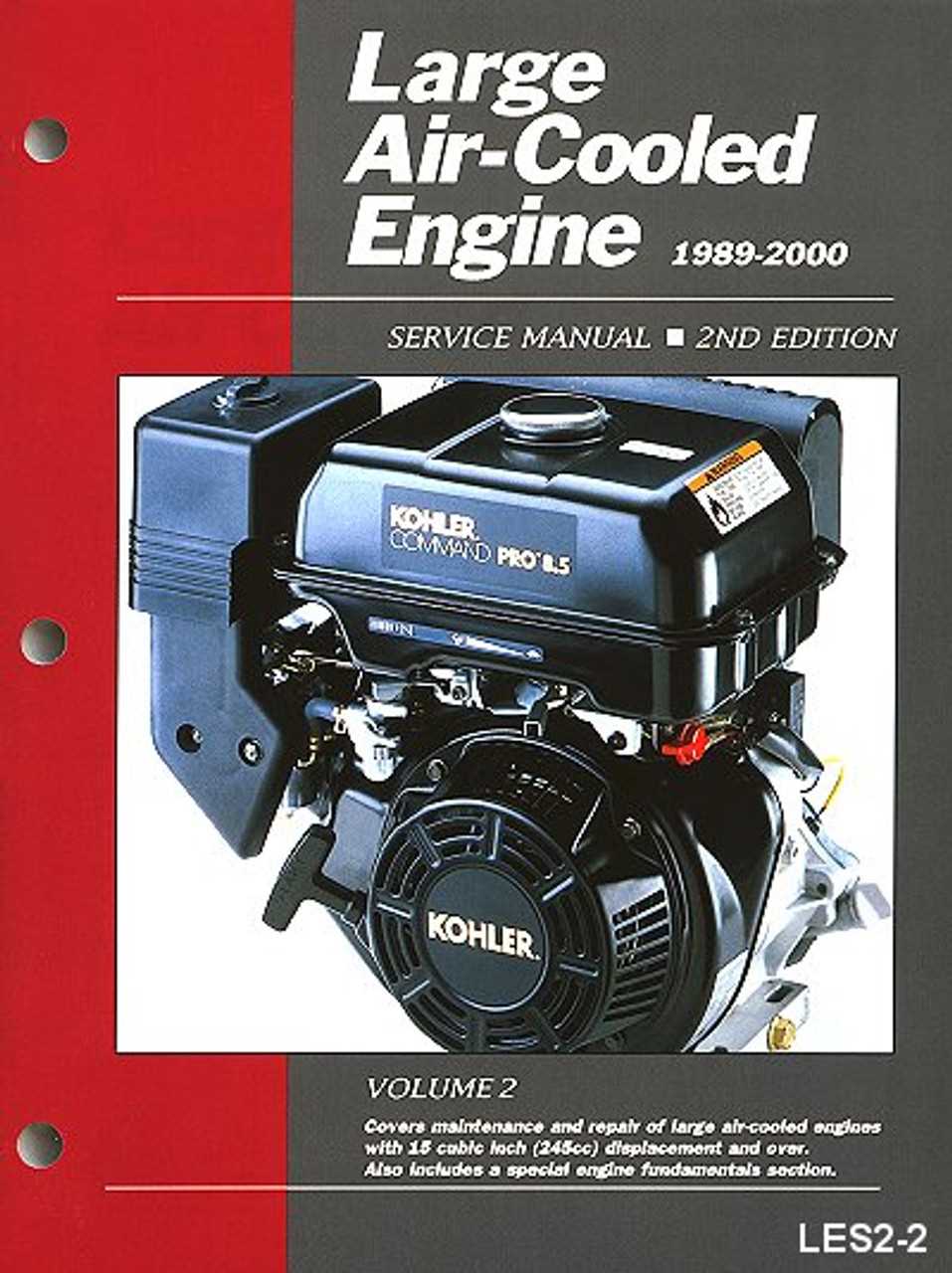

Comprehensive Guide to Wisconsin VG4D Repair Manual

In the world of machinery, understanding the intricacies of engine upkeep is essential for optimal performance and longevity. This section offers invaluable insights into various aspects of engine servicing, focusing on techniques and procedures that can enhance operational efficiency. By following the guidelines provided, users can ensure that their engines function smoothly and reliably.

