Mercruiser Alpha One Gen 2 Repair Guide

Understanding the complexities of marine propulsion systems is essential for optimal performance and longevity. This section delves into the intricacies of servicing and maintaining specific components that are crucial for efficient operation in aquatic environments. With proper knowledge and techniques, users can ensure their systems run smoothly, enhancing their overall boating experience.

In-depth insights into various parts will be explored, highlighting common challenges and solutions. By addressing maintenance needs proactively, one can prevent potential issues before they escalate, safeguarding both the equipment and the enjoyment of navigating through waters.

The focus will be on practical steps and considerations for keeping your marine engine in top condition. Detailed instructions and best practices will guide users through the necessary processes, making it accessible even for those who may not be professional technicians.

Overview of Mercruiser Alpha One Gen 2

This section provides a comprehensive understanding of a specific type of marine propulsion system known for its reliability and efficiency. It is widely utilized in various watercraft, making it a popular choice among boat enthusiasts. The design incorporates advanced engineering principles to ensure optimal performance and durability in challenging aquatic environments.

Key Features

One of the standout characteristics of this system is its seamless integration with different types of vessels. Enhanced maneuverability and fuel efficiency are critical advantages, allowing for a smoother navigation experience. The unit is also equipped with a range of components that facilitate easy maintenance and adaptability to various engine setups.

Performance and Reliability

The performance of this propulsion system is complemented by its robust construction, which helps withstand harsh marine conditions. Users often report improved handling and responsiveness, contributing to a more enjoyable boating experience. Regular maintenance practices are recommended to ensure longevity and sustained performance.

Key Features and Specifications

This section outlines essential characteristics and technical details of the marine propulsion system. Understanding these elements is crucial for optimal performance and maintenance.

Engine Type: The unit features a robust internal combustion engine, designed for efficiency and reliability in various water conditions.

Power Output: It offers a notable horsepower rating, ensuring adequate thrust for different boat sizes and types.

Transmission System: The propulsion mechanism includes a sophisticated gear arrangement, providing smooth transitions and improved maneuverability.

Cooling System: An effective cooling apparatus is integrated to prevent overheating during extended use, contributing to longevity.

Weight: The overall weight of the system is optimized to maintain balance and enhance fuel efficiency.

Dimensions: The compact design allows for easy installation in various boat models, making it versatile for different applications.

Fuel Type: Designed to operate on standard gasoline, facilitating accessibility and convenience for users.

Common Issues and Troubleshooting

This section addresses frequent problems that users may encounter with their marine propulsion systems. Understanding these common challenges and their solutions can enhance the overall performance and longevity of the equipment.

Here are some typical issues and their potential solutions:

- Engine Overheating:

- Check the water intake for blockages.

- Inspect the thermostat for proper functioning.

- Ensure the cooling system is filled with the appropriate fluid.

- Rough Idling:

- Examine the fuel supply for impurities.

- Inspect spark plugs for wear and replace if necessary.

- Verify that the air intake is not obstructed.

- Shift Issues:

- Check the fluid levels in the transmission system.

- Inspect the shift cable for wear or damage.

- Ensure proper adjustment of the shifting mechanism.

- No Start Condition:

- Test the battery voltage and connections.

- Inspect the ignition system components.

- Check for fuel delivery to the engine.

Addressing these common issues promptly can help maintain optimal performance and prevent more serious complications down the line.

Maintenance Guidelines for Longevity

Regular upkeep is essential for ensuring the durability and optimal performance of marine engines. Following systematic maintenance practices not only enhances functionality but also extends the lifespan of the unit. It is crucial to adhere to specific protocols and schedules to prevent potential issues that could arise from neglect.

Routine Inspections

Conducting frequent checks on various components, such as the cooling system, fuel lines, and electrical connections, can help identify wear and tear early. Monitoring fluid levels and replacing filters as needed will also contribute to the engine’s efficiency. A proactive approach reduces the risk of unexpected breakdowns.

Seasonal Preparations

Before and after the boating season, thorough preparations are vital. This includes winterizing the engine to prevent freeze damage and ensuring all parts are cleaned and lubricated. Proper storage conditions will protect against corrosion and other environmental factors, maintaining the engine’s condition for future use.

