Comprehensive Guide to Repairing the 97 Nissan Altima

In the realm of automotive care, having access to detailed information about various aspects of vehicle functionality is essential. This section serves as a vital resource for individuals seeking guidance on addressing common issues, performing essential tasks, and understanding the intricacies of their vehicle. Whether you are a seasoned enthusiast or a novice, this information can significantly enhance your experience and knowledge.

With a focus on the intricacies of specific models, this guide provides a structured approach to understanding your vehicle’s components and systems. The insights offered here cover a broad range of topics, from routine upkeep to more complex repairs, ensuring that you are well-equipped to handle any challenge that may arise. By familiarizing yourself with these details, you can foster a greater appreciation for the engineering that drives your vehicle.

As you delve into this resource, you will uncover valuable techniques and methods that promote longevity and efficiency. Armed with the right knowledge, you can confidently navigate the various tasks required to maintain your vehicle’s performance, thereby ensuring a smoother and safer driving experience.

Essential Tools for Nissan Altima Repairs

When it comes to maintaining and fixing vehicles, having the right set of instruments is crucial. Proper tools not only make the job easier but also ensure safety and efficiency during the process. A well-equipped toolkit can significantly enhance the experience for anyone looking to perform tasks on their automobile, from routine maintenance to more complex undertakings.

Basic Hand Tools

Every automotive enthusiast should possess a collection of basic hand tools. This includes wrenches, screwdrivers, and pliers. These instruments are essential for loosening and tightening various components throughout the vehicle. A comprehensive socket set is also advisable, as it provides versatility for working on different fasteners in confined spaces.

Diagnostic Equipment

To accurately identify issues within the engine or other systems, diagnostic tools are indispensable. An OBD-II scanner can help read error codes and assess the overall health of the engine. Additionally, a multimeter is beneficial for troubleshooting electrical problems, allowing users to measure voltage, current, and resistance with precision. Investing in quality diagnostic equipment can lead to quicker and more effective troubleshooting.

Understanding the 1997 Altima Specifications

This section aims to provide a comprehensive overview of the technical details and features that define the vehicle from 1997. Understanding these specifications is essential for both enthusiasts and those interested in maintenance and modifications.

Engine and Performance

- Engine Type: The model is equipped with a 2.4-liter inline-4 engine.

- Power Output: Delivers approximately 150 horsepower.

- Transmission Options: Available with either a 5-speed manual or a 4-speed automatic transmission.

- Fuel Economy: Estimated fuel efficiency of 24 mpg in the city and 31 mpg on the highway.

Dimensions and Capacities

- Overall Length: 180.3 inches

- Width: 68.5 inches

- Height: 54.5 inches

- Wheelbase: 105.4 inches

- Seating Capacity: Designed to comfortably accommodate five passengers.

Common Issues with Nissan Altima

Many vehicle owners encounter typical challenges that can affect performance, safety, and overall reliability. Understanding these prevalent concerns can help in taking preventive measures and ensuring a smoother driving experience.

Engine Problems: One frequent issue involves the engine, where drivers may notice unusual noises or decreased efficiency. Common symptoms include rough idling or a lack of power during acceleration. Regular maintenance and timely inspections can help mitigate these problems.

Transmission Difficulties: Shifting issues are another area of concern. Drivers might experience hesitations, slipping gears, or harsh transitions between gears. Proper fluid levels and regular servicing can aid in preventing these transmission-related challenges.

Suspension Concerns: The suspension system is crucial for ride comfort and handling. Worn-out components may lead to a bumpy ride or uneven tire wear. Addressing any signs of wear early can enhance stability and comfort.

Electrical System Failures: Electrical malfunctions can manifest in various ways, including issues with lighting, dashboard displays, and starting problems. Regularly checking the battery and electrical connections can help avoid these frustrating situations.

Brake Wear: Brake performance is critical for safety. Drivers should be aware of signs such as squeaking or grinding noises, which may indicate worn pads or rotors. Routine inspections can help maintain optimal braking performance.

By being aware of these common issues and addressing them proactively, owners can enhance the longevity and reliability of their vehicles, leading to a better driving experience.

Step-by-Step Maintenance Procedures

Regular upkeep is essential for the longevity and performance of your vehicle. Following a structured approach to maintenance ensures that critical components function correctly and helps prevent unexpected breakdowns. This section outlines detailed processes that can be followed to maintain your automobile effectively.