From troubleshooting common issues to implementing routine maintenance strategies, this guide covers a wide array of topics. Users will find detailed descriptions of components, recommended practices, and diagnostic tips that are crucial for effective maintenance. Emphasizing preventive measures, this resource aims to equip operators with the knowledge necessary to address potential problems before they escalate.

Whether you are a seasoned technician or a novice enthusiast, the information contained here will serve as a helpful reference. By familiarizing yourself with these essential practices, you can take proactive steps toward ensuring the durability and performance of your engine. Embrace the journey of learning and apply these techniques to achieve the best results in engine management.

Overview of Wisconsin VG4D Engine

The engine in question represents a robust power unit designed for various applications, particularly in agricultural and industrial settings. Its reliable performance and efficiency have made it a favored choice among users requiring dependable machinery.

This particular model features a four-cylinder configuration, contributing to its balanced power delivery and operational stability. The engineering behind this unit emphasizes durability and ease of maintenance, ensuring it can withstand demanding conditions while providing consistent output.

Furthermore, this engine incorporates innovative design elements that enhance fuel efficiency and reduce emissions. Such advancements make it not only a practical option but also an environmentally conscious one. Overall, its combination of strength, efficiency, and user-friendly maintenance makes it a noteworthy choice for those seeking an effective power solution.

Common Issues with VG4D Models

Engines of this type often encounter a variety of challenges that can affect their performance and reliability. Understanding these common problems can help owners take proactive measures to ensure optimal functioning.

- Starting Difficulties: Many users report issues with ignition systems, leading to trouble when starting the engine.

- Overheating: Insufficient cooling can result in overheating, causing potential damage if not addressed promptly.

- Fuel System Problems: Clogged filters or fuel lines may hinder fuel delivery, leading to poor engine performance.

- Oil Leaks: Wear and tear on gaskets and seals can cause oil to leak, which affects lubrication and can lead to further complications.

- Unusual Noises: Owners might notice strange sounds, which can indicate issues with internal components or mounting.

By being aware of these typical issues, operators can take necessary actions to maintain their equipment effectively.

Tools Required for Repairs

When undertaking maintenance tasks on engines, having the right instruments is crucial for ensuring efficiency and effectiveness. A well-equipped workspace can make the difference between a smooth process and unnecessary frustration.

| Tool | Description |

|---|---|

| Socket Set | Essential for loosening and tightening bolts of various sizes. |

| Wrench Set | Ideal for working in tight spaces where sockets may not fit. |

| Screwdriver Set | Needed for securing and removing screws in various components. |

| Pliers | Useful for gripping, twisting, and cutting wires or other materials. |

| Torque Wrench | Ensures bolts are tightened to the manufacturer’s specifications. |

| Oil Filter Wrench | Specialized tool for removing and replacing oil filters easily. |

| Multimeter | Essential for diagnosing electrical issues by measuring voltage, current, and resistance. |

Step-by-Step Troubleshooting Guide

This section provides a systematic approach to diagnosing and resolving issues that may arise with your engine. By following the outlined steps, you can efficiently identify the root cause of the problem and implement the necessary solutions.

Initial Assessment

- Check the fuel level and quality.

- Inspect the oil level and condition.

- Examine the battery connections for corrosion and tightness.

- Look for any visible leaks or damages to components.

Systematic Troubleshooting Steps

- Verify that all electrical connections are secure and free of corrosion.

- Test the ignition system for proper operation.

- Examine the air intake and filter for obstructions.

- Conduct a compression test to assess engine health.

- Evaluate the exhaust system for blockages.

- Run diagnostics on fuel delivery components.

- Review the operation of any ancillary systems (e.g., cooling, lubrication).

Following this guide will help streamline the troubleshooting process and ensure effective resolutions to any challenges encountered.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your engine requires consistent care and attention. Adopting a proactive maintenance routine can significantly extend its lifespan and enhance efficiency. Here are some essential practices to keep in mind:

- Regular Oil Changes: Frequent oil changes are crucial for lubricating internal components and reducing wear. Follow the recommended intervals to maintain engine health.

- Check Cooling System: Ensure that the cooling system is functioning correctly to prevent overheating. Regularly inspect coolant levels and hoses for any leaks or damage.

