Comprehensive Guide to Mahindra Tractor Repair Manual

In the realm of modern agriculture, ensuring optimal performance of equipment is paramount for efficiency and productivity. Proper upkeep of these powerful machines not only prolongs their lifespan but also enhances their operational capabilities. A detailed understanding of the components and functions is essential for achieving seamless functionality.

Essential knowledge of maintenance practices empowers operators to tackle common issues and perform routine checks effectively. This section serves as a resource for individuals seeking insights into troubleshooting, servicing, and optimizing their equipment. By cultivating these skills, users can minimize downtime and maximize output.

Furthermore, familiarity with operational techniques is crucial for anyone engaged in agricultural tasks. Whether it involves addressing mechanical challenges or enhancing efficiency through preventative measures, a well-rounded approach ensures that these indispensable machines remain in peak condition. This guide aims to equip users with the necessary tools and information for successful machinery management.

Overview of Mahindra Tractors

The brand is renowned for its robust and efficient agricultural machinery, designed to meet the diverse needs of farmers and landowners. These machines are built to perform under various conditions, ensuring reliability and performance in the field.

Engineered for Excellence

The machinery features advanced engineering and technology, providing exceptional power and fuel efficiency. This makes them suitable for a wide range of applications, from plowing to harvesting, enhancing productivity significantly.

User-Friendly Design

With an emphasis on comfort and usability, the equipment is equipped with ergonomic controls and spacious cabins. This thoughtful design minimizes operator fatigue, allowing for longer work hours without compromising efficiency.

Versatile Applications

These machines are not limited to agricultural tasks alone; they can also be utilized in construction, landscaping, and other industries. Their adaptability makes them a valuable asset for anyone in need of reliable heavy-duty equipment.

Commitment to Sustainability

In addition to performance, the company focuses on environmentally friendly solutions. Many models are designed to minimize emissions and optimize fuel consumption, contributing to sustainable farming practices.

Overall, this brand stands as a testament to innovation, durability, and commitment to enhancing the productivity of its users, making it a preferred choice in the agricultural sector.

Common Issues in Mahindra Tractors

In the realm of agricultural machinery, certain challenges frequently arise, affecting performance and efficiency. Understanding these common problems can help operators maintain optimal functionality and minimize downtime.

Engine Performance: One prevalent issue involves engine power loss, which can stem from fuel quality, air intake blockages, or insufficient lubrication. Regular checks and timely maintenance can prevent these complications.

Hydraulic System Malfunctions: Hydraulic systems are crucial for effective operation, yet they can experience leaks or pressure drops. Inspecting seals and hoses periodically ensures reliable performance and reduces the risk of breakdowns.

Transmission Difficulties: Shifting issues often arise, making it challenging to change gears smoothly. These problems can be attributed to low fluid levels or worn-out components, necessitating regular inspections to maintain seamless operation.

Electrical Failures: Electrical systems can be prone to short circuits or battery failures. Ensuring connections are secure and batteries are charged will help avoid unexpected shutdowns during critical tasks.

Excessive Vibration: Unusual vibrations may indicate misalignment or imbalance within the machinery. Regular maintenance checks can help identify and resolve these issues, ensuring a smoother operation.

By being aware of these common challenges, operators can take proactive measures to enhance the longevity and reliability of their equipment.

Essential Tools for Repairing Tractors

When it comes to maintaining heavy machinery, having the right equipment is crucial for ensuring efficiency and longevity. A well-equipped workshop not only streamlines the process but also enhances safety and effectiveness. Whether addressing minor issues or undertaking significant overhauls, certain implements are indispensable for any mechanic working on large agricultural vehicles.

Basic hand tools such as wrenches, pliers, and screwdrivers form the foundation of any toolkit. These are essential for loosening and tightening components, allowing for adjustments and replacements as needed. In addition, a reliable socket set can significantly improve the ease of accessing fasteners in tight spaces.

For more complex tasks, power tools like impact wrenches and grinders can save valuable time and effort. These devices are designed to handle tougher jobs, making it easier to deal with rusted or stubborn parts. Additionally, a quality diagnostic tool can help in identifying issues quickly, providing insights that might not be apparent through visual inspection alone.

