Polaris 9550 Maintenance Guide

Ensuring the longevity and optimal performance of sophisticated machinery is crucial for both safety and efficiency. This section focuses on essential procedures and considerations for addressing common issues that may arise during the operation of high-performance devices. By following the recommended practices, users can effectively troubleshoot and resolve potential challenges.

In this guide, we will explore various techniques and tips that facilitate the upkeep of your equipment. Emphasizing preventive measures and timely interventions can greatly reduce the likelihood of major disruptions. Knowledge of fundamental processes not only enhances the functionality but also contributes to a smoother user experience.

With a comprehensive understanding of maintenance protocols, operators can navigate the complexities of their devices with confidence. Proactive measures combined with informed decision-making will lead to successful management and enhanced operational capability.

Common Issues and Symptoms

This section highlights frequent problems encountered with various models, focusing on their typical manifestations. Understanding these issues can assist users in identifying and addressing them promptly.

- Unresponsive Controls: Users may notice that buttons or remote controls do not function as expected.

- Inconsistent Performance: Variations in operation speed or efficiency can signal underlying issues.

- Unusual Noises: Strange sounds during operation often indicate mechanical problems or wear.

Identifying these symptoms early can help in taking appropriate measures, whether through troubleshooting or seeking professional assistance.

Tools Needed for Repairs

When addressing maintenance tasks, having the right equipment is essential for achieving effective results. This section outlines the various instruments and devices that will facilitate the process, ensuring efficiency and precision in every step.

| Tool Type | Description |

|---|---|

| Wrench Set | A collection of wrenches in different sizes for loosening and tightening bolts. |

| Screwdriver Kit | Assortment of screwdrivers with various head types for driving screws into different materials. |

| Pliers | Tools for gripping, twisting, and cutting wire or small components. |

| Socket Set | A set of sockets to fit over nuts and bolts, allowing for more torque. |

| Torque Wrench | A precision tool to apply a specific torque to fasteners, ensuring proper tightness. |

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues effectively, ensuring that each stage is tackled methodically. By following a systematic procedure, you can identify problems and implement solutions with greater efficiency.

Begin by gathering all necessary tools and materials, ensuring that everything is at hand before you start. A clean workspace is crucial for maintaining focus and preventing any distractions that could hinder the process.

Next, conduct a thorough inspection of the device. Look for any visible signs of wear or damage that might contribute to the malfunction. Document your findings to help streamline the next steps.

Once you have identified the issues, disassemble the unit carefully. Keep track of all components and their arrangement to facilitate reassembly later. Pay attention to any screws or fasteners that may require special handling.

After disassembly, clean all parts to remove any dirt or debris. This step is essential to ensure optimal performance once the device is reassembled.

Now, proceed to replace or repair any damaged components. Ensure that each part is compatible and functions as intended before moving on to the next stage.

Finally, reassemble the device in reverse order of disassembly. Double-check that all parts are securely fastened and that nothing is left out. Once reassembled, conduct a series of tests to confirm that everything operates smoothly.

Maintenance Tips for Longevity

Ensuring the enduring performance of your equipment requires consistent care and attention. By implementing a few key practices, you can enhance its lifespan and reliability, ultimately leading to better efficiency and reduced repair needs.

| Tip | Description |

|---|---|

| Regular Cleaning | Keep surfaces free from dirt and debris to prevent corrosion and damage. |

| Routine Inspections | Check for wear and tear regularly to identify potential issues before they escalate. |

| Proper Storage | Store in a dry, sheltered area to protect from the elements and prolong functionality. |

| Timely Repairs | Address minor issues promptly to avoid costly repairs later on. |

| Use Quality Parts | Opt for high-quality components during replacements to ensure optimal performance. |

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks on any equipment. Proper precautions help prevent accidents and injuries, creating a secure environment for the technician and the machinery involved. This section outlines essential practices to follow before and during the servicing process.

Personal Protective Equipment

Utilizing appropriate personal protective gear is crucial. This includes safety goggles to shield the eyes from debris, gloves to protect hands from sharp objects, and sturdy footwear to prevent slips and injuries. Wearing such equipment minimizes the risk of harm during the maintenance activities.

Work Area Organization

Maintaining a tidy and organized workspace is vital for safety. Ensure that tools and parts are easily accessible, and eliminate any unnecessary clutter that could pose a tripping hazard. A well-arranged area allows for better focus and reduces the likelihood of accidents while working on the equipment.

