Singer 9960 Comprehensive Repair Guide

In the world of sewing, having a comprehensive guide to understanding and fixing your equipment can significantly enhance your crafting experience. Whether you are a seasoned enthusiast or just starting out, knowing how to address common issues can save time and frustration. This section aims to equip you with essential knowledge and practical tips to keep your sewing companion in optimal condition.

By exploring various troubleshooting techniques, you can become more adept at identifying problems and implementing solutions effectively. From minor adjustments to more involved maintenance tasks, a clear understanding of your device’s components will empower you to take control of your sewing projects.

Additionally, this resource will provide insights into regular upkeep practices that help prolong the lifespan of your machine. Mastering these skills not only boosts your confidence but also ensures that your creative endeavors continue smoothly, enabling you to focus on what truly matters: bringing your imaginative designs to life.

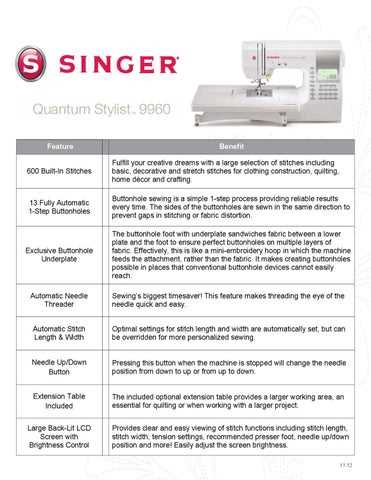

Overview and Features

This section provides a comprehensive look at a high-performance sewing machine known for its versatility and advanced capabilities. It is designed to meet the needs of both beginners and experienced users, offering a wide range of functions that enhance creativity and efficiency.

Key Characteristics

The machine features a variety of stitch options, allowing for intricate designs and professional finishes. Its automatic threading system and adjustable speed control contribute to a user-friendly experience, making it suitable for various fabric types.

Innovative Technologies

Incorporating modern technology, this device includes a built-in LCD screen for easy navigation and selection of settings. The addition of programmable functions allows for customized sewing patterns, elevating the crafting process to new heights.

Common Issues with Singer 9960

Every complex machine can encounter a variety of challenges over time. Users of advanced stitching devices often report specific difficulties that can hinder performance. Understanding these common problems can help in troubleshooting and maintaining optimal functionality.

Frequent Problems

- Thread Tension Issues: Uneven stitching may result from incorrect thread tension, leading to loose or tight stitches.

- Needle Breakage: Frequent needle breakage can occur due to using the wrong needle type or improper installation.

- Bobbin Problems: A poorly wound bobbin can cause skipping stitches or thread jams.

- Motor Malfunctions: Unresponsive foot pedals or motor failure can prevent the machine from operating correctly.

Preventive Measures

- Regularly check and adjust the thread tension settings.

- Use the appropriate needle for the fabric type being sewn.

- Ensure bobbins are wound evenly and properly placed.

- Keep the machine clean and lubricated to avoid motor issues.

Essential Tools for Repair

When it comes to maintaining and fixing your sewing machine, having the right set of instruments is crucial. These tools not only facilitate effective troubleshooting but also ensure that any adjustments made are precise and reliable. Investing in quality equipment can significantly enhance the overall performance of your device.

Basic Screwdrivers: A set of screwdrivers in various sizes is indispensable. They are needed to access internal components and to secure screws properly, ensuring everything remains in place.

Wrenches: A good pair of wrenches allows for easy tightening and loosening of bolts. This is particularly useful when changing or aligning parts that may require adjustment.

Cleaning Supplies: Keeping your equipment clean is vital for its longevity. A small brush, lint-free cloths, and specialized cleaning solutions help remove dust and debris from intricate areas.

Lubricants: Proper lubrication is key to smooth operation. A high-quality oil specifically designed for sewing machines ensures that moving parts function effortlessly.

Needle and Thread Set: Having a variety of needles and threads on hand allows for quick replacements and ensures that you can handle different fabrics and projects with ease.

By equipping yourself with these essential instruments, you will be well-prepared to tackle any issues that arise, ultimately prolonging the life of your sewing device and enhancing your crafting experience.

Step-by-Step Troubleshooting Guide

This section provides a comprehensive approach to identifying and resolving common issues encountered with your sewing device. By following a systematic process, you can effectively diagnose problems and restore functionality with ease.

