Comprehensive Guide to Repairing the 2004 Mercury Monterey

Ensuring optimal performance of your vehicle is essential for safety and longevity. This resource provides valuable insights into troubleshooting and servicing, equipping enthusiasts and owners alike with the knowledge needed to tackle various challenges. Understanding the intricate details of automotive care can save time and resources, making it a worthy investment for any driver.

With a focus on essential components and systems, this guide delves into practical solutions that facilitate efficient upkeep. Whether addressing minor issues or undertaking significant projects, having a thorough understanding of the processes involved is crucial. By empowering individuals with the right tools and techniques, this resource aims to enhance the overall driving experience.

From basic maintenance tasks to more complex repairs, the information presented here serves as a reliable companion for those looking to deepen their automotive knowledge. Familiarity with key procedures and specifications allows for informed decision-making, ultimately leading to a smoother and more enjoyable journey on the road.

Overview of the 2004 Mercury Monterey

This vehicle represents a blend of practicality and comfort, catering to families and those in need of versatile transportation solutions. With its spacious interior and thoughtful design, it aims to provide a reliable driving experience while accommodating various lifestyle needs.

The model is equipped with a robust powertrain, ensuring a smooth ride on diverse terrains. Its handling characteristics make it suitable for both urban commutes and longer journeys, emphasizing stability and control.

Inside, the cabin is designed for maximum convenience, offering ample seating and cargo space. Features like user-friendly technology and safety enhancements contribute to a sense of security for all passengers. Overall, this automobile stands out for its ability to merge functionality with comfort, making it a solid choice for many drivers.

Common Issues Faced by Owners

Vehicle ownership often comes with its own set of challenges. Many drivers encounter various difficulties that can affect performance and comfort. Understanding these frequent problems can help in proactive maintenance and decision-making.

Frequent Mechanical Problems

- Transmission Issues: Many owners report slipping gears and delayed shifting.

- Engine Performance: Problems such as rough idling and reduced power can be common.

- Suspension Concerns: Noises and instability while driving may arise due to worn-out components.

Electrical System Troubles

- Battery Failures: Frequent dead batteries can lead to starting issues.

- Lighting Malfunctions: Headlights and taillights may flicker or fail unexpectedly.

- Climate Control Problems: Inconsistent heating or cooling can diminish comfort during travel.

Maintenance Tips for Longevity

Ensuring the prolonged life of your vehicle requires consistent care and attention. Implementing a routine maintenance schedule can significantly enhance performance and reliability over time.

Regular Oil Changes: Frequent oil changes are vital for optimal engine health. Clean oil reduces friction and prevents wear, ultimately extending the engine’s lifespan.

Tire Maintenance: Check tire pressure regularly and rotate tires as recommended. Properly inflated and aligned tires improve fuel efficiency and ensure better handling.

Fluid Checks: Regularly inspect and top off essential fluids, including coolant, brake fluid, and transmission fluid. Maintaining appropriate levels helps prevent overheating and system failures.

Brake Inspection: Periodically check brake pads and rotors. Addressing wear promptly prevents further damage and enhances safety.

Battery Care: Keep battery terminals clean and secure. A well-maintained battery is crucial for reliable starts and overall electrical system performance.

Exterior and Interior Care: Regular washing and waxing protect the paint and prevent rust. Clean interiors enhance comfort and maintain value.

By diligently following these practices, you can ensure your vehicle remains in peak condition for years to come.

Tools Needed for Basic Repairs

When tackling simple maintenance tasks on your vehicle, having the right equipment is essential. This collection of instruments not only enhances efficiency but also ensures safety and accuracy during the process. A well-equipped workspace can make all the difference in achieving successful outcomes.

Essential Hand Tools: Begin with a set of sockets and wrenches, which are crucial for loosening and tightening bolts. Pliers and screwdrivers of various sizes are also necessary for handling different types of fasteners. A good quality hammer will come in handy for more stubborn components.

Specialized Equipment: Depending on the task, certain specialized tools may be required. For example, a jack and jack stands are indispensable for lifting the vehicle safely. Additionally, a torque wrench ensures that fasteners are tightened to the manufacturer’s specifications.

Measuring Instruments: Accurate measurements are vital for many repairs. A tape measure and a level can help ensure that parts are aligned correctly. A multimeter is also beneficial for electrical diagnostics and troubleshooting.

Safety Gear: Don’t forget personal protective equipment. Gloves protect your hands from grime and sharp edges, while safety glasses shield your eyes from debris. An apron or coveralls can keep your clothing clean and free from damage.

By gathering these necessary tools, you will be well-prepared to perform various maintenance tasks effectively and safely.

Step-by-Step Guide to Oil Changes

Regularly replacing the engine lubricant is essential for maintaining optimal performance and extending the lifespan of your vehicle. This process involves several straightforward steps that ensure your engine runs smoothly and efficiently. Below is a comprehensive guide to assist you in performing this vital task.

Gather Your Supplies

Before starting, make sure you have all the necessary tools and materials. You will need:

- New engine lubricant – Check your owner’s documentation for the correct type and quantity.

