Comprehensive Guide to Repairing the Enerpac P-392

Maintaining hydraulic devices is essential for ensuring their longevity and optimal performance. This section delves into the critical aspects of upkeep, providing insights that are vital for both novice and experienced users. By understanding the intricacies of these systems, you can effectively troubleshoot issues and enhance the efficiency of your machinery.

Familiarity with components is paramount when dealing with hydraulic systems. Each element plays a significant role in the overall functionality, and knowing how they interact allows for more effective diagnostics and interventions. This guide emphasizes the importance of recognizing wear patterns and understanding the typical failure modes of various parts.

Additionally, preventive strategies are discussed to help you avoid common pitfalls. Regular checks and maintenance practices can save time and resources in the long run, reducing the likelihood of unexpected breakdowns. With the right approach, you can ensure that your hydraulic equipment operates smoothly and reliably for years to come.

Understanding Enerpac P-392 Overview

This section aims to provide a comprehensive understanding of a specific hydraulic tool widely used in various industrial applications. Known for its robust performance and reliability, this equipment serves as an essential asset for professionals requiring precise lifting and clamping capabilities.

Key Features: The device boasts impressive specifications that enhance its functionality. With advanced engineering, it offers high pressure generation, ensuring efficient operation even under demanding conditions.

Applications: This tool finds utility in numerous fields, from construction to manufacturing, where heavy lifting and positioning are crucial. Its versatility allows users to tackle a range of tasks, making it a valuable component in any toolkit.

Maintenance Insights: Regular upkeep is vital for optimal performance. Understanding the mechanisms involved can help users identify potential issues before they escalate, ensuring longevity and reliability.

Conclusion: Gaining familiarity with this hydraulic apparatus is essential for maximizing its capabilities. Whether for routine tasks or specialized projects, having a solid grasp of its features and functions will undoubtedly enhance operational efficiency.

Common Issues with Enerpac P-392

In the realm of hydraulic tools, various complications may arise that can hinder performance and efficiency. Understanding these typical challenges is crucial for users aiming to maintain optimal functionality. The following sections will delve into frequent problems encountered during operation, providing insights for effective troubleshooting and resolution.

One prevalent issue involves hydraulic fluid leakage, which can result from worn seals or damaged fittings. This not only affects performance but can also lead to safety concerns if not addressed promptly. Regular inspection of seals and connections is recommended to mitigate this problem.

Another common challenge is inconsistent pressure output. This can stem from blockages within the system or malfunctioning pressure regulators. Ensuring that all components are clean and in good working order is essential for reliable pressure management.

Users may also experience difficulties with power loss during operation. This may be attributed to insufficient hydraulic fluid levels or issues with the power source. It is advisable to regularly check fluid levels and ensure that the power supply is stable to avoid disruptions.

Lastly, overheating can be a significant concern, often caused by prolonged use or inadequate cooling. Monitoring operating temperatures and allowing for appropriate cooling periods can help prevent damage to the system.

Essential Tools for Repairs

When it comes to maintaining and restoring hydraulic equipment, having the right instruments at your disposal is crucial for effective and safe work. The selection of appropriate tools not only enhances the efficiency of the tasks at hand but also ensures a higher quality of outcomes. Understanding which implements are indispensable can significantly streamline your efforts.

Wrenches are fundamental for tightening and loosening various fittings and components. A combination of adjustable and socket types is recommended to accommodate different sizes and shapes of nuts and bolts.

Screwdrivers come in various forms and are essential for accessing screws in tight spaces. Having a set with various heads ensures versatility for different applications.

Pliers are useful for gripping, twisting, and cutting materials, making them a versatile choice for many tasks. Needle-nose pliers can be particularly helpful in confined areas.

Torque Wrench is vital for applying the correct amount of torque to fasteners, preventing over-tightening that can lead to damage.

Sealant and Adhesive Tools are necessary for ensuring a tight and leak-free assembly. Utilizing the right type of sealant can significantly improve the integrity of connections.

Ultimately, a well-equipped toolbox not only supports the technical aspects of work but also enhances safety and reliability, paving the way for successful maintenance projects.

Step-by-Step Repair Process

This section outlines a comprehensive approach to restoring hydraulic equipment. By following the systematic steps, one can ensure efficient troubleshooting and effective resolution of common issues.

- Preparation

- Gather necessary tools and materials.

- Ensure a clean and organized workspace.

- Review any relevant documentation for guidance.

- Initial Assessment

- Inspect the equipment for visible damage.

- Check for leaks and unusual noises during operation.

- Test functionality to identify specific problems.

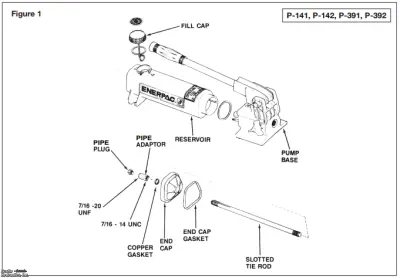

- Disassembly

- Carefully detach components, noting their arrangement.

- Use appropriate tools to avoid damage to parts.

- Keep small parts organized to facilitate reassembly.

- Cleaning

- Remove dirt and debris from components.

- Use solvent as needed to clean internal parts.

- Inspect for wear or corrosion during cleaning.

- Replacement of Parts

- Identify and procure necessary replacement components.

- Install new parts according to specifications.

- Ensure proper fit and alignment before reassembly.

- Reassembly

- Reattach all components in the correct order.

- Use torque specifications to secure fasteners.

- Double-check alignment and connection integrity.

- Final Testing

- Conduct tests to ensure proper operation.