Safety equipment, including gloves, goggles, and ear protection, should never be overlooked. Working with heavy machinery involves risks, and appropriate protective gear is essential to safeguard against potential hazards. A sturdy workbench and proper lighting further enhance the working environment, making tasks more manageable and efficient.

In summary, a comprehensive set of tools is vital for maintaining and troubleshooting machinery. From basic hand tools to advanced diagnostic equipment, each item plays a role in ensuring that machinery operates smoothly and reliably for years to come.

Step-by-Step Maintenance Procedures

Regular upkeep is essential to ensure optimal performance and longevity of your machinery. This section provides a structured approach to maintaining your equipment, covering various tasks that can enhance functionality and prevent issues.

1. Routine Checks

Start with a series of essential inspections to identify any potential problems early on:

- Inspect fluid levels: oil, coolant, and hydraulic fluids.

- Check for leaks around seals and connections.

- Examine filters for clogs or damage.

- Assess tire condition: pressure and tread wear.

2. Cleaning Procedures

Keeping your machinery clean is crucial for performance. Follow these cleaning steps:

- Wash the exterior with mild soap and water to remove dirt and debris.

- Clean air filters according to the manufacturer’s recommendations.

- Remove any buildup from the cooling system to ensure efficient operation.

- Inspect and clean electrical connections to prevent corrosion.

Electrical System Troubleshooting Guide

This section aims to assist users in identifying and resolving common issues related to the electrical components of their equipment. A systematic approach can simplify the process, enabling users to efficiently address problems and maintain optimal functionality.

Common Electrical Issues

- Battery failure

- Faulty wiring connections

- Malfunctioning ignition system

- Defective sensors

- Blown fuses

Troubleshooting Steps

- Check the battery charge: Ensure the battery is fully charged and connections are clean.

- Inspect wiring: Look for any visible damage or loose connections in the wiring harness.

- Examine the ignition: Test the ignition system components for continuity and proper operation.

- Test sensors: Use a multimeter to check the functionality of sensors.

- Replace blown fuses: Identify and replace any blown fuses in the electrical system.

By following these guidelines, users can effectively diagnose and rectify electrical issues, ensuring their equipment operates smoothly and reliably.

Engine Repair and Maintenance Tips

Ensuring optimal performance of your machinery requires regular attention to its internal components. A well-maintained engine not only extends its lifespan but also enhances efficiency. Here are essential practices to keep in mind for effective upkeep.

| Tip | Description |

|---|---|

| Regular Oil Changes | Changing the oil at recommended intervals prevents buildup of contaminants and maintains lubrication. |

| Check Air Filters | Inspecting and replacing air filters ensures proper airflow, enhancing combustion and performance. |

| Monitor Coolant Levels | Maintaining adequate coolant prevents overheating, which can lead to serious engine damage. |

| Inspect Belts and Hoses | Regularly checking for wear and tear on belts and hoses prevents unexpected breakdowns and leaks. |

| Fuel System Maintenance | Cleaning injectors and checking the fuel filter help maintain optimal fuel flow and efficiency. |

By implementing these strategies, you can significantly enhance the reliability and performance of your engine. Regular inspections and proactive maintenance can save time and resources in the long run.

Hydraulic System Diagnostics

Understanding the intricacies of fluid power systems is essential for effective troubleshooting and maintenance. By examining various components and their interactions, one can identify issues that may impair performance, ensuring smooth operation and longevity.

Common Symptoms of Hydraulic Issues

| Symptom | Possible Cause |

|---|---|

| Weak lifting capacity | Low fluid levels or leaks |

| Unresponsive controls | Faulty valve or pump |

| Overheating | Clogged filters or low fluid |

| Noisy operation | Air in the system or cavitation |

Diagnostic Steps

Begin with a visual inspection for leaks and damage. Check fluid levels and quality, and replace any contaminated fluid. Utilize pressure gauges to assess pump performance, and verify the functionality of control valves. Systematic evaluation will ultimately lead to identifying root causes and appropriate solutions.