Engine Oil Change

Changing the engine lubricant is one of the most vital tasks in vehicle care. Begin by gathering the necessary tools and materials: a new oil filter, the appropriate type and amount of oil, a wrench, an oil catch pan, and a funnel. First, ensure the engine is warm to facilitate oil drainage. Next, position the catch pan under the oil pan and remove the drain plug, allowing the old oil to flow out completely. Replace the drain plug once all oil has drained. Install the new oil filter, ensuring it is properly seated. Finally, fill the engine with new oil using the funnel, and check the dipstick to confirm the correct level.

Tire Inspection and Rotation

Regularly checking and rotating your tires is crucial for safety and efficient fuel consumption. Start by examining the tire pressure with a gauge, adjusting it to the manufacturer’s recommended levels. Inspect each tire for signs of wear, such as uneven tread or bulges. Rotate the tires according to a specific pattern, typically front-to-back or side-to-side, depending on whether they are directional or not. Ensure that all lug nuts are tightened to the proper specifications after reinstallation.

Electrical Systems Diagnostics Explained

Understanding the intricacies of electrical systems is crucial for maintaining vehicle performance. Diagnosing issues within these systems requires a systematic approach, focusing on identifying faults and ensuring proper functionality. Through careful analysis and testing, one can uncover the root causes of electrical malfunctions, leading to effective solutions.

First and foremost, it is essential to familiarize oneself with the components of the electrical system. This includes the battery, alternator, wiring harnesses, and various sensors that work in harmony to power critical functions. Regular checks can help in spotting wear or damage before they escalate into significant problems.

Moreover, utilizing diagnostic tools can greatly enhance the accuracy of troubleshooting efforts. Multimeters and oscilloscopes are invaluable in measuring voltage, current, and resistance, enabling technicians to pinpoint discrepancies in electrical flow. Understanding the readings provided by these instruments is key to successful diagnosis.

In addition, performing visual inspections of wiring and connectors can reveal hidden issues. Loose connections, corrosion, or frayed wires are common culprits that can lead to system failures. Addressing these concerns promptly can prevent further complications and ensure a reliable electrical system.

Ultimately, effective diagnostics rely on a combination of knowledge, tools, and experience. By mastering these techniques, one can maintain the integrity of the vehicle’s electrical systems, ensuring optimal performance and longevity.

Engine Overhaul Techniques for Altima

Rebuilding an engine is a complex yet rewarding process that demands precision, patience, and a solid understanding of various techniques. This section outlines essential practices that can enhance the performance and longevity of the internal combustion unit, ensuring it runs efficiently after a comprehensive refurbishment.

Preparation and Inspection

Before diving into the overhaul, proper preparation is crucial. This phase includes the following steps:

- Gather all necessary tools and equipment.

- Establish a clean and organized workspace to minimize contamination.

- Conduct a thorough inspection of engine components to identify wear and damage.

- Document findings for reference during reassembly.

Reassembly Techniques

After cleaning and refurbishing parts, the reassembly process begins. Follow these guidelines for optimal results:

- Utilize new gaskets and seals to prevent leaks.

- Torque bolts to the manufacturer’s specifications to avoid stress fractures.

- Apply assembly lube to moving parts to ensure smooth operation.

- Double-check alignment of timing components to maintain engine synchronization.

By adhering to these techniques, one can achieve a successful engine overhaul, leading to improved performance and reliability of the vehicle.

Transmission Troubleshooting Methods

Diagnosing issues with a vehicle’s transmission system can be a challenging task, yet it is crucial for maintaining optimal performance. A systematic approach helps identify the root causes of malfunctions, ensuring that the appropriate corrective measures are taken. By understanding various troubleshooting techniques, drivers can effectively address problems before they escalate.

Visual Inspection: Begin by conducting a thorough visual examination of the transmission. Look for signs of fluid leaks, damaged components, or loose connections. Ensuring that all visible parts are intact can often reveal obvious issues that require immediate attention.

Fluid Level and Condition: Checking the transmission fluid level and its condition is vital. Low fluid levels can lead to overheating and improper shifting, while dirty or burnt fluid may indicate internal damage. Always use the recommended type of fluid for optimal results.

Diagnostic Tools: Utilize diagnostic scanners to retrieve any stored trouble codes from the vehicle’s computer. These codes can provide insights into specific issues affecting the transmission system, allowing for targeted troubleshooting efforts.

