Comprehensive Guide to Repairing Detroit Diesel Series 60

Understanding the intricacies of engine maintenance is essential for those who wish to ensure long-lasting and efficient performance. This guide offers detailed insights, focusing on essential techniques for preserving engine health. Readers will gain knowledge of fundamental adjustments, periodic checks, and methods to troubleshoot common operational issues, all aimed at promoting smoother functionality and preventing early wear.

Engine performance can be optimized through the correct approach to upkeep. This includes a balanced blend of routine inspections, timely servicing, and attention to specific operational nuances. By following best practices and systematic routines, individuals can significantly extend the lifespan of their equipment, ensuring it remains reliable under demanding conditions.

The following sections delve into core areas, highlighting structured steps for handling various mechanical components, identifying early signs of wear, and applying proactive measures. This guide empowers users with valuable insights to handle their equipment confidently, equipping them with knowledge for both basic and advanced maintenance techniques.

Detroit Diesel Series 60 Repair Manual

This guide offers detailed insights into the maintenance and upkeep of robust engines commonly used in heavy-duty applications. Covering all aspects from operational principles to intricate component adjustments, it provides practical information for ensuring smooth performance and extending engine life. Through structured guidance, this resource supports users in performing key tasks effectively and avoiding common issues.

Understanding System Components and Functions

In this section, you’ll explore the primary elements of the engine, including core parts responsible for fuel injection, cooling, and exhaust. Each component is explained with its function and importance in the system, helping operators and technicians to diagnose and address potential performance dips. Proper comprehension of these elements is crucial to managing both regular maintenance and unexpected repairs.

Step-by-Step Maintenance Instructions

Here, the manual provides a clear walkthrough of essential upkeep routines, from oil changes to air filter inspections, ensuring the engine remains at optimal efficiency. It also details specific intervals for servicing tasks, helping users prevent wear and maximize durability. By following these structured guidelines, operators can confidently maintain peak engine condition and minimize downtime.

Understanding the Series 60 Engine

This section provides an overview of a powerful engine known for its reliability, efficiency, and adaptability in various heavy-duty applications. Recognized for its innovation and engineering quality, this engine has gained respect among professionals seeking consistent performance and longevity in demanding environments.

Core Features and Capabilities

One of the main strengths of this engine is its advanced design that emphasizes fuel economy while maintaining strong output. Featuring refined components that reduce wear, it allows operators to achieve extended service intervals. Additionally, its modular setup simplifies the process of replacing parts, making it easier to perform regular maintenance and reduce downtime.

Efficient Power Delivery

Another hallmark of this engine is its precise power distribution, which ensures efficient performance across a range of speeds and loads. By utilizing sophisticated control systems, the engine adapts to varying demands, delivering optimal power without compromising fuel efficiency. This balance of power and economy makes it a popular choice for high-demand applications, where every drop of fuel and every hour of operation count.

Common Issues and Troubleshooting Tips

Understanding frequent technical problems and knowing how to address them is essential for optimal performance. Identifying early signs of potential issues can help prevent larger malfunctions and extend the operational life of your system.

Overheating is a typical concern in engine systems, often caused by coolant circulation issues or blocked airflow. Regularly inspect cooling components, including the radiator and coolant hoses, to ensure they are clear and functioning as intended. Replacing worn parts and checking coolant levels can also help maintain stable temperatures.

Low Power Output may result from restricted airflow or fuel supply inconsistencies. Check air filters, fuel lines, and injectors for any signs of clogging or wear. Cleaning or replacing these elements can improve efficiency and restore proper power levels.

Unusual Noises can indicate worn bearings or loose parts. Listen for knocking, rattling, or other abnormal sounds and inspect the relevant areas. Tightening bolts, replacing damaged components, or lubricating moving parts may resolve the issue and prevent further complications.

Starting Difficulties often stem from weak electrical connections or battery-related issues. Verify battery health, clean connections, and inspect starter wiring for signs of wear. A consistent start-up process is typically restored by addressing these common electrical problems.

Regular maintenance and timely troubleshooting of these issues can significantly reduce repair costs and improve system longevity, ensuring reliable operation and peak efficiency.

Maintenance Practices for Optimal Performance

Consistent and attentive maintenance is essential to ensure long-term efficiency and peak functioning of heavy-duty machinery. Regular inspections, component care, and timely adjustments significantly reduce wear and extend the lifespan of essential parts, allowing for smoother operation in demanding conditions. Preventive measures, combined with a proactive approach, can prevent minor issues from escalating into costly repairs.

Key Areas to Monitor

Monitoring critical areas of the engine helps maintain performance standards. Lubrication levels should be checked routinely to avoid excessive friction. Proper oil pressure and quality play a crucial role in safeguarding moving parts. Air and fuel filters also require consistent attention to ensure the intake system remains clean, supporting efficient combustion and power output.