- Inspect Air Filters: Clean or replace air filters periodically to maintain proper airflow. This helps improve combustion efficiency and overall performance.

- Fuel Quality: Use high-quality fuel to minimize deposits and improve combustion. Regularly check for any contaminants in the fuel system.

- Battery Maintenance: Inspect battery terminals for corrosion and ensure connections are secure. A well-maintained battery ensures reliable starting and operation.

- Routine Inspections: Perform regular checks on belts, hoses, and other components. Early detection of wear can prevent costly repairs down the line.

By incorporating these practices into your routine, you can enhance the longevity and reliability of your engine, ensuring it performs at its best for years to come.

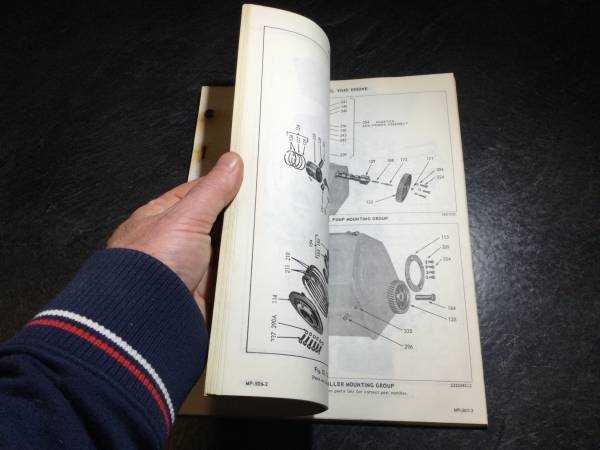

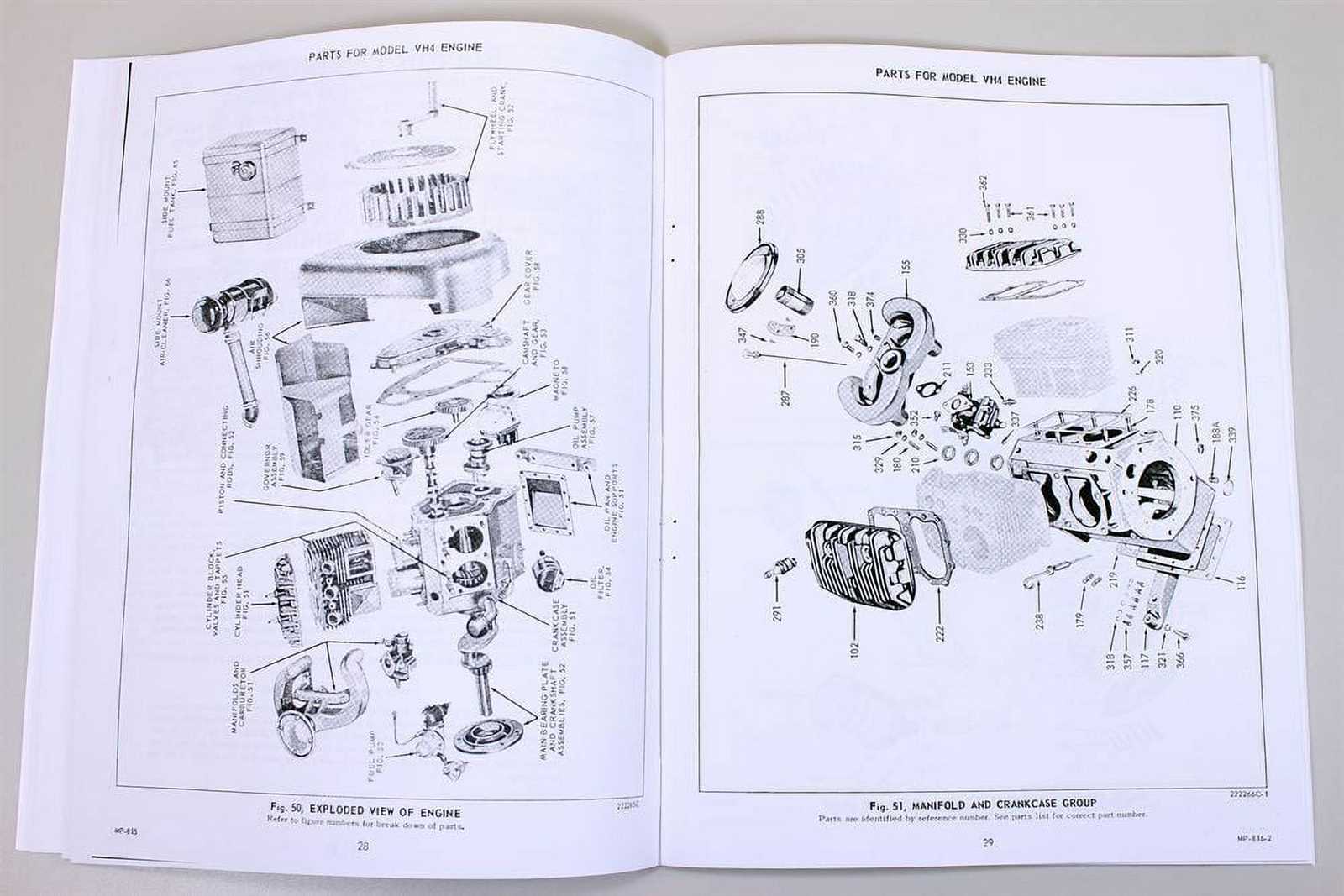

Replacing Key Engine Components

Maintenance and enhancement of vital engine parts can significantly improve performance and longevity. Understanding the procedure for component replacement is essential for ensuring reliable operation.

Essential Components to Consider

- Pistons

- Rings

- Valves

- Gaskets

- Crankshaft

Replacement Procedure Overview

- Prepare the workspace, ensuring all necessary tools are available.

- Disconnect the power source and remove any obstructing components.

- Carefully extract the component, taking note of any connecting parts.