Test Drive: A controlled test drive can help identify transmission behavior under various conditions. Pay attention to any unusual noises, slipping, or hesitation during acceleration, as these symptoms can offer clues about the underlying problems.

Component Testing: If initial methods do not reveal the issue, individual components may need to be tested. This includes checking solenoids, sensors, and electrical connections to ensure they function correctly. Faulty components can disrupt the entire system’s performance.

By employing these troubleshooting methods, vehicle owners can gain a clearer understanding of transmission issues, facilitating timely repairs and prolonging the lifespan of their automobile.

Suspension and Steering Adjustments

The proper functioning of a vehicle’s suspension and steering system is essential for ensuring a smooth ride and maintaining control during operation. This section covers the key adjustments that can enhance vehicle handling and comfort, contributing to an overall improved driving experience.

Key Components to Consider

- Shock Absorbers

- Struts

- Ball Joints

- Control Arms

- Steering Rack and Pinion

Adjustment Procedures

- Inspect the current condition of the shock absorbers and struts. Replace them if they show signs of wear or leakage.

- Ensure that ball joints and control arms are properly lubricated and free from damage.

- Check the alignment of the wheels. Adjust toe, camber, and caster settings as necessary to meet manufacturer specifications.

- Evaluate the steering system for play or stiffness, adjusting the steering rack if needed.

- Regularly test drive the vehicle after making adjustments to ensure improved handling and ride quality.

Brake System Repairs and Maintenance

Ensuring optimal performance of the braking mechanism is crucial for vehicle safety. Regular upkeep and timely interventions can prevent extensive issues and enhance the overall driving experience. This section outlines essential procedures for maintaining and addressing common problems within the braking system.

Common Brake Issues

- Squeaking or Grinding Noises: These sounds often indicate worn-out pads or damaged rotors.

- Pulsation During Braking: This may be caused by warped rotors, leading to uneven pressure on the braking surface.

- Soft or Spongy Brake Pedal: This could suggest air in the hydraulic lines or low fluid levels.

Maintenance Tips

- Regularly check the brake fluid level and top up as necessary to maintain proper hydraulic pressure.

- Inspect brake pads and rotors periodically for wear and replace them when necessary to ensure safe stopping power.

- Flush the brake system every two years to remove moisture and contaminants from the fluid.

By adhering to these guidelines, one can significantly extend the lifespan of the braking system and enhance driving safety.

Cooling System and Radiator Insights

The cooling mechanism of a vehicle plays a crucial role in maintaining optimal operating temperatures for the engine. It is designed to prevent overheating while ensuring efficient performance. Understanding the various components and their functions can help in troubleshooting and maintaining this essential system.

At the heart of the cooling mechanism lies the radiator, which serves as the primary heat exchanger. Its function is to dissipate excess heat generated by the engine while circulating coolant to absorb and transfer this heat effectively.

- Components of the Cooling System:

- Radiator: The main unit that cools the hot coolant from the engine.

- Water Pump: Circulates the coolant throughout the system.

- Thermostat: Regulates the flow of coolant based on temperature.

- Coolant Reservoir: Holds extra coolant and helps maintain proper levels.

Regular maintenance of the cooling system is essential for preventing potential issues. Here are some key practices:

- Check the coolant levels regularly to ensure they are within the recommended range.

- Inspect hoses and connections for any signs of wear or leaks.

- Flush the cooling system periodically to remove debris and contaminants.

- Monitor the temperature gauge for any fluctuations indicating overheating.

By staying proactive with these maintenance tips, one can significantly enhance the longevity and efficiency of the cooling system, ensuring the engine operates smoothly and reliably.

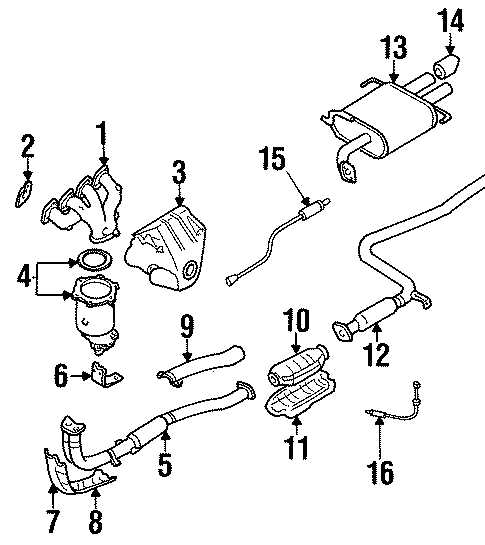

Exhaust System Components and Fixes

The exhaust system plays a critical role in ensuring optimal performance and reducing harmful emissions from the engine. It consists of various parts that work together to channel exhaust gases away from the engine, while also minimizing noise and ensuring efficient fuel combustion. Understanding these components is essential for troubleshooting issues and implementing effective solutions.