Ensuring System Cleanliness

Cleanliness within engine systems, such as cooling and exhaust, promotes optimal efficiency. Regular removal of debris in cooling systems prevents overheating, while ensuring exhaust pathways are clear helps maintain proper emission levels. Addressing these areas prevents buildup that could impact overall functionality and compromise energy efficiency over time.

Fuel System Diagnostics and Solutions

Understanding the nuances of fuel systems is essential for maintaining performance and preventing operational issues. This section provides insights into common symptoms associated with fuel-related problems and presents actionable steps for identifying and addressing these issues effectively. By gaining a solid grasp of diagnostic methods, operators can improve efficiency and prolong the life of the machinery.

Common Symptoms and Initial Checks

Frequent challenges within the fuel system often manifest as reduced power, irregular idling, or difficulty starting. To begin diagnostics, examine fuel filters and check for possible air leaks in the lines. Replacing clogged filters or tightening loose fittings can resolve minor issues. Additionally, verify fuel quality and contamination levels, as low-quality fuel can lead to debris buildup, impeding fuel flow and performance.

Advanced Diagnostics and Resolution Methods

When basic troubleshooting doesn’t resolve the problem, further diagnostics may be necessary. Tools such as fuel pressure gauges and flow meters are valuable for measuring system performance. If pressure levels are irregular, inspect injectors for clogs or wear. Cleaning or replacing faulty injectors often restores normal operation. In cases of persistent issues, examining the fuel pump and lines for blockages or wear is advisable. Regularly scheduled maintenance, focusing on fuel system components, can also prevent future malfunctions and extend equipment longevity.

Cooling System Inspection and Repair

The effectiveness of a cooling mechanism is crucial for maintaining optimal performance and longevity of an engine. Regular assessment and maintenance of this system ensure that it functions efficiently, preventing overheating and potential damage. This section outlines essential steps for examining and servicing the cooling apparatus, emphasizing the importance of timely intervention.

Inspection Process: Begin by checking for any visible signs of leakage, corrosion, or damage in the components, including hoses, radiator, and water pump. Ensure that all connections are secure and that there are no obstructions affecting airflow. Monitoring coolant levels and quality is also vital; the fluid should be free from contaminants and at the recommended level.

Maintenance Steps: If any issues are detected, address them promptly. Replace worn or damaged hoses and seals to prevent leaks. Flushing the cooling system periodically is essential to remove debris and build-up that can hinder performance. Ensure the thermostat operates correctly, as it regulates coolant flow and maintains the desired temperature.

Final Checks: After completing maintenance tasks, refill the cooling system with the appropriate mixture of coolant and water. Run the engine and monitor for any irregularities in temperature or performance. This proactive approach not only extends the lifespan of the engine but also enhances overall operational efficiency.

Comprehensive Guide to Engine Overhaul

Revitalizing an internal combustion unit is a complex yet rewarding endeavor that demands meticulous attention and precise execution. This process aims to restore the functionality and performance of the power source, ensuring it operates at optimal efficiency. A systematic approach is essential to achieve a successful overhaul, covering everything from disassembly to reassembly.

Commencing with the assessment phase, it is crucial to evaluate the current condition of the engine. Identifying signs of wear or damage will inform the necessary steps for rejuvenation. The disassembly phase follows, requiring careful documentation of each component to prevent confusion during reassembly.

Cleaning all parts thoroughly is vital to eliminate contaminants that could hinder performance. Once cleaned, inspection of each element ensures that only those meeting the required standards are reused. Any components showing significant wear should be replaced with high-quality alternatives to guarantee longevity.

Afterward, the reassembly process can begin. This phase demands meticulous attention to torque specifications and alignment to ensure a proper fit and function. Finally, once everything is in place, conducting tests and adjustments will confirm that the unit operates smoothly and efficiently, ready to tackle future challenges.

Electrical System Components and Fixes

This section delves into the various elements that constitute the electrical framework of the engine. Understanding these components is vital for diagnosing issues and ensuring optimal performance. Effective troubleshooting can prevent prolonged downtime and enhance efficiency.

Key Components

- Batteries

- Alternator

- Starter Motor

- Wiring Harness

- Fuses and Relays

- Sensors

Troubleshooting and Solutions

- Battery Issues: Check for corrosion on terminals and ensure a secure connection. Replace any faulty batteries that fail to hold a charge.

- Alternator Malfunction: Test the alternator output using a multimeter. Replace if it produces inadequate voltage.

- Starter Problems: Inspect the starter motor and associated wiring for damage. Repair or replace as necessary.

