Comprehensive Repair Guide for Stihl 031 AV Chainsaw

In the realm of outdoor power tools, effective upkeep is crucial for ensuring longevity and optimal performance. This guide is designed to provide enthusiasts and users with essential insights into the intricacies of maintaining their equipment. By understanding the underlying mechanics and common issues, one can enhance the reliability and efficiency of their machinery.

Whether you’re a seasoned professional or a casual user, navigating the complexities of tool care can be daunting. This resource aims to demystify the processes involved in ensuring that your equipment operates smoothly. Through systematic troubleshooting and preventive measures, you’ll gain the confidence to tackle any challenges that may arise.

Empower yourself with knowledge that not only saves time and money but also fosters a deeper connection with your tools. Armed with the right information, you’ll be well-prepared to keep your equipment running at peak performance, ready for any task that lies ahead.

Understanding the Stihl 031 AV Chainsaw

This section aims to provide a comprehensive overview of a well-known power tool designed for cutting and logging tasks. Its robust construction and efficient design make it a favored choice among both professionals and enthusiasts. By delving into its features, operation, and maintenance, users can enhance their familiarity and effectiveness with this invaluable piece of equipment.

The chainsaw’s performance is attributed to several key components that work in harmony to deliver optimal results. Understanding these elements is crucial for maximizing efficiency and ensuring longevity.

| Feature | Description |

|---|---|

| Engine Type | Powerful two-stroke engine designed for high performance and durability. |

| Weight | Lightweight construction for easy maneuverability during use. |

| Bar Length | Available in various lengths to accommodate different cutting needs. |

| Vibration Control | Integrated system to minimize operator fatigue and enhance comfort. |

| Safety Features | Equipped with chain brake and throttle lock for user protection. |

Proper operation and routine upkeep are vital for maintaining performance and safety. Understanding how to care for this tool will ensure it remains a reliable companion in various cutting applications.

Common Issues with Stihl 031 AV

When operating a chainsaw, various challenges may arise that can hinder performance and efficiency. Understanding these common problems is essential for ensuring smooth operation and longevity of the equipment. This section explores frequent malfunctions that users encounter, providing insight into troubleshooting and maintenance.

Typical Problems

Owners often report a range of issues, from starting difficulties to operational inconsistencies. Identifying the root causes can help in addressing these concerns effectively.

| Issue | Description | Possible Solutions |

|---|---|---|

| Difficulty Starting | The engine may not ignite easily. | Check the fuel mixture and ignition system. |

| Loss of Power | Inadequate cutting power during operation. | Inspect the air filter and carburetor settings. |

| Excessive Vibration | Unusual shaking during use. | Examine the chain tension and bar alignment. |

| Chain Stopping | The chain may frequently halt during cutting. | Ensure proper lubrication and chain tension. |

Preventive Measures

Regular maintenance is vital in preventing these issues. Cleaning components, checking fuel quality, and ensuring proper storage can greatly enhance the reliability of the tool.

Essential Tools for Repair

When it comes to maintaining and fixing outdoor equipment, having the right set of instruments is crucial. These tools not only ensure efficiency but also enhance safety during the maintenance process. A well-equipped toolkit can significantly simplify tasks and extend the lifespan of your machinery.

Basic Tools Required

Understanding the fundamental tools can help you tackle most issues effectively. Below is a list of essential items that every technician should have on hand:

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening and tightening screws of various sizes. |

| Wrench Set | Essential for gripping and turning nuts and bolts. |

| Pliers | Helpful for gripping, twisting, and cutting wires. |

| Socket Set | Allows for easier access to fasteners in tight spaces. |

| Torque Wrench | Ensures fasteners are tightened to the correct specifications. |

Advanced Instruments for Complex Issues

For more intricate tasks, certain advanced tools may be necessary. These instruments can help diagnose and resolve more challenging problems effectively:

| Tool | Purpose |

|---|---|

| Multimeter | Measures voltage, current, and resistance in electrical components. |

| Fuel Pressure Gauge | Checks the pressure in the fuel system to ensure proper function. |

| Compression Tester | Evaluates the compression in the engine cylinders. |

| Inspection Camera | Allows for visual inspection of hard-to-reach areas. |

| Cleaning Kits | Helps maintain and clean components for optimal performance. |

Step-by-Step Disassembly Guide

This section provides a detailed procedure for dismantling a specific type of outdoor power equipment. Following these instructions will help ensure that each component is removed safely and efficiently, allowing for effective maintenance or part replacement. Careful attention to each step is essential to avoid damage and ensure proper reassembly later on.

