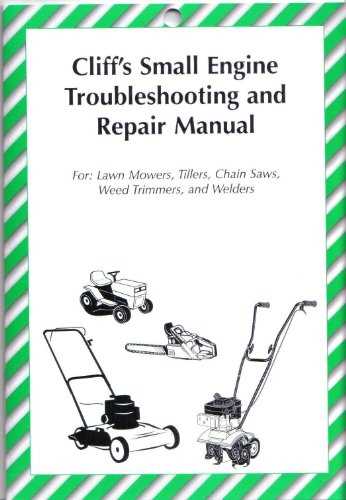

Comprehensive Guide to Small Motor Repairs

This section aims to provide essential information for those interested in maintaining and troubleshooting compact power units. Understanding the nuances of these devices can significantly enhance their performance and longevity.

Throughout this guide, you will find valuable insights and techniques for addressing common issues that may arise. Whether you are a novice or have some experience, the practical tips and methods outlined here will equip you with the knowledge needed to ensure optimal functionality.

Regular maintenance is crucial for preventing potential problems and ensuring that your equipment operates smoothly. By following the guidelines presented, you can effectively manage the care of your unit and tackle any challenges that may come your way.

Understanding Small Motor Components

Grasping the intricacies of compact engines requires familiarity with their essential parts and their functions. Each element plays a crucial role in the overall operation, ensuring efficiency and reliability.

The Power Source serves as the heart of the device, providing the necessary energy for movement. It typically operates on various fuel types or electricity, depending on the design.

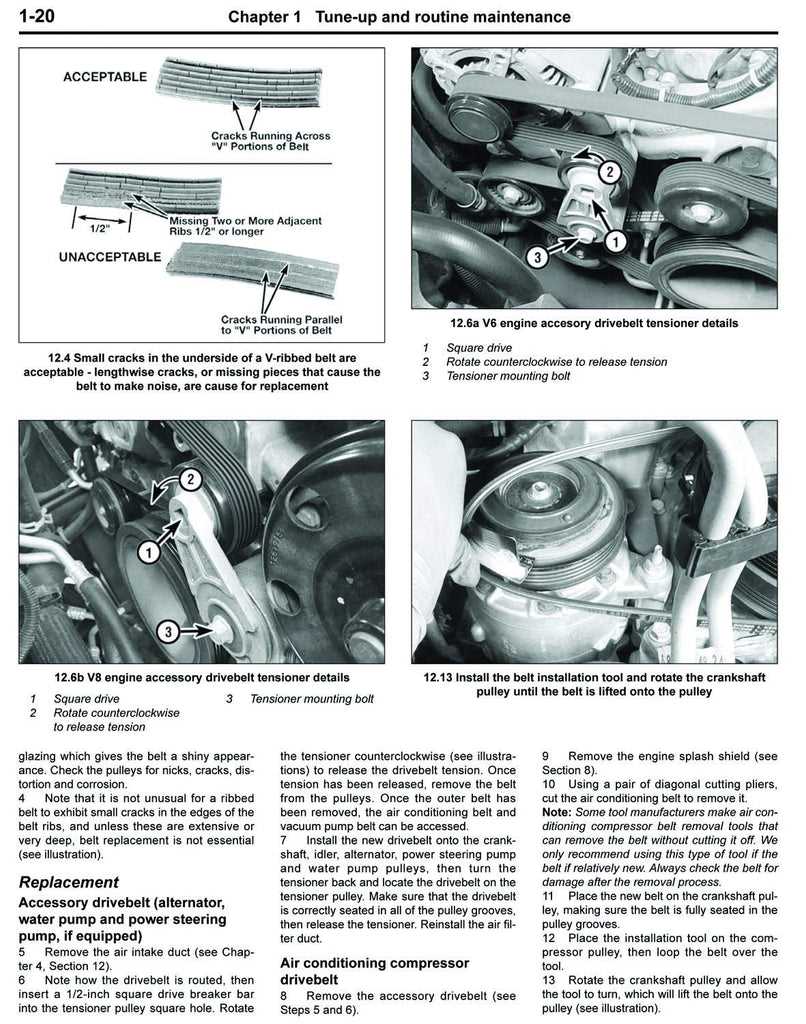

The Transmission System connects the power source to the working components, facilitating the transfer of energy. This system often includes gears and belts, which adjust speed and torque to optimize performance.