- Wiring Faults: Look for frayed or damaged wires within the harness. Repair or replace damaged sections to maintain proper function.

- Fuse and Relay Failures: Regularly inspect fuses for integrity. Replace any blown fuses and test relays for functionality.

- Sensor Calibration: Ensure that sensors are properly calibrated. Faulty sensors may require cleaning or replacement.

Injector Testing and Replacement Procedures

Ensuring optimal performance of the fuel delivery system is crucial for engine efficiency. This section outlines the methods for assessing and replacing components responsible for fuel injection. Proper evaluation and timely substitutions can significantly enhance engine functionality and longevity.

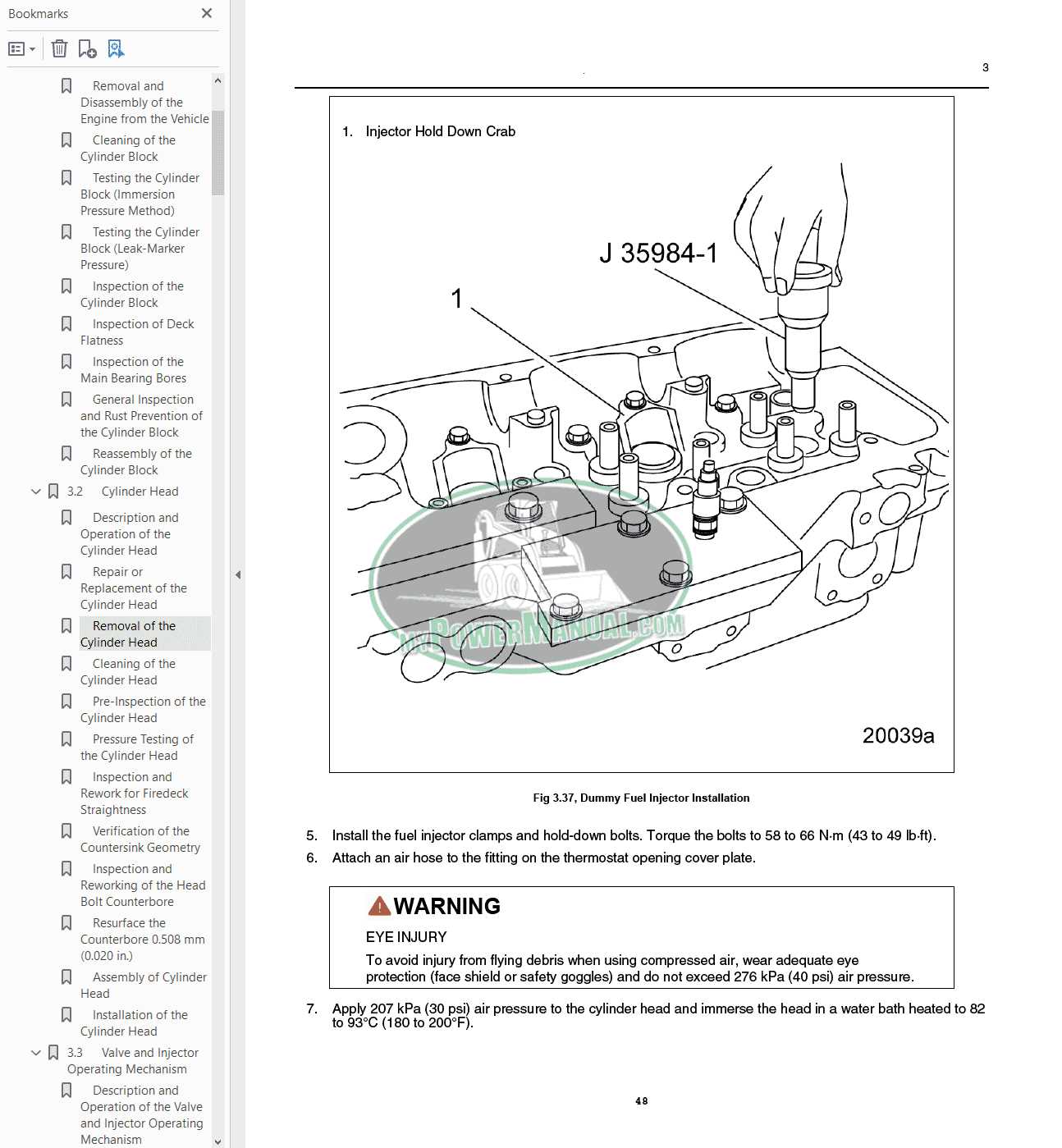

Testing Procedure: Begin by examining the fuel injectors for any visible signs of damage or wear. A functional test can be conducted using a specialized diagnostic tool to measure the spray pattern and atomization of fuel. Ensure that the injectors are receiving adequate pressure and are free of blockages.