Tools Required for Repairs

When undertaking maintenance tasks on your watercraft, having the right instruments is crucial for efficiency and effectiveness. The proper equipment ensures that you can address various issues that may arise, from simple adjustments to more complex fixes.

Essential Hand Tools

Start with a basic set of hand tools, including wrenches, screwdrivers, and pliers. These tools are fundamental for loosening or tightening fasteners and making necessary adjustments. Socket sets are also vital for accessing hard-to-reach areas.

Specialized Equipment

In addition to standard tools, consider having specialized equipment on hand. Multimeters are useful for electrical diagnostics, while compression testers can help evaluate engine performance. Additionally, gaskets and sealants are essential for ensuring watertight integrity during reassembly.

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing mechanical issues effectively. Following a structured sequence ensures that each task is performed thoroughly, minimizing the risk of overlooking critical elements.

1. Assessment: Begin by thoroughly examining the unit to identify any visible signs of malfunction or wear. Document all findings to create a clear picture of the current state.

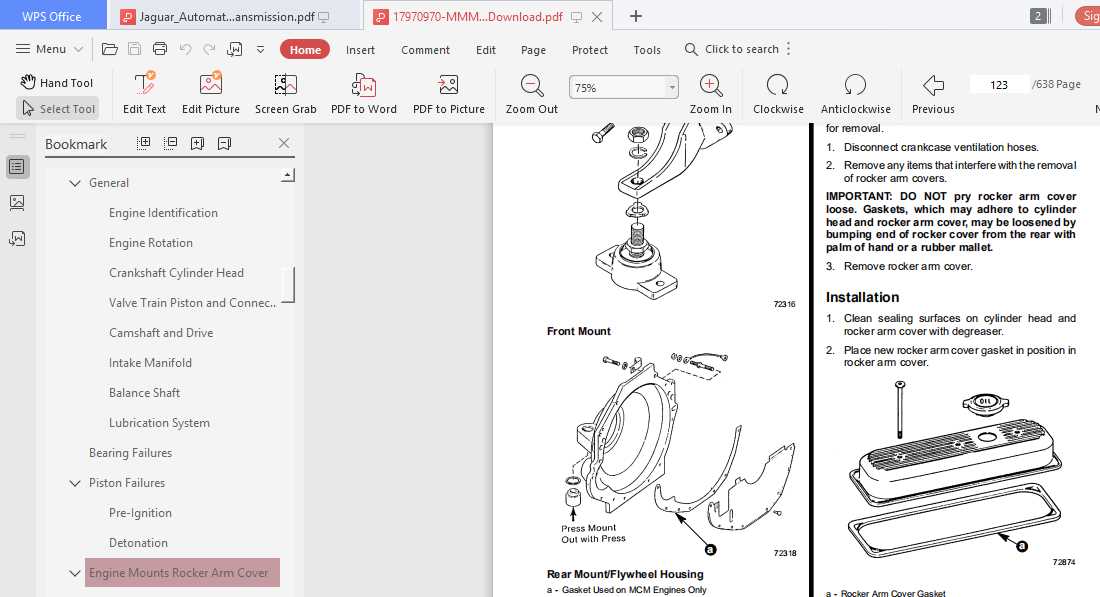

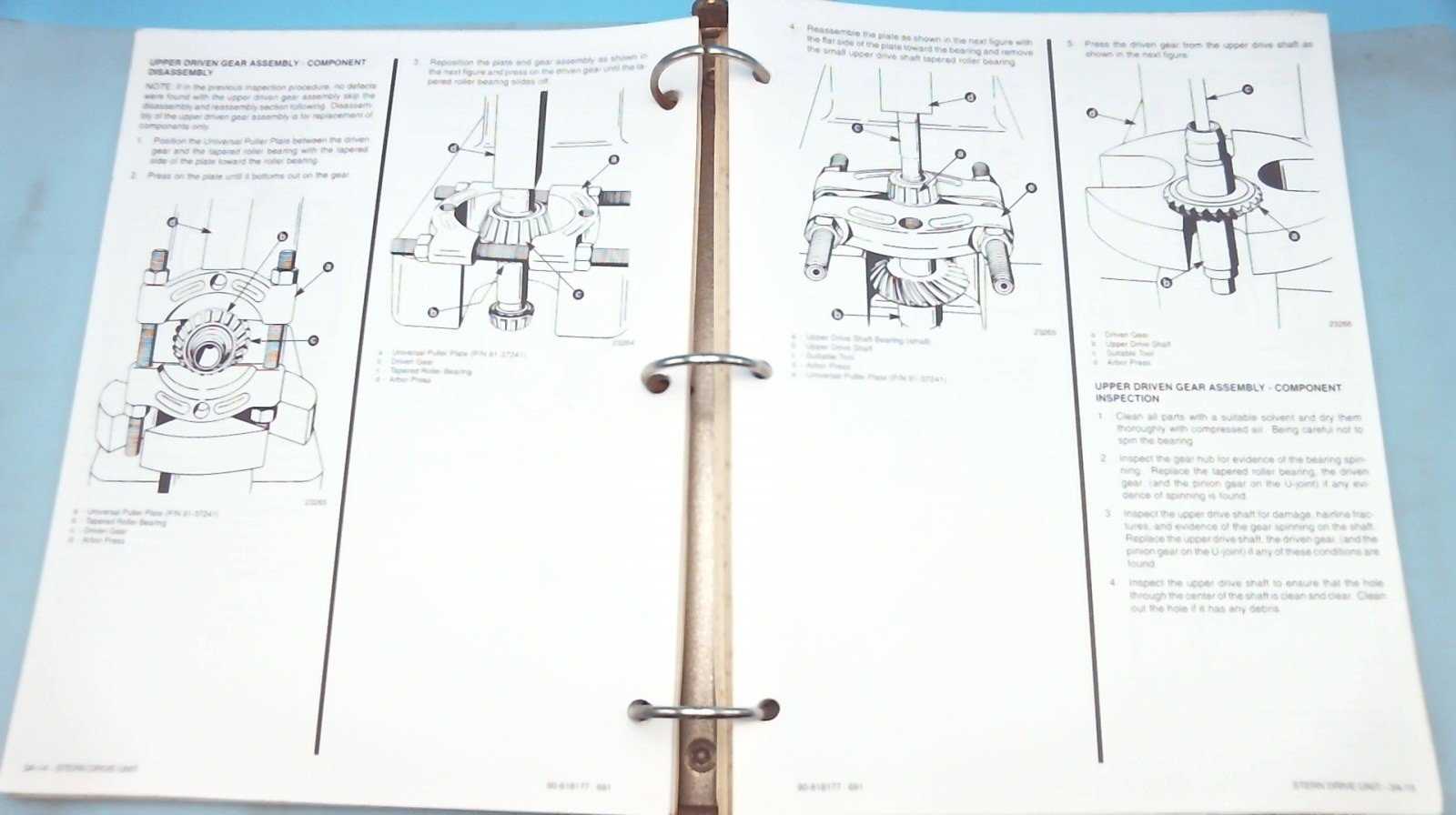

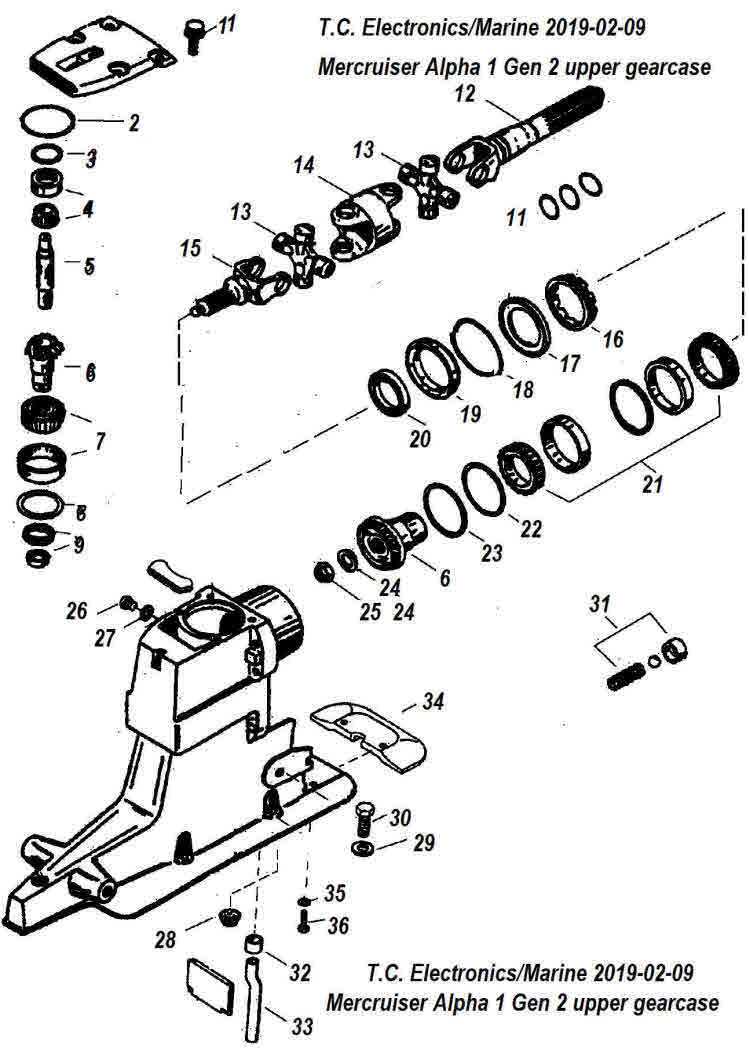