- Install the new component, ensuring a proper fit and alignment.

- Reassemble all removed parts and reconnect the power source.

Following these steps can lead to successful installation and improved engine efficiency.

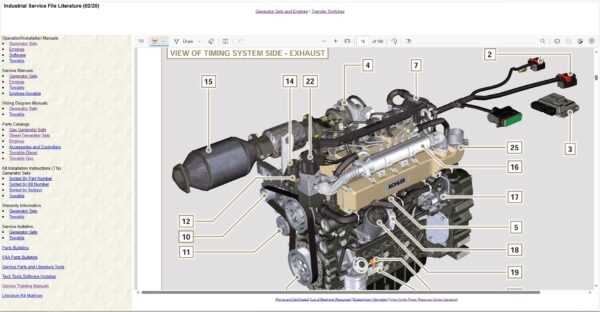

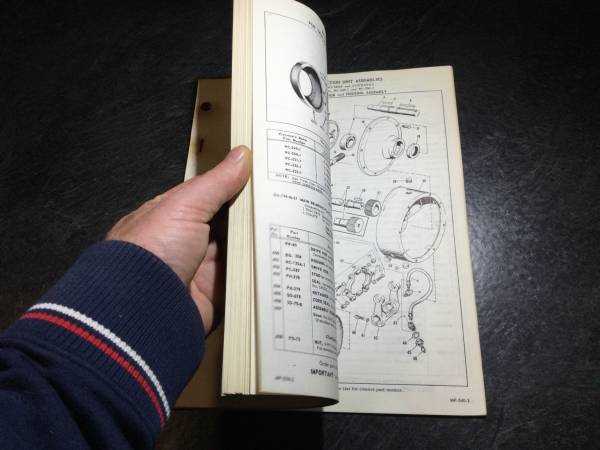

Electrical System Diagnostics

Diagnosing issues within the electrical framework of an engine is crucial for maintaining optimal performance and reliability. Effective troubleshooting involves understanding the components involved and their interactions within the system.

The following steps outline a systematic approach to identifying electrical problems:

- Visual Inspection: Start by examining all visible wiring, connectors, and components for signs of wear, corrosion, or damage.

- Check Battery Condition: Assess the battery’s voltage and state of charge. Ensure terminals are clean and connections are secure.

- Test Electrical Connections: Use a multimeter to measure continuity in circuits. Look for open or short circuits that could disrupt function.

- Examine Fuses and Relays: Inspect fuses for continuity and relays for proper operation. Replace any that are faulty.

- Assess Grounding Points: Ensure all grounding points are clean and securely connected to prevent voltage drops.

- Evaluate Component Functionality: Test individual electrical components, such as sensors and switches, to ensure they operate correctly.