Replacing Tires and Wheels

Changing the rolling components of your machinery is crucial for optimal performance and safety. Over time, wear and tear can diminish their efficiency, making it necessary to undertake this task regularly.

Preparation Steps

Before starting, ensure you have the right tools at hand, such as a jack, lug wrench, and replacement parts. It’s essential to work on a flat, stable surface to avoid accidents during the process. Always consult the specific guidelines for your equipment to identify the correct specifications.

Procedure

Begin by loosening the fasteners on the existing components while the equipment is still on the ground. Once loosened, lift the unit using the jack and remove the old parts. Carefully position the new wheels and tires, tightening the fasteners in a star pattern for even distribution. Finally, lower the machinery and check for stability before use.

Note: Regular maintenance can greatly extend the lifespan of your components, ensuring efficiency and safety during operation.

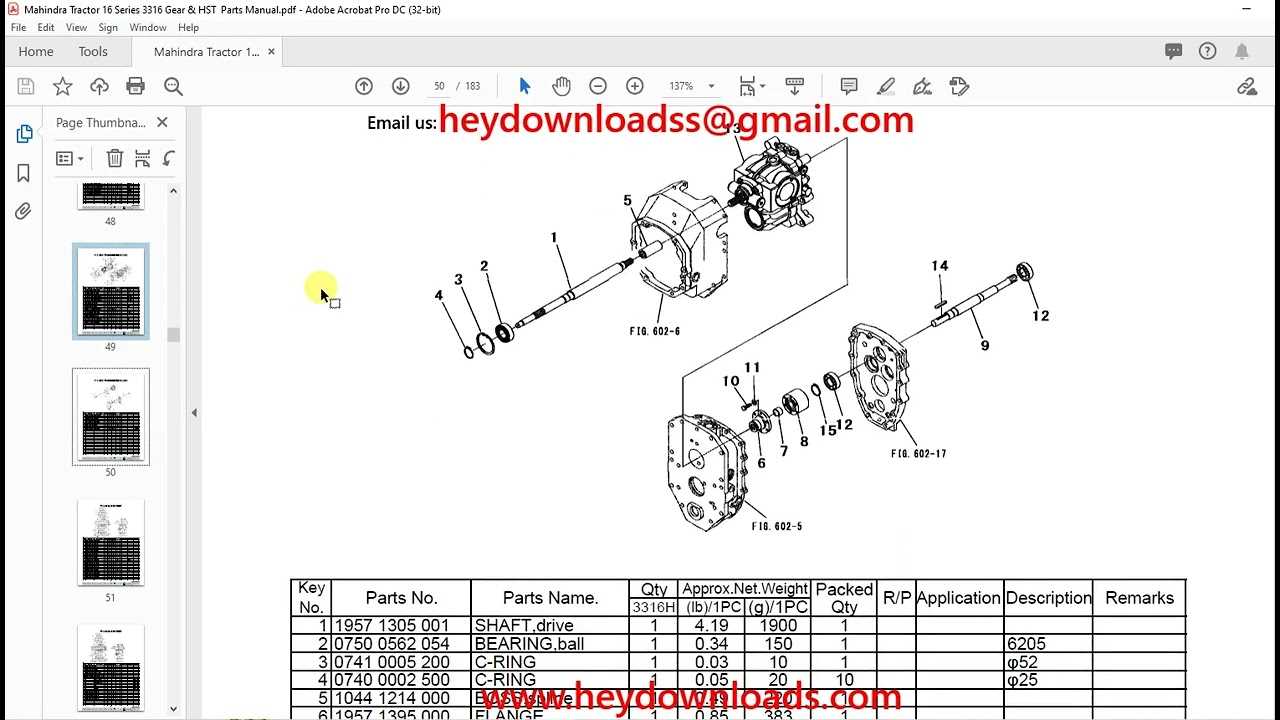

Transmission Repair Techniques

This section outlines essential strategies for addressing issues within the power transfer system of machinery. Understanding these techniques is crucial for maintaining optimal functionality and ensuring longevity in performance. Proper diagnostics and systematic procedures can significantly enhance the effectiveness of maintenance efforts.

