Comprehensive Guide to Rotax DD2 Repair Manual

In the world of high-performance engines, understanding the intricacies of maintenance and functionality is crucial. This section aims to provide enthusiasts and technicians with essential knowledge to ensure optimal operation and longevity of their engines. By delving into various aspects of upkeep, users can enhance their familiarity with the machinery, making them better equipped to handle challenges that may arise during usage.

Maintaining the efficiency of such complex systems requires attention to detail and an awareness of common issues. This guide covers vital techniques and practices that contribute to seamless performance. Whether you are addressing routine checks or troubleshooting unexpected behaviors, the insights shared here will empower you to navigate through any difficulties confidently.

Additionally, this resource emphasizes the significance of proactive measures in preventing potential complications. Understanding how to care for the engine not only improves reliability but also enhances the overall experience for users. With comprehensive instructions and tips, you will gain a deeper understanding of your machinery, ensuring it runs smoothly for years to come.

Having the right equipment is crucial when it comes to maintaining and fixing engines. A well-equipped toolkit ensures that tasks can be performed efficiently and effectively, minimizing downtime and enhancing overall performance. In this section, we will explore some of the key tools that every mechanic should have on hand to tackle various challenges.

Key Tools to Consider

| Tool | Description | Purpose |

|---|---|---|

| Socket Set | A collection of various sizes of sockets | Used for loosening and tightening nuts and bolts |

| Torque Wrench | Precision tool for measuring torque | Ensures that fasteners are tightened to specified settings |

| Screwdriver Set | Includes both flathead and Phillips screwdrivers | Essential for driving screws of different types |

| Pliers | Multi-purpose gripping tool | Used for holding, bending, and cutting wires |

| Wrench Set | A range of open-end and box-end wrenches | Vital for turning nuts and bolts in tight spaces |

Additional Essential Tools

In addition to the primary tools, there are several other instruments that can be beneficial for troubleshooting and maintenance tasks. Multimeters, for instance, are invaluable for electrical diagnostics, while a good set of feeler gauges can aid in precise adjustments. Furthermore, a reliable set of cutting tools is essential for any modifications or repairs that may be needed.

Step-by-Step Maintenance Guide

This section provides a comprehensive approach to the upkeep of your engine system. Proper care not only extends the life of the unit but also ensures optimal performance during operation. Following a structured maintenance routine is essential for avoiding common issues and enhancing reliability.

Routine Checks

Begin by conducting regular inspections of the key components. Check for any signs of wear or damage, including the fuel lines, air filter, and spark plugs. Ensure that all connections are secure and that there are no leaks present. Regular monitoring helps identify potential problems early, allowing for timely intervention.

Cleaning and Lubrication

Maintain the cleanliness of the engine by removing dirt and debris. Utilize suitable cleaning agents that won’t harm any surfaces. Additionally, apply lubricant to moving parts to reduce friction and prevent wear. Consistent cleaning and lubrication are critical for smooth operation and longevity.