By following these diagnostic procedures, one can systematically pinpoint electrical malfunctions, ensuring a more efficient troubleshooting process and enhancing the overall performance of the engine.

Fuel System Repair Techniques

Effective maintenance of the fuel system is crucial for optimal engine performance. Addressing issues promptly can enhance efficiency and longevity. This section outlines essential methods for diagnosing and resolving common fuel system challenges.

| Technique | Description |

|---|---|

| Fuel Filter Replacement | Regularly changing the fuel filter prevents contaminants from clogging the system and ensures a clean fuel supply. |

| Injector Cleaning | Utilizing specialized cleaning solutions can help remove deposits from injectors, improving spray patterns and overall performance. |

| Fuel Line Inspection | Checking for leaks or blockages in fuel lines is essential for maintaining proper fuel flow and preventing pressure loss. |

| Pressure Testing | Conducting pressure tests can identify issues with the fuel pump and ensure that the system is operating within specified parameters. |

Implementing these techniques will help maintain a well-functioning fuel system, ultimately leading to better engine operation and reliability.

Cooling System Inspection Procedures

The effective functioning of the cooling system is vital for maintaining optimal performance and preventing overheating. Regular assessments can help identify potential issues before they escalate, ensuring longevity and reliability. This section outlines essential steps to thoroughly evaluate the cooling mechanism.

Visual Examination

Begin with a comprehensive visual inspection of the cooling components. Look for any signs of leakage, corrosion, or damage in hoses, radiators, and water pumps. Pay special attention to connections and fittings, as these areas are often prone to wear. Ensure that the coolant level is adequate and that the fluid is free from contamination.

Functional Testing

After the visual check, perform functional tests to assess the system’s efficiency. Start the engine and observe the temperature gauge to ensure it remains within the normal operating range. Additionally, listen for unusual noises that may indicate a malfunctioning component. Conducting these tests regularly can help maintain optimal operational conditions and prevent overheating.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance tasks is paramount. Adhering to specific guidelines can significantly reduce the risk of accidents and injuries. Awareness of potential hazards and proper preparation creates a secure working environment.

Proper Personal Protective Equipment

Wearing appropriate protective gear is essential. Equip yourself with gloves, safety goggles, and ear protection to safeguard against physical injuries and harmful substances. Regularly inspect your equipment for any wear or damage to maintain effectiveness.

Work Area Organization

Maintaining an organized workspace helps prevent mishaps. Keep tools and materials neatly stored and readily accessible. Ensure adequate lighting to enhance visibility and reduce the likelihood of accidents. Always prioritize cleanliness to avoid tripping hazards and other potential dangers.

Finding Replacement Parts

Locating suitable components for machinery can be a daunting task, but understanding where to look can simplify the process significantly. Whether you are performing routine maintenance or addressing a specific issue, having access to quality parts is essential for ensuring optimal performance.

Authorized Dealers

One of the most reliable sources for acquiring components is through authorized dealers. These vendors specialize in genuine parts and often provide additional support, such as installation guidance or troubleshooting tips. It is advisable to check the manufacturer’s website for a list of certified distributors.

Online Marketplaces

Another effective option is to explore online marketplaces. Numerous platforms offer a wide range of components, often at competitive prices. When purchasing online, it is important to verify the seller’s reputation and read customer reviews to ensure the quality of the items being offered. Additionally, consider looking for warranty information to protect your investment.

Resources for Further Assistance

For individuals seeking additional support in addressing mechanical issues, numerous options are available to enhance understanding and facilitate solutions. These resources provide valuable insights and expert guidance to ensure effective troubleshooting and maintenance.

- Online Forums: Communities dedicated to engine enthusiasts often share experiences, advice, and troubleshooting tips.

- Instructional Videos: Platforms such as YouTube feature step-by-step tutorials that visually demonstrate repair techniques.

- Technical Publications: Manuals and guides produced by manufacturers offer in-depth information about specific models and systems.

- Local Workshops: Hands-on assistance from professionals can be invaluable; workshops may provide courses or one-on-one support.

- Trade Shows and Expos: Industry events allow networking with experts and accessing the latest innovations and resources.

Utilizing these tools can empower individuals to tackle challenges with confidence and enhance their overall knowledge of mechanical systems.