2. Disassembly: Carefully dismantle the components in a logical order. Utilize appropriate tools to avoid damaging parts, and keep track of screws and fasteners for reassembly.

3. Inspection: Inspect each component for damage, corrosion, or signs of failure. Pay particular attention to seals and gaskets that may need replacement.

4. Cleaning: Clean all parts using suitable cleaning agents. Remove any dirt, grease, or debris to ensure optimal performance of the reassembled unit.

5. Replacement: Replace any damaged or worn components with new, high-quality alternatives. Ensure compatibility with existing parts to maintain functionality.

6. Reassembly: Begin reassembling the unit in reverse order of disassembly. Ensure that each part is secured properly, following the manufacturer’s specifications.

7. Testing: Once reassembled, conduct thorough tests to confirm that the unit operates as intended. Monitor for unusual noises or performance issues that may indicate further problems.

8. Final Checks: Perform a final inspection to ensure all components are correctly installed and functioning. Document any observations and keep a record for future reference.

Replacing Essential Components

Maintaining the functionality of key parts in your marine propulsion system is crucial for optimal performance. This section covers the process of substituting vital components, ensuring that your vessel operates smoothly and efficiently.

Key Components to Replace

- Water Pump

- Gear Lubricant

- Fuel Filter

- Impeller

Replacement Steps

- Gather Necessary Tools: Ensure you have all required tools for the replacement process.

- Remove the Old Component: Carefully detach the worn part following the manufacturer’s guidelines.

- Install the New Component: Position the new part securely and ensure all connections are tight.

- Test Functionality: Run the system to verify proper operation after the replacement.

Lubrication and Fluid Recommendations

Proper maintenance of your marine engine is essential for optimal performance and longevity. This section outlines the necessary fluids and lubricants that ensure smooth operation and protect critical components from wear and tear.

Engine Oil: It is vital to select the appropriate engine lubricant. A high-quality marine-grade oil should be used to provide superior protection against corrosion and oxidation. Regularly check oil levels and change the oil according to the manufacturer’s guidelines to maintain engine health.

Gear Lube: The lubricant used in the drive system is crucial for ensuring efficient operation. Use a high-performance gear oil specifically designed for marine applications. Regularly inspect and replace the gear lube to prevent overheating and ensure smooth gear engagement.

Coolant: Maintaining the correct coolant level and type is necessary for regulating engine temperature. Use a marine-specific antifreeze to prevent freezing and protect against corrosion. Regularly check the coolant system for leaks and ensure that the coolant is at the proper level.

