Nissan Sentra 2011 Comprehensive Repair Guide

In the realm of automotive care, having access to a detailed resource can make all the difference in ensuring longevity and performance. This section serves as a crucial reference point for those seeking to enhance their understanding of vehicular upkeep, encompassing everything from routine checks to intricate repairs.

Automobiles are complex machines that require regular attention and knowledge of their components. Familiarizing oneself with the various systems and potential issues can empower owners to address challenges effectively. Whether it’s a minor adjustment or a significant overhaul, being equipped with the right information is essential for any car enthusiast or everyday driver.

Within this guide, readers will discover insights into maintenance strategies, diagnostic procedures, and solutions to common mechanical dilemmas. Each topic is designed to provide clarity and confidence, ensuring that all necessary actions can be taken with precision. Engaging with this knowledge can lead to improved vehicle reliability and an enhanced driving experience.

Overview of 2011 Nissan Sentra

This section provides a comprehensive examination of a compact vehicle known for its reliability and efficiency. Designed to cater to a diverse range of drivers, this model boasts a blend of comfort, practicality, and performance, making it an appealing choice in its category.

The exterior features a modern design with clean lines and a streamlined profile, enhancing both aesthetics and aerodynamics. Inside, the cabin offers ample space, ergonomic seating, and a well-organized layout, contributing to a pleasant driving experience.

Under the hood, the powertrain delivers a balanced combination of fuel efficiency and responsive performance, ideal for daily commuting and longer journeys alike. The vehicle is equipped with various technological enhancements aimed at improving safety and convenience, reflecting contemporary automotive trends.

Key characteristics include user-friendly interfaces, advanced safety features, and a reputation for low maintenance costs. Overall, this model stands out as a practical option for those seeking a dependable and versatile vehicle.

Common Issues with Nissan Sentra

Vehicles of a specific model often encounter a range of recurring problems that can affect their performance and longevity. Understanding these typical issues can assist owners in maintaining their automobiles effectively and addressing concerns before they escalate.

One frequent complaint involves the transmission. Owners may experience slipping or rough shifting, which can indicate a need for adjustments or fluid changes. Another common area of concern is the braking system, where squeaking or decreased responsiveness can signal worn-out pads or other components that require attention.

Furthermore, the electrical system may present challenges, including issues with the battery or alternator, leading to difficulties in starting the vehicle. It’s also important to note that the cooling system can be prone to leaks, potentially causing overheating if not addressed promptly.

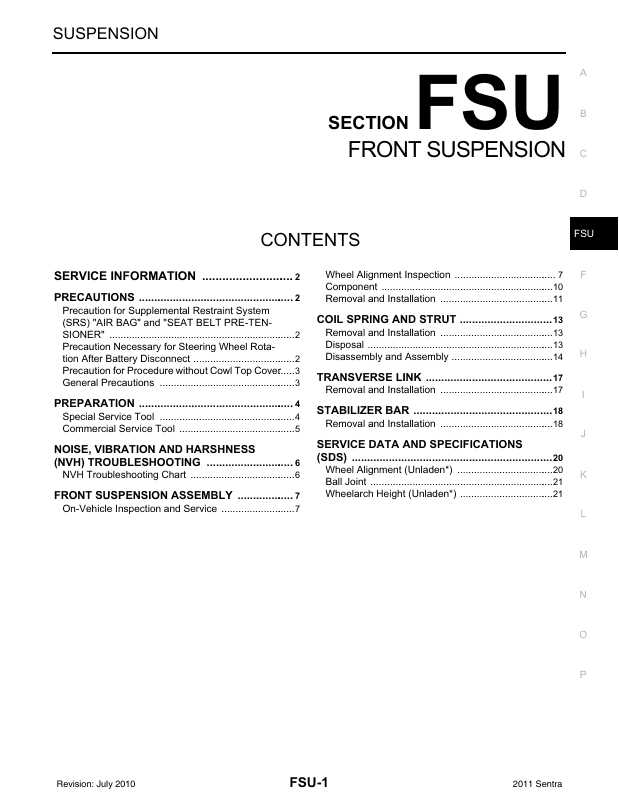

Lastly, suspension components, such as shocks and struts, may wear out over time, resulting in a less comfortable ride and poor handling. Regular maintenance and timely repairs can mitigate these common problems and enhance the overall driving experience.

