Comprehensive Guide to Repairing Your Craftsman Tiller

In the realm of garden cultivation, efficient tools are essential for nurturing your green spaces. Understanding how to maintain and troubleshoot your equipment can significantly enhance its longevity and performance. This guide aims to equip you with the knowledge necessary to ensure your machinery operates at its best, allowing you to focus on what truly matters–growing healthy plants.

From simple adjustments to more complex fixes, mastering the upkeep of your gardening implements can save both time and money. Whether you’re facing common issues or seeking to optimize performance, being well-informed empowers you to tackle any challenges that arise. By familiarizing yourself with the components and functionality of your tools, you can enhance your gardening experience and achieve the results you desire.

As we delve into this guide, you’ll find step-by-step instructions and valuable tips tailored to address various situations. Each section is designed to provide clarity and confidence, ensuring that even those new to equipment maintenance can follow along easily. Embrace the opportunity to learn and take control of your gardening tools, transforming your approach to outdoor projects.

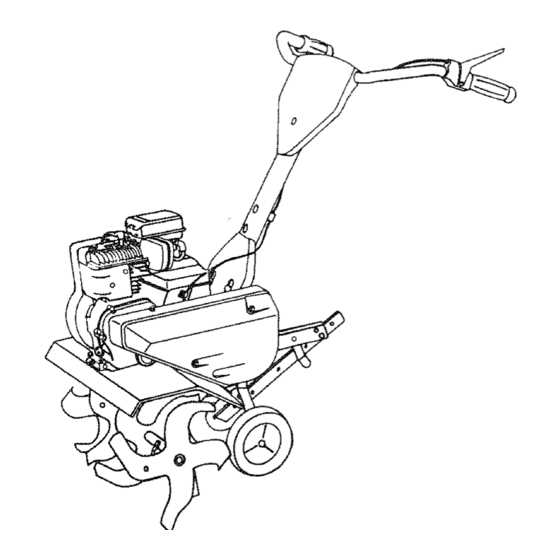

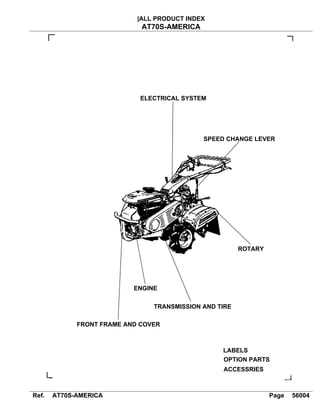

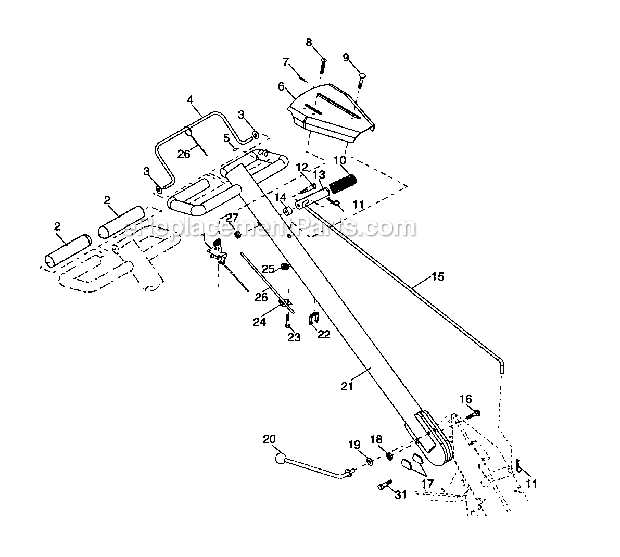

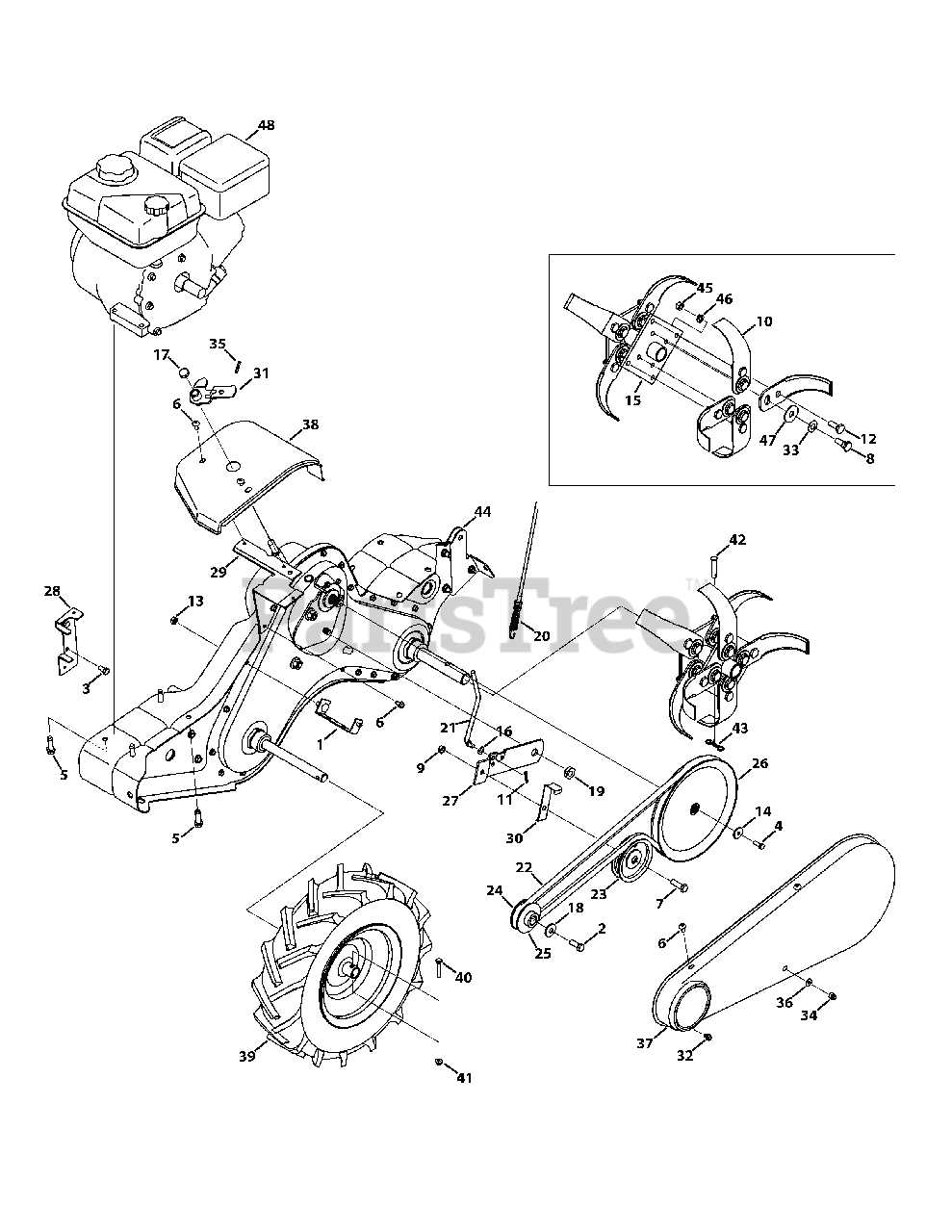

Understanding Craftsman Tiller Components

Gaining insight into the various parts of a gardening tool is essential for effective maintenance and optimal performance. Each element plays a vital role in ensuring the machinery operates smoothly, contributing to the overall efficiency of soil preparation and garden management.

Key Parts Overview

The fundamental components of a gardening implement include the engine, transmission, and working tools. Understanding how these elements interact can enhance both the longevity and functionality of the device.

