Comprehensive Guide to Avionics Repair Station Manual

In the realm of aviation, the functionality and reliability of electronic systems are paramount. This section aims to elucidate essential protocols and practices that ensure the optimal performance of these sophisticated devices. By adhering to established standards, professionals can maintain the integrity and safety of aircraft operations.

The intricacies involved in the upkeep of these vital components require a comprehensive understanding of technical specifications and operational procedures. From routine inspections to troubleshooting complex issues, a systematic approach is crucial. This document serves as a foundational resource, equipping technicians with the necessary knowledge to perform their duties with precision and confidence.

Furthermore, cultivating a culture of safety and accountability is integral to the successful maintenance of electronic systems in aviation. By fostering an environment where best practices are prioritized, the likelihood of errors can be significantly reduced. Ultimately, the goal is to ensure that every aircraft equipped with these technologies is safe and reliable for all its journeys.

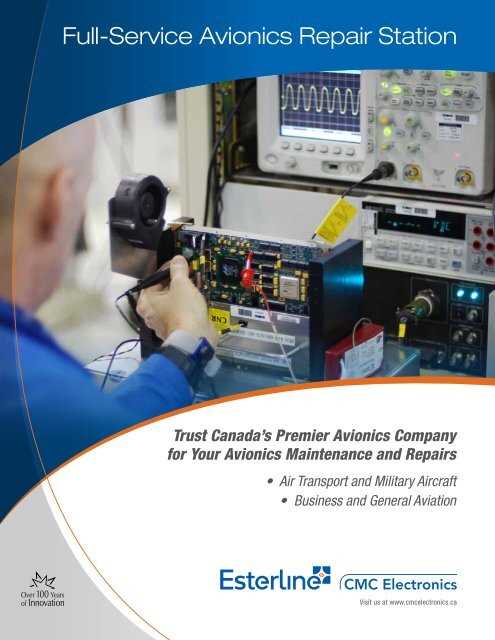

Understanding Avionics Repair Stations

This section delves into the intricate world of specialized facilities that focus on the maintenance and troubleshooting of airborne electronic systems. These locations play a crucial role in ensuring that aircraft are equipped with reliable technology, which is vital for safe operations in the sky.

Key components of these establishments include:

- Expert technicians trained in electronic systems.

- Advanced diagnostic tools for effective troubleshooting.

- Compliance with strict regulatory standards to ensure safety and reliability.

Within these facilities, several processes are essential for maintaining and restoring electronic components:

- Inspections to identify potential issues.

- Repairs to address identified malfunctions.

- Upgrades to improve performance and functionality.

The significance of these centers cannot be overstated, as they help sustain the operational integrity of aviation technology, ultimately contributing to the safety and efficiency of air travel.

Key Components of Avionics Systems

Understanding the vital elements of electronic systems used in aviation is crucial for ensuring safety and efficiency in flight operations. These components work in unison to provide navigation, communication, and monitoring capabilities essential for modern aircraft functionality.

| Component | Description |

|---|---|

| Navigation Systems | Devices that assist pilots in determining their position and plotting routes, utilizing technologies such as GPS and inertial navigation. |

| Communication Systems | Equipment that facilitates voice and data transmission between the aircraft and air traffic control, as well as among crew members. |

| Flight Control Systems | Automated systems that help pilots manage aircraft performance and stability, including autopilot and flight management systems. |

| Monitoring Systems | Instruments that provide real-time data on the aircraft’s status, including engine performance, fuel levels, and environmental conditions. |

| Display Systems | Screens and indicators that present critical flight information to pilots in a user-friendly format, enhancing situational awareness. |

Each of these elements plays a significant role in the overall operation and safety of aircraft, underscoring the importance of understanding their functionalities and interconnections.

Regulatory Requirements for Repair Stations

The framework governing maintenance facilities is critical for ensuring safety and reliability within the aviation sector. These guidelines are established by various authorities to uphold standards that protect both equipment and personnel involved in the servicing processes.

| Regulatory Body | Key Requirements |

|---|---|

| FAA | Certification processes, personnel qualifications, and record-keeping protocols. |

| EASA | Compliance with Part-145 regulations, staff training, and operational quality assurance. |

| Transport Canada | Licensing criteria, safety management systems, and audit mechanisms. |

Adhering to these mandates is essential for maintaining operational integrity and ensuring the highest level of safety in the aviation industry.