- Oil filter – Replace it to prevent contamination.

- Wrench set – For removing the oil drain plug.

- Oil catch pan – To collect old lubricant.

- Funnel – For pouring new lubricant.

- Rags – For cleaning spills and wiping surfaces.

Performing the Change

Follow these steps to complete the task:

- Prepare the vehicle: Park on a level surface and turn off the engine. Allow it to cool down.

- Lift the vehicle: Use ramps or jack stands for easier access underneath.

- Drain the old lubricant: Place the catch pan under the oil pan, remove the drain plug, and let the old oil flow out completely.

- Replace the oil filter: Use the wrench to remove the old filter. Apply a bit of new oil to the gasket of the new filter before installing it.

- Reinstall the drain plug: Once the oil has drained, replace and tighten the drain plug securely.

- Add new lubricant: Using a funnel, pour the new oil into the engine. Check the dipstick to ensure the correct level.

- Start the engine: Allow it to run for a few minutes while checking for leaks. Turn off the engine and recheck the oil level.

By following these simple steps, you can ensure your vehicle remains in top condition and performs at its best.

Understanding the Electrical System

The electrical system of a vehicle is a complex network that plays a crucial role in its overall functionality. It powers essential components, ensuring that everything from the ignition to the lighting operates smoothly. A solid grasp of this system can help in diagnosing issues and maintaining optimal performance.

Key Components

At the heart of the electrical framework are the battery, alternator, and wiring harness. The battery serves as the primary energy source, while the alternator recharges it during operation. The wiring harness connects various electrical components, facilitating communication and power distribution throughout the vehicle.

Troubleshooting Tips

When encountering electrical problems, it’s essential to start with the basics. Check the battery for proper voltage and connections. Inspect the alternator to ensure it’s functioning correctly. Additionally, examining the wiring for any signs of wear or damage can help pinpoint issues. Understanding these elements will empower you to address common electrical challenges effectively.

Replacing Brakes: A How-To

Ensuring the safety and performance of your vehicle often requires attention to the braking system. This guide will walk you through the essential steps for replacing brake components, enabling you to restore optimal functionality and enhance your driving experience.

Tools and Materials Needed: Before beginning, gather all necessary tools and parts. You will need a jack, jack stands, a lug wrench, brake pads, rotors, and appropriate brake fluid. Make sure to have safety goggles and gloves for protection.

Step 1: Prepare the Vehicle Start by parking on a flat surface and engaging the parking brake. Loosen the lug nuts on the wheels where you will be working, then lift the vehicle using the jack and secure it with jack stands. Remove the wheel to access the brake assembly.

Step 2: Remove Old Brake Components Locate the caliper and remove the bolts securing it in place. Carefully slide the caliper off the rotor, taking care not to stress the brake line. Remove the old pads and check the rotor for wear. If it shows signs of damage, consider replacing it.

Step 3: Install New Brake Parts Position the new brake pads into the caliper bracket, ensuring they are aligned properly. If replacing the rotor, slide the new one onto the hub. Reattach the caliper over the new pads and secure it with the previously removed bolts.

Step 4: Final Checks and Reassembly Before reattaching the wheel, check the brake fluid level and top off if necessary. Replace the wheel and tighten the lug nuts securely. Lower the vehicle from the jack stands and perform a final check on all components.

Step 5: Test the Brakes Start the vehicle and gently press the brake pedal a few times to seat the new pads. Conduct a test drive in a safe area to ensure the brakes function correctly and there are no unusual noises.

Following these steps will help you successfully replace your braking components, ensuring safety and reliability on the road.

Diagnosing Engine Performance Problems

Identifying issues that affect engine performance is crucial for maintaining optimal functionality and efficiency. Various symptoms may indicate underlying problems, ranging from poor acceleration to unusual noises. A systematic approach to troubleshooting can help pinpoint the source of these issues and facilitate timely repairs.

Begin by observing any noticeable changes in the vehicle’s behavior. Common indicators include diminished power output, irregular idling, or increased fuel consumption. Utilizing onboard diagnostics can provide error codes that offer insights into specific malfunctions. Additionally, performing visual inspections of components such as spark plugs, air filters, and fuel lines can reveal wear or damage that may be impacting performance.

Next, consider conducting tests related to fuel delivery and ignition systems. Ensuring that the fuel injectors are functioning correctly and that the ignition system is generating adequate spark are vital steps. Compression tests can also help assess the overall health of the engine, as low compression may signify internal issues.

Lastly, don’t overlook the importance of routine maintenance. Regular oil changes, filter replacements, and system checks can prevent many performance-related problems from developing. By staying proactive and attentive to the engine’s needs, owners can enhance longevity and reliability.