Key elements of the exhaust assembly include the manifold, catalytic converter, muffler, and exhaust pipes. The manifold collects exhaust gases from the engine cylinders and directs them into the exhaust stream. A malfunctioning manifold can lead to exhaust leaks, reduced engine performance, and increased emissions. In such cases, inspecting for cracks or loose fittings is crucial, as repairs may involve resealing or replacing the entire unit.

The catalytic converter is vital for converting harmful gases into less toxic emissions. Signs of failure can include a decrease in power or unusual odors. Regular checks can prevent issues, and replacement may be necessary if the component is clogged or damaged. Additionally, the muffler is responsible for noise reduction. A damaged muffler can lead to increased sound levels and may require welding or replacement to restore proper function.

Finally, the exhaust pipes facilitate the flow of gases from the manifold to the tailpipe. Corrosion or damage to these pipes can cause leaks, resulting in a drop in efficiency and potential safety hazards. Inspecting the exhaust system regularly for signs of wear or rust can help identify problems early, allowing for timely fixes and maintenance to keep the system running smoothly.

Bodywork and Interior Restoration Tips

Restoring the exterior and interior of a vehicle can greatly enhance its appearance and functionality. This process involves addressing various elements, from repairing dents and scratches to refurbishing upholstery and trim. A well-executed restoration not only revives the aesthetic appeal but also improves the overall driving experience.

Assessing Damage: Before starting any restoration work, it’s crucial to evaluate the condition of the vehicle thoroughly. Look for signs of rust, paint damage, or structural issues on the body. Inside, inspect the seats, dashboard, and flooring for wear and tear. Documenting these areas will help prioritize tasks and plan the necessary repairs.

Surface Preparation: For successful painting or refinishing, proper surface preparation is essential. Clean the areas thoroughly, removing dirt, grease, and old paint. For bodywork, sanding the damaged areas smooths the surface, making it ready for repair compounds or primer. In the interior, consider removing seats and trim to access hard-to-reach areas.

Repair Techniques: Various techniques can be employed for bodywork restoration. For minor dents, using a hairdryer followed by a cold spray can sometimes pop them out. For larger damage, filler compounds may be necessary. When it comes to interior repairs, stitching and patching techniques can help restore fabric and leather surfaces, while vinyl repair kits can fix scratches and tears.

Finishing Touches: After repairs, it’s time to focus on aesthetics. A fresh coat of paint can transform the exterior, while detailing the interior, including cleaning carpets and treating surfaces, enhances overall appearance. Adding new accessories, such as floor mats or custom seat covers, can personalize the vehicle further.

Regular Maintenance: Once the restoration is complete, maintaining the vehicle’s condition is vital. Regular cleaning and applying protective coatings can help prevent future damage. Keeping an eye on any signs of wear will allow for timely repairs, ensuring the vehicle remains in excellent shape for years to come.

Final Checklists for Altima Service

When it comes to vehicle maintenance, having a comprehensive list of essential tasks can make a significant difference. This section outlines crucial points to consider to ensure your automobile operates smoothly and efficiently after servicing. Following these guidelines will help you catch potential issues early and maintain the longevity of your vehicle.

Essential Maintenance Tasks

Begin with a thorough examination of fluid levels, including engine oil, coolant, and brake fluid. Ensure that each component is filled to the recommended levels and inspect for any signs of leaks. Additionally, check the state of the air and fuel filters, as clean filters contribute to optimal engine performance. Don’t overlook tire pressure; proper inflation enhances safety and fuel efficiency.

Final Inspections

Once the maintenance tasks are complete, conduct a visual inspection of belts and hoses for any signs of wear or damage. Test all lights and indicators to confirm they are functioning correctly. Finally, take the vehicle for a short drive to listen for unusual sounds and verify that all systems are operating as intended. Keeping track of these final checks will help ensure a reliable and enjoyable driving experience.