Common Avionics Equipment Repairs

This section explores typical maintenance procedures and solutions for various electronic systems used in aviation. Understanding the common issues that arise with these systems is essential for ensuring safety and functionality in flight operations.

- Communication Systems

- Faulty microphone connections

- Transmitter malfunctions

- Receiver sensitivity issues

- Navigation Devices

- GPS signal loss

- Inaccurate course indications

- Calibration of altimeters

- Flight Control Interfaces

- Autopilot disengagement problems

- Joystick calibration errors

- Software updates and troubleshooting

- Displays and Indicators

- Screen flickering or blackouts

- Faulty sensor readings

- Backlight issues

Addressing these common challenges promptly can enhance overall aircraft performance and safety, allowing for reliable operation during critical missions.

Safety Protocols in Avionics Maintenance

Ensuring the highest level of safety during the upkeep of aviation electronics is paramount. A well-structured framework of protocols not only protects personnel but also enhances the integrity of the equipment being serviced. These measures are essential for preventing accidents and ensuring compliance with industry standards.

Key safety protocols should encompass various aspects of the maintenance environment, from equipment handling to personal protective gear. Adherence to these guidelines helps mitigate risks associated with electronic repairs and diagnostics.

| Safety Measure | Description |

|---|---|

| Personal Protective Equipment (PPE) | Use of gloves, goggles, and ear protection to safeguard against hazards. |

| Grounding Procedures | Ensuring all electronic components are properly grounded to prevent static discharge. |

| Fire Safety | Availability of extinguishers and adherence to fire evacuation routes. |

| Tool Maintenance | Regular inspection and proper storage of tools to prevent malfunctions. |

| Training and Certification | Ongoing education and certification for technicians to ensure compliance with safety standards. |

By implementing these essential measures, organizations can create a safer working environment that fosters efficiency and reliability in electronic maintenance operations.

Quality Assurance Procedures Explained

Ensuring the highest standards of performance and reliability in technical operations is crucial for maintaining safety and efficiency. Quality assurance processes play a pivotal role in verifying that all activities align with regulatory requirements and internal benchmarks. This section delves into the essential practices that uphold the integrity of the systems involved.

Key Components of Quality Assurance

Quality assurance encompasses various elements that work in harmony to foster a culture of excellence. The following components are vital:

- Document Control: Maintaining accurate records of all procedures, processes, and outcomes ensures traceability and accountability.

- Training and Competency: Regular training programs are essential to keep personnel skilled and informed about the latest practices and technologies.

- Audits and Inspections: Scheduled evaluations help identify discrepancies and opportunities for improvement, ensuring compliance with standards.

- Corrective Actions: Implementing systematic responses to identified issues promotes continuous improvement and prevents recurrence.

Implementation Strategies

To effectively integrate quality assurance into everyday practices, organizations should consider the following strategies:

- Establish clear quality objectives that align with overall business goals.

- Develop standard operating procedures (SOPs) that guide daily operations.

- Foster open communication to encourage feedback and reporting of potential issues.

- Utilize performance metrics to evaluate the effectiveness of quality initiatives.

By prioritizing these procedures, organizations can create a robust framework that not only meets compliance standards but also enhances overall operational excellence.

