Comprehensive Repair Guide for Stihl MS 441 Chainsaw

The efficient operation of a powerful cutting tool hinges on its meticulous upkeep. This section aims to illuminate essential practices that ensure optimal performance and longevity of your equipment. Regular attention to detail can significantly enhance functionality and prevent common issues.

Within these guidelines, enthusiasts will discover vital troubleshooting techniques and restoration strategies. Whether you are a seasoned user or a newcomer, understanding the intricacies of your tool will lead to improved efficiency and reliability.

As we delve deeper into the specifics, it becomes clear that proper care not only extends the life of your device but also enhances safety during its use. Mastering these techniques is the ultimate way to empower your cutting experience and maximize productivity.

Understanding the Stihl MS 441

This section delves into the features and functionalities of a high-performance cutting tool designed for various outdoor tasks. It is essential for users to grasp its capabilities, maintenance needs, and operational guidelines to ensure optimal performance and longevity.

Key Features

- Powerful Engine: Engineered for efficient cutting and durability.

- Lightweight Design: Facilitates ease of handling during extended use.

- Advanced Air Filtration: Promotes longer intervals between maintenance sessions.

- Ergonomic Handle: Ensures comfort and reduces fatigue.

Maintenance Tips

- Regularly check and clean the air filter to maintain airflow.

- Inspect the chain tension frequently for optimal performance.

- Sharpen the cutting chain to enhance cutting efficiency.

- Use appropriate fuel mixtures to prolong engine life.

Understanding these aspects will help users maximize the potential of this robust tool while ensuring safety and efficiency in all tasks.

Common Issues with the MS 441

Many users encounter various challenges when operating their cutting tools. Understanding these common problems can significantly enhance performance and prolong the lifespan of the equipment. Below are some frequently reported issues and their potential solutions.

1. Engine Starting Difficulties

One of the most prevalent concerns is trouble with starting the engine. This can stem from several factors, including:

- Insufficient fuel supply

- Clogged air filters

- Faulty spark plug

- Improper choke settings

Regular maintenance of these components can help prevent starting issues.

2. Performance Degradation

Users may notice a decline in cutting performance, which can be attributed to:

- Worn-out cutting chain

- Poorly aligned guide bar

- Inadequate lubrication

- Accumulation of debris in the sprocket

Addressing these aspects promptly can restore the tool’s efficiency and ensure optimal operation.

Tools Needed for Repairing MS 441

When undertaking maintenance tasks on outdoor power equipment, having the right instruments is essential for achieving effective results. This section outlines the necessary implements that will facilitate the process of servicing and ensuring optimal performance of the machine.

| Tool | Purpose |

|---|---|

| Wrench Set | To loosen and tighten bolts and nuts securely. |

| Screwdriver Set | For adjusting and removing screws from various components. |

| Chain Tool | To maintain and adjust the cutting chain effectively. |

| File | To sharpen the cutting edges for improved efficiency. |

| Fuel Container | For safe storage and handling of fuel mixtures. |

| Protective Gear | To ensure safety during maintenance tasks. |

| Cleaning Brush | To remove debris and keep components free of obstructions. |

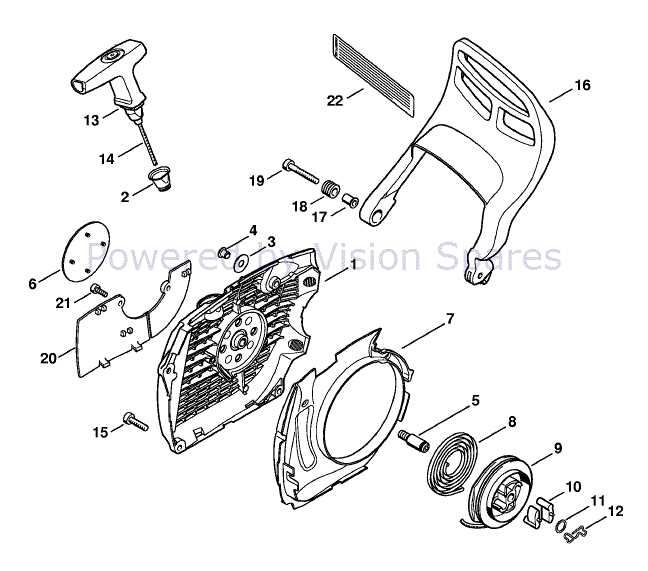

Step-by-Step Repair Process

This section outlines a comprehensive approach to addressing issues with your equipment. By following a structured method, you can effectively diagnose problems, perform necessary adjustments, and ensure optimal functionality. Each step is designed to guide you through the process, from initial assessment to final testing.

