercedes ML 270 CDI

When it comes to keeping a luxury automobile in top condition, a thorough understanding of its systems and components is essential. This section aims to provide insights into the various aspects of maintaining a specific model, ensuring that owners can address common issues effectively.

Equipped with detailed instructions and tips, this guide serves as a resource for enthusiasts and everyday drivers alike. Whether you are dealing with mechanical challenges or routine upkeep, having access to reliable information can greatly enhance the ownership experience.

From troubleshooting common problems to understanding the intricacies of specific parts, this guide empowers individuals to take charge of their vehicle’s health. With the right knowledge, you can ensure that your automobile continues to perform at its best for years to come.

Overview of the Mercedes ML 270 CDI

The subject of this section is a remarkable vehicle renowned for its robust performance and versatile design. It seamlessly blends luxury and utility, making it a popular choice among enthusiasts of high-quality automobiles. This model showcases a blend of advanced engineering and comfort features, aimed at providing a superior driving experience.

Under the hood, this vehicle is equipped with a powerful engine that delivers impressive torque and efficiency. It has been designed to tackle various terrains with ease, offering both on-road stability and off-road capability. The spacious interior is complemented by a range of technological advancements that enhance both safety and entertainment for passengers.

With its distinctive styling and practical features, this vehicle stands out in its class. Owners appreciate the attention to detail and quality craftsmanship that have gone into its construction. Whether for daily commuting or adventurous journeys, this model offers a balance of performance and luxury that caters to diverse driving needs.

Common Issues with the Vehicle

Many drivers encounter a variety of challenges with their SUVs over time. These problems can stem from normal wear and tear, manufacturing quirks, or maintenance lapses. Understanding these issues can help owners anticipate potential repairs and address them promptly.

One prevalent concern involves electrical components, where failures may occur in the wiring or control units, leading to malfunctions in features such as lights and infotainment systems. Additionally, issues with the suspension system can lead to an uncomfortable ride or difficulty in handling, often resulting from worn-out bushings or shocks.

Another frequent problem relates to engine performance. Drivers might notice a decrease in power or unusual noises, indicating that components such as the turbocharger or injectors could require inspection. Regular maintenance of fluids and filters is essential to prevent these complications from escalating.

Lastly, the cooling system is critical for engine longevity. Overheating due to coolant leaks or a failing thermostat can lead to severe damage if not addressed swiftly. Owners are encouraged to monitor their vehicles regularly and seek professional evaluations for any warning signs.

Essential Tools for Repairs

When it comes to maintaining and restoring a vehicle, having the right equipment is crucial for effective outcomes. This section highlights the indispensable instruments and devices that every enthusiast should have at their disposal. Properly selected tools not only enhance the efficiency of the work but also ensure safety throughout the process.

1. Socket Set: A comprehensive socket set is vital for loosening and tightening various fasteners. Look for one that includes a range of sizes to accommodate different components.

2. Wrenches: Both adjustable and fixed wrenches are necessary for tackling bolts in tight spaces. Having a variety of sizes will allow for better accessibility and grip.

3. Screwdrivers: A selection of flathead and Phillips screwdrivers is essential for tasks involving screws. Magnetic tips can be particularly useful for handling small parts.

4. Pliers: Needle-nose and slip-joint pliers provide versatility when gripping, twisting, or cutting wires and cables. Their various shapes allow access to hard-to-reach areas.

5. Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specifications, preventing over-tightening that could lead to damage.

6. Jack and Stands: A reliable jack and sturdy stands are crucial for lifting the vehicle safely, allowing for easy access to the undercarriage during maintenance tasks.

Equipping oneself with these essential tools can significantly enhance the overall experience and success of vehicle maintenance, making the process smoother and more enjoyable.

Step-by-Step Maintenance Guide

This guide provides a systematic approach to ensuring optimal performance and longevity of your vehicle. Regular upkeep not only enhances functionality but also helps in identifying potential issues before they escalate.

- Check Fluid Levels

- Engine oil

- Coolant

- Brake fluid

- Transmission fluid

- Inspect Filters

- Air filter

- Fuel filter

- Cabin air filter

- Examine Tires

- Tire pressure

- Tread depth

- Alignment and balance

- Brake System Check

- Inspect brake pads and discs

- Check brake lines for leaks

- Test brake fluid condition

- Battery Maintenance

- Check battery terminals for corrosion

- Ensure battery charge level is adequate

- Inspect cables for wear

Following this guide will help maintain your vehicle’s efficiency and safety. Regular inspections and timely interventions are key to a reliable driving experience.