Tools Required

- Screwdriver set (flat and Phillips)

- Wrench set

- Pliers

- Clean cloth

- Container for small parts

Disassembly Steps

- Begin by disconnecting the spark plug wire to prevent accidental starts.

- Remove the housing cover by unscrewing the screws located on the sides.

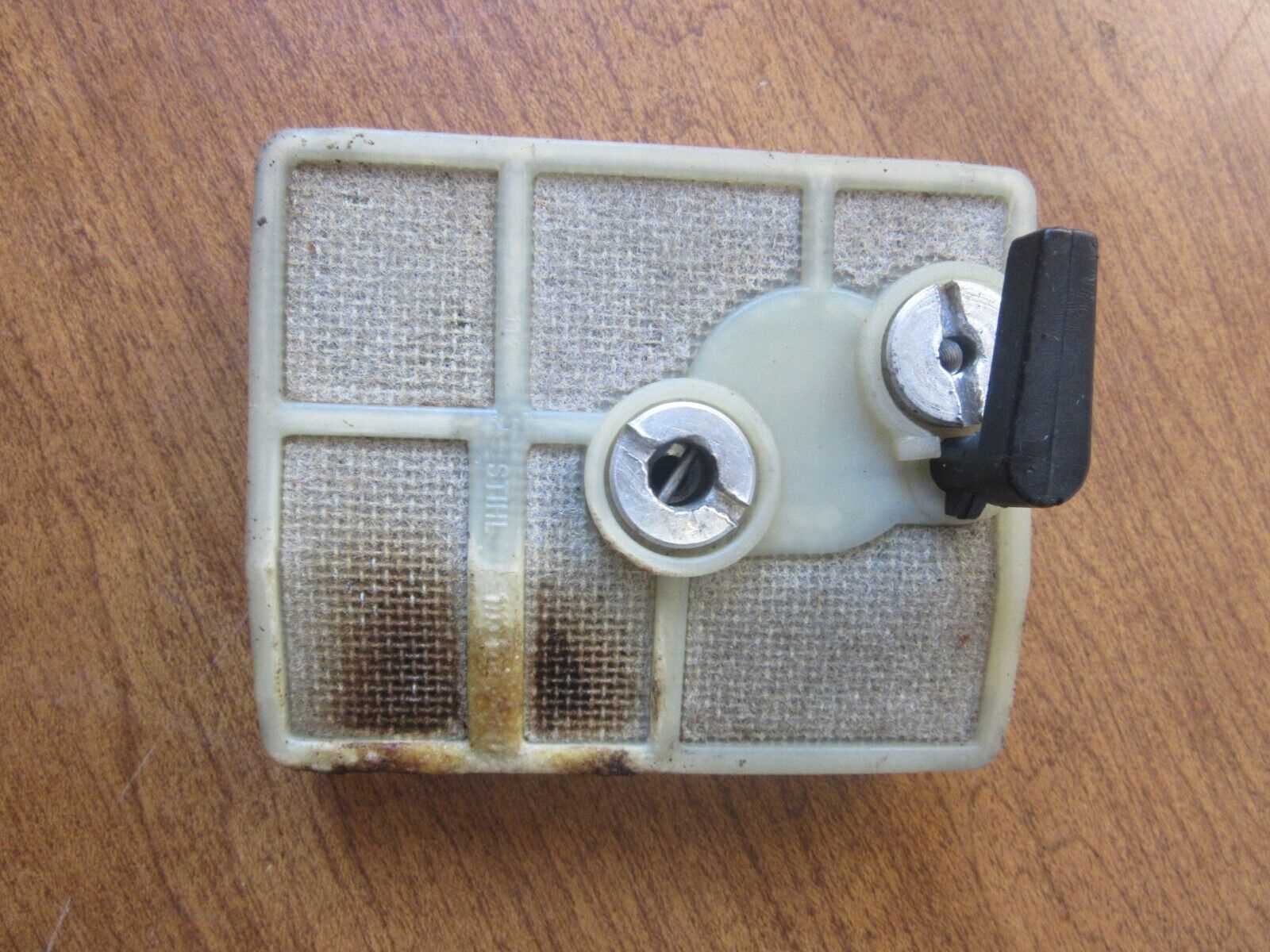

- Carefully take out the air filter, ensuring no debris enters the intake.