Fuel: Always use high-quality fuel to prevent engine issues. Consider using fuel additives that enhance performance and protect the fuel system from deposits and corrosion. Regularly monitor fuel quality and replace stale fuel as necessary.

By adhering to these lubrication and fluid recommendations, you will significantly enhance the reliability and efficiency of your marine engine.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when undertaking maintenance tasks. Proper precautions not only protect individuals but also prevent damage to equipment and surroundings.

Before starting any work, familiarize yourself with the tools and components involved. Always wear appropriate personal protective equipment, such as gloves and safety goggles, to minimize risks of injury. It is essential to work in a well-ventilated area to avoid inhaling harmful fumes or dust.

Make sure to disconnect any power sources to prevent accidental starts during the process. Keep your workspace organized and free from clutter to reduce the likelihood of accidents. Additionally, having a fire extinguisher nearby is a wise precaution when working with flammable materials.

Finally, always consult available resources for specific guidelines and safety measures related to the task at hand. Taking these steps ensures a safer and more efficient working experience.

Testing After Repair Completion

Once the maintenance process has been finalized, it is essential to conduct a series of evaluations to ensure the system functions as intended. This step is crucial to verify that all components operate smoothly and safely, providing optimal performance during use.

Start by performing a visual inspection to identify any potential issues, followed by systematic testing of various functionalities. Each test should be documented to track performance metrics and any discrepancies that may arise.

| Test Procedure | Description | Status |

|---|---|---|

| Visual Inspection | Check for visible damages or loose connections. | Pass/Fail |

| Fluid Levels | Verify all fluid levels are appropriate. | Pass/Fail |

| System Functionality | Test all operational features under normal conditions. | Pass/Fail |

| Performance Metrics | Record performance data and compare to standards. | Pass/Fail |

By meticulously following these testing protocols, any underlying issues can be detected and addressed promptly, ensuring reliable performance for future operations.

Upgrading and Modifying the System

This section explores various enhancements and adjustments that can be made to improve the performance and functionality of the system. Whether you’re looking to boost efficiency or add new features, understanding the options available is essential for optimal results.

Performance Enhancements

- Engine Tuning: Adjusting fuel injection and ignition timing can lead to better power output.

- Propeller Upgrades: Choosing the right propeller size and pitch can enhance speed and acceleration.

- Exhaust System Modifications: Installing a high-performance exhaust can improve engine breathing and sound.

Additional Features

- Electronics Integration: Adding modern navigation and communication devices can enhance safety and ease of use.

- Comfort Upgrades: Installing better seating or climate control can improve the overall experience.

- Safety Enhancements: Upgrading lights and adding additional safety equipment increases reliability on the water.

Resources for Further Information

For those seeking additional insights and guidance on maintenance and troubleshooting, a variety of resources are available. These can enhance understanding and facilitate effective solutions for common issues.

- Online Forums: Community-driven platforms where enthusiasts share experiences and advice.

- Instructional Videos: Visual tutorials that demonstrate repair techniques and maintenance tips.

- Technical Websites: Dedicated sites offering detailed articles and guides related to boat mechanics.

- Books and Manuals: Comprehensive literature that covers specific systems and operational procedures.

- Local Workshops: Hands-on classes that provide practical knowledge and expert guidance.

Utilizing these resources can significantly improve one’s capability to manage and resolve issues effectively.

Frequently Asked Questions

This section addresses common inquiries regarding the maintenance and troubleshooting of marine propulsion systems. Here, users can find concise answers to typical issues and concerns that arise during usage.

- What are the signs of a malfunctioning unit?

Look for symptoms such as unusual noises, decreased performance, or warning lights on the dashboard.

- How often should maintenance be performed?

Regular inspections and servicing should be conducted at least once a year, or as recommended by the manufacturer.

- What tools are needed for basic troubleshooting?

A standard toolkit, including wrenches, screwdrivers, and a multimeter, is typically sufficient for most tasks.

- Can I perform repairs myself?

Yes, many minor repairs can be completed by the owner with the proper knowledge and tools; however, complex issues may require professional assistance.

- Where can I find replacement parts?

Replacement components can be sourced from authorized dealers, marine supply stores, or online retailers specializing in boating equipment.