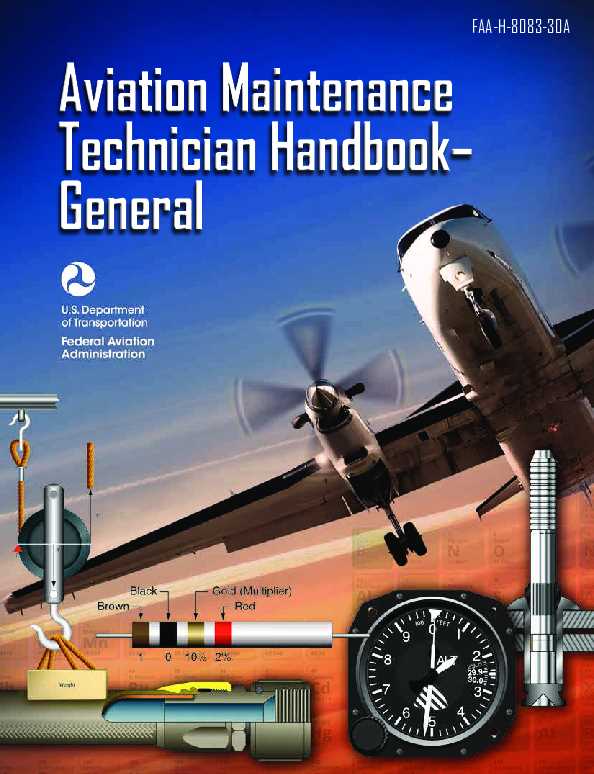

Training and Certification for Technicians

Ensuring the highest standards of competence and safety in the field requires a comprehensive approach to education and validation of skills. Technicians must undergo rigorous training programs that encompass both theoretical knowledge and practical experience. These programs are essential for equipping professionals with the necessary tools to effectively manage complex systems and ensure their optimal functionality.

Training Requirements

Training programs typically cover a range of topics, including electronics principles, system diagnostics, and maintenance procedures. These courses are designed to provide hands-on experience, allowing technicians to apply their knowledge in real-world scenarios. Continuous education is also crucial, as technology is constantly evolving.

Certification Process

The certification process involves a series of assessments to validate the technician’s expertise. This not only enhances their professional standing but also assures employers of their qualifications. Certifications may require passing written exams and demonstrating practical skills, ensuring that all technicians meet the industry’s stringent requirements.

| Certification Level | Prerequisites | Duration | Renewal |

|---|---|---|---|

| Basic Technician | High School Diploma | 6 months | Every 2 years |

| Advanced Technician | Basic Certification + 2 years experience | 1 year | Every 3 years |

| Master Technician | Advanced Certification + 5 years experience | 1.5 years | Every 5 years |

Tools and Technology in Repairs

The effectiveness of any maintenance operation relies heavily on the selection and application of specialized equipment and advanced methodologies. The right tools not only enhance efficiency but also ensure precision and reliability in the tasks performed. This section explores the essential devices and technologies that play a pivotal role in ensuring successful outcomes in the field of electronic system maintenance.

Essential Tools

- Diagnostic Equipment: Instruments that identify faults and assess system performance.

- Calibration Devices: Tools that ensure measurements and adjustments are accurate.

- Hand Tools: Basic implements like screwdrivers, pliers, and wrenches that are crucial for assembly and disassembly.

- Soldering Tools: Equipment necessary for joining electronic components securely.

- Test Instruments: Devices such as multimeters and oscilloscopes used to measure electrical parameters.

Advanced Technologies

- Automated Testing Systems: These facilitate quick and accurate evaluations of complex systems.

- 3D Printing: A revolutionary approach for creating custom parts on-demand, reducing lead times significantly.

- Software Solutions: Programs that assist in tracking maintenance activities and analyzing performance data.

- Virtual Reality (VR) Training: Innovative methods for training personnel in a simulated environment, enhancing skill acquisition.

Utilizing these tools and technologies effectively can dramatically improve maintenance workflows, leading to higher standards of safety and functionality in electronic systems. Continuous advancements in this field promise to further streamline processes and enhance the capabilities of technicians.