Initial Assessment

Begin by carefully inspecting the unit for any visible signs of wear or damage. Check components such as the chain, bar, and engine casing for irregularities. Ensure that all fasteners are secure and that the fuel system is functioning properly. Document any findings to streamline the troubleshooting process.

Disassembly and Inspection

Once the initial evaluation is complete, proceed with disassembling the unit. Take note of the order in which components are removed, as this will facilitate reassembly. Examine internal parts for signs of deterioration or malfunction. Replace any damaged elements and clean all surfaces to enhance performance. Reassemble the unit methodically, ensuring that each part is correctly positioned and secured.

Maintenance Tips for Longevity

Proper upkeep of your equipment is essential for ensuring its durability and optimal performance. By adhering to a few fundamental practices, you can significantly extend the lifespan of your tools and maintain their efficiency over time.

- Regular Cleaning: After each use, clean the exterior and internal components to prevent buildup of debris and residue.

- Chain Maintenance: Regularly check and adjust the tension of the cutting chain. Ensure it is properly lubricated to reduce wear.

- Air Filter Care: Inspect and clean the air filter periodically to maintain airflow and engine efficiency.

- Fuel Quality: Use high-quality fuel and store it properly to prevent degradation. Replace old fuel before long periods of inactivity.

- Sharpening Blades: Keep the cutting blades sharp to enhance cutting efficiency and reduce strain on the engine.

Implementing these practices will not only boost the performance of your equipment but also save you time and costs associated with repairs and replacements.

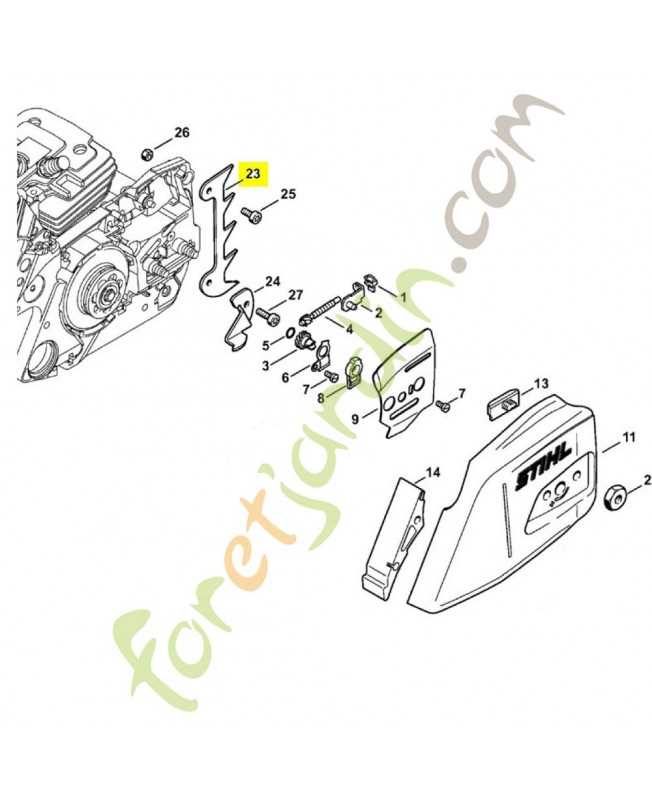

Identifying Parts for Replacement

Understanding the components of your equipment is crucial for effective maintenance and longevity. Recognizing which parts may need substitution can prevent further damage and enhance performance. This section provides guidance on how to identify essential elements for potential replacement.

When assessing parts, consider the following key areas:

- Visual Inspection: Regularly check for signs of wear, such as cracks, corrosion, or discoloration.

- Performance Issues: Notice any irregularities in operation, like unusual noises or decreased efficiency.

- Component Lifespan: Familiarize yourself with the expected lifespan of various elements to anticipate when replacements may be needed.

To assist in the identification process, utilize the following steps:

- Consult the parts list or schematic for your equipment model.

- Cross-reference damaged components with manufacturer specifications.

- Document the part numbers for easier ordering.

- Seek expert advice if uncertain about any components.

Being proactive about identifying parts for substitution not only maintains the equipment’s efficiency but also ensures safety during operation.

Troubleshooting Starting Problems

Starting difficulties can be frustrating and may arise from a variety of factors. Identifying the root cause is essential for effective resolution. This section outlines common issues and solutions to help restore functionality.

Common Causes of Starting Issues

- Fuel Quality: Using stale or contaminated fuel can hinder engine performance.

- Ignition System: A faulty spark plug or ignition coil may prevent the engine from firing.

- Air Filter: A clogged air filter can restrict airflow, leading to poor combustion.

- Battery Condition: Low battery voltage can affect starting, especially in electric models.