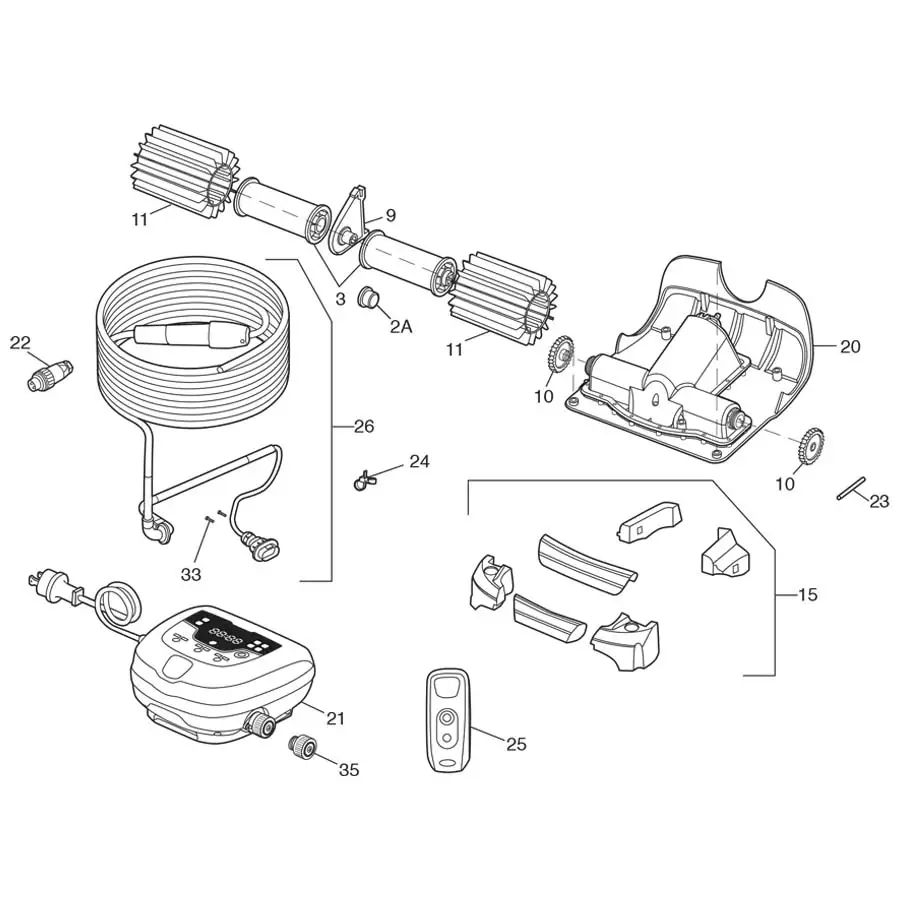

Parts Replacement Guidelines

Replacing components in a device requires careful consideration and a systematic approach to ensure optimal performance. Understanding the appropriate procedures and standards for substitution can significantly extend the lifespan of the equipment.

Before beginning the replacement process, it is essential to gather all necessary tools and new parts. Verify compatibility with the existing system to avoid issues that may arise from improper installations. Take note of any specific recommendations from the manufacturer regarding installation techniques and maintenance practices.

During the replacement, ensure to handle all components with care, as improper handling can lead to damage. Follow a step-by-step procedure to avoid confusion and guarantee that each part is secured correctly. After replacing the components, perform thorough testing to confirm that the system operates as intended.

Troubleshooting Electrical Problems

Electrical issues can often lead to operational disruptions, making it essential to identify and address them promptly. Understanding the underlying causes can help restore functionality and ensure efficient performance. This section provides guidance on diagnosing common electrical faults and implementing effective solutions.

Identifying Common Issues

Begin by examining the power source and connections. Loose or corroded terminals can disrupt the flow of electricity, leading to malfunctioning components. Check for blown fuses or tripped breakers, as these are often indicators of underlying electrical faults. Regular maintenance of electrical connections is crucial to prevent future complications.

Testing Components

Use a multimeter to measure voltage and continuity across various components. This tool allows for accurate diagnostics, helping to pinpoint malfunctioning parts. If readings are outside normal ranges, consider replacing the affected components. Timely interventions can significantly enhance the longevity and performance of the system.

Cleaning and Care Instructions

Maintaining the functionality and appearance of your device is essential for ensuring its longevity. Regular cleaning and proper care not only enhance performance but also prevent potential issues that may arise from neglect.

Regular Cleaning Steps

- Start by disconnecting the device from any power source.

- Use a soft, damp cloth to wipe down the exterior surfaces.

- For stubborn stains, a mild detergent can be used. Ensure it is thoroughly rinsed off afterward.

- Check and clean any filters or accessible areas according to the manufacturer’s recommendations.

Storage and Maintenance Tips

- Store the device in a dry and cool environment to prevent moisture buildup.

- Ensure that all components are properly secured to avoid damage during storage.

- Inspect the device periodically for any signs of wear or malfunction, addressing issues promptly.

- Follow any specific guidelines provided for seasonal maintenance if applicable.

When to Seek Professional Help

In certain situations, it becomes essential to consult an expert for assistance. While some issues can be tackled independently, others may require specialized knowledge and skills to ensure proper resolution. Recognizing these instances is crucial for maintaining optimal performance and safety.

It is advisable to seek assistance from a professional when you encounter persistent problems that do not improve with basic troubleshooting. If your device exhibits unusual behavior, such as strange noises or erratic functioning, it may indicate underlying issues that need expert evaluation.

Additionally, if you lack the confidence or experience to perform specific tasks, relying on a qualified technician can prevent potential damage. Always prioritize safety and efficiency by considering professional help when faced with complex challenges.

FAQs About Polaris 9550 Repairs

This section addresses common inquiries related to maintenance and troubleshooting of a specific model of robotic devices. Understanding these frequent concerns can aid users in effective problem-solving and enhancing the longevity of their equipment.

What are the most common issues faced?

Users often report challenges such as inconsistent navigation, battery performance issues, or problems with the cleaning mechanism. Identifying these issues early can lead to simpler solutions and better performance.

How can I maintain my device?

Regular upkeep is crucial. Cleaning the filters, checking for debris in the brushes, and ensuring proper storage conditions can significantly extend the life of the unit. Following manufacturer guidelines for care can also prevent many issues.