Step-by-Step Repair Guide

This section provides a comprehensive approach to troubleshooting and fixing issues with your vehicle. Following a structured methodology can significantly enhance the efficiency of the process and ensure that you address all potential problems.

- Gather Necessary Tools and Materials

- Wrenches and sockets

- Screwdrivers

- Jack and jack stands

- Safety goggles and gloves

- Replacement parts as needed

- Identify the Problem

Before beginning any work, take the time to accurately diagnose the issue. Listen for unusual sounds, check for warning lights on the dashboard, and note any irregular performance.

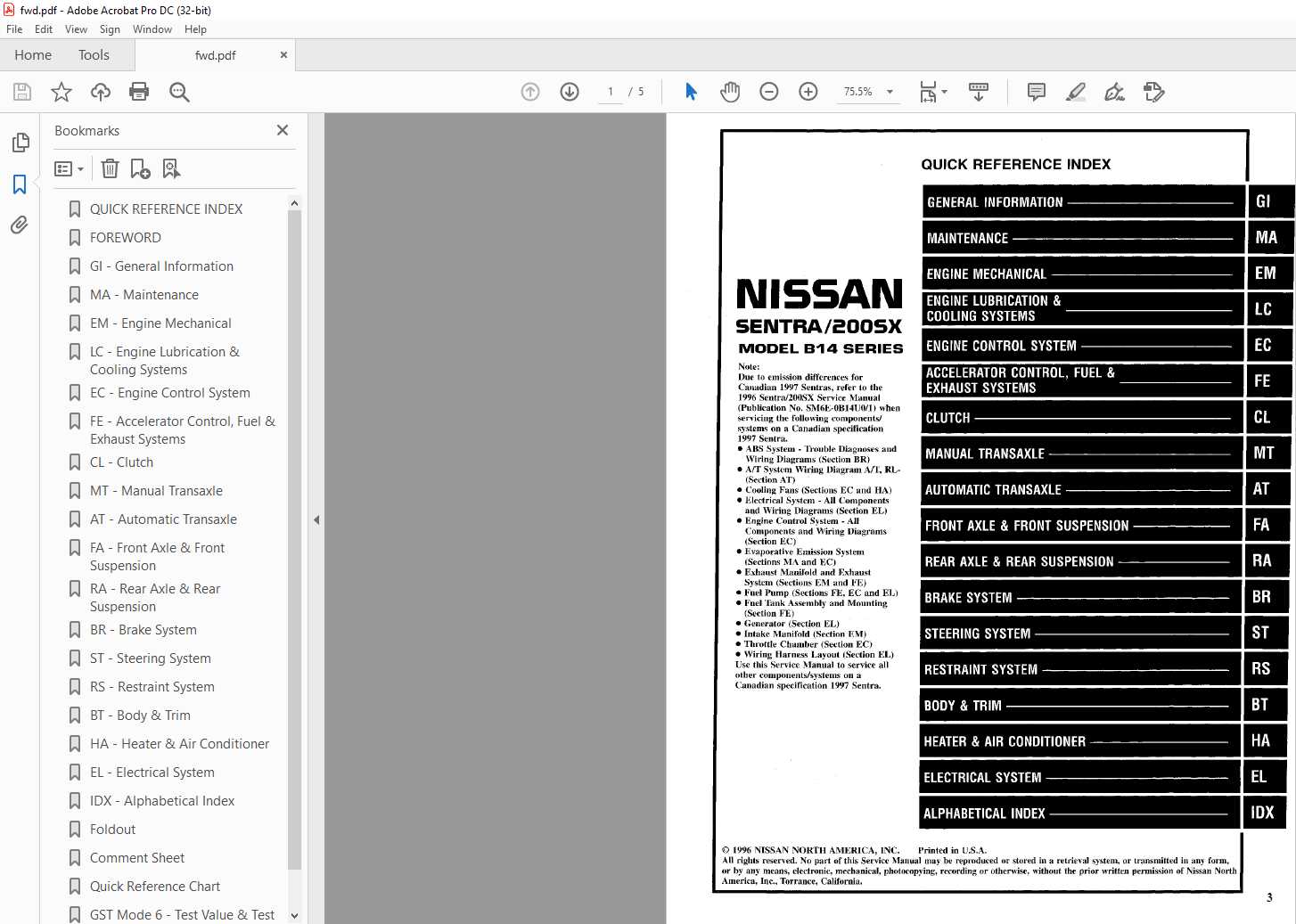

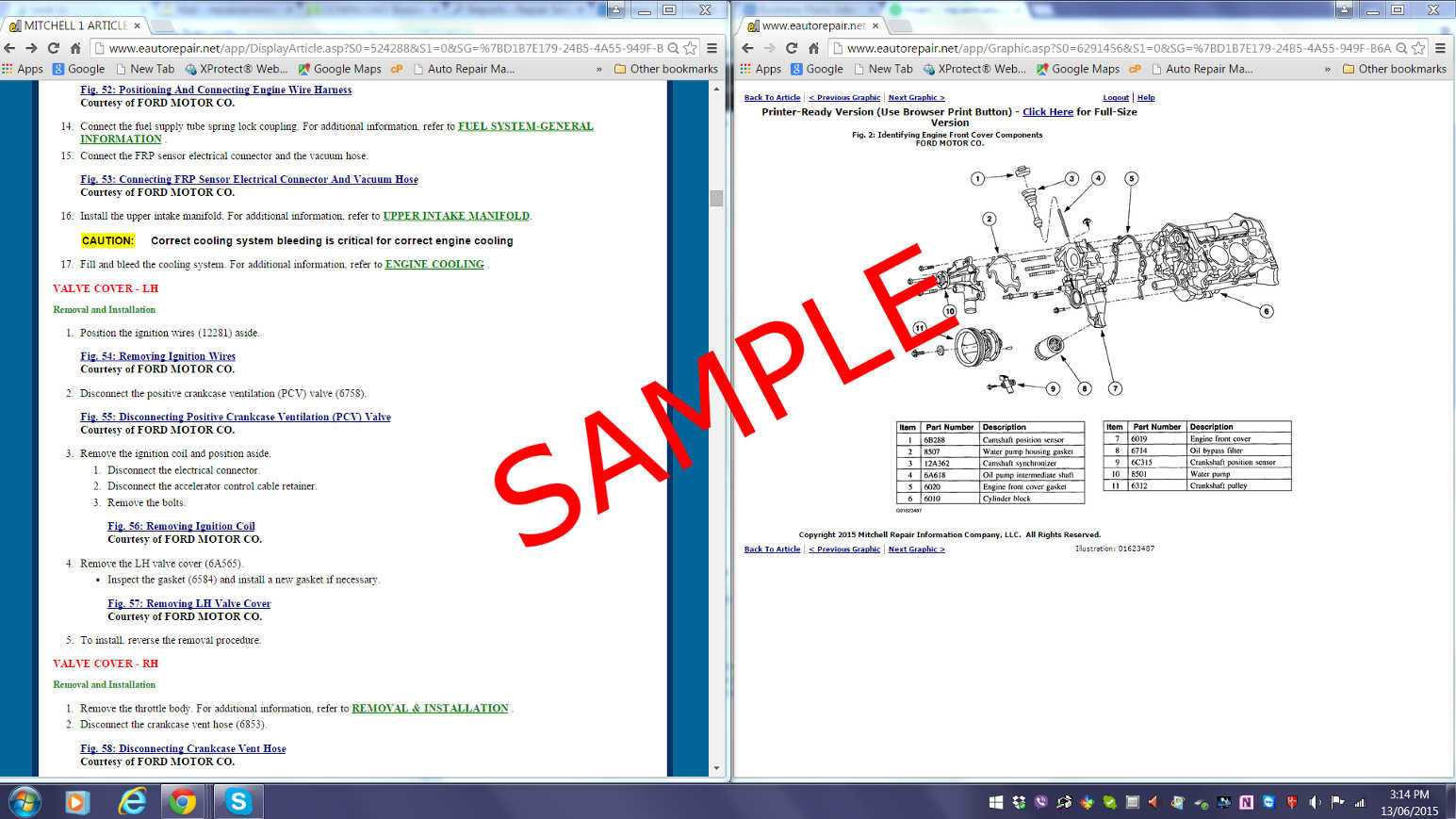

- Consult Documentation

Refer to reliable sources for specifications and procedures specific to your model. Understanding manufacturer recommendations is crucial for successful repairs.