Common Issues and Solutions

| Issue | Possible Cause | Solution |

|---|---|---|

| Machine won’t start | Power source disconnected | Check the power cord and outlet; ensure connections are secure. |

| Thread jams frequently | Incorrect threading | Re-thread the upper and bobbin threads according to the manual. |

| Stitches are uneven | Improper tension settings | Adjust the tension dial until the stitches are balanced. |

| Machine makes unusual noises | Lack of lubrication | Apply sewing machine oil to the moving parts as recommended. |

Final Checks

After performing the above steps, conduct a test run with scrap fabric to ensure that all adjustments have resolved the issues. If problems persist, consulting a professional may be necessary for further assistance.

Maintaining Your Sewing Machine

Proper upkeep of your stitching device is essential for optimal performance and longevity. Regular maintenance not only enhances the efficiency of the machine but also prevents potential issues that could arise from neglect. By following a few straightforward practices, you can ensure that your equipment remains in excellent working condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Cleaning | After each use | Remove dust and lint from the exterior and interior components to prevent buildup. |

| Oiling | Monthly | Apply appropriate lubricants to moving parts to ensure smooth operation. |

| Needle Replacement | Every 6-8 hours of sewing | Change the needle regularly to avoid fabric damage and ensure clean stitches. |

| Thread Tension Check | Every project | Adjust the tension settings as needed to achieve the desired stitch quality. |

| Professional Servicing | Annually | Consider having a technician inspect and service your device for comprehensive maintenance. |

By adhering to these guidelines, you will not only prolong the lifespan of your equipment but also enhance your overall sewing experience.

Replacing Parts on Singer 9960

Maintaining your sewing machine involves the occasional need to swap out worn or damaged components. This process not only enhances the machine’s performance but also extends its lifespan. Understanding how to effectively replace parts is essential for ensuring optimal functionality and reliability.

Before starting the replacement process, gather the necessary tools, such as screwdrivers and pliers, to facilitate a smooth operation. Always ensure the device is unplugged to avoid any accidental activation. Refer to the specific component guidelines to identify which parts may need replacement, including the needle, presser foot, or bobbin case.

Carefully remove the existing part by loosening any screws or fasteners. Take note of the arrangement and orientation to ensure proper installation of the new component. Once the old part is removed, align the new piece correctly and secure it in place. After replacement, perform a test run to confirm that everything is functioning correctly.

Regular inspections and timely replacements will keep your machine in top shape, allowing you to enjoy seamless sewing experiences. Remember, proper maintenance is key to preserving the quality of your work.

Frequently Asked Questions

This section addresses common inquiries related to maintenance and troubleshooting of sewing devices. Here, users can find helpful answers to typical concerns, enhancing their understanding and improving their experience.

Common Issues and Solutions

- Why is my machine not stitching properly?

- Check if the needle is correctly installed and not damaged.

- Ensure that the thread is threaded correctly through the machine.

- Examine the bobbin for proper placement and tension.

- What should I do if the fabric is not feeding?

- Make sure the presser foot is lowered.

- Inspect the feed dogs to confirm they are functioning.

- Adjust the fabric thickness setting as needed.

Maintenance Tips

- Regularly clean the machine to remove lint and debris.

- Oil moving parts as specified in the guidelines to ensure smooth operation.

- Perform a tension adjustment if stitches appear loose or too tight.

Resources for Further Assistance

When encountering difficulties with your device, it’s essential to know where to seek help. A variety of resources are available that can provide guidance and support for troubleshooting and maintenance. These options can help you resolve issues efficiently and enhance your experience.

Online Forums and Communities

- Explore dedicated websites where users share their experiences and solutions.

- Join social media groups focused on your specific model for real-time assistance.

- Participate in discussions to learn from others who have faced similar challenges.

Official Support Channels

- Visit the manufacturer’s official website for detailed information and updates.

- Contact customer service for personalized help with your device.

- Access instructional videos and articles designed to assist users.