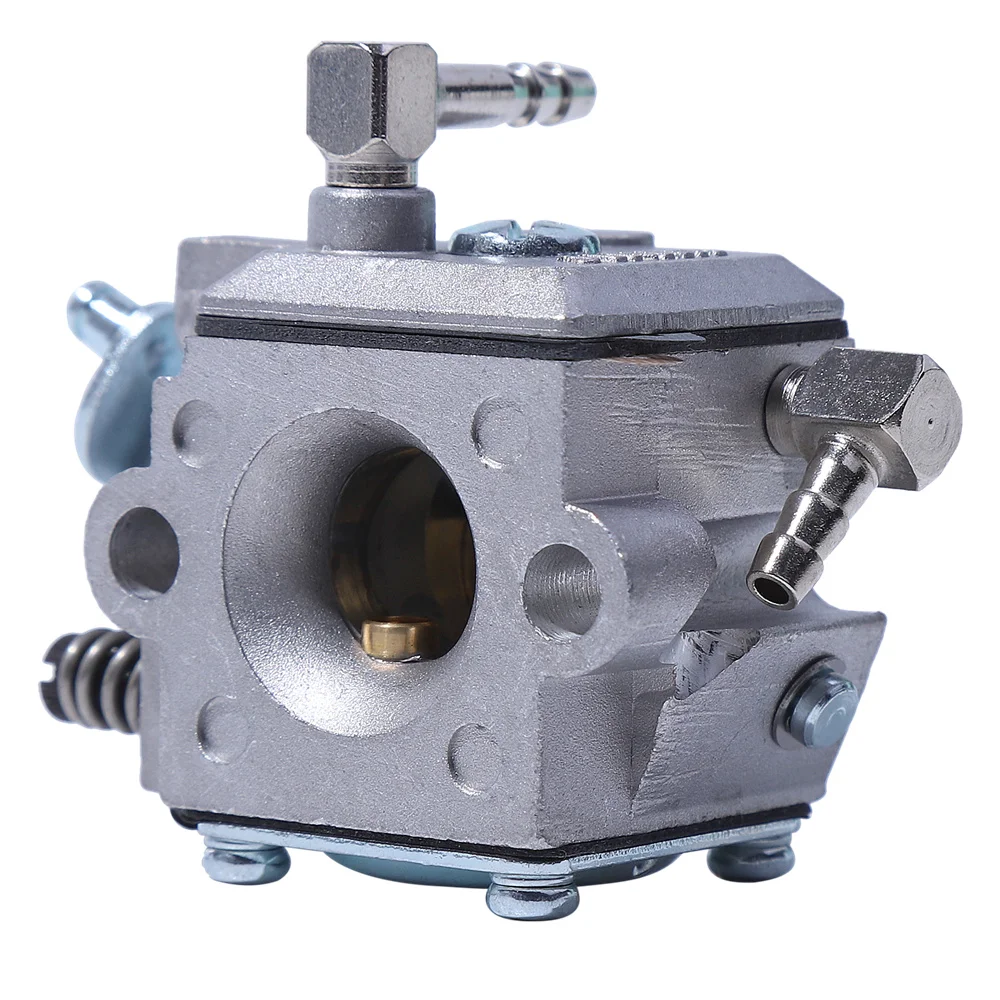

- Unscrew and detach the carburetor, noting any gaskets that may need replacement.

- Disconnect the fuel lines, taking care to catch any residual fuel in a container.

- Remove the starter assembly by unscrewing the retaining screws.

- Finally, detach the ignition module, ensuring all connections are noted for reassembly.

With these steps completed, you should have successfully disassembled the equipment. Ensure that all parts are stored safely for reinstallation or further inspection.