Replacement Steps: If testing reveals any deficiencies, proceed with the removal of the faulty injectors. Disconnect the fuel lines and electrical connectors carefully. Follow with the installation of new components, ensuring all connections are secure and free from leaks. Re-test the system to confirm proper operation.

Regular checks and maintenance of the fuel injection components are vital for maintaining optimal engine performance and preventing potential failures.

Turbocharger Maintenance and Servicing

Proper upkeep and servicing of the turbocharger are essential for ensuring optimal performance and longevity. Regular attention to this component helps to prevent potential failures and maintains efficient engine operation. This section provides insights into routine care and procedures necessary for maintaining this vital part of the system.

Routine Maintenance Procedures

To keep the turbocharger in excellent working condition, consider the following essential tasks:

- Regular inspection for signs of wear or damage.

- Monitoring oil levels and ensuring proper lubrication.

- Checking for air leaks in the intake and exhaust systems.

- Cleaning or replacing the air filter to ensure unobstructed airflow.

- Inspecting the wastegate operation and actuator function.

Servicing Tips

When it comes to servicing, adherence to the following guidelines can enhance performance:

- Perform a thorough cleaning of the turbocharger to remove carbon buildup.

- Replace any damaged or worn gaskets to prevent leaks.

- Ensure that all connections are secure to maintain optimal pressure.

- Consider upgrading to high-performance oil to improve lubrication.

- Consult with a professional for advanced diagnostics if issues arise.

Essential Tools for Series 60 Repairs

When undertaking maintenance tasks on advanced engines, having the right equipment is crucial for achieving effective outcomes. A well-equipped toolkit not only enhances efficiency but also ensures precision during each procedure. Below are key instruments necessary for successful maintenance activities.

Must-Have Equipment

- Torque Wrench: Ensures accurate fastening of components to manufacturer specifications.

- Compression Gauge: Measures cylinder compression to assess engine performance.

- Multimeter: Essential for diagnosing electrical systems and ensuring proper functionality.

- Socket Set: A versatile assortment for various fastener sizes, facilitating quick assembly and disassembly.

- Fuel Pressure Gauge: Monitors fuel system pressure, crucial for optimal engine operation.

Additional Handy Tools

- Feeler Gauges: Used to check and adjust valve clearances accurately.

- Oil Filter Wrench: Simplifies the removal and installation of oil filters.

- Magnetic Pickup Tool: Useful for retrieving dropped parts in hard-to-reach areas.

- Breaker Bar: Provides added leverage for loosening stubborn bolts.

- Work Light: Ensures proper visibility in low-light environments, enhancing safety and precision.

Transmission Compatibility and Adjustments

Understanding the relationship between the drivetrain components is essential for optimal performance. Ensuring that the transmission is well-matched with the engine enhances the overall efficiency and reliability of the system. Proper adjustments and compatibility checks can significantly impact the longevity and functionality of the vehicle.

When assessing compatibility, it is crucial to consider various factors such as gear ratios, torque ratings, and mounting configurations. These elements play a vital role in achieving a harmonious interaction between the engine and transmission.

| Component | Specification | Notes |

|---|---|---|

| Transmission Type | Manual / Automatic | Choose based on application needs |

| Gear Ratios | Standard / Custom | Verify compatibility with power output |

| Torque Capacity | Varies by model | Ensure adequate rating for engine output |

| Mounting Style | Rigid / Flexible | Check for alignment and fit |

| Control Mechanism | Electronic / Hydraulic | Consider integration with existing systems |

Regular adjustments are necessary to maintain the optimal performance of the drivetrain. This includes checking fluid levels, ensuring correct linkage alignment, and recalibrating electronic controls when necessary. A well-maintained system not only enhances driving experience but also minimizes wear and tear on components.

Preventive Measures for Longevity

Ensuring the extended lifespan of your engine relies on a series of proactive strategies. These approaches not only enhance performance but also reduce the likelihood of unexpected breakdowns. By committing to regular maintenance and employing best practices, you can significantly increase the operational life of your machinery.

Regular Maintenance Checks

Frequent inspections are essential in identifying potential issues before they escalate. Scheduling routine examinations allows for the early detection of wear and tear, ensuring that all components function optimally. Pay special attention to critical elements such as fluid levels, filters, and belts, as these are vital for smooth operation.

Quality Fuel and Lubricants

Utilizing high-quality fuels and lubricants is crucial for the overall health of your system. Poor-grade products can lead to increased deposits and corrosion, adversely affecting engine performance. Always adhere to manufacturer recommendations regarding fuel types and oil specifications to maintain efficiency and protect vital components.