Engine Disassembly and Reassembly

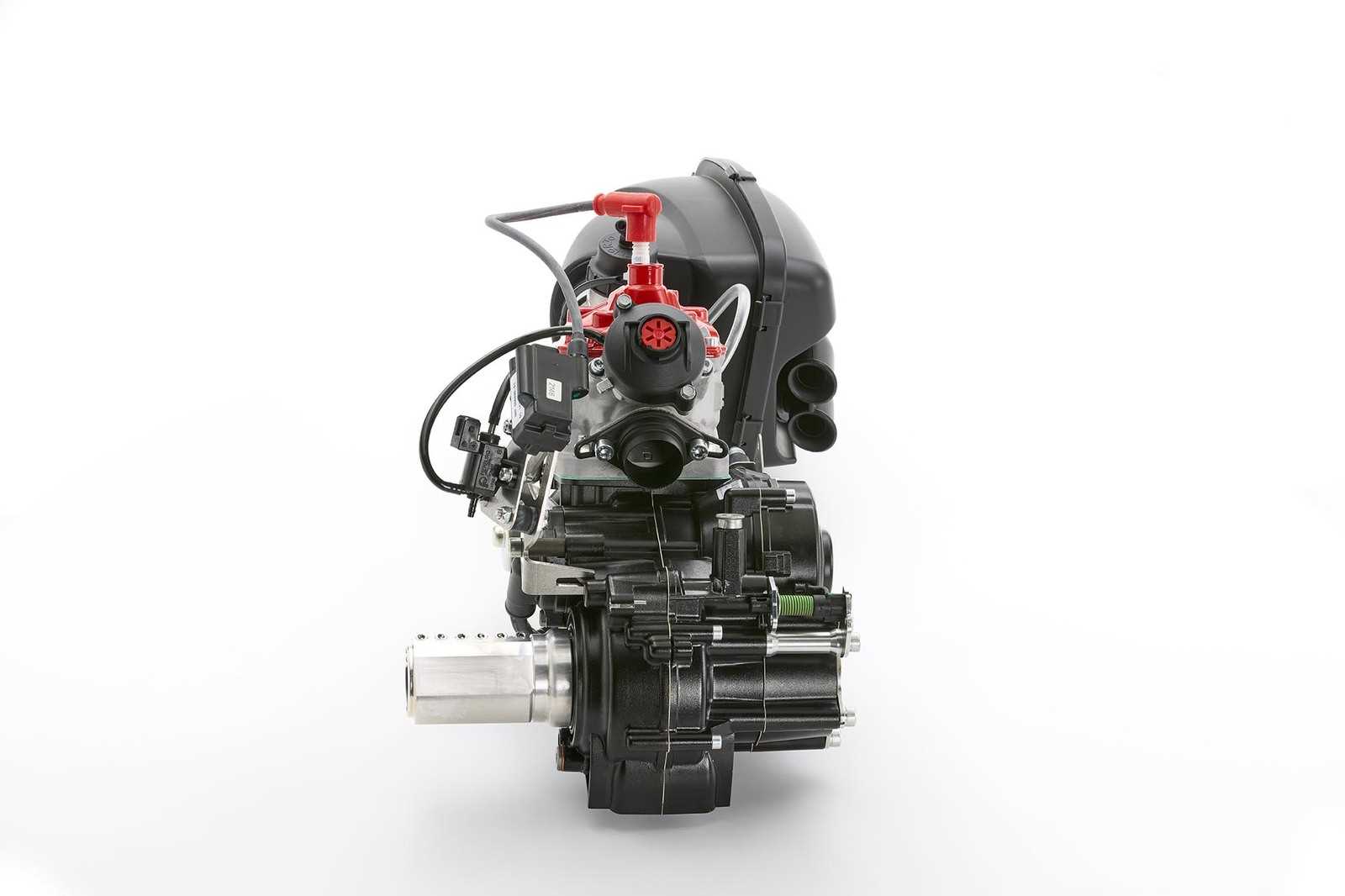

Understanding the process of taking apart and putting back together an engine is essential for effective maintenance and performance optimization. This section provides a comprehensive overview of the steps involved, ensuring that enthusiasts and technicians alike can approach the task with confidence.

Disassembly requires careful planning and organization. Begin by preparing a clean workspace to avoid losing components. Documenting each step through photographs or notes can greatly aid in reassembly. Start by removing any external accessories, such as the carburetor and exhaust system, to gain access to the engine block.

Next, detach the cylinder head, being cautious not to damage the gasket surfaces. Continue by removing the cylinder and piston assembly, paying attention to the orientation of each component. Use appropriate tools to prevent stripping any fasteners, and place each part in labeled containers for easy identification during reassembly.

Reassembly should be approached with the same level of meticulousness. Begin by inspecting all components for wear or damage, replacing parts as necessary. Follow the reverse order of disassembly, ensuring that all gaskets and seals are replaced to maintain proper function. Torque specifications should be adhered to strictly to avoid future issues.