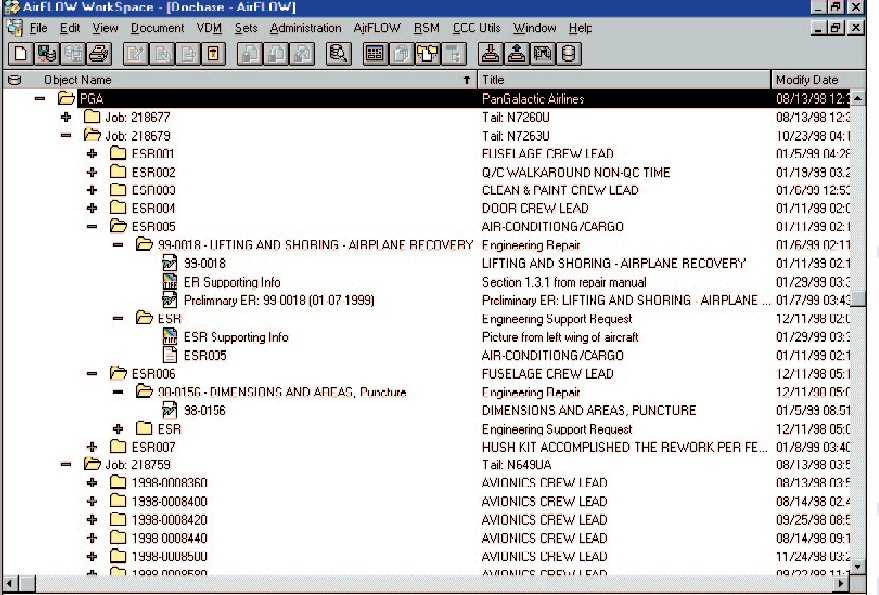

Documentation and Record Keeping

Maintaining precise records and documentation is essential for ensuring operational integrity and compliance within any technical environment. Accurate tracking of activities, services performed, and components used not only supports effective management but also enhances safety and reliability in all procedures.

Importance of Thorough Documentation

Comprehensive records serve multiple purposes, including legal compliance, performance evaluation, and maintenance history. They provide a clear audit trail, allowing for the assessment of practices over time. Moreover, thorough documentation is crucial for troubleshooting and ensuring that all actions taken can be traced and reviewed as needed.

Best Practices for Record Keeping

Implementing a systematic approach to documentation is vital. Establishing clear guidelines for what information should be recorded, how it should be stored, and who is responsible for it is key to efficiency. Utilizing digital systems can further streamline processes, allowing for easy access and retrieval of information. Regular audits of documentation practices should be conducted to ensure compliance with industry standards and to identify areas for improvement.

Challenges in Avionics Repair Operations

The field of aircraft electronics maintenance faces a myriad of difficulties that can hinder efficiency and effectiveness. These challenges stem from the intricate nature of modern aviation technology and the high standards required for safety and reliability. Understanding these obstacles is crucial for enhancing operational procedures and ensuring optimal performance.

Technological Complexity

Modern aircraft systems are increasingly sophisticated, integrating advanced software and hardware components. This complexity necessitates that technicians possess extensive knowledge and skills. Additionally, keeping up with constant technological advancements can be daunting. Continuous training and education are essential to equip personnel with the latest information, yet the fast pace of innovation can make this a significant challenge.

Regulatory Compliance

Meeting industry regulations poses another major hurdle. Organizations must adhere to strict guidelines set forth by governing bodies, which can vary by region. The process of maintaining compliance often requires rigorous documentation and audits, consuming valuable time and resources. Moreover, non-compliance can lead to severe repercussions, including financial penalties and damage to reputation.

Future Trends in Avionics Maintenance

The landscape of aircraft systems support is evolving rapidly, driven by advancements in technology and changing regulatory frameworks. As the industry adapts, new methodologies and tools are being introduced to enhance efficiency, safety, and reliability in the upkeep of complex electronic systems. This section explores the emerging trends that are set to shape the future of maintenance practices in the aviation sector.

Increased Automation

One of the most significant shifts is the move towards greater automation in maintenance processes. Automated diagnostics and predictive analytics are becoming commonplace, allowing technicians to identify issues before they escalate. By harnessing data from various sensors and systems, maintenance crews can optimize their workflows and reduce downtime.

Remote Monitoring and Support

The rise of connectivity has enabled real-time monitoring of aircraft systems, facilitating remote troubleshooting and support. This trend not only streamlines operations but also minimizes the need for on-site personnel, significantly cutting costs. Additionally, remote access to expert knowledge ensures that maintenance teams can resolve complex issues swiftly and efficiently.

Importance of Customer Communication

Effective interaction with clients is essential for fostering trust and ensuring satisfaction. Clear dialogue helps in understanding customer needs, addressing concerns, and delivering tailored solutions. It creates a foundation for a strong relationship that benefits both parties.

Timely updates play a crucial role in maintaining transparency. By keeping clients informed about progress and potential issues, organizations can minimize misunderstandings and enhance overall experience. Regular communication reassures clients that their interests are prioritized.

Additionally, active listening allows for a deeper understanding of client expectations. This feedback loop is invaluable for continuous improvement and helps in refining services to meet evolving demands. Ultimately, strong customer communication can lead to increased loyalty and positive word-of-mouth.