- Monitor for leaks and unusual performance.

- Make adjustments as needed based on test results.

Following these steps methodically will enhance the likelihood of successful resolution and prolong the lifespan of the equipment.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of hydraulic equipment requires regular upkeep and attention. Proper maintenance not only enhances performance but also extends the lifespan of the machinery, ultimately saving time and costs associated with replacements.

Routine Inspection

Conducting frequent checks helps identify potential issues before they escalate. Pay attention to seals, hoses, and connections to prevent leaks and ensure optimal operation.

Proper Lubrication

Maintaining appropriate lubrication levels is crucial. Use high-quality oils and greases to minimize friction and wear, which can lead to equipment failure.

| Maintenance Activity | Frequency |

|---|---|

| Visual Inspection | Weekly |

| Fluid Level Check | Monthly |

| Filter Replacement | Every 6 months |

| Complete System Check | Annually |

Safety Precautions During Repairs

When engaging in maintenance tasks, it is essential to prioritize safety to prevent accidents and injuries. Proper preparation and awareness of potential hazards can significantly enhance the overall safety of the work environment. Adopting specific safety measures ensures that both the technician and equipment remain unharmed throughout the process.

Personal Protective Equipment (PPE)

Wearing appropriate personal protective equipment is crucial when undertaking any service work. This includes safety goggles to shield the eyes from debris, gloves to protect the hands from sharp objects and chemicals, and sturdy footwear to minimize the risk of slips and falls. Additionally, hearing protection may be necessary when operating loud machinery.

Work Environment Safety

Maintaining a clean and organized workspace is vital for minimizing risks. Ensure that all tools are in good condition and stored properly after use. Keep the area well-ventilated to prevent the buildup of harmful fumes, and be mindful of potential trip hazards. Familiarize yourself with emergency procedures and have first aid supplies readily available to address any incidents that may occur.

Replacement Parts and Accessories

Ensuring the longevity and efficiency of hydraulic equipment requires access to suitable components and supplementary items. This section highlights the essential replacement parts and accessories that can enhance the functionality and reliability of your machinery.

- Seals and O-rings: Critical for preventing leaks and maintaining pressure within the system.

- Hoses: Various lengths and diameters to accommodate different setups and applications.

- Filters: Necessary for keeping the hydraulic fluid clean and free from contaminants.

- Couplers: Facilitate quick connections and disconnections between hoses and devices.

- Pump components: Including pistons and valves that may wear over time and require replacement.

Using high-quality parts ensures optimal performance and extends the operational life of your equipment. Regular maintenance and timely replacements contribute significantly to efficient operation.

- Identify the specific part needed based on the model and application.

- Check compatibility with existing equipment to ensure seamless integration.

- Consult with suppliers for genuine parts to avoid issues with fit and performance.

Investing in the right accessories can also enhance usability and safety, providing better control and adaptability in various work environments.

Understanding the User Manual

Having a comprehensive guide at your disposal is crucial for the effective operation and maintenance of any technical equipment. Such documentation serves as a roadmap, providing essential information about the device’s features, proper usage, troubleshooting techniques, and safety precautions. This section delves into the importance of familiarizing oneself with the documentation to ensure optimal performance and longevity of the equipment.

Key Sections to Explore

When examining the documentation, several critical areas warrant close attention. Understanding these sections can greatly enhance user experience and equipment handling.

| Section | Description |

|---|---|

| Introduction | Offers an overview of the equipment and its intended applications. |

| Operating Instructions | Details the correct procedures for using the device effectively and safely. |

| Troubleshooting | Provides solutions to common issues that may arise during operation. |

| Maintenance Guidelines | Outlines routine care and servicing to ensure reliability and performance. |

| Safety Information | Highlights essential safety practices to prevent accidents and injuries. |

Importance of Thorough Review

Taking the time to read and understand the entire document is vital. Users who are well-versed in the guidelines are better equipped to maximize the utility of their equipment, minimize downtime, and avoid costly repairs. Regular consultation of the guide will also empower users to make informed decisions regarding maintenance and operation, ultimately contributing to a safer and more efficient working environment.

Where to Find Technical Support

Accessing reliable assistance is crucial for resolving issues with hydraulic equipment. Several resources are available to ensure you can receive guidance, whether you require troubleshooting help or in-depth technical knowledge. From official channels to online forums, these options can facilitate effective problem-solving.

Official customer service lines offer expert advice and can direct you to the appropriate resources for your specific equipment. Additionally, many manufacturers maintain websites with extensive documentation, FAQs, and downloadable resources that provide valuable information. Online communities and forums also serve as excellent platforms for sharing experiences and solutions with fellow users.

For those seeking hands-on help, local service centers often provide repair services and expert consultations. Ensuring you have access to these support channels can ultimately enhance your operational efficiency and prolong the lifespan of your machinery.

Comparing Enerpac Models for Reference

This section aims to provide a comprehensive comparison of various hydraulic models available in the market, highlighting their features, applications, and suitability for different tasks. Understanding the nuances between these options can help users make informed decisions tailored to their specific needs.

When evaluating hydraulic devices, it’s essential to consider factors such as lifting capacity, pressure ratings, and design configurations. Each model may offer unique benefits that cater to diverse operational requirements, from industrial use to more specialized applications.

Another critical aspect to compare is the compatibility of accessories and attachments, which can enhance functionality and versatility. By examining these components, users can determine which models will best integrate into their existing systems, thereby maximizing efficiency and effectiveness.

Ultimately, a detailed analysis of these models not only aids in selecting the most appropriate equipment but also ensures that users can achieve optimal performance while adhering to safety standards and operational protocols.