As you reassemble the engine, take care to align all components accurately, ensuring smooth operation. Finally, perform a thorough inspection before testing the engine to verify that it operates correctly and efficiently. This methodical approach will contribute to the longevity and performance of the engine.

Electrical System Troubleshooting

This section focuses on diagnosing issues related to the electrical components of the engine system. Understanding how to systematically identify problems can enhance performance and ensure safety during operation.

Common electrical issues may stem from various sources, including wiring faults, connector problems, or component failures. To effectively troubleshoot these issues, consider the following steps:

- Inspect Wiring:

- Check for frayed or damaged wires.

- Ensure that all connections are secure.

- Look for signs of corrosion or dirt on terminals.

- Test Components:

- Use a multimeter to check voltage and continuity.

- Evaluate the performance of switches and relays.

- Examine the condition of fuses for any signs of failure.

- Review Ground Connections:

- Ensure all ground points are clean and tight.

- Test for voltage drops across ground connections.

- Consult Wiring Diagrams:

- Refer to the specific wiring diagrams for accurate troubleshooting.

- Trace circuits to identify possible breakpoints or shorts.

By following these guidelines, you can efficiently identify and rectify electrical issues, leading to improved functionality and reliability of the engine system.

Fuel System Maintenance Tips

Ensuring the optimal performance of the fuel system is crucial for the longevity and efficiency of your engine. Regular upkeep helps prevent issues that can arise from fuel contamination and wear over time. Here are some essential practices to maintain the fuel system effectively.

Regular Inspection

- Check for any signs of leaks or damage in fuel lines and connections.

- Inspect filters and replace them as needed to ensure clean fuel flow.

- Monitor the fuel tank for rust or debris that could affect fuel quality.

Fuel Quality Management

- Use high-quality fuel to minimize impurities that can clog the system.

- Consider adding fuel stabilizers to prevent degradation when the vehicle is not in use.

- Avoid storing fuel for extended periods; it’s best to use fresh fuel regularly.

By adhering to these maintenance tips, you can enhance the reliability and efficiency of your fuel system, leading to smoother operation and fewer repairs in the long run.

Cooling System Inspection Procedures

The examination of the cooling system is crucial for ensuring optimal performance and longevity of the engine. Regular assessments can help identify potential issues before they escalate, thereby maintaining the efficiency of the power unit. This section outlines the systematic approach for inspecting the cooling components, ensuring they function effectively to prevent overheating.

Visual Inspection

Begin with a thorough visual examination of the entire cooling system. Look for any signs of leakage, corrosion, or physical damage to hoses, radiators, and fittings. Ensure that all connections are secure and that there are no cracks or wear in the rubber components. Pay close attention to the condition of the coolant reservoir, as it should be free from debris and maintain the proper fluid level.

Functional Testing

After the visual assessment, conduct functional tests to evaluate the cooling system’s performance. Start the engine and allow it to reach operating temperature, monitoring the temperature gauge for any unusual fluctuations. Check the flow of coolant by observing the radiator’s upper and lower hoses; they should be warm to the touch, indicating proper circulation. Additionally, inspect the thermostat’s operation to ensure it opens and closes at the designated temperature, contributing to effective cooling regulation.

Understanding Engine Performance Metrics

Evaluating the efficiency and capability of an engine involves analyzing several key performance indicators. These metrics provide insights into how well the power unit operates under various conditions, reflecting its overall effectiveness in delivering power and efficiency. A thorough understanding of these measurements is essential for optimizing performance and ensuring reliability.

One crucial aspect to consider is the engine’s horsepower, which indicates the power output available for propulsion. This metric is vital for assessing an engine’s ability to achieve desired speeds and acceleration. Alongside horsepower, torque plays a significant role in performance; it measures the twisting force the engine generates, impacting the vehicle’s ability to accelerate from a standstill or climb steep inclines.