Identifying Engine Problems

Recognizing issues within an engine is crucial for maintaining its performance and longevity. By observing specific symptoms and understanding their implications, users can address potential malfunctions before they escalate into more severe complications. The following guide outlines common indicators of engine trouble and provides a framework for assessment.

| Symptom | Possible Causes | Recommended Actions |

|---|---|---|

| Difficulty starting | Fuel delivery issues, battery problems | Check fuel levels, inspect battery connections |

| Excessive smoke | Oil leaks, fuel mixture problems | Examine seals, adjust fuel settings |

| Unusual noises | Loose components, worn parts | Tighten bolts, replace damaged elements |

| Overheating | Cooling system failures, blocked airflow | Inspect coolant levels, clear vents |

| Reduced power | Clogged filters, engine wear | Clean or replace filters, check compression |

By systematically evaluating these symptoms, users can pinpoint issues effectively, ensuring the engine operates smoothly and reliably over time.

Fuel System Maintenance Tips

Proper upkeep of the fuel system is crucial for the efficient operation of outdoor power equipment. Regular attention ensures optimal performance, reduces the risk of malfunctions, and prolongs the lifespan of your machinery.

Here are some essential practices to maintain the fuel system:

- Regular Inspection: Routinely check fuel lines and connections for any signs of wear or leaks.

- Use Fresh Fuel: Always use fresh fuel to prevent issues caused by stale or contaminated gasoline.

- Clean Fuel Filter: Periodically clean or replace the fuel filter to ensure unobstructed fuel flow.

- Inspect the Fuel Tank: Keep the fuel tank clean and free from debris or contaminants.

- Proper Fuel Mixture: Follow the manufacturer’s guidelines for fuel-to-oil ratios, ensuring the correct mixture for two-stroke engines.

Implementing these maintenance tips can help avoid costly repairs and ensure that your equipment runs smoothly. Regular care is key to reliable performance and longevity.