| Component | Function |

|---|---|

| Engine | Powers the machine and drives the working tools. |

| Transmission | Transmits power from the engine to the wheels and working tools. |

| Working Tools | Processes the soil by turning and aerating it. |

Maintenance Tips

Regular inspection and care of each component can significantly improve performance and prevent breakdowns. Checking for wear and tear, as well as ensuring proper lubrication, are crucial steps in maintaining efficiency.

Common Issues with Tiller Performance

Maintaining optimal functionality in soil cultivation machinery is essential for achieving desired results. Various factors can lead to diminished efficiency, affecting the overall performance of these valuable tools. Understanding and addressing these common problems can enhance productivity and prolong the lifespan of the equipment.

Insufficient Power and Torque

One frequent issue encountered is inadequate power output, which can stem from various sources. A clogged air filter may restrict airflow, resulting in poor combustion and reduced engine performance. Similarly, fuel delivery problems, such as old or contaminated fuel, can prevent the engine from operating at full capacity. Regular maintenance, including checking and replacing filters and using fresh fuel, can mitigate these issues.

Difficulty in Soil Penetration

Another common challenge is the inability to penetrate tough soil effectively. This can be attributed to worn or damaged tines, which may need sharpening or replacement. Additionally, incorrect depth settings can hinder progress. Ensuring that the tool is properly calibrated for the specific soil conditions is crucial for efficient operation.

Step-by-Step Repair Procedures

This section provides a comprehensive guide to fixing common issues encountered during the operation of garden machinery. By following these detailed instructions, you can effectively troubleshoot and restore your equipment to optimal working condition.