- Prepare the Workspace

Ensure that your work area is clean and well-lit. Having ample space will facilitate better movement and organization as you tackle the task.

- Execute Repairs

Follow a systematic approach to make the necessary adjustments or replacements. Adhere to safety protocols to avoid accidents during the process.

- Test the Vehicle

After completing the repairs, conduct a thorough test drive to verify that the issue has been resolved and the vehicle operates smoothly.

- Document the Process

Keep a record of the repairs performed, including dates and parts used. This information can be valuable for future maintenance and resale.

Tools Needed for Repairs

When undertaking maintenance or troubleshooting tasks on your vehicle, having the right equipment is essential for achieving optimal results. Various instruments and devices can streamline the process, ensuring efficiency and effectiveness while minimizing the risk of damage.

Essential Hand Tools

Begin with a reliable set of wrenches, sockets, and pliers. These are crucial for loosening and tightening components throughout the vehicle. Additionally, a quality ratchet and torque wrench will help you apply the correct force to fasteners, which is vital for safety and performance.

Diagnostic Equipment

A digital multimeter is indispensable for troubleshooting electrical issues. Furthermore, an OBD-II scanner allows you to read diagnostic trouble codes, providing insight into the vehicle’s systems and identifying potential problems.

Specialized Tools

Depending on the task at hand, you might need specialized tools such as piston ring compressors or brake bleeder kits. These tools are designed for specific functions and can greatly enhance your ability to perform detailed work accurately.

Safety Gear

Finally, do not overlook the importance of safety equipment. Always wear gloves and safety goggles to protect yourself from debris and chemicals. A sturdy mechanic’s creeper can also make working underneath the vehicle more comfortable and secure.

Equipping yourself with these tools will facilitate a smoother and more successful maintenance experience, allowing you to keep your vehicle in top condition.

Routine Maintenance Tips

Regular upkeep is essential for ensuring the longevity and optimal performance of your vehicle. By adhering to a consistent maintenance schedule, you can prevent potential issues and enhance your driving experience. This section outlines key practices that will help keep your automobile in excellent condition.

Checking Fluid Levels

Maintaining proper fluid levels is crucial for the efficient operation of your vehicle. Regularly inspect engine oil, coolant, brake fluid, and transmission fluid. Top off any low levels as needed and replace fluids according to the manufacturer’s recommendations to ensure smooth performance and avoid mechanical problems.

Tire Care

Tires play a vital role in vehicle safety and efficiency. Monitor tire pressure regularly and adjust it to the recommended levels. Additionally, check for tread wear and rotate your tires periodically to promote even wear. Proper alignment and balancing will further enhance handling and extend the life of your tires.

Understanding Engine Components

Engines are intricate systems composed of various parts that work in harmony to convert fuel into motion. Each component plays a crucial role in the overall functionality and efficiency of the engine. Gaining insight into these parts allows for better maintenance and troubleshooting, ultimately enhancing the longevity and performance of the vehicle.

Key Engine Parts

Among the essential elements are the cylinders, where fuel combustion occurs, and the pistons that convert the energy generated into mechanical movement. The crankshaft transforms the linear motion of the pistons into rotational force, while the camshaft regulates the timing of valve openings and closings, ensuring optimal airflow during the combustion process.

Supporting Systems

In addition to the core components, supporting systems such as the cooling system and lubrication system are vital. The cooling system prevents overheating by dissipating excess heat, while the lubrication system reduces friction between moving parts, ensuring smooth operation. Understanding how these systems interconnect enhances the overall comprehension of engine performance and reliability.

Electrical System Troubleshooting

The electrical system in vehicles plays a critical role in ensuring proper functionality and performance. Troubleshooting electrical issues requires a systematic approach to identify and resolve potential problems efficiently. By following a structured method, you can pinpoint malfunctions and restore the vehicle’s electrical components to optimal condition.