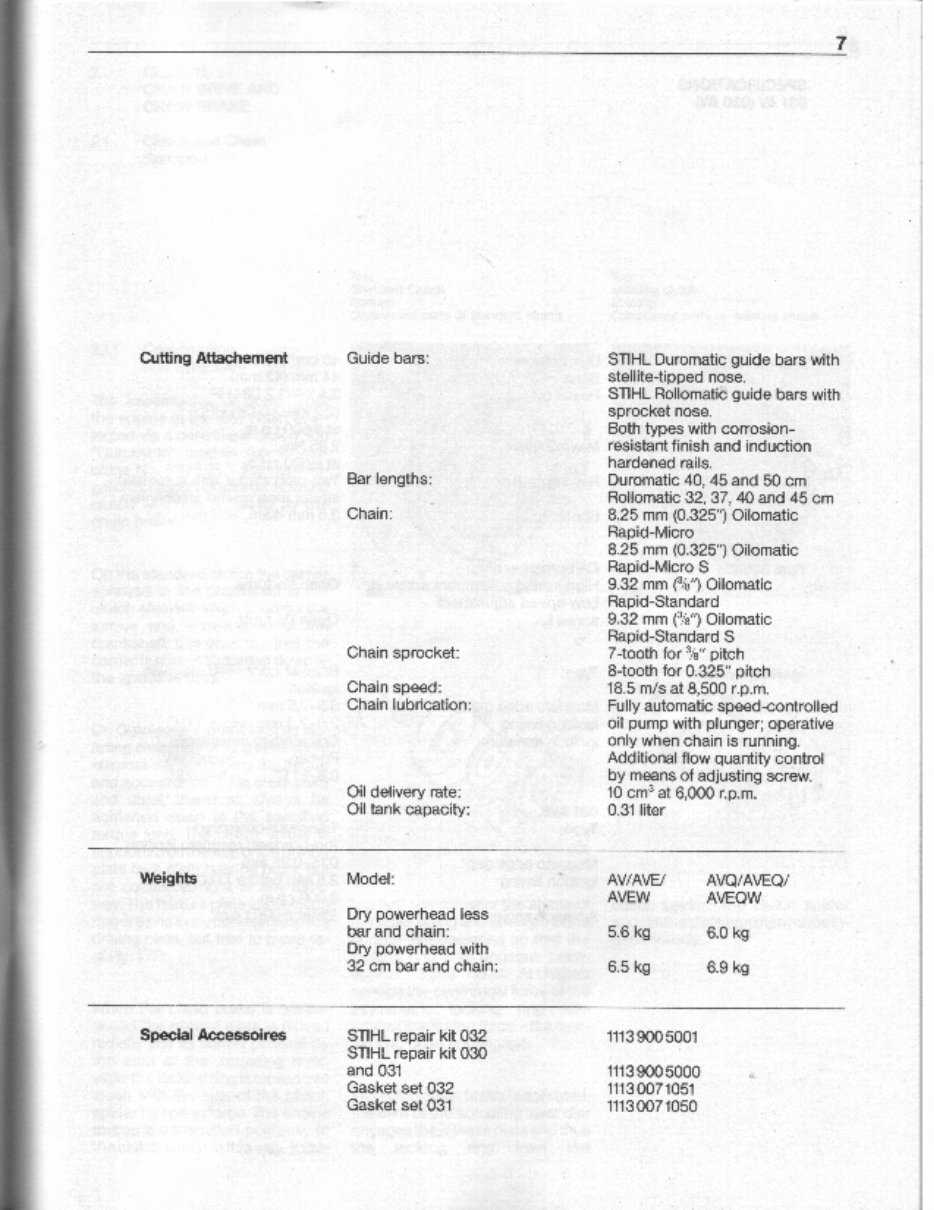

Chain and Bar Adjustments Explained

Maintaining optimal performance in cutting equipment requires careful attention to the chain and bar settings. Proper adjustments ensure efficiency, prolong tool lifespan, and enhance safety during operation. This section delves into the essential aspects of managing these components for peak functionality.

Chain Tension is critical for effective cutting. An overly tight chain can cause excessive wear on both the chain and the bar, while a loose chain may derail during use, posing a safety risk. To achieve the right tension, it is essential to adjust the tensioning mechanism until the chain can be lifted slightly from the bar but still maintains contact.

Bar Alignment also plays a significant role in performance. A misaligned bar can lead to uneven wear and inefficient cutting. Ensure that the bar is properly seated in its mounting area and that the guide rails are parallel to the cutting path. Regularly check for wear or damage to the bar, and replace it if necessary to maintain optimal cutting efficiency.

Lubrication of the chain and bar is another vital factor in maintaining performance. A well-lubricated chain reduces friction, minimizes wear, and helps prevent overheating. Always check the oil reservoir and ensure that the lubrication system is functioning correctly before use.

In summary, regular checks and adjustments of the chain tension, bar alignment, and lubrication are essential practices that enhance the effectiveness and safety of cutting equipment. Adhering to these guidelines will contribute to a smoother and more efficient cutting experience.

Electrical Components Troubleshooting

Troubleshooting electrical components is crucial for ensuring the optimal performance of power tools. Identifying issues within the electrical system can prevent further damage and enhance longevity. This section will guide you through the essential steps to diagnose and address common electrical faults.

Begin by inspecting the power source. Check for any visible damage to the plug or cord, as frayed wires can lead to inadequate power supply. If the tool does not power on, testing the outlet with a multimeter can determine if it is functioning correctly.

Next, examine the switch. A faulty switch may cause intermittent power or total failure. Use a multimeter to check for continuity. If no continuity is detected, replacement of the switch is necessary.

Moving on to the motor. Listen for unusual noises during operation, which could indicate internal issues. Checking the motor’s windings for shorts can also reveal potential problems. If the motor is overheating, inspect the ventilation to ensure it is not obstructed.

Lastly, evaluate any electronic components. Circuit boards and sensors may fail over time. Look for burnt traces or loose connections. Testing these components individually can help pinpoint the source of malfunction.

By systematically checking these elements, you can effectively troubleshoot electrical issues and restore functionality.

Reassembling Your Chainsaw Safely

Proper assembly of your cutting tool is crucial for both performance and safety. Ensuring that all components are correctly aligned and securely fastened can prevent accidents and enhance the longevity of your equipment. This section provides essential guidelines for reassembling your chainsaw, focusing on safety and efficiency.

Essential Safety Tips

- Always wear protective gear, including gloves and goggles, to safeguard against sharp parts.

- Work in a clean, well-lit area to avoid losing small components.

- Double-check that the chainsaw is powered off and unplugged before starting the assembly.

Step-by-Step Reassembly Process

- Begin by laying out all parts systematically to ensure nothing is missing.

- Refer to your documentation for correct assembly order and torque specifications.

- Securely attach the chain and bar, ensuring the tension is appropriate for optimal cutting performance.

- Reinstall the air filter and cover, making sure they fit snugly.