The Control Mechanism allows the operator to manage the device effectively. It can involve levers, buttons, or digital interfaces, providing intuitive access to different settings and functions.

Cooling and Lubrication Systems are vital for maintaining optimal operating temperatures and reducing friction among moving parts. These systems help prolong the lifespan of the device and enhance its efficiency.

By understanding these fundamental elements, individuals can better appreciate how compact engines operate and identify areas that may require attention during maintenance or troubleshooting.

Common Issues with Small Motors

Understanding frequent complications associated with compact engines is crucial for effective maintenance and longevity. Various factors can contribute to performance problems, including wear and tear, environmental conditions, and improper usage. Identifying these issues early can prevent more severe damage and ensure smooth operation.

Below is a table outlining typical challenges encountered with compact engines, along with possible symptoms and suggested solutions:

| Issue | Symptoms | Suggested Solutions |

|---|---|---|

| Overheating | Unusual noises, smoke, reduced power | Check cooling system, ensure proper lubrication, and inspect airflow. |

| Starting difficulties | Engine cranks slowly, fails to ignite | Examine battery condition, inspect spark plugs, and clean fuel lines. |

| Vibrations | Excessive shaking, unstable operation | Inspect mounting and alignment, check for wear on components. |

| Fuel leaks | Visible fuel stains, strong odor | Check hoses and connections for cracks, replace damaged parts. |

| Loss of power | Reduced acceleration, difficulty maintaining speed | Inspect air filter, clean carburetor, and check fuel quality. |

Tools Required for Repairs

Having the right instruments is essential for effectively addressing any issues that may arise with your device. Proper tools not only facilitate the process but also ensure a high-quality outcome. Below is a list of essential items that you will need to get started.

- Screwdrivers: A set of various sizes, including flathead and Phillips, is crucial for removing and securing fasteners.

- Wrenches: Adjustable and socket wrenches will help you tackle different nuts and bolts with ease.

- Pliers: Needle-nose and standard pliers are useful for gripping and manipulating components.

- Multimeter: This tool is essential for measuring voltage, current, and resistance, allowing you to diagnose electrical issues.

- Wire Strippers: Necessary for preparing wires for connections and repairs.

- Heat Gun: Useful for shrinking tubing and loosening adhesive materials.

- Work Surface: A clean, flat area to organize your tools and components is vital for efficiency and safety.

Ensure you have these instruments on hand before beginning any tasks. Being well-prepared will make the process smoother and more effective.

Step-by-Step Repair Process

This section provides a comprehensive approach to fixing issues systematically. By following these structured steps, you can efficiently diagnose and resolve problems, ensuring the device functions optimally.

Preparation

- Gather necessary tools and materials.

- Ensure a clean, organized workspace.

- Review the specific challenges associated with the unit.

Diagnosis

- Inspect the device for visible signs of damage.

- Test components individually to identify malfunctioning parts.

- Document findings for reference during the fixing process.

By adhering to this structured approach, you can streamline the fixing process and enhance the performance of the equipment.

Maintaining Small Motors Effectively

Proper upkeep of compact machinery is essential for ensuring optimal performance and longevity. Regular attention to specific components not only enhances functionality but also prevents costly breakdowns. This section highlights key practices for sustaining these devices in peak condition.

| Maintenance Task | Frequency | Description |

|---|---|---|

| Cleaning | Every 30 hours | Remove dust and debris from exterior surfaces to prevent overheating. |

| Lubrication | Every 50 hours | Apply appropriate lubricants to moving parts to reduce friction. |

| Inspection | Monthly | Check for wear and tear on components, replacing any damaged parts. |

| Air Filter Check | Every 20 hours | Ensure the air filter is clean to maintain optimal airflow. |

| Fuel Quality | Regularly | Use fresh fuel to avoid starting issues and engine performance problems. |

Diagnosing Electrical Problems

Identifying issues related to electrical systems requires a systematic approach. Understanding the various components involved and their functions is essential for effective troubleshooting. This section will guide you through the key steps to pinpoint and resolve electrical malfunctions.