-

Identify the Problem: Begin by observing the machinery to determine the specific issue. Common symptoms may include:

- Difficulty starting

- Unusual noises

- Poor performance

- Excessive vibrations

-

Gather Necessary Tools: Before starting, collect all required tools and replacement parts. Essential items may include:

- Wrenches

- Screwdrivers

- Socket set

- Replacement belts or filters

-

Disconnect Power Source: For safety, ensure that the equipment is turned off and disconnected from any power source before proceeding with any maintenance.

-

Inspect Components: Check key parts for wear or damage. Focus on:

- Air filter

- Fuel lines

- Spark plug

- Blades or tines

-

Perform Repairs: Depending on your findings, carry out the necessary actions, such as:

- Replacing filters

- Tightening loose bolts

- Changing the spark plug

- Adjusting or replacing belts

-

Reassemble and Test: Once repairs are complete, reassemble any disassembled parts and ensure everything is securely in place. Start the machine to verify that the issue has been resolved.

-

Routine Maintenance: To prevent future problems, establish a regular maintenance schedule that includes:

- Cleaning filters

- Inspecting belts

- Checking fluid levels

- Sharpening cutting edges

Essential Tools for Tiller Maintenance

Proper upkeep of garden machinery is crucial for ensuring optimal performance and longevity. Having the right instruments at your disposal not only simplifies the process but also enhances efficiency. Below is a list of indispensable items that every owner should consider for effective maintenance.

1. Wrench Set: A comprehensive set of wrenches is vital for tightening and loosening various bolts and nuts. Ensure you have both metric and standard sizes to accommodate different components.

2. Screwdriver Set: Flathead and Phillips screwdrivers are essential for accessing and adjusting various parts of your equipment. A magnetic tip can be particularly useful for retrieving screws in hard-to-reach areas.

3. Spark Plug Tool: This specialized tool simplifies the removal and installation of spark plugs, which are critical for the engine’s performance. Regular checks and replacements can prevent many operational issues.

4. Oil Change Kit: Having a quality oil change kit on hand ensures that you can easily replace the engine oil. This is crucial for maintaining lubrication and preventing overheating.

5. Cleaning Supplies: Brushes, rags, and cleaning solutions are necessary for keeping your machinery in top shape. Regular cleaning helps to prevent rust and ensures all parts function smoothly.

6. Safety Gear: Protecting yourself while working is paramount. Invest in gloves, goggles, and ear protection to safeguard against potential hazards during maintenance tasks.

Equipped with these essential tools, you will be better prepared to perform routine tasks, troubleshoot issues, and extend the lifespan of your equipment.

Preventative Measures for Longevity

Maintaining the efficiency and lifespan of garden equipment requires proactive care and attention. By implementing specific practices, users can ensure optimal performance while minimizing the risk of unexpected failures. These strategies focus on routine inspections, proper storage, and essential maintenance tasks that collectively contribute to the durability of the machinery.

| Preventative Measure | Description | Frequency |

|---|---|---|

| Regular Cleaning | Remove dirt and debris after each use to prevent buildup that can hinder operation. | After each use |

| Lubrication | Apply appropriate lubricant to moving parts to reduce friction and wear. | Monthly |

| Inspect Belts and Cables | Check for signs of wear or damage; replace as necessary to avoid malfunction. | Every 3 months |

| Fuel System Maintenance | Use fresh fuel and clean filters to ensure efficient operation. | Seasonally |

| Storage Practices | Store in a dry, sheltered area to protect from moisture and environmental damage. | Year-round |

Troubleshooting Electrical Problems

Addressing electrical issues in garden machinery can often seem daunting, but a systematic approach can simplify the process. Identifying the symptoms and methodically checking components will help isolate the root cause of the malfunction. This section provides guidance on common electrical faults and how to diagnose them effectively.

Common Symptoms and Initial Checks

Frequent signs of electrical difficulties include the equipment failing to start, intermittent power loss, or unusual noises during operation. Begin troubleshooting by ensuring that all connections are secure and free from corrosion. Inspect the power source for any disruptions and verify that switches and circuit breakers are functioning correctly. A thorough examination of the wiring for visible damage or wear is also essential.

Testing Components

If initial checks do not reveal the issue, proceed to test individual electrical components. Using a multimeter can help assess the functionality of fuses, relays, and other critical parts. Pay close attention to any discrepancies in voltage readings, as these can indicate underlying problems. Replacing defective components promptly can prevent further complications and restore proper operation.

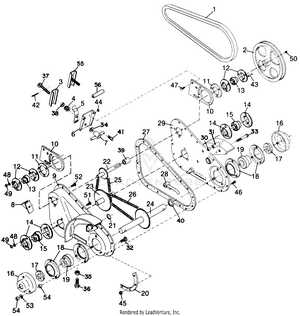

How to Replace Tiller Belts

Maintaining your outdoor equipment often requires attention to specific components that wear out over time. One such essential part is the belt system, which plays a crucial role in transferring power from the engine to the working mechanisms. Replacing these belts when they become worn or damaged is vital for ensuring optimal performance and longevity of your machinery.