- Reconnect any electrical components, confirming that all connections are secure.

- Finish by checking all screws and bolts for tightness before powering on the tool.

Following these guidelines will help you reassemble your cutting equipment safely, ensuring it operates efficiently and effectively.

Preventive Maintenance Practices

Regular upkeep of equipment is essential for ensuring optimal performance and longevity. Implementing systematic practices not only reduces the likelihood of unexpected failures but also enhances overall efficiency. By adopting a proactive approach, users can minimize downtime and maintain their tools in peak condition.

Routine Inspection: Conducting frequent checks on key components is vital. Look for signs of wear, damage, or any irregularities. Addressing minor issues early can prevent more significant problems down the line.

Cleaning: Keeping the equipment clean is crucial for preventing buildup that can hinder functionality. After each use, remove debris and contaminants to ensure smooth operation. Regular cleaning of air filters and cooling systems helps maintain airflow and temperature regulation.

Lubrication: Proper lubrication of moving parts reduces friction and wear. Use the recommended lubricants and apply them according to the manufacturer’s guidelines. Regular lubrication helps in extending the lifespan of components.

Storage: How equipment is stored significantly impacts its condition. Store tools in a dry, cool place to avoid rust and degradation. Cover them to protect against dust and moisture, ensuring they remain in good working order.

Replacement of Wear Parts: Some components have a limited lifespan and should be replaced periodically. Stay informed about which parts are prone to wear and establish a replacement schedule to avoid any operational disruptions.

By adhering to these preventive practices, users can ensure that their equipment remains reliable and efficient, ultimately enhancing productivity and reducing long-term costs.

Upgrading Parts for Performance

Enhancing the efficiency and power of your equipment can significantly improve its overall functionality. By selecting the right components, you can achieve better performance, increased durability, and a more enjoyable user experience. This section explores various options for upgrading essential parts to maximize output and reliability.

Air Filters: Replacing standard air filters with high-performance variants can improve airflow and boost engine efficiency. A cleaner intake system allows for better combustion, resulting in enhanced power and reduced fuel consumption.

Fuel System Modifications: Upgrading to a high-flow fuel pump and high-quality fuel lines can ensure a consistent fuel supply under heavy loads. Additionally, using a performance carburetor can optimize fuel-air mixtures, enhancing acceleration and throttle response.

Exhaust Systems: Switching to a performance exhaust can significantly reduce back pressure and improve exhaust flow. This modification not only increases power output but can also lead to a more pleasing sound during operation.

Ignition Components: Installing a high-performance ignition system can result in more efficient spark generation. This leads to smoother starts and better overall engine performance, especially under demanding conditions.

By carefully selecting and upgrading these components, users can transform their machinery into more powerful, efficient tools, capable of tackling even the toughest tasks with ease.

Finding Replacement Parts Easily

Locating suitable components for your equipment can significantly enhance its performance and longevity. Ensuring you have the right parts not only aids in maintenance but also boosts efficiency. Here are some effective strategies to streamline your search for necessary items.

Utilizing Online Resources

- Check manufacturer websites for specific part numbers and availability.

- Explore online marketplaces where users frequently list spare components.

- Join forums or social media groups dedicated to enthusiasts of similar machinery.

Local Suppliers and Workshops

- Visit local hardware stores that specialize in outdoor equipment.

- Establish relationships with repair shops; they often have connections for sourcing parts.

- Attend community events or expos where vendors display their products and services.

By leveraging these resources, you can simplify the process of finding the right components, ensuring your equipment remains in optimal condition.

Resources for Further Assistance

For those seeking additional support and guidance, a variety of resources are available to enhance your understanding and troubleshooting capabilities. These platforms can provide valuable insights and solutions to common issues, ensuring that you can maintain and optimize your equipment effectively.

Online Communities

Engaging with fellow enthusiasts and experts can significantly aid in problem-solving. Consider exploring the following platforms:

- Forums dedicated to equipment maintenance

- Social media groups focused on outdoor machinery

- Reddit communities discussing related topics

Instructional Videos

Visual aids can be incredibly helpful. Look for:

- YouTube channels that specialize in machinery tutorials

- Online courses covering operational techniques

- Webinars hosted by industry professionals

Utilizing these resources can greatly enhance your repair skills and overall knowledge of your tools.