Common Symptoms of Electrical Failures

Typical signs of electrical issues include unusual noises, inconsistent power supply, and failure to start. Noticing these symptoms early can prevent more significant complications. Pay close attention to any irregular behavior, as it often indicates underlying problems.

Steps for Effective Diagnosis

Begin by inspecting the wiring for signs of wear or damage. Use a multimeter to check for continuity and voltage levels in various components. Ensuring connections are secure is crucial, as loose or corroded terminals can lead to performance issues. Documenting your findings will help track progress and identify persistent issues more effectively.

Reassembling After Repairs

This section focuses on the essential steps required to correctly reassemble components following maintenance or service work. Properly returning parts to their original configuration is crucial for ensuring optimal functionality and performance.

Before starting the reassembly process, it is important to prepare adequately. Follow these guidelines:

- Gather all necessary tools and components.

- Review any documentation or notes made during disassembly.

- Ensure all parts are clean and free of debris.

When reassembling, follow these steps to ensure accuracy:

- Begin by placing the main components in their designated positions.

- Secure each part using appropriate fasteners, making sure they are tightened to the specified torque values.

- Reconnect any wiring or hoses, ensuring proper alignment and routing.

- Double-check the placement of all elements to avoid future issues.

After everything is in place, conduct a final inspection to confirm that all parts are properly assembled and secured. This thorough approach will help prevent complications during operation.

Testing Motor Performance

Evaluating the efficiency and functionality of a compact engine is essential for ensuring optimal operation. This process involves a series of assessments that help identify any issues affecting performance. By conducting thorough examinations, one can determine the overall condition and reliability of the unit.

The initial step in the evaluation is to verify the power output, which can be measured using specialized tools. This will provide a clear indication of whether the engine is operating within its expected parameters. Additionally, analyzing the response time under varying loads can reveal how well the engine adapts to different conditions.

Moreover, monitoring temperature fluctuations during operation is crucial. Excessive heat may indicate underlying problems that need to be addressed promptly. Regularly checking the vibrations produced can also highlight any irregularities in operation, serving as an early warning sign of potential failure.

Finally, maintaining a record of these tests over time will allow for a comprehensive understanding of performance trends, facilitating proactive maintenance and ensuring long-lasting functionality.

Safety Precautions During Repairs

When engaging in the maintenance of mechanical devices, it is essential to prioritize personal safety and the integrity of the equipment. Understanding the inherent risks and implementing protective measures can prevent accidents and ensure a smooth process.

- Always wear appropriate personal protective equipment (PPE), such as gloves and safety goggles, to shield against potential hazards.

- Ensure the workspace is well-ventilated to avoid inhaling harmful fumes or dust particles.

- Disconnect power sources before beginning any task to prevent unintentional activation.

- Keep tools organized and within reach to minimize the risk of accidents during the process.

Furthermore, it is advisable to read the relevant guidelines and familiarize oneself with the specific characteristics of the device being handled. This knowledge can significantly enhance safety and efficiency.

- Maintain a clean and clutter-free workspace to reduce the risk of slips and falls.

- Do not attempt to work on equipment that is damaged or unstable.

- Seek assistance when needed, especially for tasks that require significant strength or expertise.

By adhering to these safety practices, individuals can create a secure environment that promotes effective maintenance and minimizes the likelihood of injuries.

When to Seek Professional Help

Understanding when to call in an expert can save time, money, and frustration. Certain situations indicate that the issue may be beyond basic troubleshooting or maintenance. Recognizing these signs is essential for ensuring optimal functionality and safety.

Common Indicators for Professional Assistance

Look for these warning signs that suggest it’s time to seek outside expertise:

| Indicator | Description |

|---|---|

| Persistent Issues | Problems that reoccur despite attempts to fix them often require expert intervention. |

| Unusual Sounds | Strange noises can signal underlying issues that need a professional assessment. |

| Performance Decline | Notable decreases in efficiency or power typically necessitate a specialist’s evaluation. |

Safety Considerations

In some cases, attempting to address issues without adequate knowledge can pose safety risks. If there’s a chance of harm or if the device operates in a sensitive environment, it’s wise to consult a qualified technician.