Common Issues and Diagnostic Steps

Identifying the root cause of transmission problems is the first step toward effective resolution. Here are some prevalent issues and corresponding diagnostic methods:

- Slipping Gears: Check fluid levels and condition; inspect linkage adjustments.

- Unusual Noises: Listen for grinding or whining sounds, indicating wear or damage.

- Fluid Leaks: Inspect seals and gaskets for deterioration or misalignment.

Repair Techniques

Once issues are diagnosed, the following methods can be applied to restore functionality:

- Fluid Replacement: Regularly change transmission fluid to prevent overheating and maintain lubrication.

- Seal and Gasket Replacement: Replace worn seals to eliminate leaks and ensure proper pressure.

- Component Inspection: Examine gears and bearings for signs of wear; replace as necessary.

- Adjustment of Linkages: Fine-tune cable and lever connections for improved responsiveness.

Implementing these techniques can lead to enhanced performance and reliability in the power transfer system. Regular maintenance and attention to detail are key components in sustaining operational efficiency.

Implementing Safety Measures During Repairs

Ensuring a secure environment during maintenance tasks is crucial for preventing accidents and injuries. By adhering to safety protocols, individuals can safeguard themselves and others while working on complex machinery. This section outlines essential precautions that should be taken to promote a safe working atmosphere.

Personal Protective Equipment (PPE) is vital for anyone involved in maintenance work. Wearing appropriate gear such as gloves, goggles, and steel-toed boots can significantly reduce the risk of injury. It is important to inspect PPE regularly to ensure it is in good condition and suitable for the tasks at hand.

Clear Workspace Organization plays a significant role in safety. Keeping tools and materials organized prevents accidents caused by clutter. Designate specific areas for tools and ensure that all items are stored properly after use. This practice not only enhances safety but also improves efficiency during work.

Prior to commencing any tasks, conducting a Risk Assessment is essential. Identifying potential hazards allows individuals to implement necessary control measures. Ensure that everyone involved is aware of the risks and knows the procedures for handling emergencies.

Proper Training is another critical aspect of safety. Individuals should be well-trained in operating machinery and understanding its functions. Regular training sessions can keep skills sharp and reinforce safety practices, reducing the likelihood of accidents.

Finally, maintaining Emergency Preparedness is imperative. Ensure that first aid kits are readily available and that personnel are aware of emergency protocols. Conduct regular drills to familiarize everyone with the steps to take in case of an unforeseen incident.

Finding Genuine Replacement Parts

When it comes to maintaining machinery, sourcing authentic components is crucial for optimal performance and longevity. Utilizing original parts ensures compatibility and reliability, safeguarding the integrity of your equipment.

To locate these genuine components, start by exploring authorized dealerships or trusted suppliers. Online platforms often provide a wealth of options, but verify the credibility of the source to avoid counterfeit items.

Additionally, joining forums or community groups dedicated to equipment enthusiasts can yield valuable insights and recommendations on where to find reputable parts. Networking with other users can enhance your search for authenticity.

Ultimately, investing time in finding the right components will pay off, ensuring your machinery operates at its best for years to come.

Resources for Mahindra Tractor Owners

For enthusiasts and operators of agricultural machinery, having access to the right tools and information is essential for optimal performance and maintenance. This section provides a collection of invaluable resources aimed at enhancing your experience and ensuring the longevity of your equipment.

| Resource Type | Description | Link |

|---|---|---|

| Online Forums | Join communities of fellow users to share experiences, tips, and troubleshooting advice. | Visit Forum |

| Official Website | Access product information, specifications, and official updates from the manufacturer. | Visit Website |

| YouTube Tutorials | Watch videos that provide step-by-step guides on maintenance and usage. | Visit YouTube |

| Parts Suppliers | Find authorized dealers for replacement components and accessories. | Visit Supplier |

| Local Workshops | Locate professional services for repairs and routine maintenance in your area. | Find Workshops |

Utilizing these resources can greatly enhance your ownership experience, providing essential support and guidance for both routine tasks and unexpected challenges.