Additionally, fuel efficiency is a critical metric, often expressed in terms of miles per gallon or liters per 100 kilometers. This figure helps determine the operational cost and environmental impact of the engine, guiding decisions related to fuel types and driving habits. Moreover, monitoring engine temperature and RPM (revolutions per minute) can provide valuable information regarding the engine’s health and operational limits, aiding in preventive maintenance and performance enhancement.

Lastly, understanding emissions data is increasingly important in today’s regulatory landscape. These measurements inform how well the engine complies with environmental standards, impacting both legal compliance and public perception. By focusing on these performance metrics, individuals can gain a comprehensive understanding of engine capabilities, leading to improved performance and longevity.

Replacement Parts and Upgrades

Ensuring optimal performance of your engine often involves the timely replacement of components and the introduction of enhancements. This section delves into the various parts that may require attention and the upgrades available to elevate functionality and reliability.

Common Replacement Components

Regular maintenance may necessitate replacing certain key elements to maintain efficiency and safety. The following table outlines frequently replaced parts along with their typical uses:

| Part | Description | Recommended Interval |

|---|---|---|

| Piston | Essential for combustion, ensuring optimal power output. | Every 50 hours of operation |

| Fuel Filter | Prevents contaminants from entering the fuel system. | Every 100 hours of operation |

| Ignition Coil | Responsible for generating the spark needed for combustion. | Every 200 hours of operation |

Available Upgrades

Upgrading components can significantly enhance performance and longevity. Consider the following options:

- High-Performance Carburetor: Increases fuel delivery efficiency, improving throttle response.

- Lightweight Flywheel: Reduces rotational mass, allowing for quicker acceleration.

- Enhanced Exhaust System: Improves exhaust flow, which can lead to better horsepower and torque.

Safety Precautions During Repairs

Ensuring a safe working environment is crucial when engaging in maintenance tasks. By adhering to specific safety measures, individuals can minimize risks and enhance their overall efficiency. This section outlines essential guidelines to follow while undertaking such activities.

Personal Protective Equipment (PPE)

Utilizing appropriate personal protective equipment is fundamental to safeguarding oneself from potential hazards. Always wear suitable gear to protect against injuries. Key items include:

| Type of PPE | Description |

|---|---|

| Safety Goggles | Protects eyes from debris and harmful substances. |

| Gloves | Prevents cuts and exposure to chemicals. |

| Steel-Toed Boots | Offers foot protection from heavy objects. |

| Hearing Protection | Reduces the risk of hearing damage in loud environments. |

Work Area Organization

Maintaining a tidy workspace is vital for safety. Clutter can lead to accidents, so it’s essential to keep tools and materials organized. Ensure that the area is well-lit and free from any obstructions. Additionally, being aware of emergency exits and having a first-aid kit readily available can further enhance safety during maintenance activities.

Frequently Asked Questions

This section addresses common inquiries that enthusiasts may have regarding their karting engine systems. We aim to provide clear and concise answers to enhance your understanding and assist you in troubleshooting various aspects of your equipment.

1. What should I do if my engine fails to start?

First, ensure that the fuel supply is adequate and that the ignition system is functioning properly. Check for any loose connections or damaged components that might affect performance.

2. How often should I perform maintenance on my engine?

Regular upkeep is essential for optimal performance. It is advisable to conduct routine checks after every few races, focusing on the oil levels, spark plugs, and air filters.

3. What type of fuel is recommended for optimal performance?

Using high-octane fuel specifically designed for racing applications will help achieve better performance. Always refer to the specifications provided for your engine model.

4. How can I improve the overall performance of my kart?

Performance can be enhanced through several modifications, such as optimizing the gearing ratio, fine-tuning the carburetor settings, and ensuring that the tires are properly inflated for the track conditions.

5. Is it necessary to seek professional help for troubleshooting?

While many issues can be resolved independently, consulting with a professional mechanic is recommended for complex problems or if you’re unsure about the required procedures.