To begin the replacement process, gather the necessary tools such as wrenches, screwdrivers, and replacement belts that match the specifications of your equipment. Start by disconnecting the power source to prevent any accidents. Next, access the belt compartment, which may involve removing certain panels or covers. Carefully examine the existing belts for signs of wear, such as fraying or cracking.

Once you have identified the need for replacement, remove the old belts by loosening any tensioning mechanisms and carefully sliding them off the pulleys. It is important to take note of the belt routing, as this will guide you in installing the new belts correctly. Position the new belts on the pulleys, ensuring they are seated properly and aligned with the manufacturer’s guidelines.

After securing the new belts in place, adjust the tension as required to avoid slippage during operation. Reassemble any components that were removed during the process and double-check that everything is secure. Finally, reconnect the power source and run a test to ensure that the equipment operates smoothly, confirming that the replacement was successful.

Oil Change Guidelines for Tillers

Regular maintenance of your gardening equipment is essential for optimal performance and longevity. One crucial aspect of this upkeep involves the replacement of engine lubricant. This process ensures that the internal components remain well-lubricated, reducing wear and enhancing efficiency.

When to Change the Oil

It’s advisable to replace the lubricant after the initial usage period, typically after the first five hours of operation. Following this, regular intervals, such as every 20 to 50 hours of use, are recommended. Always consult your equipment’s specifications for precise guidelines.

Steps for Changing the Oil

1. Gather Your Materials: You will need fresh lubricant, a drain pan, a funnel, and a wrench.

2. Prepare the Equipment: Ensure the machine is on a level surface and has cooled down. This will prevent burns and allow for a safer process.

3. Drain the Old Oil: Remove the drain plug and allow the used lubricant to flow into the pan completely. Be cautious of any residual fluid.

4. Replace the Filter: If your device has a filter, remove the old one and install a new one to ensure clean operation.

5. Add New Oil: Using a funnel, pour in the appropriate type and amount of fresh lubricant as specified in the guidelines.

6. Check the Level: After adding, check the oil level with the dipstick to ensure it meets the required specifications.

Regularly changing the lubricant not only improves performance but also extends the life of your gardening equipment, making this maintenance task well worth the effort.

Cleaning and Caring for Your Tiller

Maintaining your gardening equipment is essential for ensuring its longevity and optimal performance. Regular cleaning and proper care not only enhance efficiency but also help prevent potential issues that could arise from neglect. By following a few simple steps, you can keep your machinery in top condition, ready for every gardening task.

After each use, it’s important to remove any debris, such as soil and plant material, that may have accumulated. Use a brush or a cloth to clean the surfaces, paying special attention to the blades and wheels. This prevents rust and wear, ensuring that everything functions smoothly during your next session in the garden.

Inspect the fuel and oil levels regularly. Clean or replace air filters as needed to ensure that the engine runs efficiently. Using fresh fuel will help avoid starting problems and improve overall performance. Additionally, consider lubricating moving parts to reduce friction and wear over time.

Store your equipment in a dry, sheltered location to protect it from the elements. Covering it with a tarp or placing it in a shed can shield it from moisture and dust. Regularly check for any signs of corrosion or damage, and address these issues promptly to avoid more significant repairs down the line.

By incorporating these maintenance habits into your routine, you can ensure that your equipment remains reliable and efficient, ready to tackle any gardening project you undertake.

Safety Tips During Repairs

When undertaking maintenance tasks on machinery, it is crucial to prioritize safety to prevent accidents and injuries. Understanding the inherent risks associated with mechanical work helps create a secure environment for both the individual and the equipment.

Always wear appropriate personal protective equipment. This includes safety goggles to protect your eyes from debris, gloves to shield your hands from sharp edges and hot surfaces, and sturdy footwear to provide support and prevent slipping.

Ensure proper ventilation when working with fuel or oil. Fumes can be harmful, so it’s best to conduct these tasks in a well-ventilated area to minimize exposure to potentially toxic substances.

Disconnect power sources before starting any maintenance. This simple step prevents accidental starts and ensures that you can work safely without the risk of the machine operating unexpectedly.

Keep your workspace organized. A clutter-free area reduces the chances of tripping or misplacing tools, making it easier to focus on the task at hand without distraction.

Use the right tools for the job. Employing appropriate equipment not only makes the work more efficient but also minimizes the risk of damage to the machinery and injury to yourself.

Follow the manufacturer’s guidelines regarding disassembly and reassembly. Familiarizing yourself with specific instructions helps ensure that you do not overlook critical safety measures.

By adhering to these safety precautions, you can effectively reduce the risks associated with maintenance tasks, ensuring a safer and more efficient working environment.