Steps for Troubleshooting

- Check Fuel: Ensure the fuel is fresh and free of contaminants.

- Inspect the Spark Plug: Remove and examine for wear or carbon buildup; replace if necessary.

- Examine the Air Filter: Clean or replace the air filter to ensure proper airflow.

- Test the Battery: Measure voltage and ensure connections are secure and clean.

By following these steps, users can often diagnose and address starting issues effectively. If problems persist, seeking professional assistance may be advisable.

How to Adjust Carburetor Settings

Proper tuning of the fuel delivery system is crucial for optimal engine performance. Making precise adjustments can enhance efficiency, improve throttle response, and reduce emissions. This guide outlines the essential steps for modifying the settings to achieve the desired performance level.

Before beginning the adjustment process, ensure that the engine is clean and in good working condition. Regular maintenance will help prevent issues that could interfere with the tuning process.

| Adjustment Step | Description |

|---|---|

| 1. Prepare the Engine | Start the engine and let it warm up to operating temperature. This ensures that the adjustments are made under typical conditions. |

| 2. Locate the Adjustment Screws | Identify the high-speed and low-speed adjustment screws on the carburetor. These are usually marked as ‘H’ and ‘L’. |

| 3. Adjust Low-Speed Setting | Turn the low-speed screw clockwise to lean the mixture or counterclockwise to enrich it. Aim for smooth idling and responsive throttle. |

| 4. Adjust High-Speed Setting | Make similar adjustments to the high-speed screw. Fine-tune until the engine runs smoothly at full throttle without hesitation. |

| 5. Test Performance | After adjustments, take the unit for a test run. Observe the performance and make any necessary refinements to the settings. |

Remember to consult the specific guidelines for your engine type, as variations may exist. Consistent monitoring and adjustments can significantly enhance the longevity and efficiency of the machinery.

Cleaning and Servicing the Air Filter

The air filter plays a crucial role in maintaining the efficiency and longevity of your equipment. Regular maintenance of this component ensures that the engine receives clean air, which is essential for optimal performance. Neglecting the filter can lead to decreased power and increased wear on the engine over time.

To begin the cleaning process, first, remove the air filter from its housing. This typically involves unscrewing or unclipping it, depending on the design. Once detached, gently tap the filter to remove loose dirt and debris. For a more thorough cleaning, use compressed air to blow out any stubborn particles, taking care to do this from the inside out to avoid pushing dirt further into the filter.

If the filter is heavily soiled or damaged, consider replacing it with a new one. Regular inspection for wear and tear is vital, as a compromised filter can significantly affect engine performance. After cleaning or replacing the filter, reattach it securely, ensuring that all fastenings are tight.

Maintenance Tip: It’s advisable to check the air filter after every few uses, especially in dusty environments. Keeping this component clean will help enhance engine efficiency and extend its lifespan.

Safety Precautions During Repairs

Ensuring safety during maintenance activities is crucial for preventing accidents and injuries. Proper precautions not only protect the individual performing the work but also safeguard the tools and equipment involved. Understanding and adhering to these safety measures can significantly reduce the risks associated with handling machinery.

Personal Protective Equipment

Wearing appropriate personal protective equipment (PPE) is essential. This includes gloves, goggles, and sturdy footwear. Protective eyewear shields your eyes from debris, while gloves provide a firm grip and protect against cuts. Proper footwear helps in maintaining stability and reduces the likelihood of slips or falls.

Work Environment Safety

Maintaining a clean and organized workspace is vital. Ensure that all tools are in good condition and that the area is free from clutter. Adequate lighting can prevent accidents by allowing for better visibility. Additionally, be mindful of your surroundings, particularly if working outdoors, where uneven terrain may pose a hazard.

Where to Find OEM Parts

Finding original equipment manufacturer (OEM) components is essential for maintaining the optimal performance and longevity of your machinery. These parts are specifically designed to fit and function with your device, ensuring reliability and efficiency. Locating the right sources for these authentic components can significantly enhance your repair and maintenance experience.

Authorized Dealers

The most reliable source for genuine parts is through authorized dealers. These establishments are officially recognized by the manufacturer and offer a comprehensive selection of components. You can visit their physical locations or browse their online platforms to access the inventory. Moreover, knowledgeable staff can provide guidance and support in selecting the correct parts for your specific needs.

Online Marketplaces

Numerous online marketplaces specialize in OEM parts, providing convenience and accessibility. Websites dedicated to power equipment often have extensive catalogs where you can search by model number or part name. When using these platforms, ensure you check the seller’s ratings and reviews to confirm the authenticity of the parts. Additionally, consider subscribing to notifications for sales or discounts on OEM items.