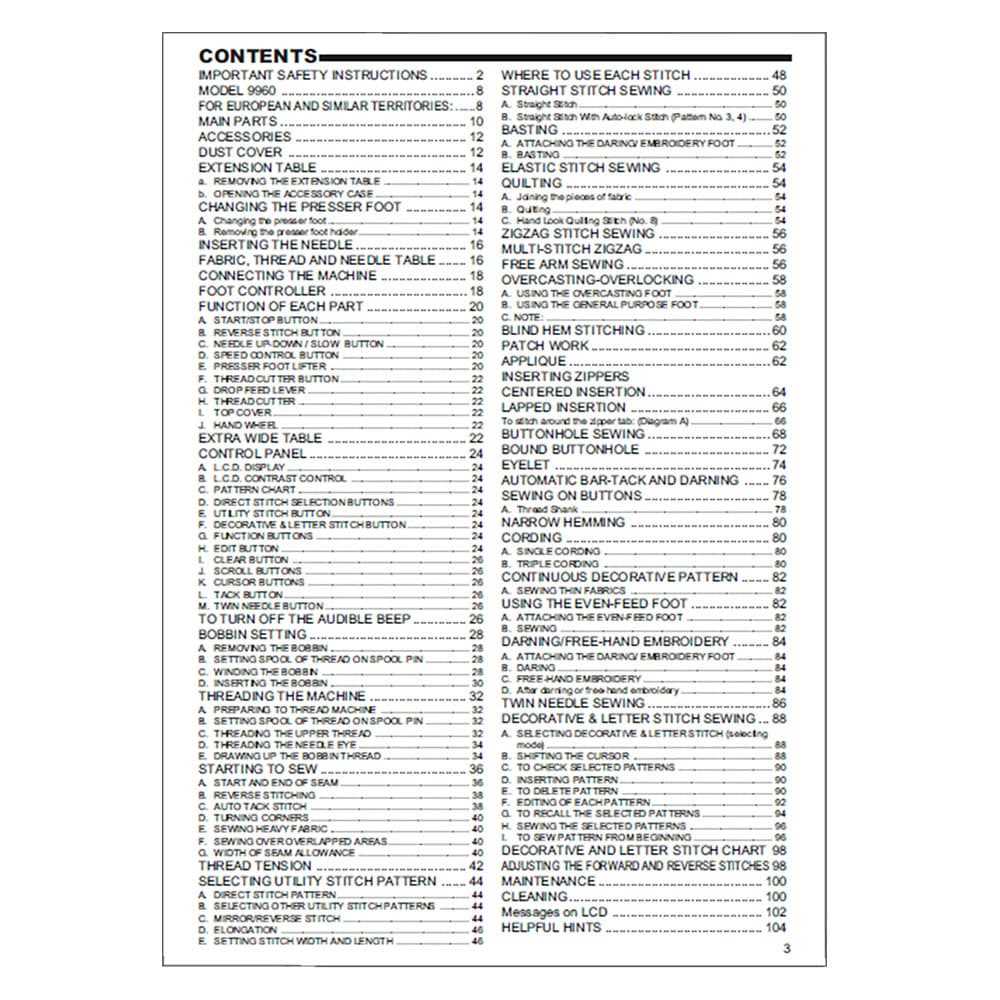

Understanding the User Manual

The guide serves as an essential resource for users, providing detailed information about operation, features, and maintenance of the device. A well-structured document enables users to navigate through functionalities efficiently, ensuring they can maximize the benefits of their equipment.

Familiarization with the layout of the document is crucial. Typically, it includes sections on setup, troubleshooting, and care instructions. Each segment is designed to address common queries and offer step-by-step guidance, making it easier for users to resolve issues independently.

Moreover, the inclusion of diagrams and illustrations enhances comprehension, allowing users to visualize procedures. Key terms are often highlighted, aiding quick reference during usage. Understanding these elements can significantly improve the user experience, fostering confidence in handling the device effectively.

Safety Precautions During Repairs

Ensuring safety is paramount when undertaking maintenance tasks on electronic devices. Adhering to specific guidelines not only protects the individual performing the work but also safeguards the equipment from potential damage.

Before commencing any servicing, consider the following essential precautions:

- Disconnect Power: Always unplug the device from its power source to prevent electrical shock or short circuits.

- Use Proper Tools: Employ the correct tools for the job to minimize the risk of injury and avoid damaging components.

- Wear Protective Gear: Utilize safety glasses and gloves to protect against sharp edges and flying debris.

- Work in a Well-Lit Area: Ensure your workspace is adequately illuminated to enhance visibility and reduce errors.

- Follow Manufacturer Guidelines: Reference any provided instructions to maintain proper procedures during the process.

By observing these safety measures, individuals can contribute to a more secure and effective environment while handling maintenance tasks on electronic devices.