Using the Repair Manual Effectively

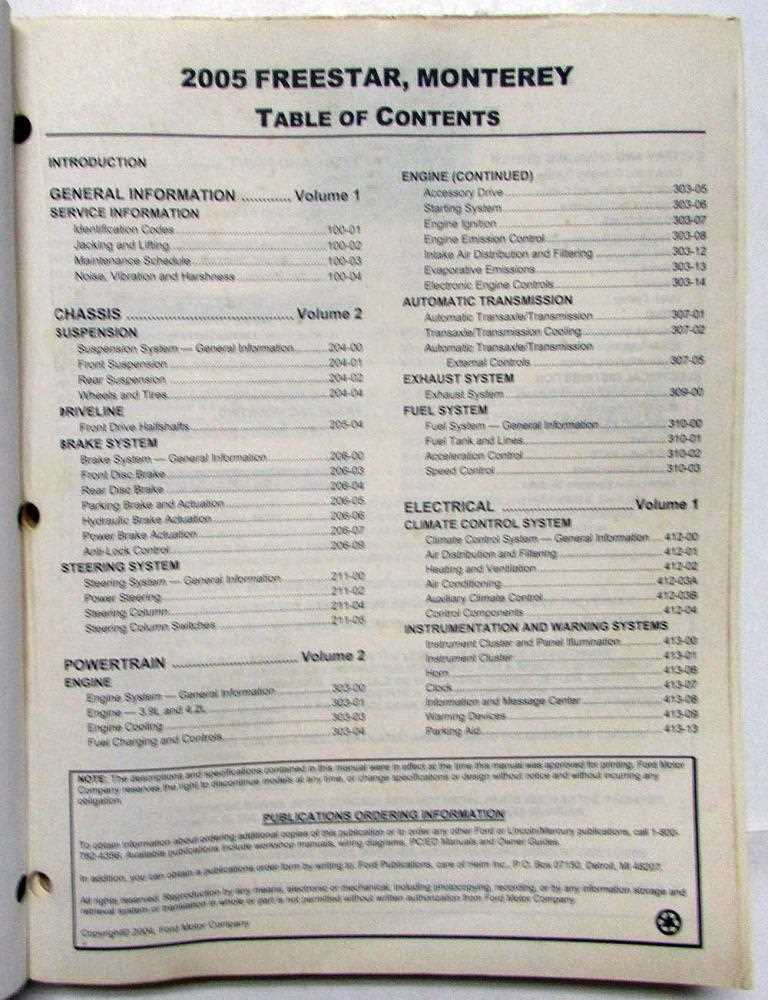

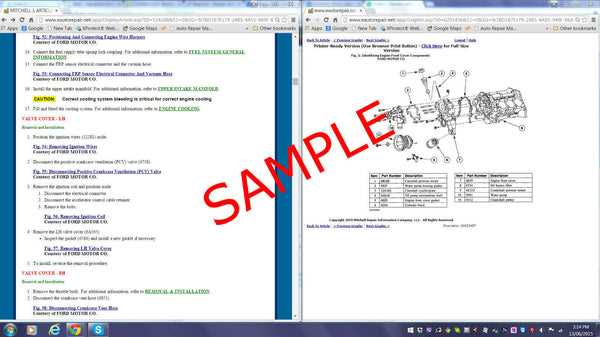

Maximizing the benefits of a comprehensive guide can significantly enhance your experience when tackling vehicle maintenance and troubleshooting. Familiarizing yourself with the structure and content of the resource enables you to locate necessary information swiftly and perform tasks with greater confidence.

Start by understanding the layout; most resources are organized into sections covering various aspects of vehicle upkeep, such as diagnostics, component specifications, and assembly instructions. By recognizing these divisions, you can navigate the content more efficiently.

Next, prioritize your objectives. Before diving into any task, clearly define what you aim to achieve. Whether it’s fixing a specific issue or conducting routine checks, knowing your goal helps you focus on relevant sections, saving time and effort.

Utilize the index and table of contents to pinpoint specific topics quickly. These features are invaluable for locating information on particular components or procedures, allowing you to skip unnecessary pages and dive right into the relevant details.

Lastly, take notes and document your findings. As you work through different processes, jotting down important points or modifications can streamline future projects and serve as a helpful reference for recurring tasks.

Recommended Service Intervals and Checks

Maintaining a vehicle is crucial for ensuring its longevity and performance. Regular inspections and scheduled servicing can prevent major issues and enhance driving safety. This section outlines essential intervals for maintenance tasks that every owner should follow to keep their vehicle in optimal condition.

General Maintenance Schedule

The following table summarizes the key service intervals and necessary checks for optimal vehicle upkeep:

| Service Item | Interval (miles or months) | Notes |

|---|---|---|

| Oil Change | 5,000 miles / 6 months | Use manufacturer-recommended oil type. |

| Air Filter Replacement | 15,000 miles | Check more frequently in dusty conditions. |

| Tire Rotation | 5,000 miles | Ensures even tire wear. |

| Brake Inspection | 10,000 miles | Check pads and rotors for wear. |

| Battery Check | Every 12 months | Clean terminals and check connections. |

| Fluid Levels Check | Every 3 months | Inspect oil, coolant, brake, and transmission fluids. |

Additional Recommendations

In addition to the standard service items, consider scheduling a comprehensive inspection annually. This should include checking the suspension, exhaust system, and belts for any signs of wear or damage. Keeping a detailed log of all service activities can help track maintenance history and anticipate future needs.