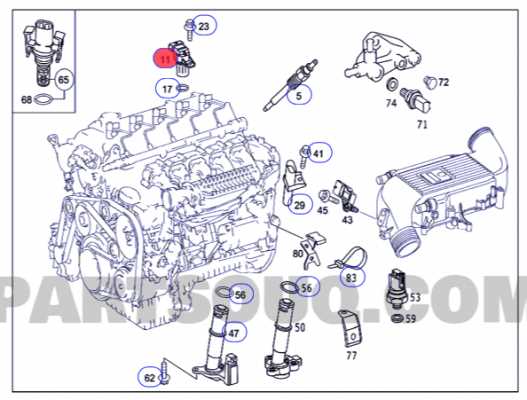

Understanding the Engine Components

The heart of any vehicle lies within its power unit, comprising a range of intricate parts that work harmoniously to produce motion. Each component plays a crucial role in ensuring optimal performance, efficiency, and reliability. By gaining insight into these elements, one can appreciate the complexity and engineering that drives modern transportation.

At the core, the assembly consists of various key parts, including the block, cylinder head, and crankshaft. The block serves as the foundation, housing the cylinders where fuel and air mix for combustion. Above it, the cylinder head seals the combustion chamber and contains vital elements such as valves and camshafts that regulate airflow. Meanwhile, the crankshaft converts linear motion into rotational force, enabling the vehicle to move.

Other essential components include the intake and exhaust systems, which manage the flow of air and gases in and out of the engine. The fuel delivery system ensures the proper mixture of air and fuel, while the cooling system prevents overheating, maintaining an efficient operating temperature. Each of these parts must function seamlessly to ensure the engine operates smoothly and efficiently.

Electrical System Troubleshooting

Diagnosing issues within the electrical system of a vehicle requires a systematic approach to identify faults efficiently. By understanding the components involved and applying methodical testing, one can effectively address malfunctions that may affect performance or functionality.

Common Electrical Problems

- Dead battery or charging issues

- Faulty wiring or connections

- Malfunctioning sensors or control modules

- Blown fuses or relays

- Defective switches or components

Troubleshooting Steps

- Inspect the battery for signs of corrosion and ensure terminals are securely connected.

- Check for any blown fuses and replace them as needed.

- Use a multimeter to measure voltage across various components, ensuring they meet manufacturer specifications.

- Examine wiring for frays, shorts, or loose connections that could disrupt the electrical flow.

- Test sensors and modules for proper operation, replacing any that show signs of failure.

Replacing Key Fluid Types

Maintaining optimal performance of your vehicle requires regular attention to various essential liquids. These fluids play critical roles in ensuring the smooth operation of different systems, from the engine to the braking mechanisms. Periodic replacement not only enhances efficiency but also extends the lifespan of vital components.

Engine Oil is one of the most crucial fluids, serving to lubricate and protect engine parts. It is advisable to change it at regular intervals to prevent degradation and maintain effective lubrication.

Transmission Fluid ensures smooth gear shifts and proper function of the transmission system. Regular checks and timely replacement are necessary to avoid shifting issues and potential damage to transmission components.

Coolant is essential for regulating engine temperature, preventing overheating. Flushing and replacing the coolant periodically helps maintain effective heat exchange and protects against corrosion.

Brake Fluid is vital for safe stopping. Over time, it can absorb moisture, leading to reduced braking efficiency. Regular checks and replacements are crucial for maintaining optimal braking performance.

Power Steering Fluid aids in steering ease and responsiveness. Replacing it as recommended can prevent steering issues and ensure smooth handling.

Following the manufacturer’s guidelines for these essential liquids is key to maintaining the vehicle’s reliability and performance over time.

Brake System Inspection Procedures

The brake system is crucial for ensuring vehicle safety and optimal performance. Regular assessment of its components can prevent potential failures and enhance overall functionality. This section outlines essential steps for evaluating the braking mechanism.

Visual Inspection: Begin by examining all visible parts of the braking assembly. Look for any signs of wear, such as cracked or warped rotors, worn pads, or leaking fluid. Ensure that all connections are secure and free of corrosion.

Fluid Check: Inspect the brake fluid reservoir to ensure that the fluid level is adequate. Low fluid levels may indicate leaks or excessive wear in the braking components. It is also important to check the fluid’s condition; contaminated fluid can compromise braking efficiency.