Common Electrical Issues

- Dead battery

- Faulty alternator

- Blown fuses

- Wiring harness damage

- Malfunctioning sensors

Troubleshooting Steps

- Inspect the battery connections for corrosion and tightness.

- Check the voltage output of the alternator.

- Examine fuses and replace any that are blown.

- Look for visible signs of wear or damage in wiring.

- Test sensors for correct operation using a multimeter.

By systematically addressing these areas, you can effectively diagnose and rectify issues within the electrical framework of your vehicle. Regular maintenance and timely interventions are essential for sustaining the reliability of the electrical system.

Brake System Repair Instructions

The braking mechanism is crucial for safe vehicle operation, requiring regular maintenance and timely interventions to ensure optimal performance. Proper procedures for servicing this system can prevent accidents and extend component lifespan.

Before beginning any work, it is essential to gather the necessary tools and materials:

- Jack and jack stands

- Wrench set

- Brake fluid

- New brake pads and rotors (if applicable)

- Brake cleaner

- Protective gloves and eyewear

Follow these steps for effective maintenance:

- Preparation: Park the vehicle on a flat surface and engage the parking brake. Disconnect the battery to prevent any electrical issues.

- Wheel Removal: Use the jack to lift the vehicle and secure it with jack stands. Remove the wheels to access the brake components.

- Inspection: Examine the brake pads and rotors for wear. Replace any parts that show significant wear or damage.

- Cleaning: Clean the brake components using brake cleaner to remove dust and debris. Ensure that all surfaces are free from contaminants.

- Component Replacement: If necessary, install new brake pads and rotors, ensuring proper alignment. Tighten all bolts to the manufacturer’s specifications.

- Brake Fluid Check: Inspect the brake fluid level and top up if needed. Bleed the brakes to remove any air from the lines, ensuring proper hydraulic function.

- Reassembly: Reattach the wheels, lower the vehicle, and reconnect the battery. Ensure all tools are removed from the work area.

- Test Drive: Perform a test drive to confirm that the brakes function correctly, listening for any unusual noises or vibrations.

Adhering to these guidelines will enhance safety and performance. Regular checks and timely maintenance are key to sustaining the effectiveness of the braking system.

Transmission and Drivetrain Insights

Understanding the intricacies of the power delivery system is crucial for optimal vehicle performance. This section delves into the essential components and functionality of the transmission and drivetrain, offering valuable insights for maintaining and troubleshooting these vital systems.

Key Components

The transmission and drivetrain consist of several critical parts that work together to transfer power from the engine to the wheels. Key components include:

| Component | Function |

|---|---|

| Transmission | Shifts power and adjusts torque for varying speeds. |

| Driveshaft | Transmits torque from the transmission to the differential. |

| Differential | Distributes power to the wheels while allowing for differences in wheel speed during turns. |

| Axles | Connect the differential to the wheels, enabling rotation. |

Common Issues and Solutions

Identifying potential problems within the power delivery system can prevent more significant issues down the line. Common concerns include slipping gears, unusual noises, and fluid leaks. Regular inspection and timely maintenance are key to ensuring longevity and performance.

DIY vs. Professional Repairs

When it comes to maintaining and fixing vehicles, car owners often face the decision between tackling the job themselves or hiring a skilled technician. Each approach offers distinct advantages and drawbacks, impacting not only the cost but also the quality of the work performed.

Do-It-Yourself (DIY) projects can be rewarding and cost-effective. Engaging in personal repairs allows individuals to gain valuable knowledge about their vehicles, fostering a deeper connection and understanding of how things work. However, this route requires time, effort, and sometimes, a level of expertise that may be beyond the casual enthusiast. Mistakes can lead to further complications, potentially resulting in higher expenses down the line.

On the other hand, seeking help from professionals guarantees a level of expertise and experience that can often lead to more reliable results. Technicians come equipped with specialized tools and training, enabling them to address complex issues efficiently. Nevertheless, this convenience typically comes at a higher financial cost, and some owners may feel a loss of control over the repair process.

Ultimately, the choice between self-service and professional assistance depends on individual preferences, skills, and the specific circumstances surrounding each repair situation. Balancing cost, convenience, and personal capability is key to making the best decision for vehicle upkeep.