Performance Testing: Conduct a test drive to assess the responsiveness of the brakes. Pay attention to any unusual noises or sensations, such as grinding or vibration. Note any pulling to one side, which could suggest uneven wear or a malfunctioning component.

Component Measurement: Utilize appropriate tools to measure rotor thickness and pad wear. Replacement may be necessary if any component falls below the manufacturer’s specified limits. Regular monitoring of these measurements can prevent further issues down the line.

Final Assessment: After completing the inspection, document all findings and any actions taken. Establish a schedule for future inspections to maintain optimal performance and safety standards.

Suspension and Steering Adjustments

Proper tuning of the suspension and steering systems is crucial for enhancing vehicle performance and ensuring a smooth driving experience. These adjustments not only improve handling but also contribute to overall safety on the road. Regular checks and modifications can significantly enhance the comfort and responsiveness of the vehicle.

Key Suspension Adjustments

- Spring Tension: Adjusting the tension of the springs can help achieve the desired ride height and load capacity.

- Shock Absorber Settings: Modifying the settings of shock absorbers ensures optimal damping, enhancing ride quality and stability.

- Alignment: Regular alignment checks prevent uneven tire wear and improve steering accuracy.

Steering System Modifications

- Toe Adjustment: Fine-tuning the toe angle can enhance steering response and improve tire longevity.

- Camber Adjustment: Adjusting the camber angle optimizes tire contact with the road, affecting handling characteristics.

- Power Steering Fluid: Regular checks and replacements of the steering fluid maintain optimal system performance.

Transmission Repair Techniques

Effective methods for addressing issues related to the gearbox are essential for maintaining optimal vehicle performance. This section delves into various strategies and practices aimed at diagnosing and resolving common problems associated with these complex systems.

Regular Diagnostics play a crucial role in identifying issues before they escalate. Utilizing advanced diagnostic tools allows technicians to monitor the health of the transmission, providing valuable insights into potential failures.

Fluid Management is another key aspect. Ensuring that the transmission fluid is at the correct level and in good condition can significantly extend the lifespan of the system. Regular changes of the fluid can prevent the buildup of contaminants that may lead to wear and tear.

Component Inspection is vital during the maintenance process. By examining parts such as the torque converter, gears, and seals, professionals can pinpoint areas of concern. Early identification of wear can facilitate timely repairs, preventing more extensive damage.

Rebuilding Techniques may be necessary for severe cases. This process involves disassembling the transmission and replacing worn components with new or refurbished ones. Such an approach not only restores functionality but can also enhance overall performance.

Expert Consultation is advisable when dealing with intricate issues. Engaging with specialists who have extensive experience can provide additional insights and advanced techniques that ensure thorough and effective resolutions.

Bodywork and Exterior Fixes

This section focuses on essential maintenance and restoration tasks related to the outer structure and aesthetic components of a vehicle. Keeping the body in excellent condition not only enhances the appearance but also protects vital internal systems from environmental damage.

Assessing Damage: Begin by thoroughly inspecting the exterior for scratches, dents, or rust. Identifying issues early can prevent more significant problems later.

Repair Techniques: Common methods for addressing minor imperfections include buffing out scratches and applying touch-up paint. For deeper dents, consider using a hair dryer and compressed air for effective dent removal.

Rust Treatment: If rust is present, it’s crucial to treat it promptly. Sand down the affected area, apply a rust-inhibiting primer, and finish with a matching paint to ensure long-lasting protection.

Protective Coatings: Applying a sealant or wax can help safeguard the finish from UV rays and contaminants, preserving the vehicle’s exterior for years to come.

Safety Precautions During Repairs

Ensuring safety while working on automotive maintenance is crucial. Adopting the right measures can prevent accidents and protect both the technician and the vehicle. This section outlines essential guidelines that should be followed to create a secure working environment.

| Precaution | Description |

|---|---|

| Personal Protective Equipment (PPE) | Always wear appropriate gear such as gloves, goggles, and steel-toed boots to minimize the risk of injury. |

| Ventilation | Ensure that the workspace is well-ventilated to avoid inhalation of harmful fumes or gases. |

| Secure the Vehicle | Use wheel chocks and jack stands to stabilize the vehicle before starting any work beneath it. |

| Disconnect the Battery | Always disconnect the battery before working on electrical components to prevent shocks or shorts. |

| Follow Manufacturer Guidelines | Adhere to specific instructions provided in the service documentation for proper procedures. |

By following these safety measures, individuals can effectively reduce the risk of accidents and ensure a safer working atmosphere during vehicle maintenance activities.